Komatsu PC5500E-6 Hydraulic Excavator Shop Manual 15016-upE-GB-1

$40.00

- Type Of Manual: Shop Manual

- Manual ID: 15016-upE-GB-1

- Format: PDF

- Size: 43.3MB

- Number of Pages: 1711

Category: Komatsu Shop Manual PDF

-

Model List:

- PC5500E-6 Hydraulic Excavator

- 1. COVER

- 2. Foreword

- 2.1. Introduction

- 2.2. Safety Instructions

- 3. Specifications

- 3.1. Specifications PC5500

- 4. Structure, Function

- 4.1. INTRODUCTION

- 4.2. II. SAFETY

- 4.3. III. SPECIFICATIONS

- 4.4. MAIN ASSEMBLY GROUPS

- 4.4.1. General layout

- 4.4.2. Superstructure

- 4.4.3. Power House

- 4.4.4. Hydraulic Oil Reservoir

- 4.4.5. Hydraulic Oil Cooler

- 4.4.6. Fuel tank (Fuel reservoir)

- 4.4.7. Counter weight

- 4.4.8. Cab support

- 4.4.9. Operators cab

- 4.4.10. Control blocks

- 4.4.11. Swing gears

- 4.4.12. Under carriage

- 4.5. DRIVE

- 4.5.1. Prime drive assembly

- 4.5.2. Engine and gearbox mount

- 4.5.3. Torque supports

- 4.5.4. Radiator fan Drive Assy.

- 4.5.5. Pump distributor gearbox (PTO)

