Komatsu PC450-7K, PC450LC-7K Hydraulic Excavator Shop Manual UEBM002300

$40.00

- Type Of Manual: Shop Manual

- Manual ID: UEBM002300

- Format: PDF

- Size: 51.0MB

- Number of Pages: 766

Category: Komatsu Shop Manual PDF

-

Model List:

- PC450-7K Hydraulic Excavator

- PC450LC-7K Hydraulic Excavator

- 0.0.1. HOW TO READ THE SHOP MANUAL

- 0.0.2. HOISTING INSTRUCTIONS

- 0.0.3. METHOD OF DISASSEMBLING, CONNECTING PUSHPULL TYPE COUPLER

- 0.0.4. COATING MATERIALS

- 0.0.5. STANDARD TIGHTENING TORQUE

- 0.0.6. ELECTRIC WIRE CODE

- 0.0.7. CONVERSION TABLE

- 0.0.8. UNITS

- 1.1. GENERAL

- 1.1.1. SPECIFICATION DRAWINGS

- 1.1.2. SPECIFICATIONS

- 1.1.3. WEIGHT TABLE

- 1.1.4. FUEL, COOLANT AND LUBRICANTS

- 2. ERVER.pdf

- 2.1. STRUCTURE, FUNCTION AND MAINTENANCE STANDARD

- 2.1.1. ENGINE RELATED PARTS

- 2.1.2. RADIATOROIL COOLERAFTERCOOLER

- 2.1.3. POWER TRAIN

- 2.1.4. FINAL DRIVE

- 2.1.5. SWING MACHINERY

- 2.1.6. SWING CIRCLE

- 2.1.7. TRACK FRAME AND RECOIL SPRING

- 2.1.8. IDLER

- 2.1.9. CARRIER ROLLER

- 2.1.10. TRACK ROLLER

- 2.1.11. TRACK SHOE

- 2.1.12. HYDRAULIC PIPING DRAWING

- 2.1.13. HYDRAULIC TANK

- 2.1.14. HYDRAULIC PUMP

- 2.1.15. LS(pc)EPC VALVE

- 2.1.16. variable volume valve

- 2.1.17. CONTROL VALVE

- 2.1.18. MAIN RELIEF VALVE

- 2.1.19. CLSS

- 2.1.20. SELF PRESSURE REDUCING VALVE

- 2.1.21. SWING MOTOR

- 2.1.22. CENTER SWIVEL JOINT

- 2.1.23. TRAVEL MOTOR

- 2.1.24. TRAVEL JUNCTION VALVE

- 2.1.25. VALVE CONTROL

- 2.1.26. TRAVEL PPC SHUTTLE VALVE

- 2.1.27. WORK EQUIPMENT SWING PPC VALVE

- 2.1.28. TRAVEL PPC VALVE

- 2.1.29. SERVICE PPC VALVE

