Komatsu PC25-1, PC30-7, PC40-7, PC45-1 Hydraulic Excavator Shop Manual SEBM020S0707

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM020S0707

- Format: PDF

- Size: 22.5MB

- Number of Pages: 387

Category: Komatsu Shop Manual PDF

-

Model List:

- PC25-1 Hydraulic Excavator

- PC30-7 Hydraulic Excavator

- PC40-7 Hydraulic Excavator

- PC45-1 Hydraulic Excavator

- 0.1. HOW TO READ THE SHOP MANUAL

- 0.2. HOISTING INSTRUCTIONS

- 0.3. COATING MATERIALS

- 0.4. STANDARD TIGHTENING TORQUE

- 0.5. ELECTRIC WIRE CODE

- 0.6. CONVERSION TABLE

- 0.7. WEIGHT TABLE

- 0.8. WEIGHT TABLE

- 0.9. LIST OF LUBRICANT AND WATER

- 1. STRUCTURE AND FUNCTION

- 1.1. POWER TRAIN

- 1.2. SWING CIRCLE

- 1.3. SWING MACHINERY

- 1.4. TRACK FRAME AND RECOIL SPRING

- 1.5. HYDRAULIC PIPING

- 1.6. HYDRAULIC CIRCUIT DIAGRAM

- 1.7. HYDRAULIC TANK AND FUEL TANK

- 1.8. HYDRAULIC PUMP

- 1.9. CONTROL PUMP

- 1.10. SPOOL CONTROL VALVE

- 1.11. SPOOL CONTROL VALVE

- 1.12. SWING MOTOR

- 1.13. CENTER SWIVEL JOINT

- 1.14. TRAVEL MOTOR

- 1.15. HYDRAULIC CYLINDER

- 1.16. VALVE CONTROL

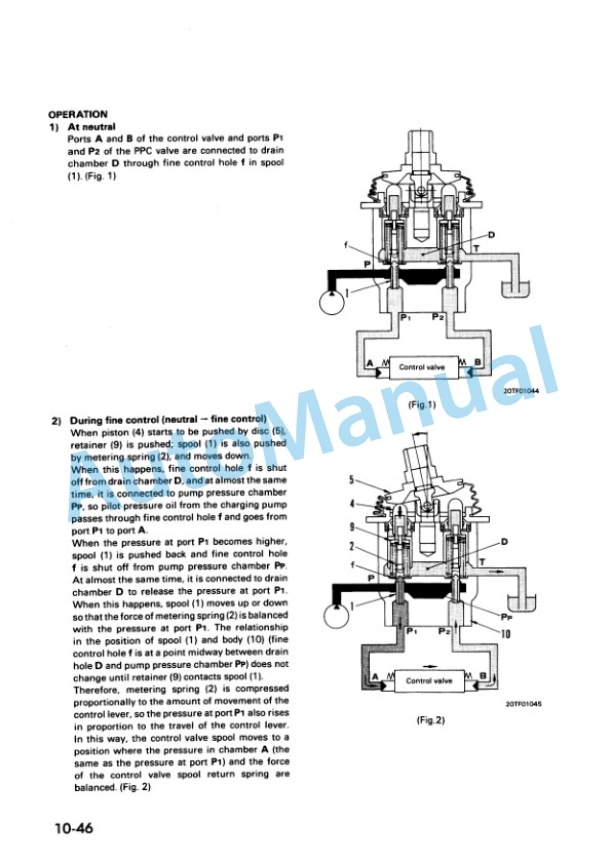

- 1.17. PPC VALVE

- 1.18. SOLENOID VALVE

- 1.19. WORK EQUIPMENT

- 1.20. HYDRAULIC BREAKER

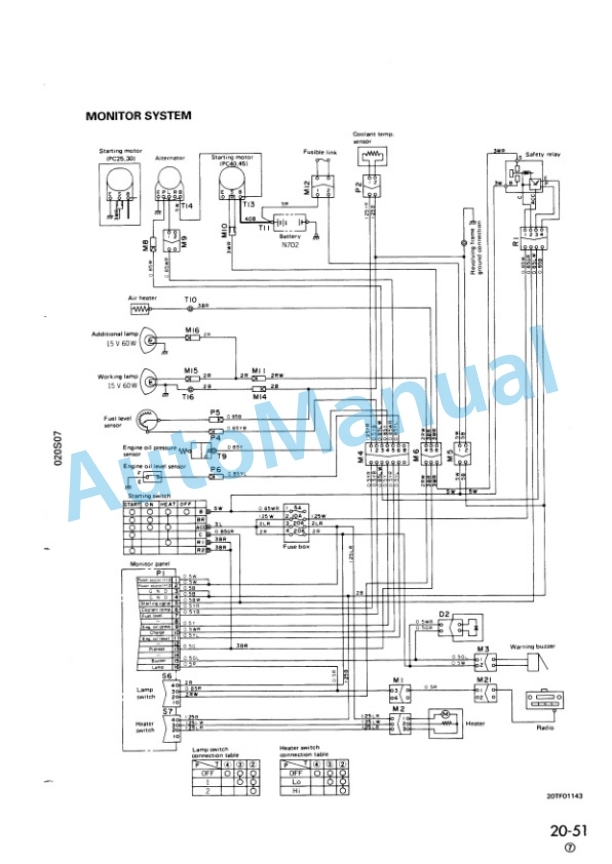

- 1.21. ELECTRICAL CIRCUIT DIAGRAM

- 1.22. MONITOR SYSTEM

- 2. TESTING AND ADJUSTING

- 2.1. TABLE OF JUDGEMENT STANDARD VALUE

- 2.2. STANDARD VALUE TABLE FOR ELECTRICAL SYSTEM

- 2.3. TOOL FOR TESTING, ADJUSTING, AND TROUBLESHOOTING

- 2.4. ADJUSTING VALVE CLEARANCE

- 2.5. MEASURING COMPRESSION PRESSURE

- 2.6. ADJUSTING FUEL INJECTION TIMING

