Komatsu PC400LC-6LM, PC400HD-6LM Hydraulic Excavator Shop Manual CEBM005302

$40.00

- Type Of Manual: Shop Manual

- Manual ID: CEBM005302

- Format: PDF

- Size: 19.8MB

- Number of Pages: 868

Category: Komatsu Shop Manual PDF

-

Model List:

- PC400LC-6LM Hydraulic Excavator

- PC400HD-6LM Hydraulic Excavator

- 1. FOREWORD

- 1.1. GENERAL

- 1.2. HOW TO READ THE SHOP MANUAL

- 1.3. HOISTING INSTRUCTIONS

- 1.4. COATING MATERIALS

- 1.5. STANDARD TIGHTENING TORQUE

- 1.6. ELECTRIC WIRE CODE

- 1.7. CONVERSION TABLES

- 2. GENERAL

- 2.1. SPECIFICATION DRAWINGS

- 2.2. WORK EQUIPMENT

- 2.3. SPECIFICATIONS

- 2.4. WEIGHT TABLE

- 2.5. FUEL COOLANT AND LUBRICANTS

- 3. STRUCTURE AND FUNCTION

- 3.1. PARTS RELATED TO ENGINE

- 3.2. RADIATOR, OIL COOLER

- 3.3. POWER TRAIN

- 3.4. FINAL DRIVE

- 3.5. SWING CIRCLE

- 3.6. SWING MACHINERY

- 3.7. TRACK FRAME, RECOIL SPRING

- 3.8. TRACK FRAME, RECOIL SPRING

- 3.9. TRACK FRAME, RECOIL SPRING

- 3.10. TRACK SHOE

- 3.11. HYDRAULIC PIPING DRAWING

- 3.12. HYDRAULIC CIRCUIT DIAGRAM

- 3.13. HYDRAULIC TANK, HYDRAULIC FILTER

- 3.14. HYDRAULIC PUMP

- 3.15. CONTROL VALVE

- 3.16. SELF REDUCING PRESSURE VALVE

- 3.17. SUCTION SAFETY VALVE

- 3.18. CLSS

- 3.19. SWING MOTOR

- 3.20. TRAVEL MOTOR

- 3.21. VALVE CONTROL

- 3.22. WORK EQUIPMENT PPC VALVE

- 3.23. TRAVEL PPC VALVE

- 3.24. SERVICE PPC VALVE

- 3.25. PPC SAFETY LOCK VALVE

- 3.26. PPC ACCUMULATOR

- 3.27. PPC SHUTTLE VALVE, TRAVEL JUNCTION VALVE

- 3.28. LSEPC VALVE

- 3.29. SOLENOID VALVE

- 3.30. BOOM HOLDING VALVE

- 3.31. WORK EQUIPMENT

- 3.32. AIR CONDITIONER

- 3.33. ACTUAL ELECTRICAL WIRING DIAGRAM

- 3.34. ENGINE CONTROL