- 4.5.6. Coupling

- 4.5.7. Air cleaner

- 4.6. HYDRAULIC OIL RESERVOIR

- 4.6.1. Hydraulic oil reservoir

- 4.6.2. Return and leak oil filter

- 4.6.3. Breather Filter

- 4.6.4. Location of electrical components

- 4.7. HYDRAULIC OIL COOLING

- 4.7.1. General

- 4.7.2. Hydraulic oil cooling circuit

- 4.7.3. Back pressure valve adjustment

- 4.7.4. Fan drive

- 4.7.5. Cooler fan drive adjustment

- 4.8. CONTROLLING

- 4.8.1. Pilot pressure supply and adjustment

- 4.8.2. Slew brakes

- 4.8.3. Travel parking brake

- 4.8.4. Check of the pilot control logic

- 4.9. COMPONENTS

- 4.9.1. Main control block and valve arrangement

- 4.9.2. Distributor manifold

- 4.9.3. Main control block

- 4.9.4. Compact valve blocks

- 4.9.5. Compact valve blocks

- 4.9.6. Auxiliary gear pumps

- 4.9.7. Hydraulic cylinder

- 4.9.8. Swing ring

- 4.10. MAIN HYDRAULIC PUMPS AND PUMP REGULATION

- 4.10.1. General

- 4.10.2. Main pump operating principles

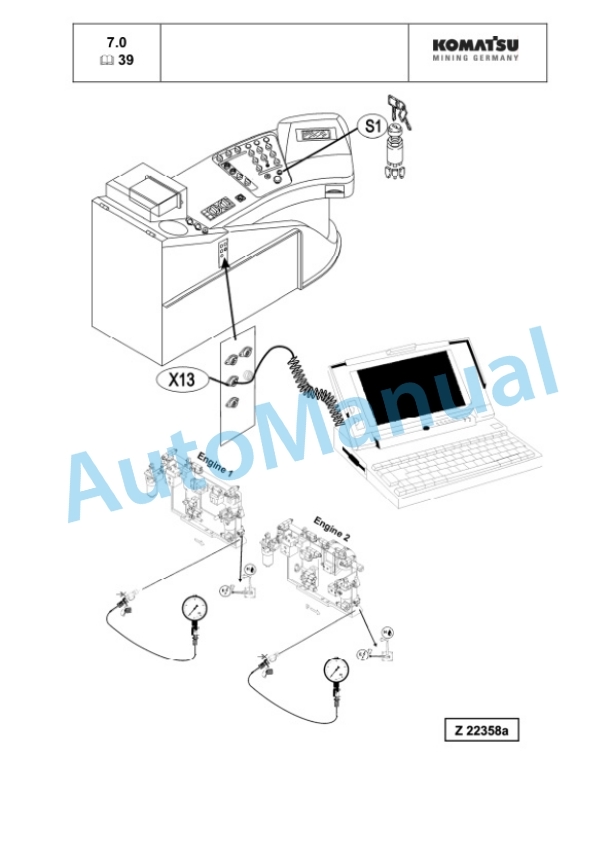

- 4.10.3. Main pump checks and adjustments

- 4.10.4. Electronic pump regulation

- 4.10.5. Pump Controller CR700

- 4.10.6. Multi Monitor

- 4.10.7. Multimonitor software instruction

- 4.10.8. Trouble shooting pump and pump regulation

- 4.11. OPERATING HYDRAULIC

- 4.11.1. SM 15046xDGB4.pdf

- 4.11.2. General layout

- 4.11.3. Floating function of boom and stick only FSA

- 4.11.4. Check and Adjustments for MRVs and SRVs

- 4.11.5. Hydraulic for the swing circuit

- 4.11.6. Travel circuit

- 4.12. TRACK TENSION SYSTEM

- 4.12.1. General layout

- 4.12.2. Track tensioning function

- 4.12.3. Track tensioning adjustment

- 4.13. ACCESS LADDER HYDRAULICALLY OPERATED

- 4.13.1. Access ladder

- 4.13.2. Access ladder functional description

- 4.14. CABLE DRUM

- 4.14.1. Functional description

- 4.15. HINTS FOR READING THE HYDRAULIC CIRCUIT DIAGRAM

- 4.15.1. General

- 4.15.2. Symbolic

- 4.16. HINTS FOR READING THE ELECTRIC CIRCUIT DIAGRAM

- 4.16.1. Designation of electrical components

- 4.16.2. Electric symbols

- 4.16.3. Symbols

- 4.17. ELECTRONIC CONTROL SYSTEM ECS

- 4.17.1. General Function

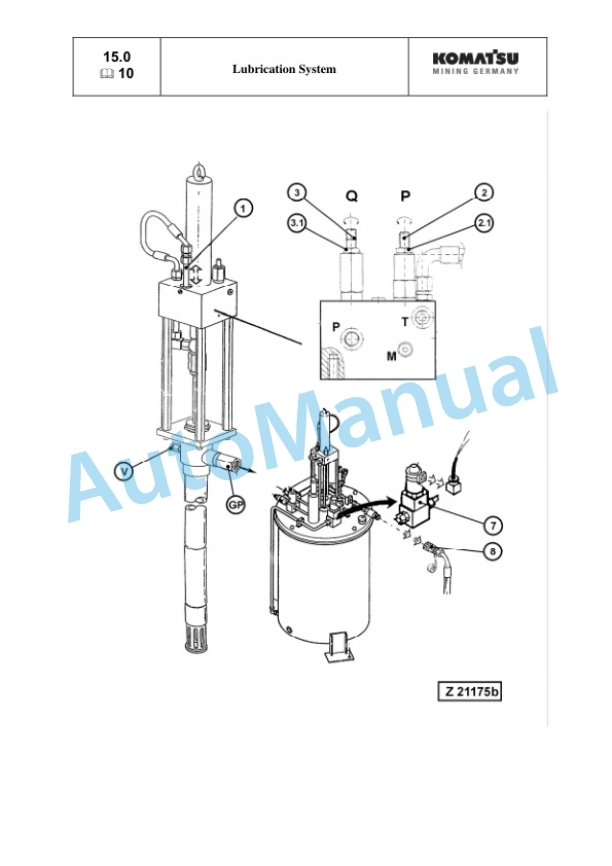

- 4.18. AUTOMATIC LUBRICATION SYSTEM

- 4.18.1. General Function

- 4.18.2. Function of a lubrication cycle

- 4.18.3. Lubrication pump drive

- 4.18.4. Lubrication pump

- 4.18.5. Lubricant Injector (metering valve)

