Komatsu PC250-6, PC250LC-6 Hydraulic Excavator Shop Manual SEBM023200

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM023200

- Format: PDF

- Size: 30.3MB

- Number of Pages: 757

Category: Komatsu Shop Manual PDF

-

Model List:

- PC250-6 Hydraulic Excavator

- PC250LC-6 Hydraulic Excavator

- 1. COVER

- 2. CONTENTS

- 3. GENERAL

- 3.1. SPECIFICATION DIMENSION DRAWINGS

- 3.2. SPECIFICATIONS

- 3.3. WEIGHT TABLE

- 3.4. FUEL,COOLANT AND LUBRICANTS

- 4. STRUCTURE AND FUNCTION

- 4.1. ENGINE RELATED PARTS

- 4.2. REDIATOR

- 4.3. RADIATOROIL COOLERAFTERCOOLER

- 4.4. POWER TRAIN

- 4.5. FINAL DRIVE

- 4.6. SWING CIRCLE

- 4.7. SWING MACHINERY

- 4.8. TRACK FRAME,RECOIL SPRING

- 4.9. TRACK SHOE

- 4.10. HYDRAULIC PIPING DRAWING

- 4.11. HYDRAULIC TANK

- 4.12. HYDRAULIC PUMP

- 4.13. LINE OIL FILTER

- 4.14. CONTROL VALVE

- 4.15. SELFREDUCING PRESSURE VALVE

- 4.16. CLSS

- 4.17. SWING MOTOR

- 4.18. CENTER SWIVEL JOINT

- 4.19. TRAVEL MOTOR

- 4.20. VALVE CONTROL

- 4.21. WORK EQUIPMENTSWING PPC VALVE

- 4.22. TRAVEL PPC VALVE

- 4.23. SERVICE PPC VALVE

- 4.24. SAFETY LOCK VALVE

- 4.25. PPC ACCUMULATOR

- 4.26. STRAIGHTTRAVEL SYSTEM

- 4.27. SOLENOID VALVE

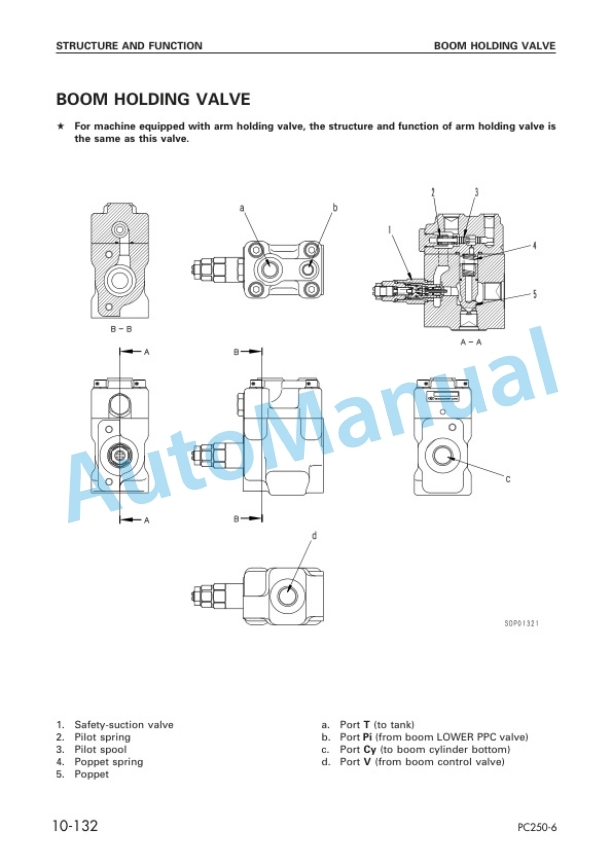

- 4.28. BOOM HOLDING VALVE

- 4.29. ADDITIONAL FILTER FOR BREAKER

- 4.30. WORK EQUIPMENT

- 4.31. AIR CONDITIONER

- 4.32. ACTUAL ELECTRIC WIRING DIAGRAM

- 4.33. ENGINE CONTROL SYSTEM

- 4.34. ELECTRONIC CONTROL SYSTEM

- 4.35. MONITOR SYSTEM

- 4.36. SENSORS

- 4.37. FRONT WINDOW AUTO PULLUP SYSTEM

- 5. TESTING AND ADJUSTING

- 5.1. TABLE OF JUDGEMENT STANDARD VALUE