- 3.35. ELECTRONIC CONTROL SYSTEM

- 3.36. MACHINE MONITOR SYSTEM

- 4. TESTING, ADJUSTING AND TROUBLESHOOTING

- 4.1. STANDARD VALUE TABLE

- 4.2. SERVICE TOOLS TABLE

- 4.3. MEASURING ENGINE SPEED

- 4.4. MEASURING EXHAUST COLOR

- 4.5. VALVE CLEARANCE

- 4.6. COMPRESSION PRESSURE

- 4.7. BLOW BY PRESSURE

- 4.8. FUEL INJECTION TIMING

- 4.9. ENGINE OIL PRESSURE

- 4.10. FAN BELT TENSION

- 4.11. A/C COMPRESSOR BELT

- 4.12. ENGINE SPEED SENSOR

- 4.13. BOOST PRESSURE

- 4.14. GOVERNOR MOTOR LEVER STROKE

- 4.15. WORK, SWING, AND TRAVEL CIRCUIT

- 4.16. TVC VALVE OUTPUT PRESSURE

- 4.17. LS VALVE OUTPUT AND DIFFERENTIAL PRESSURE

- 4.18. CONTROL CIRCUIT OIL PRESSURE

- 4.19. SOLENOID VALVE OUTPUT PRESSURE

- 4.20. PPC VALVE OUTPUT PRESSURE AND SHUTTLE VALVE

- 4.21. WORK EQUIPMENT, SWING PPC VALVE

- 4.22. TRAVEL DEVIATION

- 4.23. LOCATIONS CAUSING HYDRAULIC DRIFT OF WORK EQUIPMENT

- 4.24. MEASURING OIL LEAKAGE

- 4.25. RELEASING REMAINING PRESSURE IN HYDRAULIC CIRCUIT

- 4.26. TESTING CLEARANCE OF SWING CIRCLE BEARING

- 4.27. WEAR OF SPROCKET

- 4.28. TRACK SHOE TENSION

- 4.29. TROUBLESHOOTING GENERAL

- 4.30. TROUBLESHOOTING

- 4.31. TROUBLSHOOTING OF COMMUNICATION ABNORMALITY SYSTEM (NMODE)

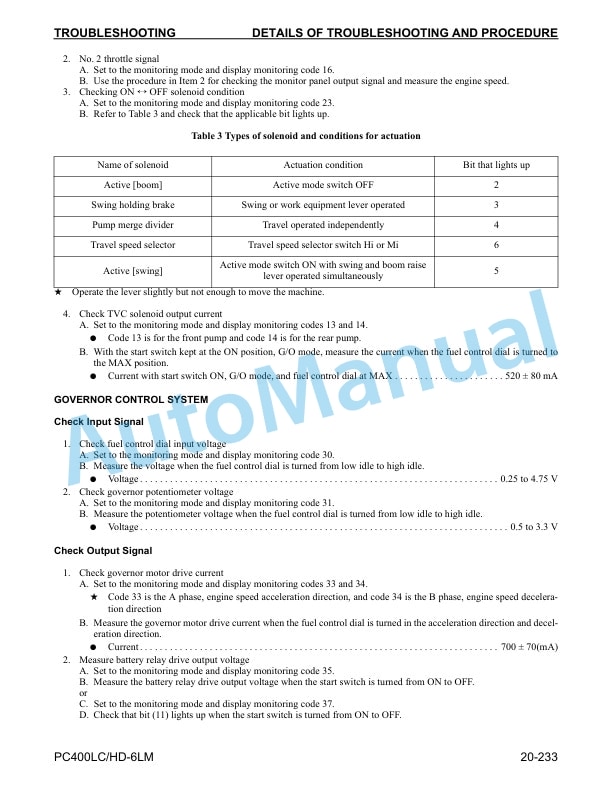

- 4.32. TROUBLESHOOTING OF GOVERNOR, PUMP CONTROLLER, GOVERNOR CONTROL SYSTEM (EMODE)

- 4.33. TROUBLESHOOTING OF ENGINE SYSTEM (SMODE)

- 4.34. TROUBLESHOOTING OF GOVERNOR PUMP CONTROLLER, PUMP CONTROL SYSTEM (CMODE)

- 4.35. TROUBLESHOOTING OF GOVERNOR, PUMP CONTROLLER, INPUT SIGNAL SYSTEM (FMODE)

- 4.36. TROUBLESHOOTING OF MACHINE MECHANICAL MODE (HMODE)

- 4.37. TROUBLESHOOTING OF MACHINE MONITOR SYSTEM (MMODE)