- 2.7. MEASURING ENGINE OIL PRESSURE

- 2.8. ADJUSTING FUEL CONTROL LEVER

- 2.9. TESTING AND ADJUSTING HYDRAULIC PRESSURE IN WORK EQUIPMENT, SWING, TRAVEL CIRCUIT

- 2.10. TESTING CONTROL CIRCUIT PRESSURE

- 2.11. MEASURING OUTPUT PRESSURE OF PPC VALVE

- 2.12. ADJUSTING PPC VALVE

- 2.13. ADJUSTING WORK EQUIPMENT, SWING PPC VALVE

- 2.14. MEASURING SOLENOID VALVE OUTLET PORT PRESSURE

- 2.15. ADJUSTING BLADE CONTROL LEVER

- 2.16. TESTING LOCATIONS CAUSING HYDRAULIC DRIFT OF WORK EQUIPMENT

- 2.17. BLEEDING AIR FROM HYDRAULIC CIRCUIT

- 2.18. RELEASING REMAINING FROM HYDRAULIC CIRCUIT

- 2.19. TESTING HYDRAULIC BREAKER GAS PRESSURE

- 2.20. TROUBLESHOOTING

- 2.20.1. SEQUENCE OF EVENTS IN TROUBLESHOOTING

- 2.20.2. PRECAUTIONS WHEN CARRYING OUT MAINTENANCE

- 2.20.3. CHECKS BEFORE TROUBLESHOOTING

- 2.20.4. ELECTRICAL CIRCUIT DIAGRAM

- 2.20.5. POSITION OF CONNECTORS FOR TROUBLESHOOTING

- 2.20.6. CONNECTION TABLE FOR CONNECTOR

- 2.20.7. METHOD OF USING TROUBLESHOOTING CHARTS

- 2.20.8. TROUBLESHOOTING OF ELECTRICAL SYSTEM (E MODE)

- 2.20.8.1. E1 THE ENGINE DOES NOT STOP WHEN THE STARTING SWITCH IS TURNED OFF

- 2.20.8.2. E2 WORK EQUIPMENT DOES NOT MOVE EVEN WHEN WORK EQUIPMENT LOCK LEVER IS RELEASED

- 2.20.8.3. E3 WORK EQUIPMENT MOVES EVEN WHEN WORK EQUIPMENT LOCK LEVER IS LOCKED

- 2.20.8.4. E4 TRAVEL SPEED DOES NOT INCREASE EVEN WHEN TRAVEL SPEED ACCELERATION PEDAL IS DEPRESSED

- 2.20.8.5. E5 TRAVEL SPEED INCREASES EVEN WHEN TRAVEL SPEED ACCELERATION PEDAL IS NOT DEPRESSED

- 2.20.9. TROUBLESHOOTING OF HYDRAULIC AND MECHANICAL SYSTEM (H MODE)