- 5.2. STANDARD VALUE TABLE FOR ELECTRICAL PARTS

- 5.3. TESTING AND ADJUSTING

- 5.3.1. TOOLS FOR TESTING,ADJUSTING,AND TROUBLESHOOTING

- 5.3.2. MEASURING ENGINE SPEED

- 5.3.3. MEASURING EXHAUST GAS COLOR

- 5.3.4. ADJUSTING VALVE CLEARANCE

- 5.3.5. MEASURING COMPRESSION PRESSURE

- 5.3.6. MEASURING BLOWBY PRESSURE

- 5.3.7. TESTING AND ADJUSTING FUEL INJECTION TIMING

- 5.3.8. MEASURING ENGINE OIL PRESSURE

- 5.3.9. TESTING AND ADJUSTING ALTERNATOR BELT TENSION

- 5.3.10. TESTING AND ADJUSTING BELT TENSION FOR AIR CONDITIONER COMPRESSOR

- 5.3.11. MEASURING SPEED SENSOR

- 5.3.12. TESTING AND ADJUSTING GOVERNOR MOTOR LEVER STROKE

- 5.3.13. TESTING AND ADJUSTING HYDRAULIC PRESSURE IN WORK EPUIPMENT,SWING,TRAVEL,CIRCUIT

- 5.3.14. TESTING AND ADJUSTING PC VALVE OUTPUT PRESSURE (SERVO PISTON INPUIT PRESSURE)

- 5.3.15. TESTING AND ADJUSTING LS VALVE OUTPUT PRESSURE (SERVO PISTON INPUT PRESSURE)AND LS DIFFERENTIAL PRESSURE

- 5.3.16. TESTING AND ADJUSTING CONTROL CIRCUIT OIL PRESSURE

- 5.3.17. TESTING SOLENOID VALVE OUTPUT PRESSURE

- 5.3.18. MEASURING PPC VALVE OUTPUT PRESSURE

- 5.3.19. ADJUSTING WORK EQUIPMENTSWING PPC VALVE

- 5.3.20. TESTING TRAVEL DEVIATION

- 5.3.21. TESTING LOCATIONS CAUSING HYDRAULIC DRIFT OF WORK EQUIPMENT

- 5.3.22. MEASURING OIL LEAKAGE

- 5.3.23. RELEASING REMAINING PRESSURE IN HYDRAULIC CIRCUIT

- 5.3.24. TESTING CLEARANCE OF SWING CIRCLE BEARING

- 5.3.25. TESTING AND ADJUSTING TRACK SHOE TENSION

- 5.3.26. BLEEDING AIR

- 5.4. TROUBLESHOOTING

- 5.4.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 5.4.2. SEQUENCE OF EVENTS IN TROUBLESHOOTING

