Komatsu PC58UU-3 Hydraulic Excavator Shop Manual SEBM023909

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM023909

- Format: PDF

- Size: 27.7MB

- Number of Pages: 521

Category: Komatsu Shop Manual PDF

-

Model List:

- PC58UU-3 Hydraulic Excavator

- 1. COVER

- 2. CONTENTS

- 3. GENERAL

- 3.1. GENERAL ASSEMBLY DRAWING

- 3.2. WORK EQUIPMENT RANGE DRAWING

- 3.3. SPECIFICATIONS

- 3.4. WEIGHT TABLE

- 3.5. LIST OF LUBRICANTS AND COOLANT

- 4. STRUCTURE,FUNCTION AND MAINTENANCE STANDARD

- 4.2. COOLING SYSTEM

- 4.3. POWER TRAIN

- 4.4. SWING CIRCLE

- 4.5. SWING MACHINERY

- 4.6. TRACK FRAME,IDLER CUSHION

- 4.7. HYDRAULIC EQUIPMENT LAYOUT DRAWING

- 4.8. HYDRAULIC TANK AND FILTER

- 4.9. HYDRAULIC PUMP

- 4.10. CONTROL VALVE

- 4.11. CLSS

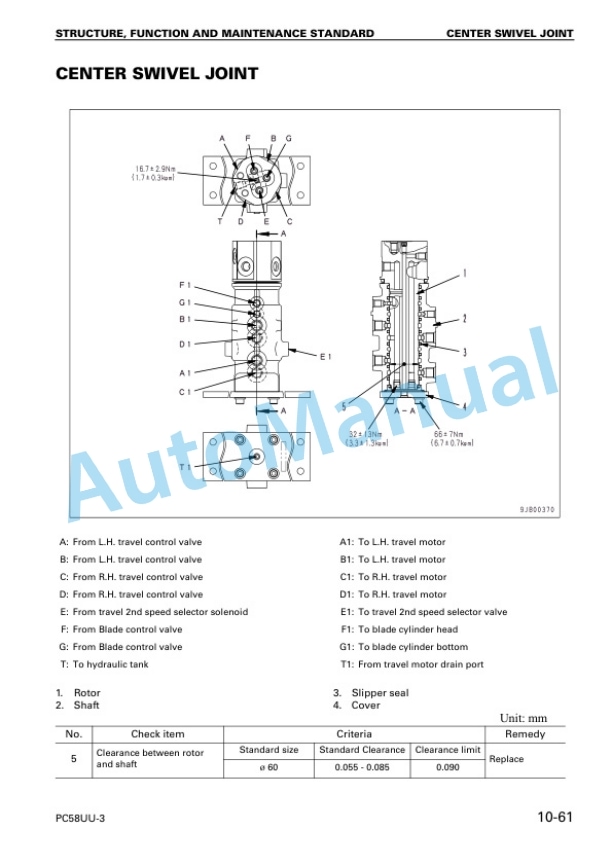

- 4.12. CENTER SWIVEL JOINT

- 4.13. TRAVEL MOTOR

- 4.14. SWING MOTOR

- 4.15. TRAVEL PPC VALVE

- 4.16. PPC VALVE

- 4.17. HYDRAULIC CYLINDER

- 4.18. SOLENOID VALVE

- 4.19. MULTI CONTROL VALVE

- 4.20. WORK EQUIPMENT

- 4.21. AIR CONDITIONING PIPING

- 4.22. ENGINE CONTROL

- 4.23. ELECTRICAL CONTROL SYSTEM

- 4.24. ELECTRICAL SYSTEM

- 4.25. MONITOR SYSTEM

- 5. TESTING AND ADJUSTING

- 5.1. STANDARD VALUE TABLUE FOR ENGING