- 2.20.9.1. H1 SPEEDS OF WORK EQUIPMENT, TRAVEL, SWING ARE ALL SLOW

- 2.20.9.2. H2 THERE IS EXCESSIVE DROP IN ENGINE SPEED, OR ENGINE STALLS

- 2.20.9.3. H3 WORK EQUIPMENT, TRAVEL, SWING DO NOT MOVE, OR SPEED IS EXTREMELY SLOW

- 2.20.9.4. H4 ALL WORK EQUIPMENT, TRAVEL, SWING LACK POWER

- 2.20.9.5. H5 ABNORMAL NOISE GENERATED (FROM AROUND PUMP)

- 2.20.9.6. H6 WORK EQUIPMENT (BOOM, ARM, BUCKET) SPEED IS SLOW

- 2.20.9.7. H7 WORK EQUIPMENT (BOOM, ARM, BUCKET) LACKS POWER

- 2.20.9.8. H8 EXCESSIVE HYDRAULIC DRIFT

- 2.20.9.9. H9 EXCESSIVE TIME LAG

- 2.20.9.10. H10 WHEN MACHINE IS TRAVELING, IT DEVIATES NATURALLY TO ONE SIDE

- 2.20.9.11. H11 EXCESSIVE DEVIATION WHEN STARTING (PC30, 40)

- 2.20.9.12. H12 TRAVEL LACKS POWER (OR SPEED IS SLOW)

- 2.20.9.13. H13 TRAVEL SPEED DOES NOT SWITCH

- 2.20.9.14. H14 MACHINE DOES NOT MOVE (ONE SIDE ONLY)

- 2.20.9.15. H15 TRAVEL LEVER IS HEAVY

- 2.20.9.16. H16 DOES NOT SWING

- 2.20.9.17. H17 SWING SPEED IS SLOW OR ACCELERATION IS POOR

- 2.20.9.18. H18 EXCESSIVE OVERRUN WHEN STOPPING SWING

- 2.20.9.19. H19 EXCESSIVE SHOCK WHEN STOPPING SWING

- 2.20.9.20. H20 EXCESSIVE ABNORMAL NOISE WHEN STOPPING SWING

- 2.20.9.21. H21 EXCESSIVE HYDRAULIC DRIFT OF SWING

- 2.20.9.22. H22 EXCESSIVE HYDRAULIC DRIFT OF BOOM SWING

- 2.20.9.23. TABLE OF FAILURE MODES AND CAUSES

- 2.20.10. TROUBLESHOOTING OF MONITOR SYSTEM (M MODE)

- 2.20.10.1. M1 MONITOR PANEL DOES NOT WORK

- 2.20.10.2. M2 MONITOR PANEL CAUTION AND GAUGE LAMPS DO NOT LIGHT UP FOR 3 SECONDS AFTER STARTING SWITCH IS TURNED ON, OR ALL LAMPS STAY

- 2.20.10.3. M3 (OIL PRESSURE CAUTION LAMP) DOES NOT LIGHT UP WHEN STARTING SWITCH IS TURNED ON (ENGINE STOPPED)

- 2.20.10.4. M4 (CHARGE CAUTION LAMP) DOES NOT LIGHT UP WHEN STARTING SWITCH IS TURNED ON (ENGINE STOPPED)

- 2.20.10.5. M5 (PREHEATING PILOT LAMP) DOES NOT LIGHT UP WHEN PREHEATING

- 2.20.10.6. M6 (ENGINE OIL LEVEL CAUTION LAMP) LIGHTS UP WHEN STARTING SWITCH IS TURNED ON (ENGINE STOPPED) (ENGINE OIL LEVEL IS NORMAL)

- 2.20.10.7. M7 (ENGINE OIL PRESSURE CAUTION LAMP) LIGHTS UP WHEN ENGINE IS RUNNING (ENGINE OIL PRESSURE IS NORMAL)

