Komatsu PC270LC-8 Hydraulic Excavator Shop Manual CEBM007202

$40.00

- Type Of Manual: Shop Manual

- Manual ID: CEBM007202

- Format: PDF

- Size: 80.5MB

- Number of Pages: 1147

Category: Komatsu Shop Manual PDF

-

Model List:

- PC270LC-8 Hydraulic Excavator

- 1. CEBM007202 PC270LC8 sn A87001 and up

- 1.1. CONTENTS

- 1.2. REVISED PAGES

- 1.3. SAFETY

- 1.4. GENERAL

- 1.5. HOW TO READ THE SHOP MANUAL

- 1.6. HOISTING INSTRUCTIONS

- 1.7. PUSH PULL COUPLER

- 1.8. COATING MATERIALS

- 1.9. EXPLANATION OF MAINTENANCE STANDARD TERMS

- 1.10. STANDARD TIGHTENING TORQUE

- 1.11. ELECTRIC WIRE CODE

- 1.12. CONVERSION TABLES

- 2. GENERAL

- 2.1. SPECIFICATION AND TECHNICAL DATA

- 2.2. TABLE OF FUEL, COOLANT AND LUBRICANTS

- 3. STRUCTURE, FUNCTION ANDMAINTENANCE STANDARD

- 3.1. ENGINE AND COOLING

- 3.2. POWER TRAIN

- 3.3. UNDERCARRIAGE AND FRAME

- 3.4. HYDRAULIC SYSTEM

- 3.5. WORK EQUIPMENT

- 3.6. CAB AND ITS ATTACHMENTS

- 3.7. ELECTRICAL SYSTEM

- 3.8. MONITOR SYSTEM

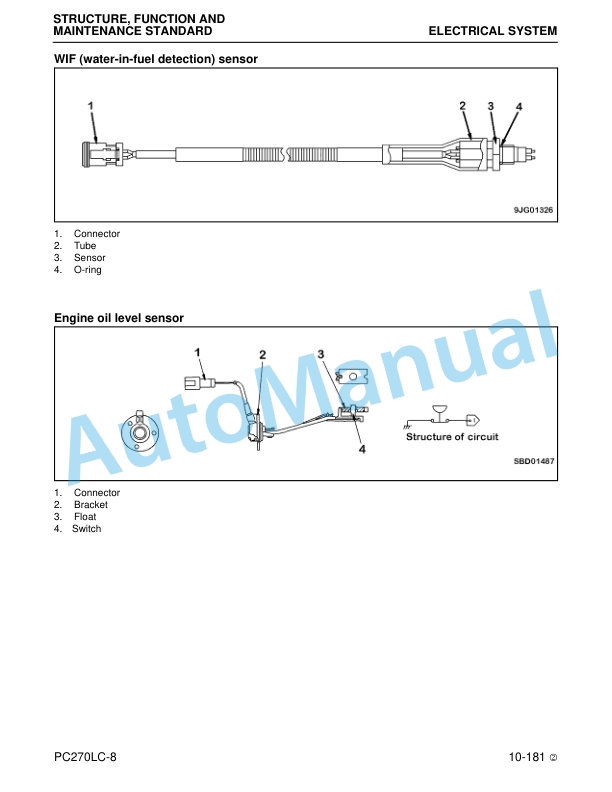

- 3.9. SENSORS

- 3.10. KOMTRAX TERMINAL SYSTEM

- 4. STANDARD VALUE TABLES

- 4.1. STANDARD SERVICE VALUE TABLE

- 5. TESTING AND ADJUSTING

- 5.1. TOOLS FOR TESTING, ADJUSTING, AND TROUBLESHOOTING

- 5.2. ENGINE SPEED

- 5.3. INTAKE AIR PRESSURE (BOOST PRESSURE)