- 5.2. STANDARD VALUE TABLE FOR CHASSIS

- 5.3. STANDARD VALUE TABLE FOR ELECTRICAL PARTS

- 5.4. TESTING AND ADJUSTING

- 5.4.1. TOOLS FOR TESTING, ADJUSTING, AND TROUBLESHOOTING

- 5.4.2. MEASURING ENGINE SPEED

- 5.4.3. MEASURING ENGINE OIL PRESSURE

- 5.4.4. MEASURING COMPRESSING PRESSURE

- 5.4.5. AD JUSTING VALVE CLEARANCE

- 5.4.6. TESTING AND ADJUSTING FUEL INJECTION TIMING

- 5.4.7. TESTING AND ADJUSTING ALTERNATOR BELT TENSION

- 5.4.8. ADJUSTING FUEL CONTROL LINKAGE

- 5.4.9. MEASURING EXHAUST COLOR

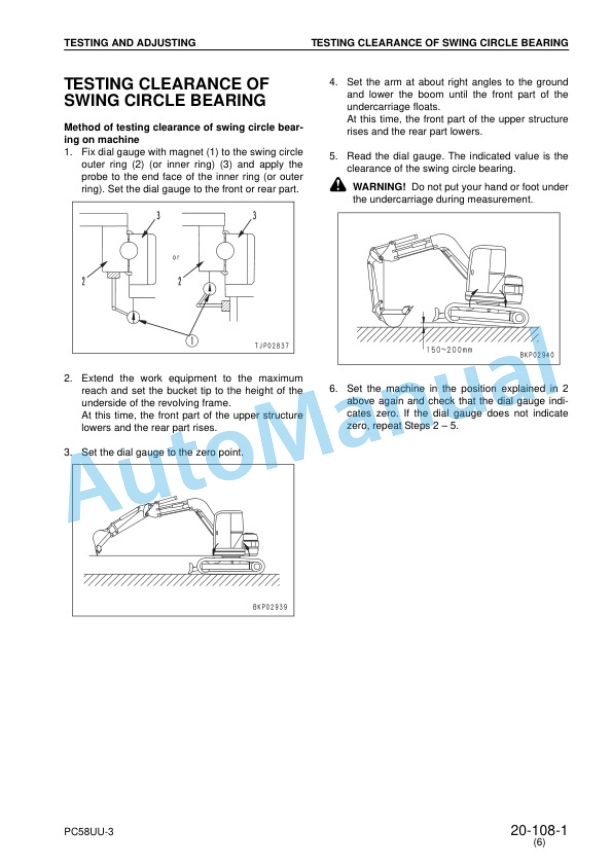

- 5.4.10. TESTING CLEARANCE OF SWING CIRCLE BEARING

- 5.4.11. CHECKING WEAR OF SPROCKET

- 5.4.12. TESTING AND ADJUSTING TRACK SHOE TENSION

- 5.4.13. ADJUSTING BRADE CONTROL LEVER

- 5.4.14. TESTING AND ADJUSTING HYDRAULIC PRESSURE IN WORK EQUIPMENT, SWING, AND TRAVEL CIRCUITS

- 5.4.15. TESTING AND ADJUSTING LS DIFFERENTIAL PRESSURE

- 5.4.16. ADJUSTING PC VALVE

- 5.4.17. TESTING AND ADJUSTING HYDRAULIC PRESSURE IN CONTROL PUMP CIRCUIT

- 5.4.18. MEASURING SOLENOID VALVE OUTPUT PRESSURE

- 5.4.19. MEASURING PPC VALVE OUTPUT PRESSURE

- 5.4.20. ADJUSTING PPC VALVE

- 5.4.21. TESTING SWING HOLDING BRAKE INLET PRESSURE

