Komatsu PC5500-11 Hydraulic Mining Shovel Operation and Maintenance Manual 15193-D-EN-11T4-P1-1.0

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: 15193-D-EN-11T4-P1-1.0

- Format: PDF

- Size: 33.0MB

- Number of Pages: 574

-

Model List:

- PC5500-11 Hydraulic Mining Shovel

- 1. FOREWORD

- 1.1. BEFORE READING THIS MANUAL

- 1.2. EC DECLARATION OF CONFORMITY

- 1.3. PRIVACY POLICY ON EXCAVATORS EQUIPPED WITH excavator MONITORING SYSTEMS FOR THE EEA

- 1.4. RADIO WAVE REGULATIONS FOR KOMTRAX AND KOMTRAX PLUS

- 1.5. OPEN SOURCE SOFTWARE (OSS)

- 1.6. DIRECTIONS OF THE EXCAVATOR

- 1.7. SPECIFICATION AND SERIAL PLATE

- 1.8. DIVISION OF THE BINDER

- 1.9. DESIGNATED USE OF THE EXCAVATOR

- 1.10. DELIVERY OF THE EXCAVATOR

- 1.11. EXPLANATION OF ABBREVIATIONS

- 2. SAFETY

- 2.1. SAFETY INFORMATION

- 2.2. OVERVIEW

- 2.3. SOUND PRESSURE AND VIBRATION LEVELS IN THE OPERATORS CAB.