- 2.1.30. SOLENOID VALVE

- 2.1.31. PPC ACCUMULATOR

- 2.1.32. return oil filter

- 2.1.33. quick return valve

- 2.1.34. LIFT CHECK VALVE

- 2.1.35. attachment circuit selector valve

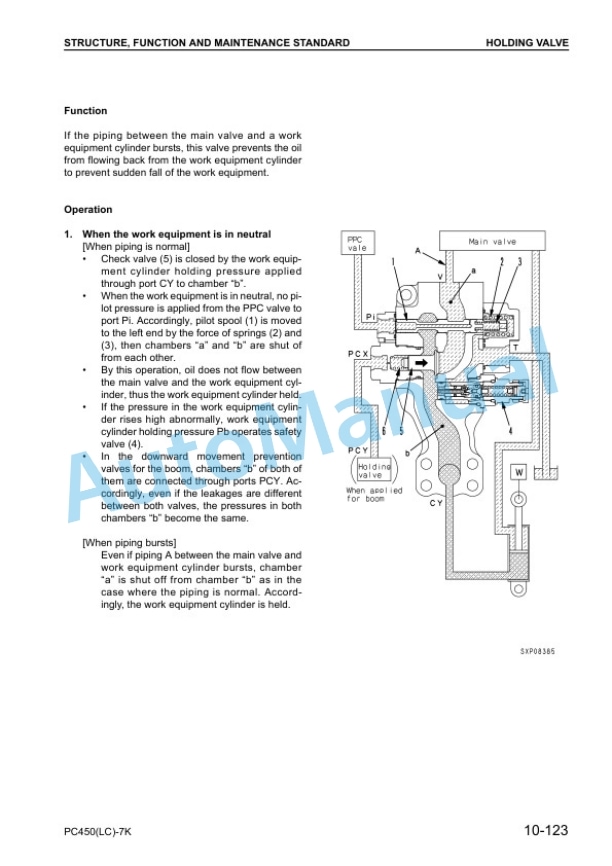

- 2.1.36. HOLDING VALVE

- 2.1.37. HYDRAULIC CYLINDER

- 2.1.38. WORK EQUIPMENT

- 2.1.39. AIR CONDITIONER

- 2.1.40. ENGINE CONTROL

- 2.1.41. ELECTRONIC CONTROL SYSTEM

- 2.1.42. MONITOR SYSTEM

- 2.1.43. SENSOR

- 3. _001.pdf

- 3.1. TESTING AND ADJUSTING

- 3.1.1. STANDARD VALUE TABLE FOR ENGINE

- 3.1.2. STANDARD VALUE TABLE FOR CHASSIS

- 4. _101.pdf

- 4.1. TESTING AND ADJUSTING

- 4.1.1. Testing, adjusting, and troubleshooting tools table

- 4.1.2. Measuring engine speed

- 4.1.3. Measuring intake air pressure (boost pressure)

- 4.1.4. Measuring exhaust temperature

- 4.1.5. Measuring exhaust gas color

- 4.1.6. Adjusting valve clearance

- 4.1.7. Measuring compression pressure

- 4.1.8. Measuring blowby pressure

- 4.1.9. Measuring engine oil pressure

- 4.1.10. Handling of fuel system devices

- 4.1.11. Releasing residual pressure from fuel system

- 4.1.12. Measuring fuel pressure

- 4.1.13. Bleeding air from fuel circuit

- 4.1.14. Inspection of fuel circuit for leakage

- 4.1.15. Adjusting engine speed sensor

- 4.1.16. Testing and adjusting fan belt and alternator belt tension

- 4.1.17. Testing and adjusting air conditioner compressor belt tension

- 4.1.18. Measuring clearance of swing circle bearing

- 4.1.19. Testing and adjusting track shoe tension

- 4.1.20. Testing and adjusting oil pressure in work equipment, swing, and travel circuits