- 5.4.22. TESTING AND ADJUSTING TRAVEL DEVIATION

- 5.4.23. MEASURING OIL LEAKAGE FROM WORK EQUIPMENT CYLINDER

- 5.4.24. BLEEDING AIR FROM EACH PART

- 5.4.25. RELEASING RESIDUAL PRESSURE FROM HYDRAULIC CIRCUIT

- 5.4.26. RELEASING RESIDUAL PRESSURE FROM HYDRAULIC TANK

- 5.4.27. PRESSURIZING HYDRAULIC TANK

- 5.4.28. RESETTING PROCEDURE OF ELECTRIC SYSTEM AND CHECK OF ITS OPERATION

- 5.4.29. PROCEDURE FOR REPLACING POTENTIOMETER

- 5.4.30. PROCEDURE FOR TESTING DIODE

- 5.5. TROUBLESHOOTING

- 5.5.1. TROUBLESHOOTING POINTS TO REMEMBER

- 5.5.2. SEQUENCE OF EVENTS IN TROUBLESHOOTING

- 5.5.3. POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE

- 5.5.4. CHECKS BEFORE TROUBLESHOOTING

- 5.5.5. CONNECTOR TYPES AND MOUNTING LOCATIONS

- 5.5.6. CONNECTOR ARRANGEMENT DIAGRAM

- 5.5.7. CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

- 5.5.8. TADAPTERBOXES AND TADAPTER TABLE

- 5.5.9. EXPLANATIONS OF CONTROL MECHANISM OF ELECTRICAL SYSTEM

- 5.5.10. METHOD OF USING JUDGEMENT TABLE

- 5.5.11. METHOD OF USING TROUBLESHOOTING CHARTS

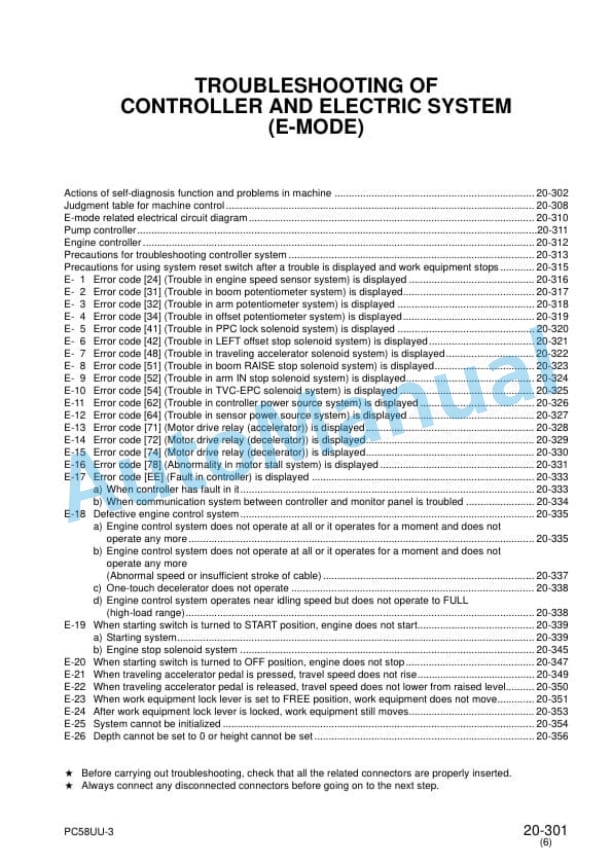

- 5.5.12. TROUBLESHOOTING OF CONTROLLER AND ELECTRIC SYSTEM(EMODE)

- 5.5.13. TROUBLESHOOTING FOR CONTROLLER INPUT SIGNAL SYSTEM(FMODE)

