Komatsu PC3000-1 Hydraulic Mining Shovel Shop Manual SMPC30006171

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SMPC30006171

- Format: PDF

- Size: 17.6MB

- Number of Pages: 479

Category: Komatsu Shop Manual PDF

-

Model List:

- PC3000-1 Hydraulic Mining Shovel

- 1. Table of Contents

- 2. Section 1 Main Assembly Groups

- 2.1. Table of Contents, Section 1

- 2.1.1. General Layout

- 2.1.2. Drive

- 2.1.3. Control Blocks, Slew Gear

- 2.1.4. Undercarriage, Travel Drive

- 2.1.5. Drivers Cab

- 3. Section 2 Drive

- 3.1. Table of Contents, Section 2

- 3.1.1. Prime Drive Assembly

- 3.1.2. Engine Mounts

- 3.1.3. Fan Drive and Cooler Assy.

- 3.1.4. Coupling

- 3.1.5. Air Filter

- 3.1.6. Pump Distributor Gear

- 3.1.7. Pump Spline Lubrication

- 3.1.8. PTO Gear Ludrication

- 4. Section 3 Hydraulic Oil Tank

- 4.1. Table of Contents, Section 3

- 4.1.1. Main Oil Tank

- 4.1.2. Return and Leak Oil Filter

- 4.1.3. Breather Filter

- 4.1.4. Location of Pressure Switches and Sensors

- 5. Section 4 Hydraulic Oil Cooling

- 5.1. Table of Contents, Section 4

- 5.1.1. General

- 5.1.2. Hydraulic Oil Cooling Circuit

- 5.1.3. Measuring / Setting the Back Pressure Valve

- 5.1.4. Fan Drive

- 5.1.5. Axial Piston Pump

- 5.1.6. Measuring and Setting of the Fan Speed

- 5.1.7. Function Check for RPMControl

- 6. Section 5 Controlling

- 6.1. Table of Contents, Section 5

- 6.1.1. Pilot Pressure Supplu

- 6.1.1.1. General

- 6.1.1.2. Function

- 6.1.2. Checks and Adjustment of Pilot Pressure

- 6.1.3. Measuring and Adjustment of Control Pressure

- 6.1.3.1. Checking of Accumulator Function

- 6.1.3.2. Checking of Accumulator Precharge Pressure

- 6.1.4. Travel Parking Brake

- 6.1.5. Function Check of Travel Parking Brake

- 6.1.6. Slew Parking (House) Brake

- 7. Section 6 Components

- 7.1. Table of Content

- 7.1.1. Main Control Blocks and High Pressure Filter (BullClam Attachment

- 7.1.2. Main Control Blocks and High Pressure Filter (Back Hoe Attachment

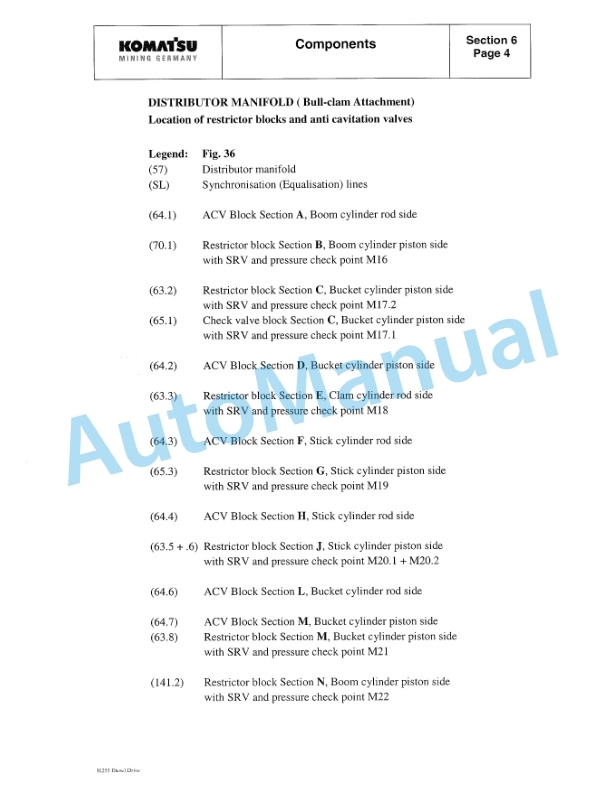

- 7.1.3. Distributor Manifold (BullClam Attachment)