- 4.18.6. End line pressure switch

- 4.18.7. Lubricant in line filter

- 4.18.8. Lubricant level sensor

- 4.18.9. Lubrication system function and controlling

- 4.18.10. Adjustment of the lubrication system with ETM

- 4.18.11. Trouble shooting lubricating system

- 5. Troubleshooting

- 5.1. Table of Contents

- 5.2. Introduction

- 5.2.1. Safety Notes

- 5.2.2. Description of this Troubleshooting Manual

- 5.2.3. General Precautions

- 5.3. Electrical Parts

- 5.3.1. Componant Locations

- 5.3.2. Engine Electrical Parts

- 5.3.3. Electrical Parts On PTO, etc

- 5.3.4. Electrical Parts on Pilot Control Frame

- 5.3.5. Electrical Parts on Main Hydraulic Reservoir

- 5.3.6. Electrical Parts on Switch Board X2

- 5.3.7. Electrical Parts on Hydraulic Ldder

- 5.3.8. Electrical Parts of Automatic Lube System

- 5.3.9. Electrical Parts on Air Cleaner and Fuel Tank

- 5.3.10. Overview Connector Types

- 5.3.11. Standard Value Table for Electrical Componants

- 5.3.12. PT100 Temperature Charts

- 5.4. Troubleshooting by Trouble Code

- 5.4.1. Message 1 Gear Lubrication out of Function (PTO)

- 5.4.2. Message 2 Engine Air Filter Restricted

- 5.4.3. Message 3 Filter for Control Oil Restricted

- 5.4.4. Message 4 Oil Tank Breather Filter Restricted

- 5.4.5. Message 5 Return Oil Filter Restricted

- 5.4.6. Message 6 Leak Oil Filter Restricted

- 5.4.7. Message 7 Hydraulic Oil Temperature Too High

- 5.4.8. Message 9 Low Idle Too High Coolant Temperature

- 5.4.9. Message 10 Engine Shutdown Too Low Engine Oil Temperature

- 5.4.10. Message 14 Too Low Hydraulic Oil Level

- 5.4.11. Message 15 Caution, Slew Gear House Brake On

- 5.4.12. Message 16 Caution, Travel Gear House Brake On

- 5.4.13. Message 17 No Clearance For Starting, Shift Engine to Low Idle

- 5.4.14. Message 18 Central Lube System Fault

- 5.4.15. Message 19 Slew Ring Gear Lubrication Fault

- 5.4.16. Message 20 Pilot Control CutOut

- 5.4.17. Message 21 Central Lube System Empty Grease Barrel

- 5.4.18. Message 22 Central Lube System Empty Grease Barre

- 5.4.19. Message 24 Engine Problem Stop All Control

- 5.4.20. Message 32 PTO Gear Lube Filter Restricted

- 5.4.21. Message 33 Cooler Fan Drive Filter Restricted

- 5.4.22. Message 39 Engine Shutdown . Main ShutOff (Gate) Volve

- 5.4.23. Message 42 Too Low Coolant Pressure

- 5.4.24. Message 43 Engine Shutdown Emergency Stop Switch Actuated

- 5.4.25. Message 44 Engine Shutdown Safety Switch Actuated

- 5.4.26. Message 45 Warning Signal from Engine Control Module

- 5.4.27. Message 48 Too High PTO Gear Oil Temperature.

- 5.4.28. Message 50 Caution, Pull Switch From Ground Man Actuated

- 5.4.29. Message 51 Engine Shutdown Pull Switch From Ground Man Actuated

- 5.4.30. Message 52 Load Limit Clam Defective

- 5.4.31. Message 53 Pressure Switch of CLS Actuated

- 5.4.32. Message 55 Refill Hyrdaulic Oil

- 5.4.33. Message 57 Load Limit Regulation Fault

- 5.4.34. Message 58 Strainer Oil Cooler Restricted

- 5.4.35. Message 59 CLS Refill Grease Container

- 5.4.36. Message 60 SLS Refill Grease Barrel

- 5.5. Troubleshooting by Symptoms

- 5.5.1. Symptoms of the Hydraulic System

- 6. Disassembly and Assembly

- 6.1. Introduction

- 6.1.1. Contents of the binder

- 6.1.2. Foreword

- 6.2. Safety

- 6.2.1. General information

- 6.2.2. Safety instructions

- 6.2.3. Grounding procedure of the high voltage system

- 6.2.4. Explanation of abbreviations

- 6.3. Superstructure

- 6.3.1. Superstructure overview

- 6.3.2. Service crane (optional)

