Komatsu PC26MR-3 Hydraulic Excavator Shop Manual WEBM007900

$40.00

- Type Of Manual: Shop Manual

- Manual ID: WEBM007900

- Format: PDF

- Size: 18.3MB

- Number of Pages: 234

Category: Komatsu Shop Manual PDF

-

Model List:

- PC26MR-3 Hydraulic Excavator

- 1. CONTENTS

- 2. REVISED PAGES

- 3. k SAFETY

- 4. FOREWORD

- 5. HOW TO READ THE SHOP MANUAL

- 6. HOISTING INSTRUCTIONS

- 7. STANDARD TIGHTENING TORQUE

- 8. COATING MATERIALS

- 9. ELECTRIC

- 10. WEIGHT TABLE

- 11. TABLE OF OIL AND COOLANT QUANTITIES

- 12. CONVERSION TABLE

- 13. STRUCTURE AND FUNCTION

- 13.1. HYDRAULIC COMPONENTS LAYOUT DRAWING

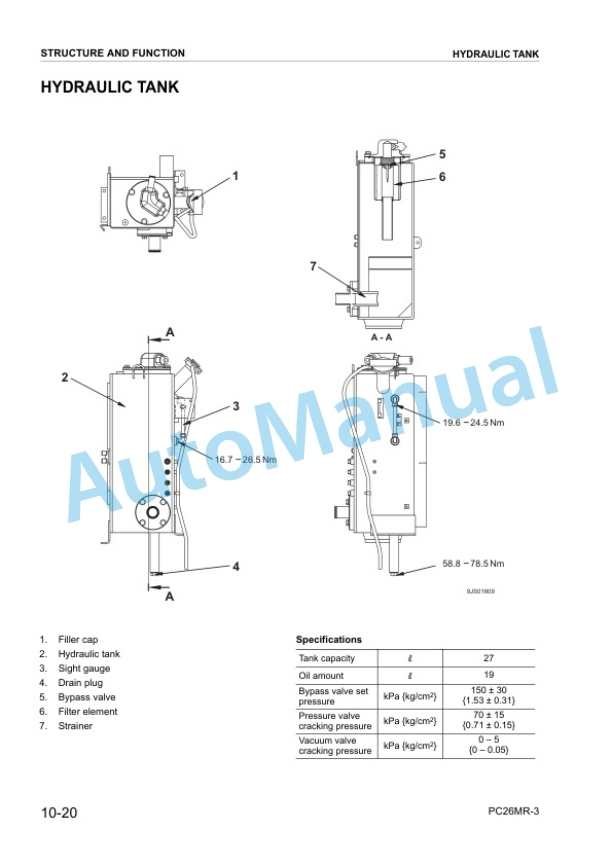

- 13.2. HYDRAULIC TANK

- 13.3. CENTER SWIVEL JOINT

- 13.4. HYDRAULIC CYLINDER

- 13.5. SOLENOID VALVE

- 13.6. HYDRAULIC PUMP

- 13.7. CONTROL VALVE

- 13.8. OPERATION FOR EACH FUNCTION AND VALVE

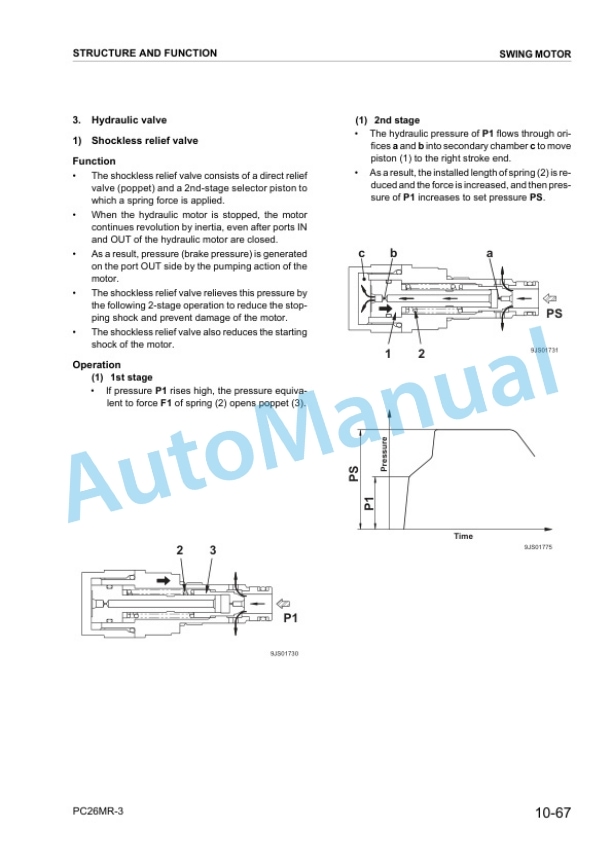

- 13.9. SWING MOTOR

- 13.10. PPC VALVES

- 13.11. WORK EQUIPMENT

- 13.12. DIMENSIONS OF EACH PART OF WORK EQUIPMENT

- 13.13. FLOOR

- 14. TESTING AND ADJUSTMENTS

- 14.1. MACHINE SPECIFICATIONS AND COMPONENTS

- 14.2. PUMP FEATURES

- 14.3. CHECK POSITIONS

- 14.4. SPECIAL TOOLS