- 5. DISASSEMBLY AND ASSEMBLY

- 5.1. METHOD OF USING MANUAL

- 5.2. SPECIAL TOOL LIST

- 5.3. SKETCHES OF SPECIAL TOOLS

- 5.4. ENGINE OIL COOLER

- 5.5. FUEL INJECTION PUMP

- 5.6. FRONT ENGINE SEAL

- 5.7. REAR ENGINE SEAL

- 5.8. AFTERCOOLER CORE

- 5.9. OIL COOLER

- 5.10. RADIATOR, OIL COOLER

- 5.11. ENGINE, MAIN PUMP

- 5.12. CENTER SWIVEL JOINT

- 5.13. SWING MACHINERY

- 5.14. REVOLVING FRAME

- 5.15. SWING CIRCLE

- 5.16. IDLER AND RECOIL SPRING

- 5.17. MAIN PUMP OIL SEAL

- 5.18. PUMP MERGE DIVIDER VALVE

- 5.19. PRESSURE COMPENSATION VALVE

- 5.20. FRONT PUMP SERVO VALVE

- 5.21. REAR PUMP SERVO VALVE

- 5.22. LSEPC SOLENOID VALVE

- 5.23. SOLENOID VALVE

- 5.24. WORK EQUIPMENT PPC VALVE

- 5.25. TRAVEL PPC VALVE

- 5.26. PPC SHUTTLE VALVE

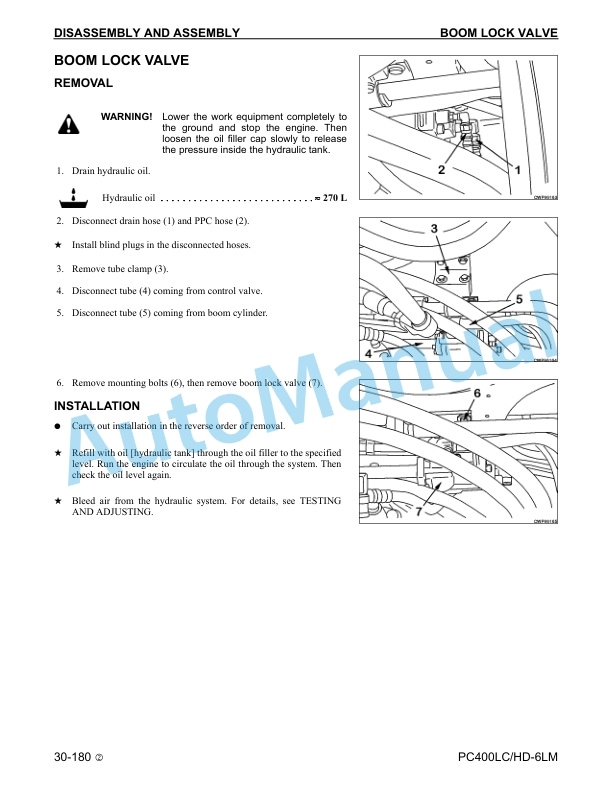

- 5.27. BOOM LOCK VALVE

- 5.28. BUCKET CYLINDER

- 5.29. HYDRAULIC CYLINDER

- 5.30. THREADED STYLE PISTON

- 5.31. AIR CONDITIONER UNIT

- 5.32. GOVERNOR, PUMP CONTROLLER

- 5.33. MONITOR PANEL

- 5.34. CONTROL STAND CASE

- 6. MAINTENANCE STANDARD

- 6.1. ENGINE MOUNT

- 6.2. RADIATOR AND OIL COOLER MOUNT

- 6.3. SWING MACHINERY

- 6.4. SWING CIRCLE

- 6.5. FINAL DRIVE

- 6.6. TRACK FRAME AND RECOIL SPRING

- 6.7. SELF REDUCING PRESSURE VALVE

- 6.8. SUCTION SAFETY VALVE

- 6.9. SWING MOTOR

- 6.10. TRAVEL MOTOR

- 6.11. WORK EQUIPMENT SWING PPC VALVE

- 6.12. TRAVEL PPC VALVE

- 6.13. SERVICE PPC VALVE

- 6.14. PPC SHUTTLE VALVE, TRAVEL JUNCTION VALVE

- 6.15. LSEPC VALVE

- 6.16. SOLENOID VALVE

- 6.17. CENTER SWIVEL JOINT

- 6.18. BOOM HOLDING VALVE

- 6.19. HYDRAULIC CYLINDER

- 6.20. WORK EQUIPMENT

- 6.21. DIMENSIONS OF WORK EQUIPMENT

- 7. OTHERS

- 7.1. Foldout 20203 Connector types and mounting location

- 7.2. Foldout 20229 Details of troubleshooting and troubleshooting procedures

- 7.3. Foldout 20353 Actions taken by controller when abnormality occurs and problems on machine