- 5.4. EXHAUST GAS COLOR

- 5.5. VALVE CLEARANCE

- 5.6. COMPRESSION PRESSURE

- 5.7. BLOWBY PRESSURE

- 5.8. ENGINE OIL PRESSURE

- 5.9. HANDLING FUEL SYSTEM PARTS

- 5.10. AIR CONDITIONER COMPRESSOR BELT

- 5.11. FAN BELT

- 5.12. SWING CIRCLE BEARING

- 5.13. TRACK CHAIN TENSION

- 5.14. WORK EQUIPMENT, SWING, AND TRAVEL CIRCUITS OIL PRESSURE

- 5.15. CONTROL CIRCUIT BASIC PRESSURE

- 5.16. OIL PRESSURE IN PUMP PC CONTROL CIRCUIT

- 5.17. OIL PRESSURE IN PUMP LS CONTROL CIRCUIT

- 5.18. SOLENOID VALVE OUTPUT PRESSURE

- 5.19. PPC VALVE OUTPUT PRESSURE

- 5.20. WORK EQUIPMENT AND SWING PPC VALVES

- 5.21. HYDRAULIC DRIFT OF WORK EQUIPMENT

- 5.22. RESIDUAL PRESSURE FROM HYDRAULIC CIRCUIT

- 5.23. OIL LEAKAGE

- 5.24. BLEEDING AIR FROM EACH PART

- 5.25. CAB TIPPING STOPPER

- 5.26. MIRRORS

- 5.27. SPECIAL FUNCTIONS OF MACHINE MONITOR

- 5.28. HANDLING VOLTAGE CIRCUIT OF ENGINE CONTROLLER

- 5.29. PREPARATION WORK FOR ELECTRICAL SYSTEM

- 5.30. PROCEDURE FOR TESTING DIODES

- 5.31. PM CLINIC SERVICE

- 6. TROUBLESHOOTING

- 6.1. GENERAL INFORMATION

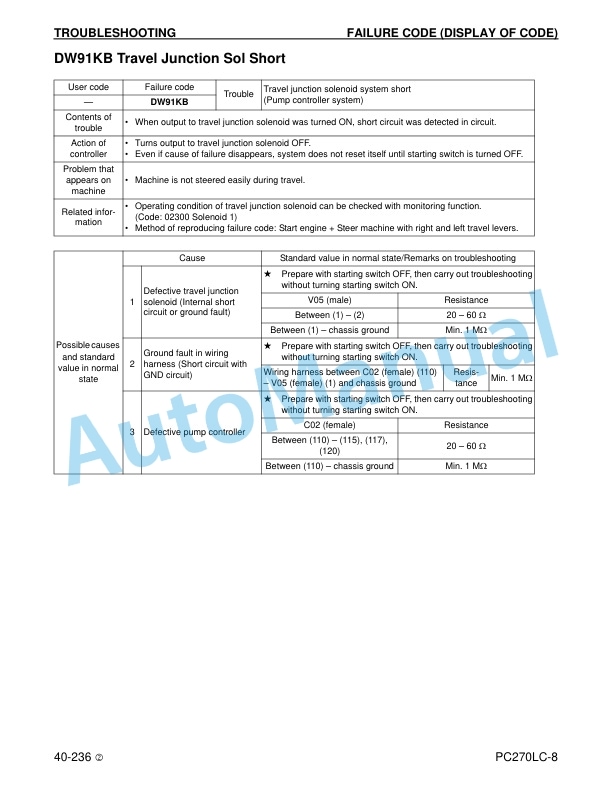

- 6.2. FAILURE CODE (DISPLAY OF CODE)

- 6.3. ELECTRICAL SYSTEM (EMODE)

- 6.4. HYDRAULIC AND MECHANICAL SYSTEM (HMODE)

- 7. DISASSEMBLY AND ASSEMBLY

- 7.1. HOW TO READ THIS SECTION

- 7.2. SPECIAL TOOLS LIST

- 7.3. SKETCHES OF SPECIAL TOOLS

- 7.4. CONNECTOR REPAIR PROCEDURES

- 7.5. ENGINE AND COOLING SYSTEM

- 7.6. POWER TRAIN

- 7.7. UNDERCARRIAGE AND FRAME

- 7.8. HYDRAULIC SYSTEM

- 7.9. WORK EQUIPMENT

- 7.10. CAB AND ITS ATTACHMENTS

- 7.11. ELECTRICAL SYSTEM

- 8. AIR CONDITIONER

- 8.1. STRUCTURE AND FUNCTION

- 8.2. TESTING AND ADJUSTING

- 8.3. TROUBLESHOOTING

- 9. DIAGRAMS AND SCHEMATICS

- 9.1. HYDRAULIC SYSTEM

- 9.2. ELECTRICAL SYSTEM

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00