- 14.5. TESTING ENGINE SPEED

- 14.6. MEASUREMENT OF EXHAUST GAS COLOR

- 14.7. ADJUSTING VALVE CLEARANCE

- 14.8. CHECKING COMPRESSION PRESSURE

- 14.9. CHECKING ENGINE OIL PRESSURE

- 14.10. TESTING AND ADJUSTING FUEL INJECTION TIMING

- 14.11. BLEEDING AIR FROM FUEL CIRCUIT

- 14.12. TESTING AND ADJUSTING FAN BELT TENSION

- 14.13. ADJUSTING FUEL CONTROL LEVER LINKAGE

- 14.14. MEASUREMENT OF CLEARANCE IN SWING CIRCLE BEARINGS

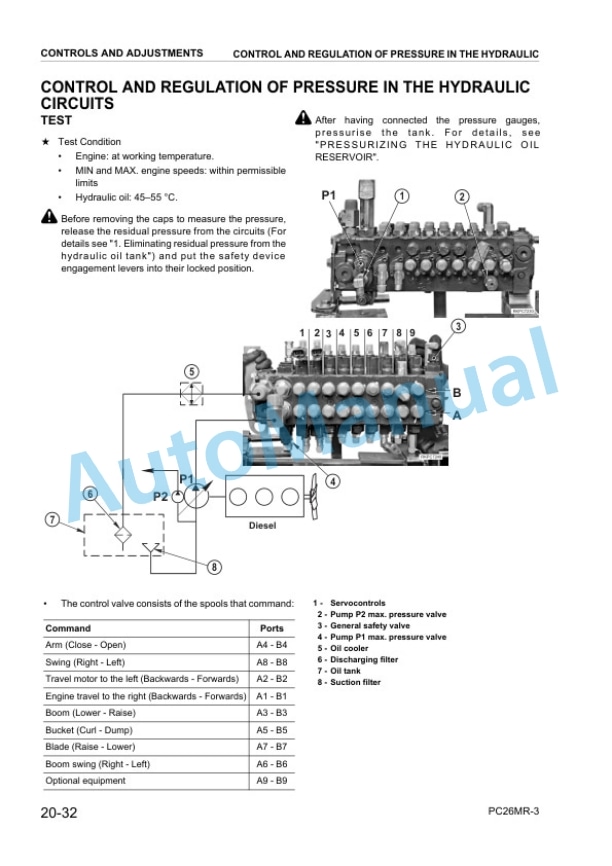

- 14.15. CONTROL AND REGULATION OF PRESSURE IN THE HYDRAULIC CIRCUITS

- 14.16. CHECKING SERVOCONTROL SUPPLY PRESSURE

- 14.17. CHECKING AND ADJUSTING THE LS DIFFERENTIAL PRESSURE. ADJUSTING THE LS VALVE

- 14.18. TESTING THE CORRECT FUNCTIONING OF THE SOLENOID VALVE UNIT

- 14.19. CHECKING PPC VALVE OUTPUT PRESSURE

- 14.20. CHECKING REVOLVING FRAME SWING BRAKE RELEASE PRESSURE

- 14.21. TESTING AND ADJUSTING TRACK SHOE TENSION

- 14.22. CHECKING DEVIATION DURING TRAVEL

- 14.23. CHECKING FOR LEAKAGE INSIDE THE CYLINDERS

- 14.24. ELIMINATING RESIDUAL PRESSURE FROM THE HYDRAULIC CIRCUITS

- 14.25. PRESSURIZING THE HYDRAULIC OIL RESERVOIR

- 14.26. BLEEDING AIR FROM CYLINDERS