- 7.4. Foldout 20354 Action taken by controller when abnormality occurs and problems on machine

- 7.5. Foldout 20355 Judgement table for governor pump controller and engine related parts

- 7.6. Foldout 20356 Electrical circuit diagram for E mode

- 7.7. Foldout 20365 E8 Engine does not start

- 7.8. Foldout 20366 E9a Engine speed is irregular

- 7.9. Foldout 20367 E9b There is hunting

- 7.10. Foldout 20368 E10 Lack of output, engine high idle speed is low

- 7.11. Foldout 20369 E11 Engine does not stop

- 7.12. Foldout 20453 Actions taken by controller when abnormality occurs and problems on machine

- 7.13. Foldout 20454 Actions taken by controller when abnormality occurs and problemss

- 7.14. Foldout 20455 Actions taken by controller when abnormality occurs and problems on machine

- 7.15. Foldout 20456 Actions taken by controller when abnromality occurs and problems on machine

- 7.16. Foldout 20457 Judgement table for governor, pump controller (pump control system) and hydraulic related parts

- 7.17. Foldout 20458 Electric circuit diagram for C mode

- 7.18. Foldout 20461 C2 E232 Short circuit in front pump TVC solenoid is displayed

- 7.19. Foldout 20462 C3 E233 Disconnection in front pump TVC solenoid system is displayed

- 7.20. Foldout 20463 C4 E236 Short circuit in rear pump TVC solenoid system is displayed

- 7.21. Foldout 20464 C5 E237 Disconnection in rar pump TVC solenid system is displayed

- 7.22. Foldout 20467 C7 E208 Disconnection in active mode, boom, solenoid system is displayed

- 7.23. Foldout 20468 C8 E203 Short circuit in swing brake solenoid system is displayed

- 7.24. Foldout 20469 C9 E213 Disconnection in swing brake solenoid system is displayed

- 7.25. Foldout 20471 C11 E214 Disconnection in pump merge divider solenoid system is displayed

- 7.26. Foldout 20473 C13 E216 Disconnection in travel speed selector solenoid system is displayed

- 7.27. Foldout 20475 C15 E235 Disconnection in active mode, swlin solenoid system is displayed

- 7.28. Foldout 20503 Electric circuit diagram for F mode

- 7.29. Foldout 20553 Table of failure modes and causes (1/2)

- 7.30. Foldout 20554 Table of fialure modes and causes (2/2)

- 7.31. Foldout 20555 H1 Speed of all work equipment, swing, travel are slow or lack power

- 7.32. Foldout 20557 H4 Abnormal noise generated around pump

- 7.33. Foldout 20557 H5 Auto decel does not work when PPC shuttle valve is cause

- 7.34. Foldout 20557 H6 Fine control ability is poor or response is poor

- 7.35. Foldout 20558 H7 Boom is slow or lacks power

- 7.36. Foldout 20559 H8 Arm is slow or lacks power

- 7.37. Foldout 20560 H9 Bucket is slow or lacks power

- 7.38. Foldout 20567 H21 Travel speed is slow

- 7.39. Foldout 20568 H22 Steering does not turn easily or lacks power

- 7.40. Foldout 20571 H26 Travel speed is slow

- 7.41. Foldout 20603 Actions taken by controller when abnormality occurs and problems on machine

- 7.42. Foldout 20604 Electric circuit diagram for M mode

- 7.43. Foldout 20637 M30 Wiper does not work or switch is not being used, but wiper is actuated include E112, E113

- 7.44. Foldout 20638 M30 (continued)

- 7.45. Foldout 20641 M31 Wiper does not work or switch is not being used, but washer motor is actuated (include E114)

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00