- 2.20.10.8. M8 (CHARGE CAUTION LAMP) LIGHTS UP WHEN ENGINE IS RUNNING

- 2.20.10.9. M9 ABNORMALITY IN COOLANT TEMPERATURE GAUGE DISPLAY

- 2.20.10.10. M10 ABNORMALITY IN FUEL GAUGE DISPLAY

- 2.20.10.11. M11 WHEN STARTING SWITCH IS TURNED ON, BUZZER DOES NOT SOUND FOR 1 SECOND

- 2.20.10.12. M12 ABNORMALITY IN SERVICE METER DISPLAY

- 2.20.10.13. M13 NIGHT LIGHTING DOES NOT LIGHT UP

- 2.20.10.14. M14 HEATER DOES NOT WORK WHEN HEATER SWITCH IS OPERATED (MACHINES WITH CAB SPECIFICATION)

- 2.20.11. TROUBLESHOOTING OF HYDRAULIC BREAKER

- 3. DISASSEMBLY AND ASSEMBLY

- 3.1. METHOD OF USING MANUAL

- 3.2. PRECAUTIONS WHEN CARRYING OUT OPERATION

- 3.3. SPECIAL TOOL LIST

- 3.4. WEIGHT TABLE

- 3.5. TIGHTENING TORQUES AND STANDARD VALUES TABLE

- 3.6. LUBRICANT AND COOLANT TABLE

- 3.7. ENGINE, HYDRAULIC PUMP ASSEMBLY

- 3.7.1. REMOVAL

- 3.7.2. INSTALLATION

- 3.8. HYDRAULIC PUMP ASSEMBLY

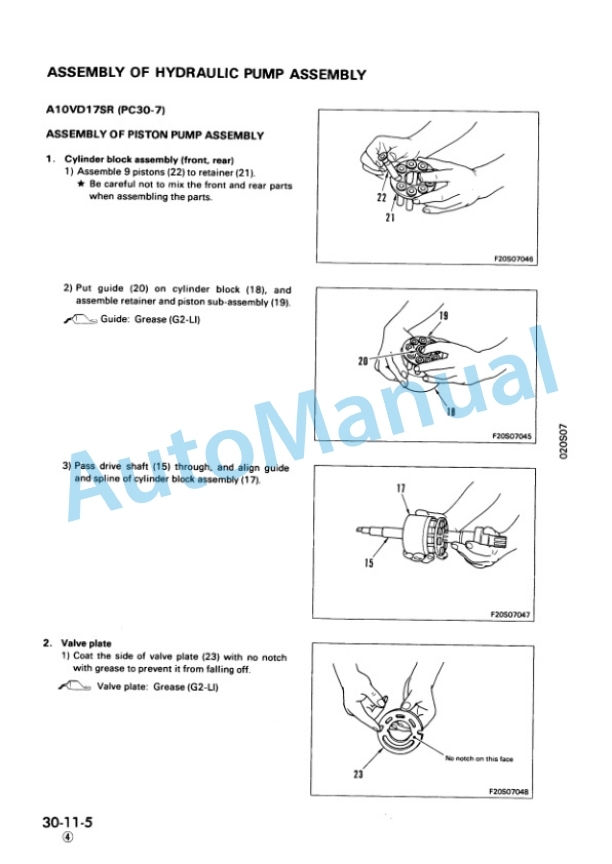

- 3.8.1. HYDRAULIC PUMP ASSEMBLY (PC307)

- 3.8.1.1. DISASSEMBLY

- 3.8.1.2. ASSEMBLY

- 3.8.2. HYDRAULIC PUMP ASSEMBLY (PC451)

- 3.8.2.1. DISASSEMBLY

- 3.8.2.2. ASSEMBLY

- 3.9. GEAR PUMP ASSEMBLY

- 3.9.1. DISASSEMBLY AND ASSEMBLY

- 3.10. CENTER SWIVEL JOINT ASSEMBLY

- 3.10.1. REMOVAL AND INSTALLATION

- 3.10.2. DISASSEMBLY AND ASSEMBLY

- 3.11. TRAVEL MOTOR ASSEMBLY

- 3.11.1. TRAVEL MOTOR ASSEMBLY (PC251, PC307, PC407)

- 3.11.1.1. DISASSEMBLY

- 3.11.1.2. ASSEMBLY

- 3.11.2. TRAVEL MOTOR ASSEMBLY (PC451)