- 5.4.3. POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE

- 5.4.4. CHECKS BEFORE TROUBLESHOOTING

- 5.4.5. CONNECTOR TYPES AND MOUNTING LOCATIONS

- 5.4.6. CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

- 5.4.7. EXPLANATION OF CONTROL MECHANISM FOR ELECTRICAL SYSTEM

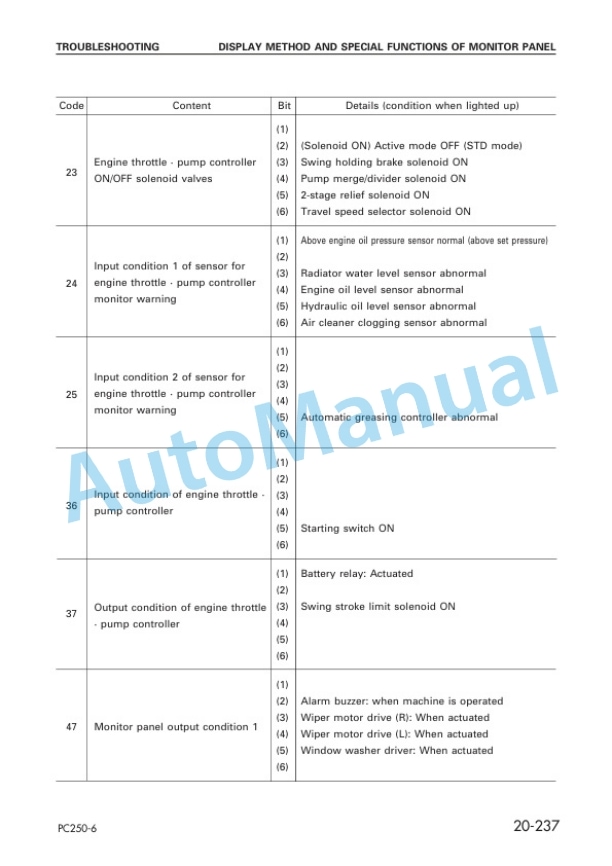

- 5.4.8. DISPLAY METHOD AND SPECIAL FUNCTIONS OF MONITOR PANEL

- 5.4.9. METHOD OF USING JUDGEMENT TABLE

- 5.4.10. METHOD OF USING TROUBLESHOOTING CHARTS

- 5.4.11. DETAILS OF TROUBLESHOOTING AND TROUBLESHOOTING PROCEDURE

- 5.4.12. SERVICE CODE TABLE

- 5.4.13. TROUBLESHOOTING OF COMMUNICATION ABNORMALITY SYSTEM (N MODE)

- 5.4.14. TROUBLESHOOTING OF ENGINE THROTTLEPUMP CONTROLLER (GOVERNOR CONTROL SYSTEM) (E MODE)

- 5.4.15. TROUBLESHOOTING OF ENGINE SYSTEM (S MODE)

- 5.4.16. TROUBLESHOOTING OF ENGINE THROTTLEPUMP CONTROLLER (PUMP CONTROL SYSTEM) (C MODE)

- 5.4.17. TROUBLESHOOTING OF ENGINE THROTTLEPUMP CONTROLLER (INPUT SIGNAL SYSTEM) (F MODE)

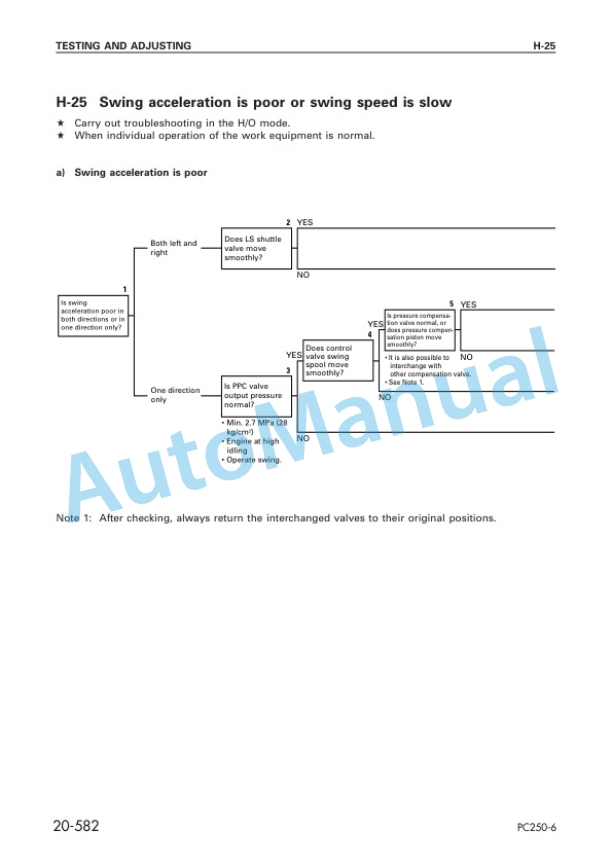

- 5.4.18. TROUBLESHOOTING OF HYDRAULIC AND MECHANICAL SYSTEM (H MODE)

- 5.4.19. TROUBLESHOOTING OF MACHINE MONITOR SYSTEM (M MODE)

