Komatsu PC60-7, PC60-7B Hydraulic Excavator Shop Manual SEBM010911

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM010911

- Format: PDF

- Size: 36.5MB

- Number of Pages: 695

Category: Komatsu Shop Manual PDF

-

Model List:

- PC60-7 Hydraulic Excavator

- PC60-7B Hydraulic Excavator

- 0.1. HOW TO READ THE SHOP MANUAL

- 0.2. HOISTING INSTRUCTIONS

- 0.3. COATING MATERIALS

- 0.4. STANDARD TIGHTENING TORQUE

- 0.5. ELECTRIC WIRE CODE

- 0.6. CONVERSION TABLE

- 0.7. TABLE OF OIL AND COOLANT CAPACITIES

- 1. STRUCTURE AND FUNCTION

- 1.1. RADIATOR, OIL COOLER

- 1.2. PTO (COUPLING)

- 1.3. ENGINE CONTROL

- 1.4. POWER TRAIN DIAGRAM

- 1.5. SWING CIRCLE

- 1.6. SWING MACHINERY

- 1.7. TRACK FRAME

- 1.8. IDLER CUSHION

- 1.9. HYDRAULIC PIPING DRAWING

- 1.10. HYDRAULIC CIRCUIT DIAGRAM

- 1.11. HYDRAULIC TANK

- 1.12. HYDRAULIC PUMP

- 1.13. CONTROL VALVE

- 1.14. SELFPRESSURE REDUCING VALVE

- 1.15. CLSS

- 1.16. SWING MOTOR

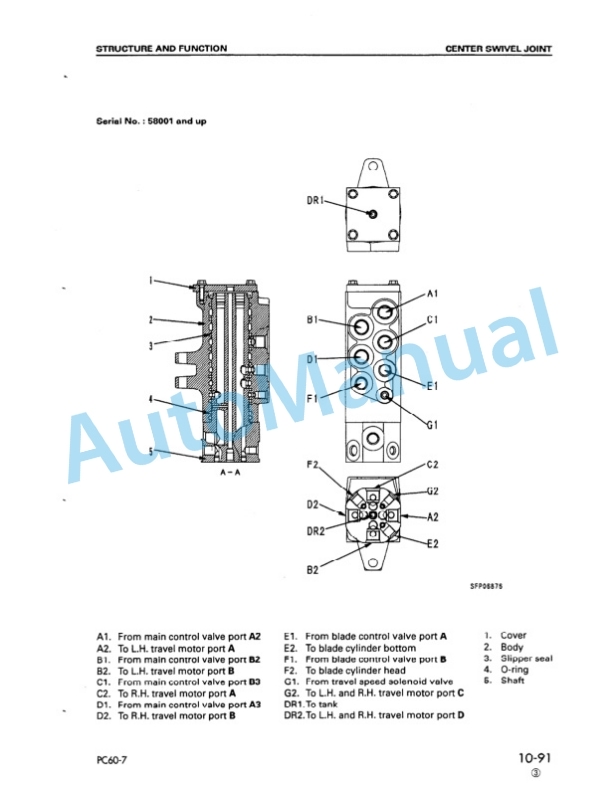

- 1.17. CENTER SWIVEL JOINT

- 1.18. TRAVEL MOTOR

- 1.19. VALVE CONTROL

- 1.20. WORK EQUIPMENT, SWING PPC VALVE

- 1.21. TRAVEL PPC VALVE

- 1.22. SERVICE PPC VALVE

- 1.23. SOLENOID VALVE

- 1.24. HYDRAULIC CYLINDER

- 1.25. WORK EQUIPMENT

- 1.26. WORK EQIPMENT PIN AUTOMATIC GREASING SYSTEM

- 1.27. ELECTRICAL ALLOCATION DIAGRAM (1/2)

- 1.28. ELECTRICAL ALLOCATION DIAGRAM (2/2)