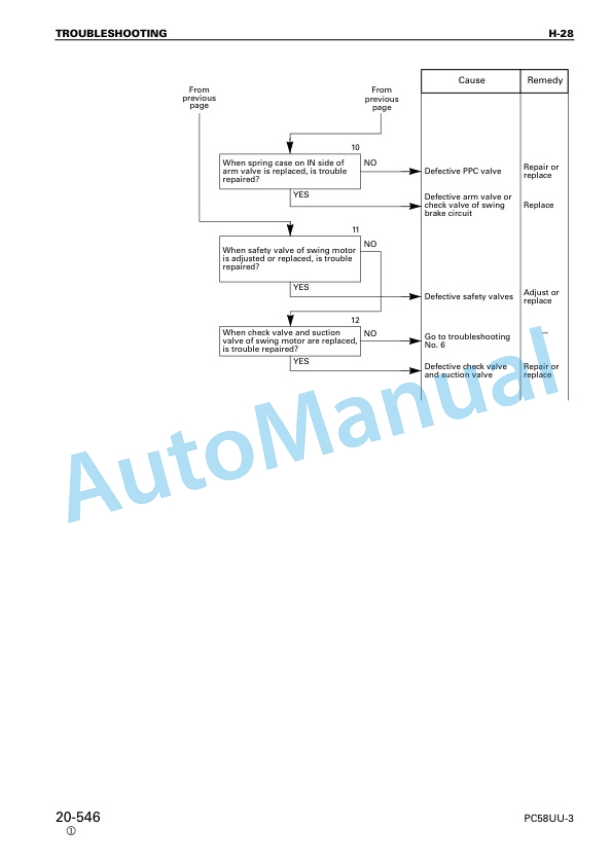

- 5.5.14. TROUBLESHOOTING FOR HYDRAULIC AND MECHANICAL SYSTEMS(HMODE)

- 5.5.15. TROUBLE SHOOTING FOR MACHINE MONITOR SYSTEM(MMODE)

- 6. DISASSEMBLY AND ASSEMBLY

- 6.1. METHOD OF USING MANUAL

- 6.2. PRECAUTIONS WHEN PERFORMING OPERATION

- 6.3. SPECIAL TOOL LIST

- 6.4. ENGINE AND WORK EQUIPMENT PUMP ASSEMBLY

- 6.4.1. REMOVAL

- 6.4.2. INSTALLATION

- 6.5. CENTER SWIVEL JOINT ASSEMBLY

- 6.5.1. REMOVAL

- 6.5.2. INSTALLATION

- 6.6. SWING MOTOR AND SWING MACHINERY ASSEMBLY

- 6.6.1. REMOVAL

- 6.6.2. INSTALLATION

- 6.7. REMOVAL OF CENTER SWIVEL JOINT ASSEMBLY

- 6.8. INSTALLATION OF REVOLVING FRAME ASSEMBLY

- 6.9. SWING CIRCLE ASSEMBLY

- 6.9.1. REMOVAL

- 6.9.2. INSTALLATION

- 6.10. RUBBER SHOE ASSEMBLY

- 6.10.1. REMOVAL

- 6.10.2. INSTALLATION

- 6.11. ROAD LINER IRON SHOE ASSEMBLY

- 6.11.1. REMOVAL

- 6.11.2. INSTALLATION

- 6.12. SWING MACHINERY ASSEMBLY

- 6.12.1. DISASSEMBLY

- 6.12.2. ASSEMBLY

- 6.13. CENTER SWIVEL JOINT ASSEMBLY

- 6.13.1. DISASSEMBLY

- 6.13.2. ASSEMBLY

- 6.14. IDLER CUSHION ASSEMBLY

- 6.14.1. DISASSEMBLY

- 6.14.2. ASSEMBLY

- 6.15. INSTALLATION OF IDLER ASSEMBLY

- 6.16. INSTALLATION OF TRACK ROLLER ASSEMBLY

- 6.17. INSTALLATION OF CARRIER ROLLER ASSEMBLY

- 6.18. INSTALLATION OF HYDRAULIC CYLINDER ASSEMBLY

- 6.19. ASSEMBLY OF WORK EQUIPMENT VALVE(NOTES)

- 7. OTHERS

- 7.1. HYDRAULIC CIRCUIT DIAGRAM

- 7.2. HYDRAULIC CIRCUIT DIAGRAM (ADDITIONAL ATTACHMENT CIRCUIT)

- 7.3. ELECTRICAL CIRCUIT DIAGRAM (1/2) SERIAL NO.2000120423

- 7.4. ELECTRICAL CIRCUIT DIAGRAM (2/2) SERIAL NO.2000120423

- 7.5. ELECTRICAL CIRCUIT DIAGRAM (1/2) SERIAL NO.2042422000

- 7.6. ELECTRICAL CIRCUIT DIAGRAM (2/2) SERIAL NO.2042422000

- 7.7. ELECTRICAL CIRCUIT DIAGRAM (1/2) SERIAL NO.22001 AND UP

- 7.8. ELECTRICAL CIRCUIT DIAGRAM (2/2) SERIAL NO.22001 AND UP

Rate this product

You may also like