Komatsu PC4000E-6 Hydraulic Mining Shovel Shop Manual 08165E-GB-2

$40.00

- Type Of Manual: Shop Manual

- Manual ID: 08165E-GB-2

- Format: PDF

- Size: 64.4MB

- Number of Pages: 1902

Category: Komatsu Shop Manual PDF

-

Model List:

- PC4000E-6 Hydraulic Mining Shovel

- 1. Foreword

- 1.1. Introduction

- 1.2. Safety Instructions

- 2. Specification

- 2.1. Specification PC4000

- 3. Structure, Function

- 3.1. INTRODUCTION

- 3.1.1. I Contents of the Binder

- 3.1.2. II Foreword

- 3.1.3. III Explanation of Abbrevations

- 3.2. II SAFETY

- 3.3. III. SPECIFICATIONS

- 3.3.1. III.I Lifting Gears

- 3.3.2. III.II Standard Tightening Torque Chart

- 3.3.3. III.III Conversion Table

- 3.3.4. III.IV General Specifications

- 3.4. MAIN ASSEMBLY GROUPS

- 3.4.1. General Layout

- 3.4.2. Superstructure

- 3.4.3. Machine House

- 3.4.4. Hydraulic Oil Reservoir

- 3.4.5. Hydraulic Oil Cooler

- 3.4.6. Fuel Tank

- 3.4.7. Counterweight

- 3.4.8. Cab Support

- 3.4.9. Operators Cab

- 3.4.10. Control Blocks

- 3.4.11. Swing Gears

- 3.4.12. Undercarriage

- 3.4.13. Backhoe Attachment (BHA)

- 3.4.14. Front Shovel Attachment (FSA)

- 3.5. DRIVE

- 3.5.1. Prime Drive Assembly

- 3.5.2. Engine and PTO Mounts

- 3.5.3. Fan Drive and Radiator Assembly

- 3.5.4. Pump Distributor Gearbox (PTO)

- 3.5.5. Geislinger Coupling

- 3.5.6. Air Filter

- 3.6. HYDRAULIC OIL TANK

- 3.6.1. General Layout

- 3.6.2. Main Oil Tank, Location of Electric Equipment.

- 3.6.3. Suction Oil Reservoir with Strainers

- 3.6.4. Return Oil Collector Tube with Strainer

- 3.6.5. Back Pressure Valve

- 3.6.6. Transfer Pump

- 3.6.7. Return and Leak Oil Filter

- 3.6.8. Breather Filter

- 3.7. HYDRAULIC OIL COOLING

- 3.7.1. General

- 3.7.2. Function of the Hydraulic Oil Cooling Circuit

- 3.7.3. Adjustment of the Back Pressure Valve

- 3.7.4. Fan Drive (Two Stage Cooler Fan RPM Control)

- 3.7.5. Adjustment of the Cooler Fan Drive Speed

- 3.8. CONTROLLING

- 3.8.1. General Layout

- 3.8.2. Control and Filter Panel Location of Components

- 3.8.3. Pilot Pressure Supply and Adjustments

- 3.8.4. Function Electro Hydraulic Control SYSTEM

- 3.8.5. Potentiometer Control (Lever, Joy Stick)

- 3.8.6. Potentiometer Control (Pedal)

- 3.8.7. Proportional Amplifier Module, Type A

- 3.8.8. Proportional Amplifier Module, Type B

- 3.8.9. Ramp Time Module

- 3.8.10. Adjustments of Amplifier Modules

- 3.8.11. Adjusting the Ramp Time Module

- 3.9. COMPONENTS

- 3.9.1. Main Control Blocks and High Pressure Filter (FSA)

- 3.9.2. Main Control Blocks and High Pressure Filter (BHA)

- 3.9.3. Distributor Manifold Location of Restrictor Blocks and Anti Cavitation Valves (FSA)

- 3.9.4. Distributor Manifold Location of Restrictor Blocks and Anti Cavitation Valves (BHA)

- 3.9.5. Single Control Blocks (Floating) for Stick and Boom (FSA)

- 3.9.6. Restrictor Block with Pressure Relief Valve

- 3.9.7. Anti cavitation valve block

- 3.9.8. Remote Control Valves

- 3.9.9. Directional Solenoid Valves (Three Positions / 4Ways)