- 1.29. ELECTRICAL CIRCUIT DIAGRAM

- 1.30. ELECTRICAL CONTROL SYSTEM

- 1.31. MACHINE MONITOR SYSTEM

- 2. TESTING AND ADJUSTING

- 2.1. STANDARD VALVE TABLE FOR ENGINE RELATED PARTS

- 2.2. STANDARD VALUE TABLE FOR CHASIS RELATED PARTS

- 2.3. STANDARD VALUE TABLE FOR ELECTRICAL RELATED PARTS

- 2.4. TOOLS FOR TESTING, ADJUSTING AND TROUBLESHOOTING

- 2.5. MEASURING ENGINE SPEED

- 2.6. MEASURING EXHAUST GAS COLOR

- 2.7. ADJUSTING VALVE CLEARANCE

- 2.8. MEASURING COMPRESSION PRESSURE

- 2.9. MEASURING BLOWBY PRESSURE

- 2.10. TESTING AND ADJUSTING FUEL INJECTION TIMING

- 2.11. MEASURING ENGINE OIL PRESSURE

- 2.12. TESTING AND ADJUSTING ALTERNATOR BELT TENSION

- 2.13. ADJUSTING ENGINE STOP SOLENOID LINKAGE

- 2.14. ADJUSTING FUEL CONTROL LINKAGE

- 2.15. TESTING AND ADJUSTING OF HYDRUALIC PRESSURE IN WORK EQUIPMENT, SWING AND TRAVEL CIRCUITS

- 2.16. ADJUSTING PC VALVE

- 2.17. MEASURING LS DIFFERENTIAL PRESSURE AND ADJUSTING LS VALVE

- 2.18. TESTING HYDRAULIC PRESSURE IN THE CONTROL CIRCUIT

- 2.19. TESTING OUTLET PRESSURE OF SOLENOID VALVE

- 2.20. MEASURING PPC VALVE OUTPUT PRESSURE

- 2.21. ADJUSTING WORK EQUIPMENT AND SWING PPC VALVE

- 2.22. TESTING TRAVEL DEVATION

- 2.23. MEASURING OIL LEAKAGE

- 2.24. RELEASING REMAINING PRESURE IN HYDRAULIC CIRCUIT

- 2.25. CHECKING OF CLEARANCE OF SWING CIRCLE BEARING

- 2.26. CHECKING AND ADJUSTING OF TRACK SHOE TENSION

- 2.27. TESTING WEAR OF SPROKET

- 2.28. BLEEDING AIR

- 2.29. AUTOMATIC GREASING CONTROLLER

- 2.30. TROUBLESHOOTING

- 2.30.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 2.30.2. SEQUENCE OF EVENTS IN TROUBLESHOOTING

- 2.30.3. POINTS TO REMEMBER WHEN CARRING OUT MAINTENANCE

- 2.30.4. CHECKS BEFORE TROUBLESHOOTING

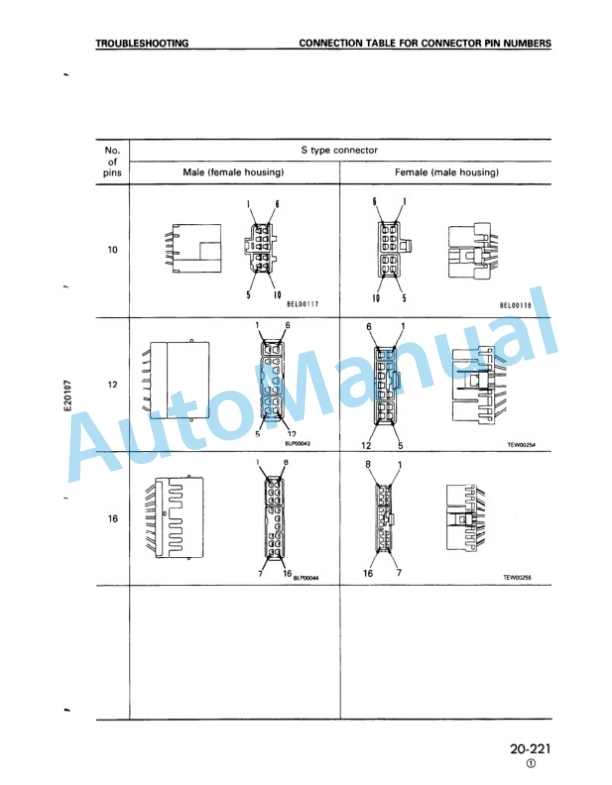

- 2.30.5. CONNECTOR TYPES AND MOUNTING LOCATIONS

- 2.30.6. CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

- 2.30.7. METHOD OF USING JUDGEMENT TABLE

- 2.30.8. METHOD OF USING TROUBLESHOOTING CHARTS

- 2.30.9. FAILURE MODES AND JUDGEMENT TABLE

- 2.30.10. TROUBLESHOOTING OF ELECTRICAL SYSTEM (E MODE)

- 2.30.11. TROUBLESHOOTING OF ENGINE (S MODE)

- 2.30.12. TROUBLESHOOTING OF HYDRAULIC AND MECHANICAL SYSTEM (H MODE)

- 2.30.13. TROUBLESHOOTING OF MACHINE MONITOR SYSTEM (M MODE)

- 2.30.14. TROUBLESHOOTING OF AUTOGREASING SYSTEM (D MODE)

