Komatsu PC490LC-10 Hydraulic Excavator Shop Manual CEBM025304

$40.00

- Type Of Manual: Shop Manual

- Manual ID: CEBM025304

- Format: PDF

- Size: 118.3MB

- Number of Pages: 1837

Category: Komatsu Shop Manual PDF

-

Model List:

- PC490LC-10 Hydraulic Excavator

- 1. CEBM025304 PC490LC10

- 1.1. CONTENTS

- 1.2. SAFETY

- 1.3. GENERAL

- 1.4. HOW TO READ THE SHOP MANUAL

- 1.5. HOISTING INSTRUCTIONS

- 1.6. HANDLING ELECTRIC EQUIPMENT AND HYDRAULIC COMPONENTS

- 1.7. PUSH PULL COUPLER

- 1.8. EXPLANATION OF MAINTENANCE STANDARD TERMS

- 1.9. HANDLING OF FUEL SYSTEM DEVICES

- 1.10. HANDLING OF INTAKE SYSTEM PARTS

- 1.11. STANDARD TIGHTENING TORQUE

- 1.12. ELECTRIC WIRE CODE

- 1.13. PRECAUTIONS FOR OPERATIONS

- 1.14. CONVERSION TABLES

- 1.15. COATING MATERIALS

- 1.16. LIST OF ABBREVIATIONS

- 2. GENERAL

- 2.1. SPECIFICATION DIMENSION DRAWINGS

- 2.2. SPECIFICATIONS

- 2.3. WEIGHT TABLE

- 2.4. FUEL, COOLANT AND LUBRICANTS

- 3. STRUCTURE AND FUNCTION

- 3.1. ENGINE AND COOLING SYSTEM

- 3.2. POWER TRAIN SYSTEM

- 3.3. UNDERCARRIAGE AND FRAME

- 3.4. HYDRAULIC SYSTEM

- 3.5. WORK EQUIPMENT

- 3.6. CAB AND ITS ATTACHMENTS

- 3.7. ELECTRICAL SYSTEM

- 3.8. MACHINE MONITOR SYSTEM

- 3.9. KOMTRAX SYSTEM

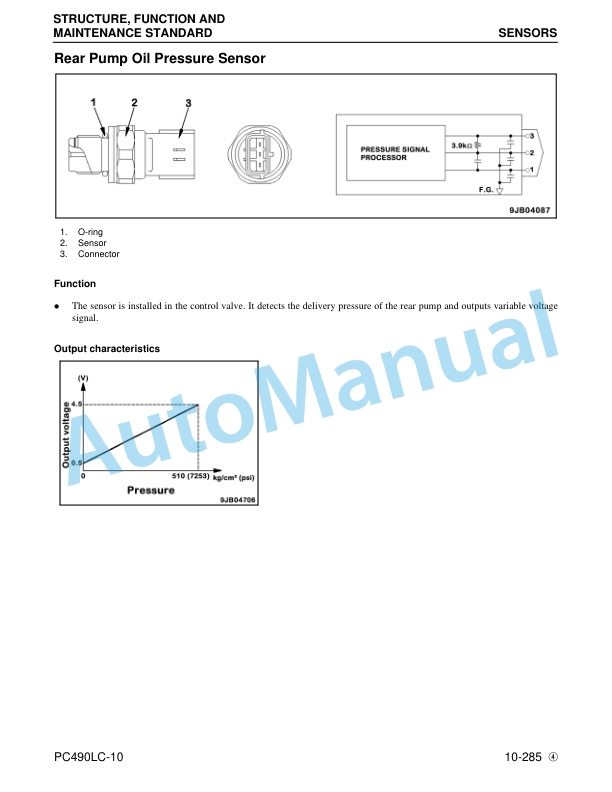

- 3.10. SENSORS

- 4. STANDARD VALUE TABLES

- 4.1. STANDARD SERVICE VALUE TABLES

- 5. TESTING AND ADJUSTING

- 5.1. GENERAL INFORMATION

- 5.2. ENGINE AND COOLING SYSTEM

- 5.3. POWER TRAIN

- 5.4. UNDERCARRIAGE AND FRAME

- 5.5. HYDRAULIC SYSTEM

- 5.6. CAB AND ITS ATTACHMENTS

- 5.7. ELECTRICAL SYSTEM

- 5.8. PM CLINIC

- 6. TROUBLESHOOTING

- 6.1. GENERAL INFORMATION ON TROUBLESHOOTING

- 6.2. DIAGNOSTIC PROCEDURE FOR WIRING HARNESS

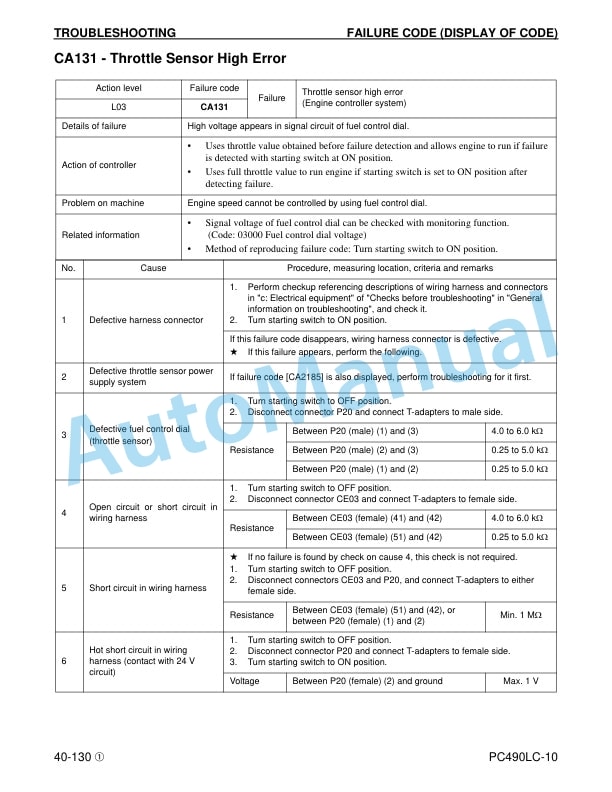

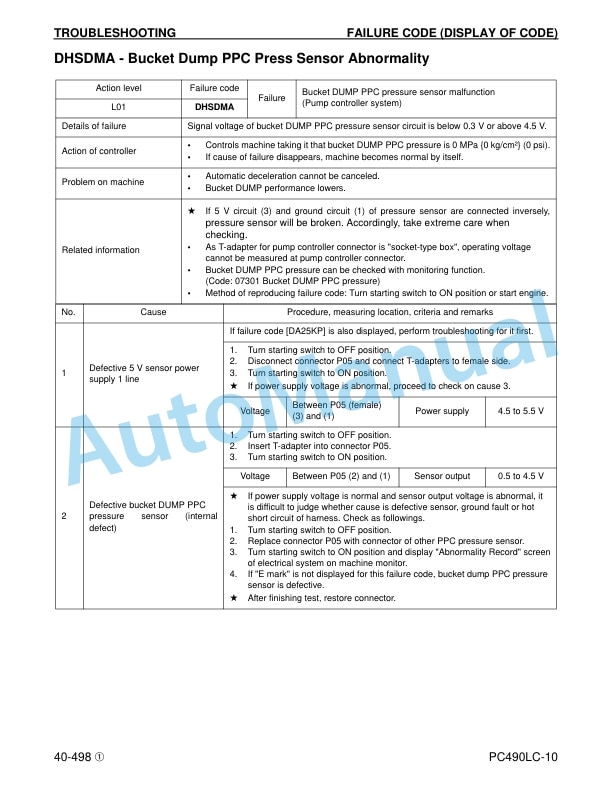

- 6.3. FAILURE CODE (DISPLAY OF CODE)