- 4.1.21. Measuring basic pressure in control circuit

- 4.1.22. Testing and adjusting oil pressure in pump PC control circuit

- 4.1.23. Testing and adjusting oil pressure in pump LS control circuit

- 4.1.24. Measuring solenoid valve output pressure

- 4.1.25. Measuring PPC valve output pressure

- 4.1.26. Adjusting play of work equipment and swing PPC valves

- 4.1.27. Testing parts which cause hydraulic drift of work equipment

- 4.1.28. Releasing residual pressure in hydraulic circuit

- 4.1.29. Measuring oil leakage

- 4.1.30. Bleeding air from each part

- 4.1.31. Testing procedure of diode

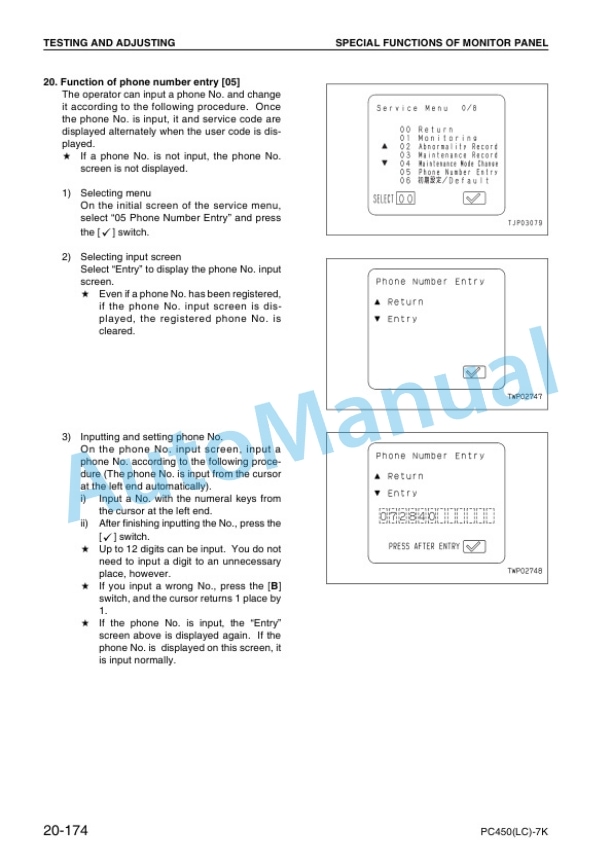

- 4.1.32. Special functions of monitor panel

- 4.1.33. Handling of highvoltage circuit of engine controller

- 4.1.34. Preparation work for troubleshooting for electrical equipment system

- 5. _101a.pdf

- 5.1. PmCLINIC SERVICE

- 5.2. PmCLINIC SERVICE PC450 (LC)7

- 5.3. UNDERCARRIAGE INSPECTION

- 6. _201.pdf

- 6.1. TROUBLESHOOTING

- 6.1.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 6.1.2. SEQUENCE OF EVENTS IN TROUBLESHOOTING

- 6.1.3. POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE

- 6.1.4. CHECKS BEFORE TROUBLESHOOTING

- 6.1.5. CLASSIFICATION AND STEPS FOR TROUBLESHOOTING

- 6.1.6. Connector arrangement drawing and electric circuit diagram of each system

- 6.1.7. CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

- 6.1.8. TBRANCH BOX AND TBRANCH TABLE

- 7. _301.pdf

- 7.1. TROUBLESHOOTING WHEN ERROR CODE ELECTRICAL SYSTEM AND FAILURE CODE MECHANICAL SYSTEM ARE DISP…

- 7.1.1. INFORMATION CONTAINED IN TROUBLESHOOTING TABLE

- 8. _501.pdf

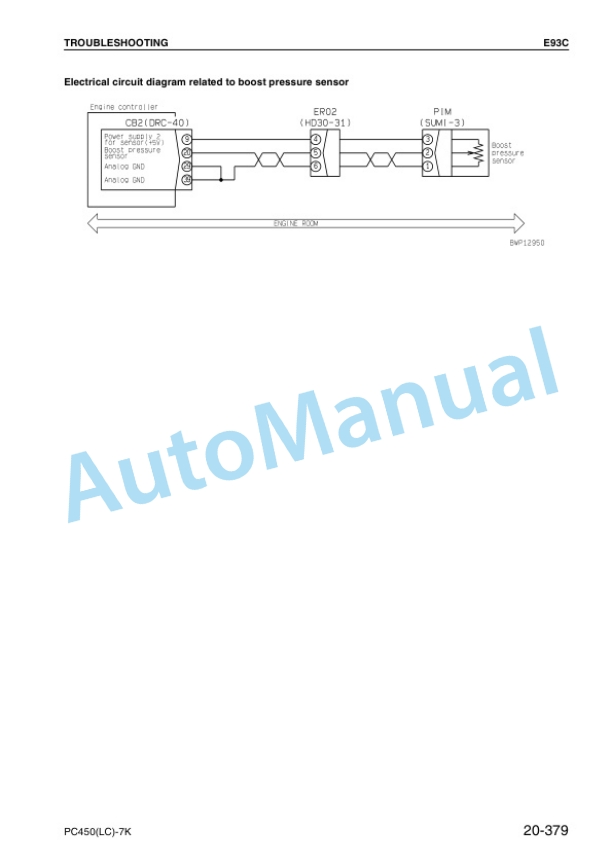

- 8.1. TROUBLESHOOTING OF ELECTRICAL SYSTEM (E MODE)