- 14.27. BLEEDING AIR FROM THE HYDRAULIC CIRCUITS

- 14.28. HOW TO OPEN AND CLOSE (TILT) FLOOR

- 14.29. KOMTRAX STATION OPENING CHECK (TC1310 station)

- 14.30. KOMTRAX SYSTEM CHECKS

- 15. REMOVAL AND INSTALLATION

- 15.1. HOW TO READ THE MANUAL

- 15.2. PRECAUTIONS TO BE TAKEN WHILE WORKING

- 15.3. SPECIAL TOOLS

- 15.4. INJECTION PUMP

- 15.4.1. Removal

- 15.4.2. Installation

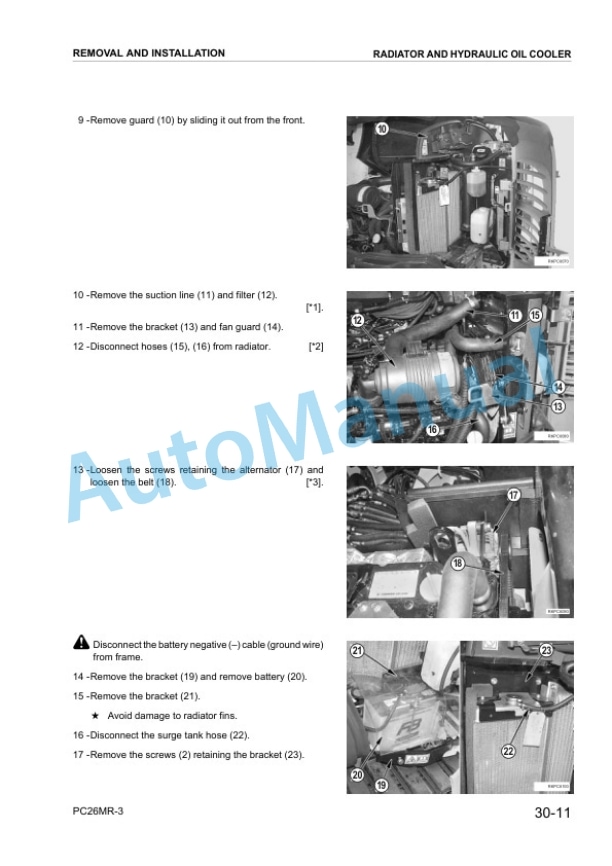

- 15.5. RADIATOR AND HYDRAULIC OIL COOLER

- 15.5.1. Removal

- 15.5.2. Installation

- 15.6. ENGINEPUMP GROUP

- 15.7. BUMPER SPRING AND PUSH CYLINDER ASSEMBLIES

- 15.7.1. Removal

- 15.7.2. Assembling

- 15.8. LOWER IDLER ROLLERS

- 15.9. SWING MOTOR ASSEMBLY

- 15.9.1. Removal

- 15.9.2. Installation

- 15.10. ENTIRE UPPER FRAME

- 15.11. WORKING EQUIPMENT

- 15.11.1. Removal

- 15.11.2. Installation

- 15.12. CONTROL VALVE

- 15.13. HYDRAULIC CYLINDERS

- 15.13.1. Assembling

- 15.13.2. CYLINDER

- 15.13.3. PISTON ROD

- 15.13.4. CYLINDER HEAD ASSEMBLY

- 15.13.5. PISTON ASSEMBLY

- 15.13.6. PISTON ROD

- 15.14. KOMTRAX STATION (FOR CANOPY)

- 15.14.1. Removal

- 15.14.2. Installation

- 15.15. KOMTRAX STATION (FOR CAB)

Rate this product

You may also like