- 7.1.4. Distributor Manifold (Back Hoe Attachment

- 7.1.5. Restrictor Block with Pressure Valve

- 7.1.6. Restrictor Block

- 7.1.7. Anti Cavitation Valve Block

- 7.1.8. Proportional Solenoid Valve

- 7.1.9. Pressure Filter

- 7.1.10. Control Blocks

- 7.1.10.1. Control Blocks and Valves

- 7.1.10.2. Valve at the Control Block

- 7.1.10.3. Load Holding Valve

- 7.1.11. Travel Brake Valve

- 7.1.12. Pressure Reducing Valve

- 7.1.13. Directional Control Valve (Solenoid Valve)

- 7.1.14. Hydraulic Cylinder

- 7.1.15. Auxiliary Pumps, Fan Drive

- 7.1.16. Auxiliary Gear Pumps

- 7.1.17. Slew Ring

- 8. Section 7 Main Hydraulic Pumps and Pump Regulation

- 8.1. Table of Content

- 8.1.1. Main Hydraulic Pump A7V / HD D

- 8.1.2. SLBearing

- 8.1.3. Function of the Pump Governor

- 8.1.4. Pump Bearing Lubrication

- 8.1.5. Pump Governor Adjustments

- 8.1.6. Pump Regulation, General

- 8.1.7. Determination of Peak Point (Engine Performance Test)

- 8.1.8. Hydraulic Regulation Adjustment, Stop Gap Operation

- 8.1.9. Detailed Explanation for Electronic Pump Regulation

- 8.1.10. Adjustments / Checks for Electronic Pump Regulation

- 8.1.11. Adjusting the RPM Sensor (MPU)

- 8.1.12. Adjustments at the ELL Module, Normal Fine Tuning

- 8.1.13. Checks / Function Test / Fault Finding at JOBSITE

- 8.1.14. EPM Module, Function and Test

- 8.1.15. ERM Module, Function and Test

- 8.1.16. ELL Module, Function and Test

- 8.1.17. Amplifier Module, Function and Test

- 8.1.18. Simplified Trouble Shooting of Electronic Regulation

- 9. Section 8 Operating Hydraulic

- 9.1. Table of Content

- 9.1.1. Hydraulic for Attachment Cylinder

- 9.1.2. Adjustments for Attachment Cylinder Hydraulic

- 9.1.3. Slew Circuit, General

- 9.1.4. Slew Motor

- 9.1.5. Slew Gear and House Brake

- 9.1.6. Slew Brake Valve

- 9.1.7. Slew Function

- 9.1.8. Checks and Adjustments

- 9.1.9. Travel Citcuit

- 9.1.10. Rotary Distributor

- 9.1.11. Travel Motor (Axial Piston Motor A2FM)

- 9.1.12. Travel Gear and House Brake

- 9.1.12.1. Travel Gear

- 9.1.12.2. Travel Gear House Brake

- 9.1.13. Travel, Function

- 9.1.14. AntiCavitation Circuit

- 9.1.15. Adjustments / Checks

- 10. Section 9 Hydraulic Tank Tension System

- 10.1. Table of Content

- 10.1.1. Hydraulic Track Tension System

- 10.1.1.1. Function

- 10.1.1.2. Pressure Increasing Valve

- 10.1.1.3. Pressure Relief Valve, Direct Operated

- 10.1.1.4. Adjustments / Pressure Checks

- 11. Section 10 Hints for the Hydraulic Circuit Diagram

- 11.1. Table of Content

- 11.1.1. Hints for Reading Circuit Diagrams

- 11.1.2. Legend of the Hydraulic Circuit Diagram

- 11.1.3. Pressure Check Points

- 11.1.4. How to Read the Circuit Diagram

- 11.2. Hydraulic Diagram (1/3)

- 11.3. Hydraulic Diagram (2/3)

- 11.4. Hydraulic Diagram (3/3)

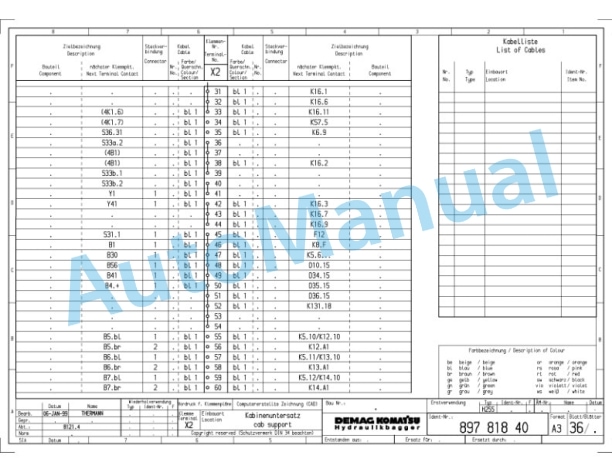

- 12. Section 11 Hints for the Electric Circuit Diagram

- 12.1. Table of Content

- 12.1.1. Markings of Electrical Components in Circuit Diagrams

- 12.1.2. Symbols

- 12.1.3. KGM Circuit Diagrams

- 12.1.3.1. General Information

- 12.1.3.2. Explanation of the Drawing Concept

- 12.1.3.3. Terminal Plans

- 12.1.3.4. Location of Main Terminal Boxes and Important Components

- 12.1.3.5. Reading a Circuit Diagram

- 12.1.4. Adjustments

- 12.1.5. Component List / Function

- 12.2. Electrical Diagrams

- 12.2.1. Electrical Diagrams 897 818 40 (1/49)