- 8.1.1. Before carrying out troubleshooting for electrical system (Emode)

- 8.1.2. INFORMATION CONTAINED IN TROUBLESHOOTING TABLE

- 9. _601.pdf

- 9.1. TROUBLESHOOTING OF HYDRAULIC AND MECHANICAL SYSTEM (H MODE)

- 9.1.1. system chart for hydraulic and mechanical system

- 9.1.2. INFORMATION CONTAINED IN TROUBLESHOOTING TABLE

- 10. _701.pdf

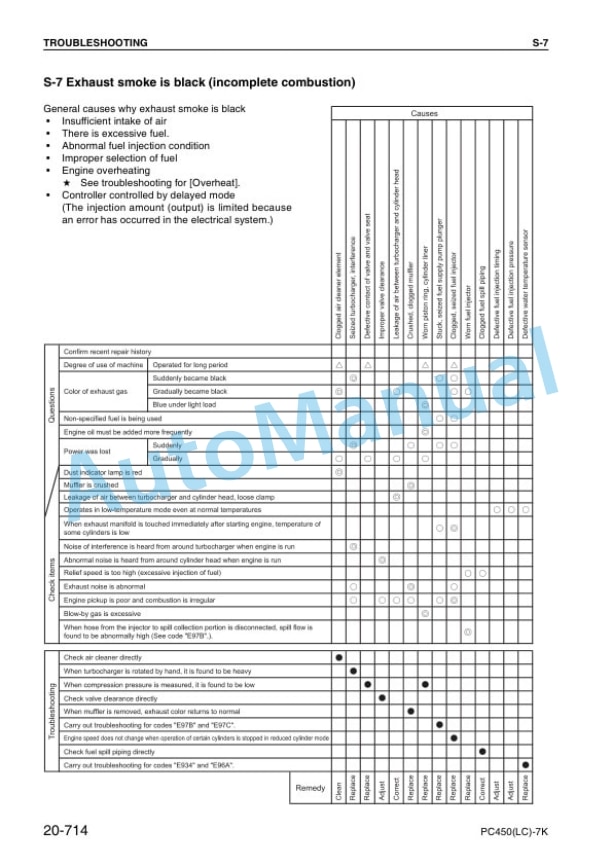

- 10.1. TROUBLESHOOTING OF ENGINE (S MODE)

- 10.1.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 10.1.2. METHOD OF USING TROUBLESHOOTING CHARTS