- 6. DISASSEMBLY AND ASSEMBLY

- 6.1. METHOD OF USING MANUAL

- 6.2. PRECAUTIONS WHEN CARRYING OUT OPERATION

- 6.3. SPECIAL TOOL LIST

- 6.4. SKETCHES OF SPECIAL TOOLS

- 6.5. STARTING MOTOR

- 6.5.1. REMOVAL AND INSTALLATION

- 6.6. ALTERNATOR

- 6.6.1. REMOVAL AND INSTALLATION

- 6.7. AIR CONDITIONER COMPRESSOR

- 6.7.1. REMOVAL AND INSTALLATION

- 6.8. AIR CONDITIONER CONDENSER

- 6.8.1. REMOVAL AND INSTALLATION

- 6.9. DRY RECEIVER

- 6.9.1. REMOVAL AND INSTALLATION

- 6.10. ENGINE OIL COOLER CORE

- 6.10.1. REMOVAL AND INSTALLATION

- 6.11. FUEL INJECTION PUMP

- 6.11.1. REMOVAL AND INSTALLATION

- 6.12. TURBOCHARGER

- 6.12.1. REMOVAL AND INSTALLATION

- 6.13. THERMOSTAT

- 6.13.1. REMOVAL

- 6.13.2. INSTALLATION

- 6.14. GOVERNOR MOTOR

- 6.14.1. REMOVAL AND INSTALLATION

- 6.15. CYLINDER HEAD

- 6.15.1. REMOVAL

- 6.15.2. INSTALLATION

- 6.16. HYDRAULIC OIL COOLER

- 6.16.1. REMOVAL AND INSTALLATION

- 6.17. RADIATOR,HYDRAULIC OIL COOLER

- 6.17.1. REMOVAL

- 6.17.2. INSTALLATION

- 6.18. ENGINE,MAIN PUMP

- 6.18.1. REMOVAL

- 6.18.2. INSTALLATION

- 6.19. DAMPER

- 6.19.1. REMOVAL AND INSTALLATION

- 6.20. FUEL TANK

- 6.20.1. REMOVAL AND INSTALLATION

- 6.21. CENTER SWIVEL JOINT

- 6.21.1. REMOVAL

- 6.21.2. INSTALLATION

- 6.21.3. DISASSEMBLY AND ASSEMBLY

- 6.22. FINAL DRIVE

- 6.22.1. REMOVAL AND INSTALLATION

- 6.22.2. REMOVAL AND INSTALLATION

- 6.23. SWING MOTOR AND SWING MACHINERY

- 6.23.1. REMOVAL

- 6.23.2. INSTALLATION

- 6.24. SWING MACHINERY

- 6.25. REVOLVING FRAME

- 6.25.1. REMOVAL

- 6.25.2. INSTALLATION

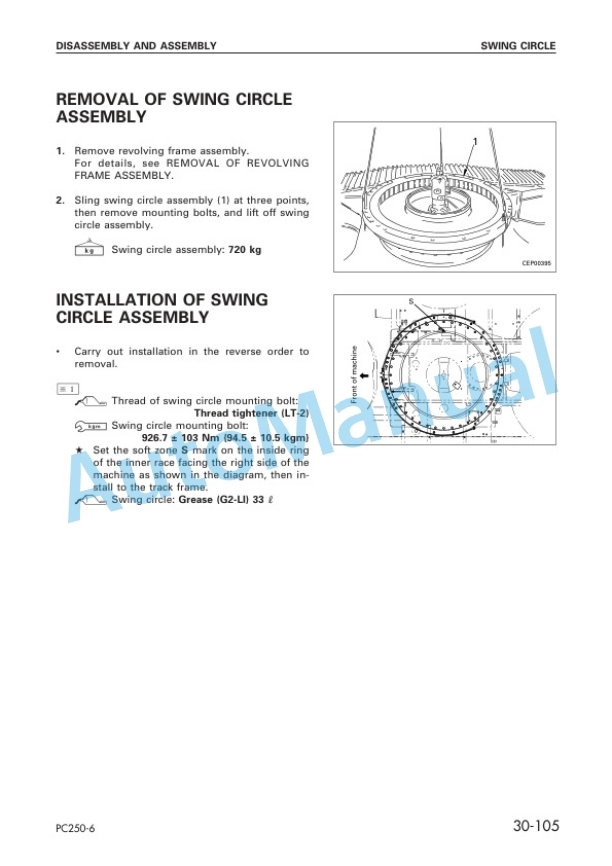

- 6.26. SWING CIRCLE

- 6.26.1. REMOVAL AND INSTALLATION

- 6.27. IDLER,RECOIL SPRING

- 6.27.1. REMOVAL AND INSTALLATION

- 6.27.2. REMOVAL AND INSTALLATION

- 6.27.3. DISASSEMBLY

- 6.27.4. ASSEMBLY

- 6.28. CARRIER ROLLER

- 6.28.1. REMOVAL AND INSTALLATION