- 12.2.2. Electrical Diagrams 897 818 40 (2/49)

- 12.2.3. Electrical Diagrams 897 818 40 (3/49)

- 12.2.4. Electrical Diagrams 897 818 40 (4/49)

- 12.2.5. Electrical Diagrams 897 818 40 (5/49)

- 12.2.6. Electrical Diagrams 897 818 40 (6/49)

- 12.2.7. Electrical Diagrams 897 818 40 (7/49)

- 12.2.8. Electrical Diagrams 897 818 40 (8/49)

- 12.2.9. Electrical Diagrams 897 818 40 (9/49)

- 12.2.10. Electrical Diagrams 897 818 40 (10/49)

- 12.2.11. Electrical Diagrams 897 818 40 (11/49)

- 12.2.12. Electrical Diagrams 897 818 40 (12/49)

- 12.2.13. Electrical Diagrams 897 818 40 (13/49)

- 12.2.14. Electrical Diagrams 897 818 40 (14/49)

- 12.2.15. Electrical Diagrams 897 818 40 (15/49)

- 12.2.16. Electrical Diagrams 897 818 40 (16/49)

- 12.2.17. Electrical Diagrams 897 818 40 (17/49)

- 12.2.18. Electrical Diagrams 897 818 40 (18/49)

- 12.2.19. Electrical Diagrams 897 818 40 (19/49)

- 12.2.20. Electrical Diagrams 897 818 40 (20/49)

- 12.2.21. Electrical Diagrams 897 818 40 (21/49)

- 12.2.22. Electrical Diagrams 897 818 40 (22/49)

- 12.2.23. Electrical Diagrams 897 818 40 (23/49)

- 12.2.24. Electrical Diagrams 897 818 40 (24/49)

- 12.2.25. Electrical Diagrams 897 818 40 (25/49)

- 12.2.26. Electrical Diagrams 897 818 40 (26/49)

- 12.2.27. Electrical Diagrams 897 818 40 (27/49)

- 12.2.28. Electrical Diagrams 897 818 40 (28/49)

- 12.2.29. Electrical Diagrams 897 818 40 (29/49)

- 12.2.30. Electrical Diagrams 897 818 40 (30/49)

- 12.2.31. Electrical Diagrams 897 818 40 (31/49)

- 12.2.32. Electrical Diagrams 897 818 40 (32/49)

- 12.2.33. Electrical Diagrams 897 818 40 (33/49)

- 12.2.34. Electrical Diagrams 897 818 40 (34/49)

- 12.2.35. Electrical Diagrams 897 818 40 (35/49)

- 12.2.36. Electrical Diagrams 897 818 40 (36/49)

- 12.2.37. Electrical Diagrams 897 818 40 (37/49)

- 12.2.38. Electrical Diagrams 897 818 40 (38/49)

- 12.2.39. Electrical Diagrams 897 818 40 (39/49)

- 12.2.40. Electrical Diagrams 897 818 40 (40/49)

- 12.2.41. Electrical Diagrams 897 818 40 (41/49)

- 12.2.42. Electrical Diagrams 897 818 40 (42/49)

- 12.2.43. Electrical Diagrams 897 818 40 (43/49)

- 12.2.44. Electrical Diagrams 897 818 40 (44/49)

- 12.2.45. Electrical Diagrams 897 818 40 (45/49)

- 12.2.46. Electrical Diagrams 897 818 40 (46/49)

- 12.2.47. Electrical Diagrams 897 818 40 (47/49)

- 12.2.48. Electrical Diagrams 897 818 40 (48/49)

- 12.2.49. Electrical Diagrams 897 818 40 (49/49)

- 13. Section 12 Electronic Text Monitoring System

- 13.1. Table of Content

- 13.1.1. Introduction

- 13.1.2. Function

- 13.1.3. Lay Out of Dash Board

- 13.1.4. Text Monitoring System

- 13.1.5. Frequency / Voltage Converter (EFDModule)

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00