- 3.11.2.1. DISASSEMBLY

- 3.11.2.2. ASSEMBLY

- 3.12. SWING MOTOR ASSEMBLY

- 3.12.1. DISASSEMBLY

- 3.12.2. ASSEMBLY

- 3.13. SWING MACHINERY ASSEMBLY

- 3.13.1. DISASSEMBLY

- 3.13.2. ASSEMBLY

- 3.14. REVOLVING FRAME ASSEMBLY

- 3.14.1. REMOVAL AND INSTALLATION

- 3.15. RECOIL SPRING ASSEMBLY

- 3.15.1. DISASSEMBLY

- 3.15.2. ASSEMBLY

- 3.16. SPOOL CONTROL VALVE ASSEMBLY

- 3.16.1. DISASSEMBLY

- 3.16.2. ASSEMBLY

- 3.17. SPOOL CONTROL VALVE ASSEMBLY

- 3.17.1. DISASSEMBLY

- 3.17.2. ASSEMBLY

- 3.18. PPC VALVE ASSEMBLY

- 3.18.1. DISASSEMBLY

- 3.18.2. ASSEMBLY

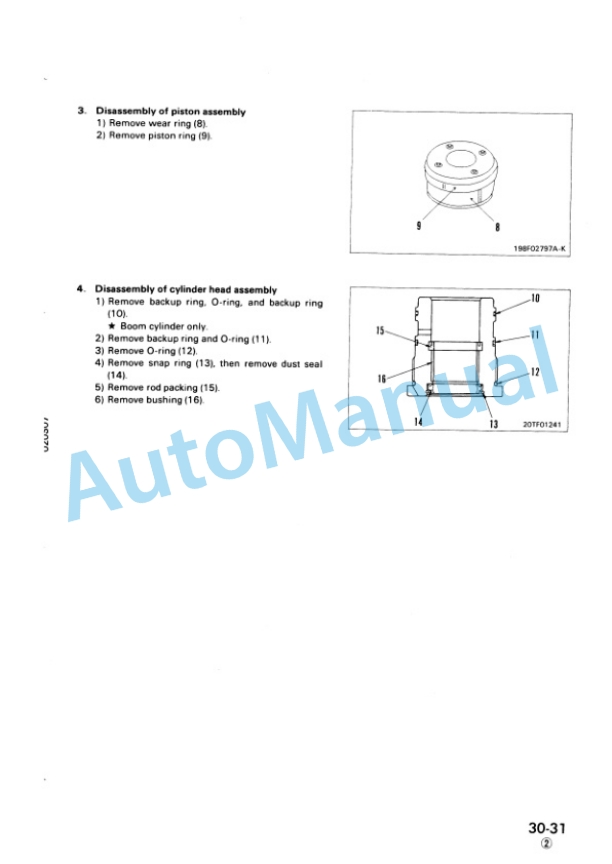

- 3.19. HYDRAULIC CYLINDER ASSEMBLY

- 3.19.1. DISASSEMBLY

- 3.19.2. ASSEMBLY

- 3.20. WORK EQUIPMENT ASSEMBLY

- 3.20.1. REMOVAL AND INSTALLATION

- 3.21. BUCKET ASSEMBLY

- 3.21.1. REMOVAL AND INSTALLATION

- 3.22. HYDRAULIC BREAKER ASSEMBLY

- 3.22.1. REMOVAL AND INSTALLATION

- 3.22.2. DISASSEMBLY

- 3.22.3. ASSEMBLY

- 3.23. HYDRAULIC BREAKER BUSHING

- 3.23.1. REMOVAL

- 3.24. CHISEL

- 3.24.1. REMOVAL AND INSTALLATION

- 4. MAINTENANCE STANDARD

- 4.1. SWING CIRCLE

- 4.2. SWING MACHINERY

- 4.3. SPROCKET

- 4.4. TRACK FRAME AND RECOIL FRAME

- 4.5. SPOOL CONTROL VALVE

- 4.6. SPOOL CONTROL VALVE

- 4.7. SWING MOTOR

- 4.8. CENTER SWIVEL JOINT

- 4.9. PPC VALVE

- 4.10. HYDRAULIC CYLINDER

- 4.11. WORK EQUIPMENT

- 4.12. HYDRAULIC BREAKER

- 4.13. PISTON, CHISEL

Rate this product

You may also like