- 6.28.2. DISASSEMBLY

- 6.28.3. ASSEMBLY

- 6.29. TRACK SHOE

- 6.29.1. REMOVAL AND INSTALLATION

- 6.30. MAIN PUMP INPUT SHAFT OIL SEAL

- 6.30.1. REMOVAL AND INSTALLATION

- 6.31. PUMP MERGEDIVIDER VALVE

- 6.31.1. DISASSEMBLY AND ASSEMBLY

- 6.32. MAIN RELIEF VALVE

- 6.32.1. DISASSEMBLY AND ASSEMBLY

- 6.33. PC VALVE

- 6.33.1. REMOVAL

- 6.33.2. INSTALLATION

- 6.34. LS VALVE

- 6.34.1. REMOVAL AND INSTALLATION

- 6.35. PC, LSEPC VALVE

- 6.35.1. REMOVAL AND INSTALLATION

- 6.36. SOLENOID VALVE

- 6.36.1. REMOVAL AND INSTALLATION

- 6.37. WORK EQUIPMENTSWING PPC VALVE

- 6.37.1. REMOVAL AND INSTALLATION

- 6.37.2. DISASSEMBLY

- 6.37.3. ASSEMBLY

- 6.38. TEAVEL PPC VALVE

- 6.38.1. REMOVAL AND INSTALLATION

- 6.38.2. DISASSEMBLY

- 6.39. BOOM LOCK VALVE

- 6.39.1. REMOVAL AND INSTALLATION

- 6.40. BUCKET CYLINDER

- 6.40.1. REMOVAL

- 6.40.2. INSTALLATION

- 6.41. HYDRAULIC CYLINDER

- 6.41.1. DISASSEMBLY

- 6.41.2. ASSEMBLY

- 6.42. WORK EQUIPMENT

- 6.42.1. REMOVAL AND INSTALLATION

- 6.43. ENGINE THROTTLEPUMP CONTROLLER

- 6.43.1. REMOVAL AND INSTALLATION

- 6.44. CONTROL STAND CASE

- 6.44.1. REMOVAL

- 6.44.2. INSTALLATION

- 6.45. MONITOR

- 6.45.1. REMOVAL AND INSTALLATION

- 7. MAINTENANCE STANDARD

- 7.1. SWING MACHINERY

- 7.2. FINAL DRIVE

- 7.3. SWING CIRCLE

- 7.4. TRACK FRAME AND RECOIL SPRING

- 7.5. SELFREDUCING PRESSURE VALVE

- 7.6. SWING MOTOR

- 7.7. TRAVEL MOTOR

- 7.8. WORK EQUIPMENTSWING PPC VALVE

- 7.9. TRAVEL PPC VALVE

- 7.10. SERVICE PPC VALVE

- 7.11. CENTER SWIVEL JOINT

- 7.12. BOOM HOLDING VALVE

- 7.13. HYDRAULIC CYLINDER

- 7.14. WORK EQUIPMENT

- 7.15. DIMENSION OF WORK EQUIPMENT

- 8. OTHERS

- 8.1. HYDRAULIC CIRCUIT DIAGRAM

- 8.2. ELECTRICAL CIRCUIT DIAGRAM (1/2)

- 8.3. ELECTRICAL CIRCUIT DIAGRAM (2/2)

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00