- 3.9.10. Proportional Solenoid Valve

- 3.9.11. High Pressure Filter

- 3.9.12. Control Blocks and Valves

- 3.9.13. Travel Brake Valve

- 3.9.14. Pressure Reducing Valve

- 3.9.15. Directional Solenoid Valves (Two Positions / 4Ways)

- 3.9.16. Pressure Increasing Valve

- 3.9.17. Hydraulic Cylinder

- 3.9.18. Swing Ring

- 3.10. MAIN HYDRAULIC PUMPS AND PUMP REGULATION

- 3.10.1. General

- 3.10.2. Main Pumps

- 3.10.3. Electronic Pump Regulation System

- 3.10.4. Hydraulic Constant Regulation System

- 3.10.5. Determination of the Peak Point (Engine Performance)

- 3.10.6. Engine Speed Sensor (Pick up)

- 3.10.7. Energy Efficiency

- 3.11. OPERATING HYDRAULICS

- 3.11.1. General

- 3.11.2. Hydraulic for the Attachment Cylinder FSA and BHA

- 3.11.3. Hydraulic for the Swing Circuit

- 3.11.4. Hydraulic for the Travel Circuit

- 3.12. HYDRAULIC TRACK TENSIONING SYSTEM

- 3.12.1. General

- 3.12.2. Pressure Increasing Valve

- 3.12.3. Tensioning Cylinder

- 3.12.4. Adjustments / Checks

- 3.12.5. Functional Test

- 3.13. ACCESS LADDER HYDRAULICALLY OPERATED

- 3.13.1. General

- 3.13.2. Function of Hydraulically Operated Access Ladder

- 3.13.3. Adjustments / Checks

- 3.14. CABLE DRUM

- 3.14.1. General

- 3.14.2. Function

- 3.15. HINTS FOR READING THE HYDRAULIC DIAGRAM

- 3.15.1. General

- 3.15.2. Symbolic

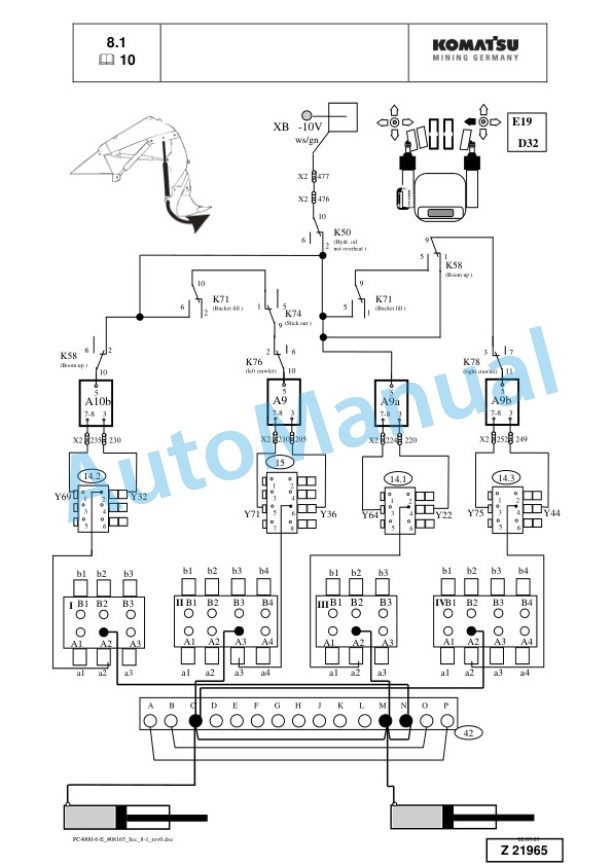

- 3.16. HINTS FOR READING THE ELECTRIC CIRCUIT DIAGRAM

- 3.16.1. Designation of electrical components

- 3.16.2. Electric symbols

- 3.16.3. Symbols

- 3.16.4. Drawing Concept

- 3.16.5. Reading a Circuit Diagram

- 3.16.6. Component List

- 3.17. ELECTRONIC CONTROL SYSTEM (ECS)