- 2.4. GENERAL PRECAUTIONS COMMON TO OPERATION ON THE EXCAVATOR

- 2.5. PRECAUTION FOR MAINTENANCE

- 2.6. ADDITIONAL SAFETY INFORMATION FOR TROUBLESHOOTING AND ADJUSTMENTS

- 2.7. SPECIAL SAFETY EQUIPMENT

- 2.8. SAFETY WARNING SIGNS

- 3. OPERATION

- 3.1. FOREWORD

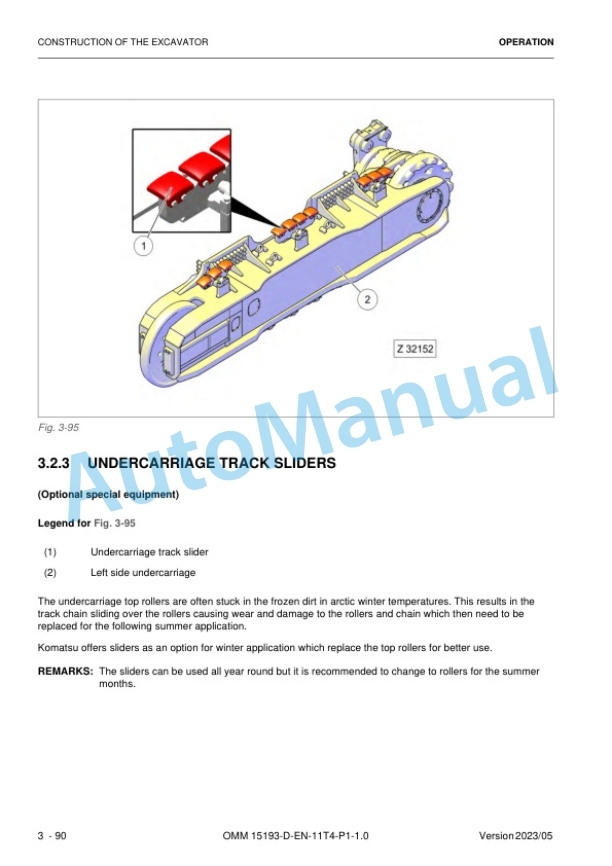

- 3.2. CONSTRUCTION OF THE EXCAVATOR

- 3.3. OPERATORS CAB CONTROLS

- 3.4. Machine monitor

- 3.5. OPERATING THE HEATER, VENTILATION AND AIR CONDITIONING

- 3.6. CAMERA SYSTEM KomVision

- 3.7. MACHINERY HOUSE

- 3.8. ELECTRICAL EQUIPMENT IN CAB BASE

- 3.9. CHECKS BEFORE STARTING THE ENGINES

- 3.10. STARTING THE ENGINES

- 3.11. MOVING THE EXCAVATOR

- 3.12. SLEWING AND BRAKING THE SUPERSTRUCTURE

- 3.13. WORKING WITH THE ATTACHMENT

- 3.14. WORKING INSTRUCTIONS

- 3.15. PARKING THE Excavator

- 3.16. STOPPING THE ENGINES

- 3.17. OPERATION OF THE LUBRICATION SYSTEM

- 3.18. TRANSFER PUMP FOR HYDRAULIC OIL

- 3.19. SERVICE CENTER

- 3.20. TRANSPORTATION AND LIFTING OF THE EXCAVATOR

- 3.21. RETRIEVAL PROCEDURE

- 3.22. EXCAVATOR STORAGE

- 3.23. TROUBLE SHOOTING

- 4. MAINTENANCE

- 4.1. FOREWORD

- 4.2. PRECAUTIONS FOR MAINTENANCE

- 4.3. fluids and lubricants

- 4.4. FILLING CAPACITIES

- 4.5. STANDARD TORQUE LIST

- 4.6. LUBRICATION AND MAINTENANCE SCHEDULE

- 4.7. SAFETY CRITICAL PARTS

- 4.8. EXTENDED SERVICE INTERVALS FOR ENGINES WITH ENGINE OIL MANAGEMENT SYSTEM

- 4.9. INITIAL SERVICING

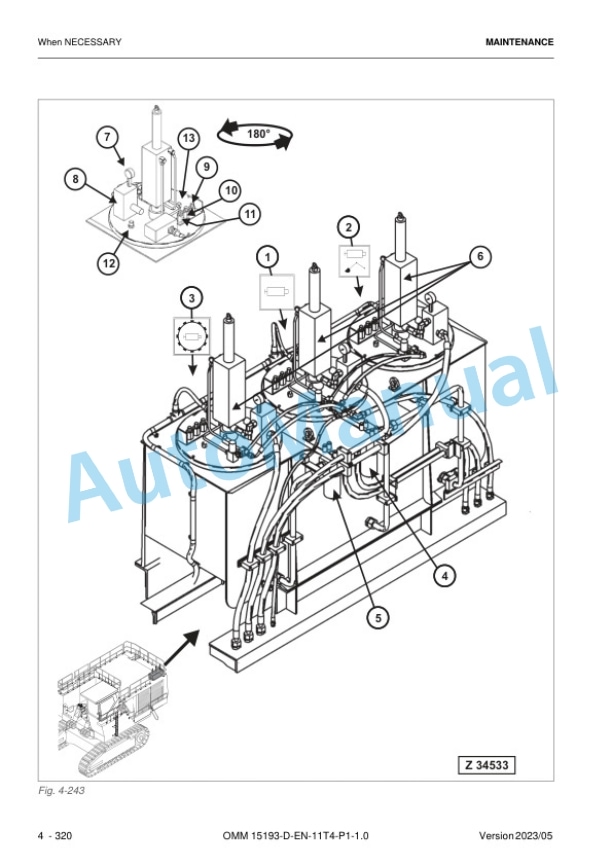

- 4.10. When NECESSARY

- 4.11. EVERY 10 OPERATING HOURS OR DAILY

- 4.12. EVERY 50 OPERATING HOURS OR WEEKLY

- 4.13. EVERY 250 OPERATING HOURS OR MONTHLY

- 4.14. EVERY 500 OPERATING HOURS OR QUARTERLY

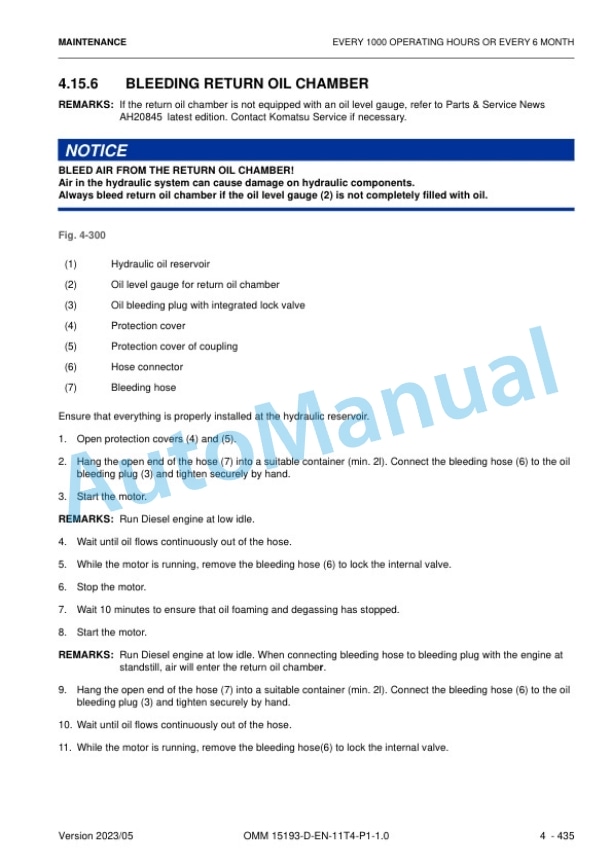

- 4.15. EVERY 1000 OPERATING HOURS OR EVERY 6 MONTH

- 4.16. EVERY 2000 OPERATING HOURS OR YEARLY

- 4.17. EVERY 3000 OPERATING HOURS HOWEVER AT LEAST ONCE A YEAR

- 4.18. CRITICAL BOLT CONNECTIONS EVERY 3000 OPERATING HOURS

- 4.19. EVERY 6000 OPERATING HOURS OR ONCE A YEAR

- 4.20. FIRE PREVENTION

- 4.21. WELD REPAIRS

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM018100

Komatsu Operation and Maintenance Manual PDF

Komatsu 170D Dump Truck Operation and Maintenance Manual DG534

Komatsu Operation and Maintenance Manual PDF

Komatsu 150A, 150FA Crane Operation and Maintenance Manual CEAMC20081

Komatsu Operation and Maintenance Manual PDF

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Field Assembly Instruction CEAW004103

Komatsu Operation and Maintenance Manual PDF

Komatsu 503 Motor Grader Operation and Maintenance Manual 2079A-H45

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM011200

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG745

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG615

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAD014800