- 11. SEC_30SERVER.pdf

- 11.1. DISASSEMBLY AND ASSEMBLY

- 11.1.1. HOW TO READ THIS MANUAL

- 11.1.2. PRECAUTIONS WHEN PERFORMING OPERATION

- 11.1.3. SPECIAL TOOL LIST

- 11.1.4. REMOVAL AND INSTALLATION OF CYLINDER HEAD ASSEMBLY

- 11.1.5. REMOVAL AND INSTALLATION OF ENGINE REAR SEAL

- 11.1.6. REMOVAL AND INSTALLATION OF ENGINE FRONT SEAL

- 11.1.7. REMOVAL AND INSTALLATION OF FUEL SUPPLY PUMP ASSEMBLY

- 11.1.8. REMOVAL AND INSTALLATION OF FUEL INJECTOR ASSEMBLY

- 11.1.9. REMOVAL AND INSTALLATION OF NOZZLE TIP

- 11.1.10. REMOVAL AND INSTALLATION OF STARTING MOTOR ASSEMBLY

- 11.1.11. REMOVAL AND INSTALLATION OF RADIATOR ASSEMBLY

- 11.1.12. REMOVAL AND INSTALLATION OF HYDRAULIC OIL COOLER ASSEMBLY

- 11.1.13. REMOVAL AND INSTALLATION OF ENGINE AND HYDRAULIC PUMP ASSEMBLY

- 11.1.14. REMOVAL AND INSTALLATION OF SWING CIRCLE ASSEMBLY

- 11.1.15. REMOVAL AND INSTALLATION OF SWING MOTOR AND SWING MACHINERY ASSEMBLY

- 11.1.16. DISASSEMBLY AND ASSEMBLY OF SWING MOTOR AND SWING MACHINERY ASSEMBLY

- 11.1.17. REMOVAL AND INSTALLATION OF SPROCKET

- 11.1.18. REMOVAL AND INSTALLATION OF TRAVEL MOTOR AND FINAL DRIVE ASSEMBLY

- 11.1.19. DISASSEMBLY AND ASSEMBLY OF FINAL DRIVE ASSEMBLY

- 11.1.20. DISASSEMBLY AND ASSEMBLY OF CARRIER ROLLER ASSEMBLY

- 11.1.21. DISASSEMBLY AND ASSEMBLY OF TRACK ROLLER ASSEMBLY

- 11.1.22. DISASSEMBLY AND ASSEMBLY OF IDLER ASSEMBLY

- 11.1.23. DISASSEMBLY AND ASSEMBLY OF RECOIL SPRING ASSEMBLY

- 11.1.24. EXPANSION AND INSTALLATION OF TRACK SHOE ASSEMBLY

- 11.1.25. REMOVAL AND INSTALLATION OF AIR CONDITIONER UNIT ASSEMBLY

- 11.1.26. REMOVAL AND INSTALLATION OF OPERATORS CAB

- 11.1.27. REMOVAL AND INSTALLATION OF MONITOR ASSEMBLY

- 11.1.28. REMOVAL AND INSTALLATION OF PUMP CONTROLLER

- 11.1.29. REMOVAL AND INSTALLATION OF ENGINE CONTROLLER

- 11.1.30. REMOVAL AND INSTALLATION OF REVOLVING FRAME ASSEMBLY

- 11.1.31. REMOVAL AND INSTALLATION OF COUNTERWEIGHT ASSEMBLY

- 11.1.32. REMOVAL AND INSTALLATION OF HYDRAULIC TANK ASSEMBLY

- 11.1.33. REMOVAL AND INSTALLATION OF HYDRAULIC PUMP ASSEMBLY

- 11.1.34. REMOVAL AND INSTALLATION OF OIL SEAL IN HYDRAULIC PUMP INPUT SHAFT

- 11.1.35. REMOVAL AND INSTALLATION OF CONTROL VALVE ASSEMBLY

- 11.1.36. DISASSEMBLY AND ASSEMBLY OF CONTROL VALVE ASSEMBLY

- 11.1.37. REMOVAL AND INSTALLATION OF CENTER SWIVEL JOINT ASSEMBLY

- 11.1.38. DISASSEMBLY AND ASSEMBLY OF of CENTER SWIVEL JOINT ASSEMBLY

- 11.1.39. DISASSEMBLY AND ASSEMBLY OF WORK EQUIPMENT PPC VALVE ASSEMBLY

- 11.1.40. DISASSEMBLY AND ASSEMBLY OF TRAVEL PPC VALVE ASSEMBLY

- 11.1.41. DISASSEMBLY AND ASSEMBLY OF HYDRAULIC CYLINDER ASSEMBLY

- 11.1.42. REMOVAL AND INSTALLATION OF WORK EQUIPMENT ASSEMBLY

- 11.1.43. REMOVAL AND INSTALLATION OF OPERATORS CAB GLASS (STUCK GLASS)

- 11.1.44. REMOVAL AND INSTALLATION OF FRONT WINDOW ASSEMBLY

- 12.1. OTHERS

- 13.1. HYDRAULIC CIRCUIT DIAGRAM (1/2)

- 13.2. HYDRAULIC CIRCUIT DIAGRAM (2/2)

- 13.3. ELECTRICAL CIRCUIT DIAGRAM (1/5)

- 13.4. ELECTRICAL CIRCUIT DIAGRAM (2/5)

- 13.5. ELECTRICAL CIRCUIT DIAGRAM (3/5)

- 13.6. ELECTRICAL CIRCUIT DIAGRAM (4/5)

- 13.7. ELECTRICAL CIRCUIT DIAGRAM (5/5)

- 14.1. AIR CONDITIONER ELECTRICAL CIRCUIT

Rate this product

You may also like