- 3.17.1. General

- 3.17.2. Specifications for Operators

- 3.17.3. Specifications for Service

- 3.17.4. Wiring of the Main Components

- 3.17.5. General Design of THE PLC

- 3.17.6. How to proceed the Maintenance and Installation

- 3.17.7. Front Connector Arrangement

- 3.17.8. Power Supply

- 3.17.9. Function Explanations with Electrical Diagram

- 3.17.10. Hints for Reading the Functional Flow Charts

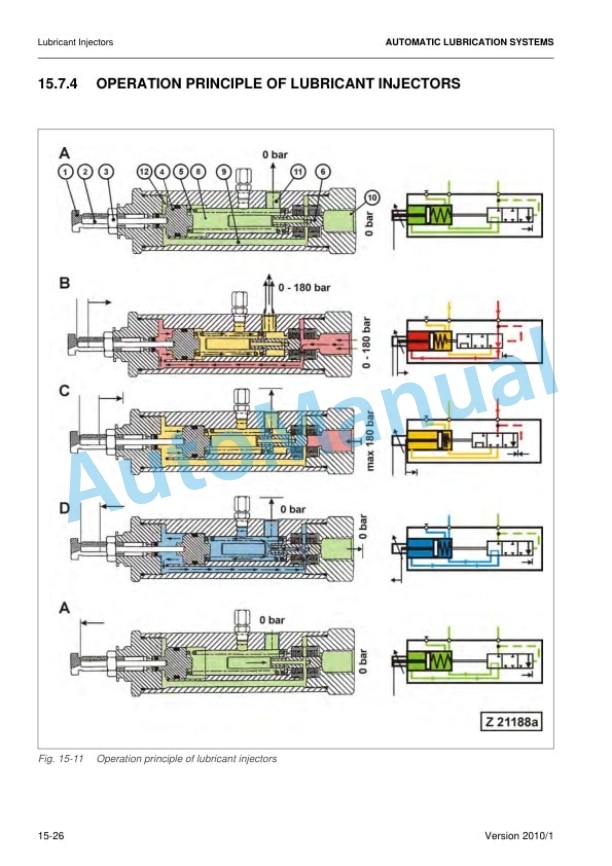

- 3.18. AUTOMATIC LUBRICATION SYSTEMS

- 3.18.1. Introduction

- 3.18.2. Central Lubrication System (CLS)

- 3.18.3. Lubrication Pump Station (SLS)

- 3.18.4. Operating and Controlling

- 3.18.5. Adjustments

- 3.18.6. Troubleshooting

- 3.18.7. Commissioning

- 4. Troubleshooting

- 4.1. Safety

- 5. Dissassembly and Assembly

- 5.1. Table of contents

- 5.2. Introduction

- 5.2.1. Contents of this binder

- 5.2.2. Preface

- 5.3. SAFETY

- 5.3.1. SAFETY INFORMATION

- 5.3.2. OVERVIEW

- 5.3.3. SOUND PRESSURE LEVEL IN THE OPERATORS CAB.

- 5.3.4. GENERAL PRECAUTIONS COMMON TO OPERATION ON THE EXCAVATOR

- 5.3.5. PRECAUTION FOR MAINTENANCE

- 5.3.6. ADDITIONAL SAFETY INFORMATION FOR TROUBLESHOOTING AND ADJUSTMENTS

- 5.3.7. SPECIAL SAFETY EQUIPMENT

- 5.4. Superstructure

- 5.4.1. Superstructure / machine house overview

- 5.4.2. Batteries

- 5.4.3. Electric motor

- 5.4.4. Coupling assembly

- 5.4.6. Hydraulics

- 5.4.7. Slew system

- 5.4.8. Lubrication pumps

- 5.4.9. Operators cab

- 5.4.10. Cab base (medium voltage switch cabinet)