- 6.3.3. Electric Motors

- 6.3.4. Batteries

- 6.3.5. Flexible coupling

- 6.3.7. Hydraulics

- 6.3.8. Slew system

- 6.3.9. Lubrication system

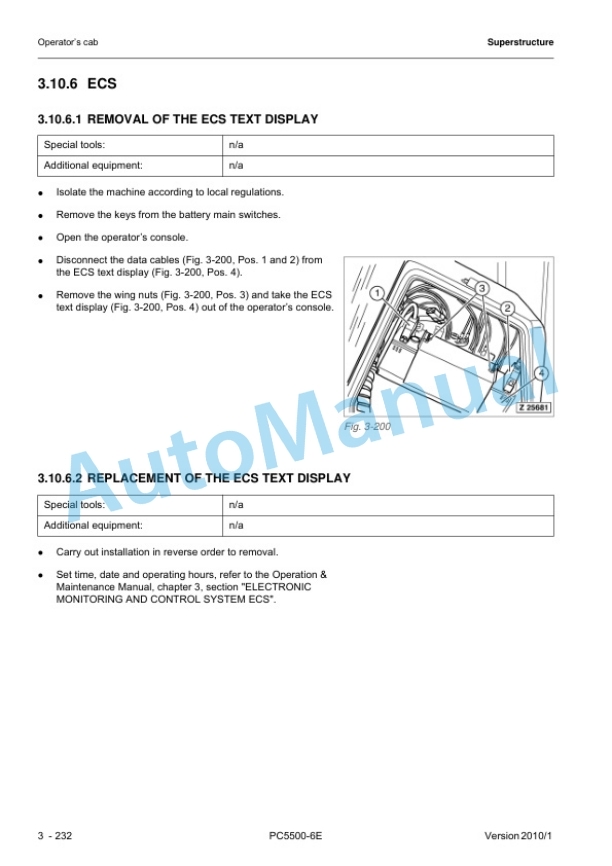

- 6.3.10. Operators cab

- 6.3.11. Cab base (medium voltage switch cabinet)

- 6.3.12. Access ladder

- 6.3.13. Counterweight

- 6.3.14. Superstructure lifting

- 6.3.15. High voltage switch cabinet

- 6.3.16. Slip ring unit

- 6.4. Undercarriage

- 6.4.1. Undercarriage overview

- 6.4.2. Travel system

- 6.4.3. Car body

- 6.5. Attachment

- 6.5.1. Backhoe

- 6.5.2. Face shovel (FSA)

- 6.5.3. Metering valves (grease injectors) at the attachment

- 6.5.4. Cylinder bypass test

- 6.6. Service Information

- 6.6.1. Fluids and lubricants

- 6.6.2. Filling capacities

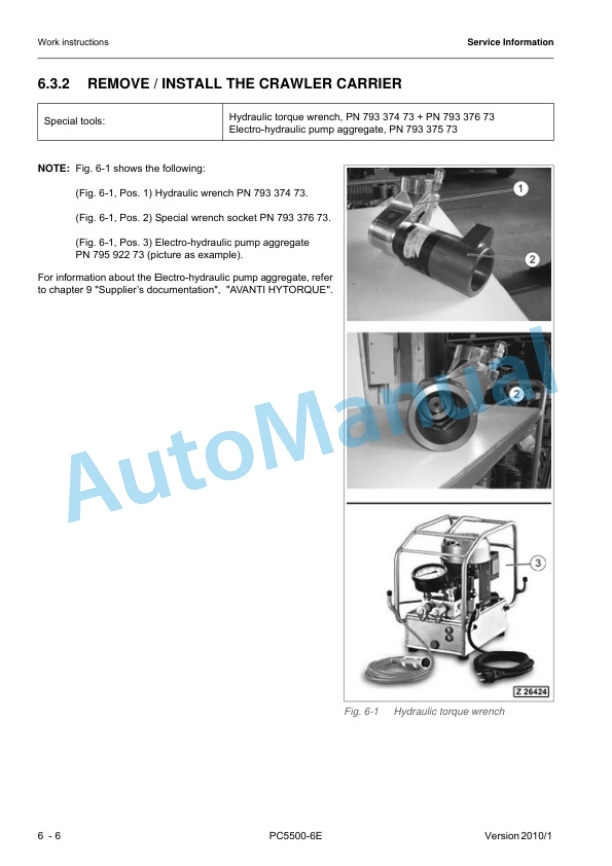

- 6.6.3. Work instructions

- 6.6.4. Weight tables

- 6.6.5. Torque charts according to KOMATSU company standard

- 6.6.6. Blind plugs

- 6.6.7. Conversion table

- 6.6.8. Tools

- 6.7. Tools catalogue

- 6.8. Parts Service News

- 6.9. Suppliers documentation

- 6.9.1. AVANTI HYTORQUE

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00