- 6.4. ELECTRICAL SYSTEM (EMODE)

- 6.5. HYDRAULIC AND MECHANICAL SYSTEM (HMODE)

- 6.6. ENGINE (SMODE)

- 6.7. GENERAL INFORMATION ON TROUBLESHOOTING

- 6.8. DIAGNOSTIC PROCEDURE FOR WIRING HARNESS

- 6.9. FAILURE CODE (DISPLAY OF CODE)

- 6.10. ELECTRICAL SYSTEM (EMODE)

- 6.11. HYDRAULIC AND MECHANICAL SYSTEM (HMODE)

- 6.12. ENGINE (SMODE)

- 7. DISASSEMBLY AND ASSEMBLY

- 7.1. HOW TO READ THIS SECTION

- 7.2. SPECIAL TOOLS LIST

- 7.3. CONNECTOR REPAIR PROCEDURES

- 7.4. ENGINE AND COOLING SYSTEM

- 7.5. POWER TRAIN

- 7.6. UNDERCARRIAGE AND FRAME

- 7.7. HYDRAULIC SYSTEM

- 7.8. WORK EQUIPMENT

- 7.9. CAB AND ITS ATTACHMENTS

- 7.10. ELECTRIC SYSTEM

- 8. MAINTENANCE STANDARD

- 8.1. ENGINE AND COOLING SYSTEM

- 8.2. POWER TRAIN

- 8.3. UNDERCARRIAGE AND FRAME

- 8.4. HYDRAULIC SYSTEM

- 8.5. PPC Valve

- 8.6. WORK EQUIPMENT

- 9. AIR CONDITIONER

- 9.1. AIR CONDITIONER

- 9.2. AIR CONDITIONER COMPONENT

- 9.3. STRUCTURE AND FUNCTION

- 9.4. AIR CONDITIONER UNIT

- 9.5. DUAL PRESSURE SWITCH

- 9.6. AIR CONDITIONER CONTROLLER

- 9.7. AIR CONDITIONER COMPRESSOR

- 9.8. AIR CONDITIONER CONDENSER

- 9.9. RECEIVER DRIER

- 9.10. SUNLIGHT SENSOR

- 9.11. OUTSIDE AIR TEMPERATURE SENSOR

- 9.12. PROCEDURE FOR TESTING AND TROUBLESHOOTING

- 9.13. PARTS AND CONNECTORS LAYOUT

- 9.14. TESTING AIR LEAKAGE (DUCT)

- 9.15. TESTING WITH SELFDIAGNOSIS FUNCTION

- 9.16. TESTING VENT (MODE) CHANGEOVER

- 9.17. TESTING FRESH/RECIRC AIR CHANGEOVER

- 9.18. TESTING SUNLIGHT SENSOR

- 9.19. TESTING (DUAL) PRESSURE SWITCH FOR REFRIGERANT

- 9.20. TESTING RELAY

- 9.21. INFORMATION IN TROUBLESHOOTING TABLE

- 9.22. FAILURE CODES FOR AIR CONDITIONER

- 9.23. HANDLING OF COMPRESSOR OIL

- 10. DIAGRAMS AND SCHEMATICS

- 10.1. HYDRAULIC SYSTEM

- 10.2. ELECTRICAL SYSTEM

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00

Komatsu Shop Manual PDF

$40.00