- 5.4.11. Access ladder

- 5.4.12. Counterweight

- 5.4.13. Superstructure Lifting

- 5.4.14. High voltage switch cabinet

- 5.4.15. Slip ring unit

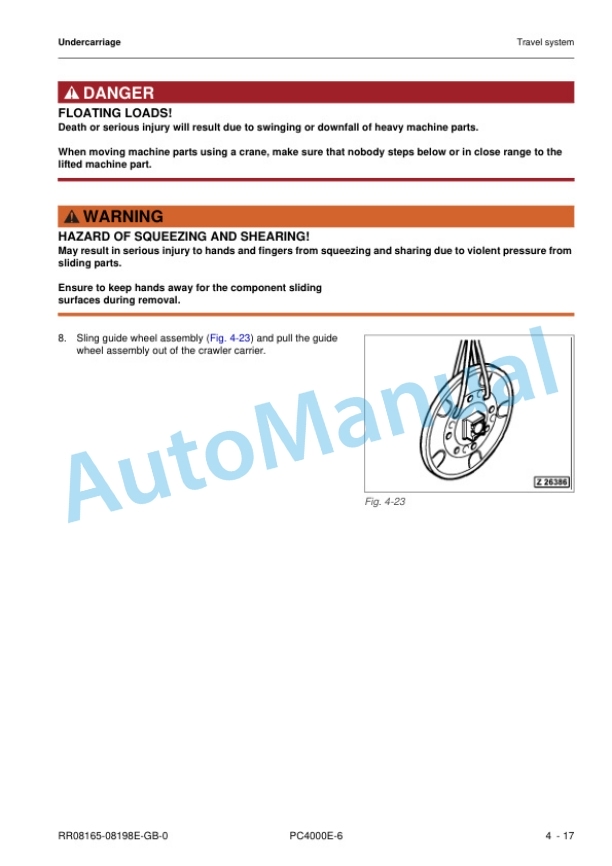

- 5.5. Undercarriage

- 5.5.1. Undercarriage overview

- 5.5.2. Travel system

- 5.5.3. Car body

- 5.5.4. Cable drum (optional)

- 5.5.5. Cable supply

- 5.6. Attachment

- 5.6.1. Backhoe

- 5.6.2. Faceshovel

- 5.6.3. Metering valves (grease injectors) at the attachment

- 5.6.4. Cylinder bypass test

- 5.7. Service Information

- 5.7.1. Classification of Voltages for KMG Electric Shovels

- 5.7.2. Fluids and lubricants

- 5.7.3. Lifting Gears

- 5.7.4. Safety hints for sling accessory

- 5.7.5. Filling capacities

- 5.7.6. Work instructions

- 5.7.7. Weight tables

- 5.7.8. Torque charts according to KOMATSU company standard

- 5.7.9. Blind plugs

- 5.7.10. Conversion table

- 5.7.11. Tools

- 5.8. Tools catalogue

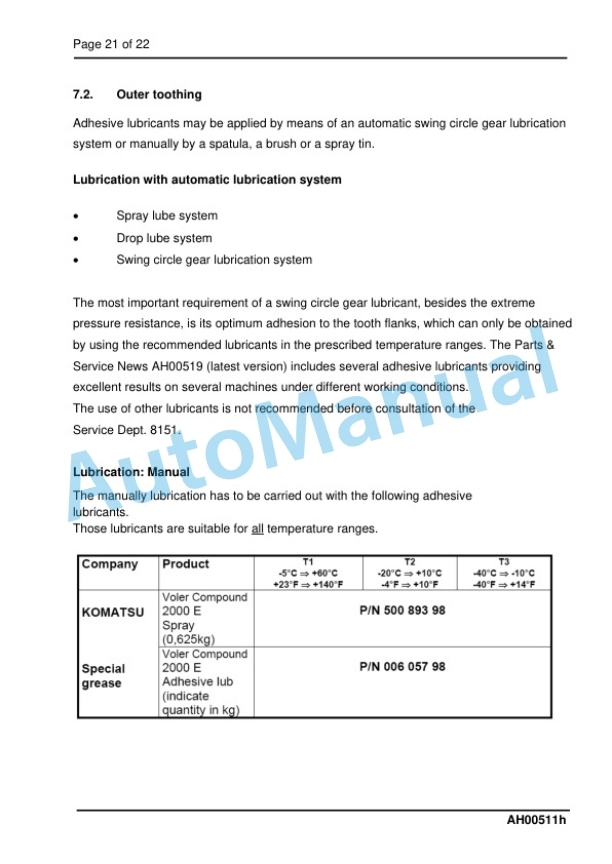

- 5.9. Parts Service News

- 5.9.1. List of the PARTS AND SERVICE NEWS

- 5.10. Suppliers documentation

Rate this product

You may also like