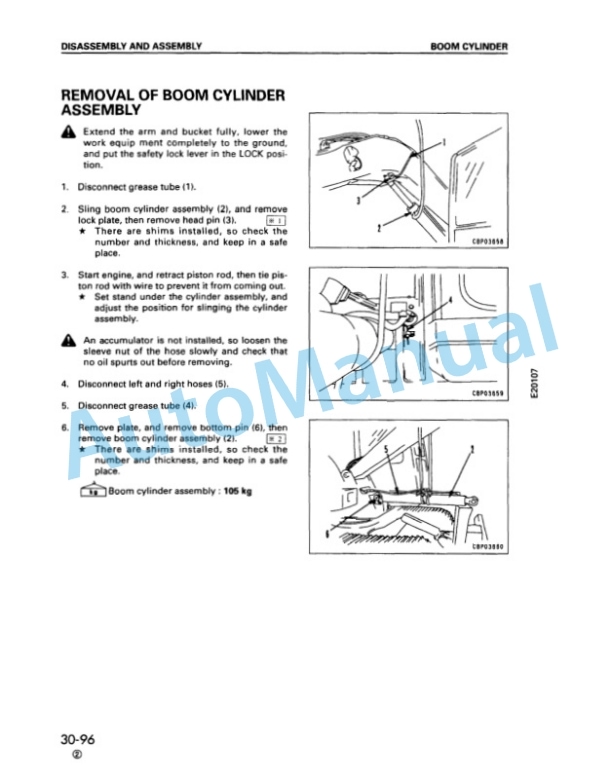

- 3. DISASSEMBLY AND ASSEMBLY

- 3.1. METHOD OF USING MANUAL

- 3.2. PRECAUTIONS WHEN CARRYING OUT OPERATION

- 3.3. SPECIAL TOOL LIST

- 3.4. SKETCHES OF SPECIAL TOOLS

- 3.5. STARTING MOTOR

- 3.5.1. REMOVAL AND INSTALLATION

- 3.6. ALTERNATOR

- 3.6.1. REMOVAL AND INSTALLATION

- 3.7. FUEL INJECTION PUMP

- 3.7.1. REMOVAL

- 3.7.2. INSTALLATION

- 3.8. WATER PUMP

- 3.8.1. REMOVAL AND INSTALLATION

- 3.9. NOZZLE HOLDER

- 3.9.1. REMOVAL AND INSTALLATION

- 3.10. THERMOSTAT

- 3.10.1. REMOVAL AND INSTALLATION

- 3.11. ENGINE OIL COOLER CORE

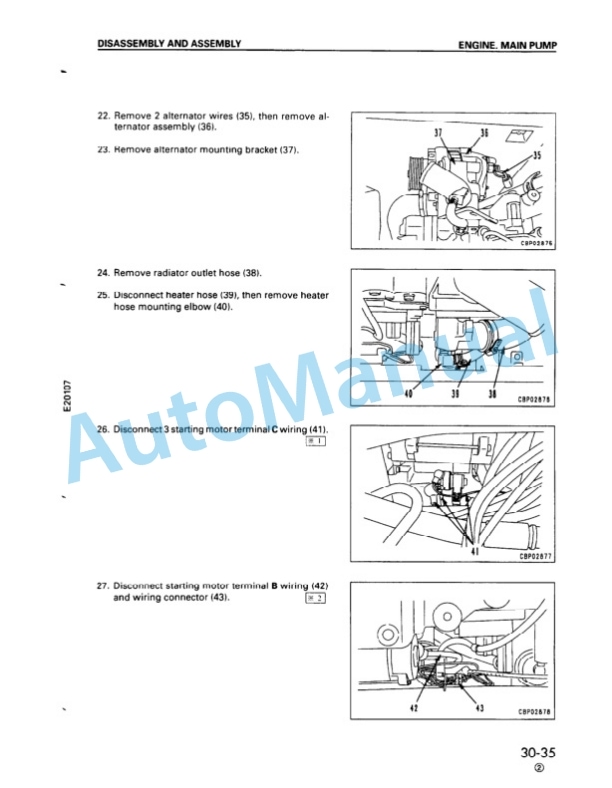

- 3.12. ENGINE, MAIN PUMP

- 3.12.1. REMOVAL

- 3.12.2. INSTALLATION

- 3.13. RADIATOR, HYDRAULIC COOLER

- 3.13.1. REMOVAL

- 3.13.2. INSTALLATION

- 3.14. FUEL TANK

- 3.14.1. REMOVAL AND INSTALLATION

- 3.15. CENTER SWIVEL JOINT

- 3.15.1. REMOVAL

- 3.15.2. INSTALLATION

- 3.15.3. DISASSEMBLY AND ASSEMBLY

- 3.16. SPROCKET

- 3.16.1. REMOVAL AND INSTALLATION

- 3.17. TRAVEL MOTOR

- 3.17.1. REMOVAL AND INSTALLATION

- 3.18. DISASSEMBLY, ASSEMBLY OF TRAVEL MOTOR GM09VL2

- 3.18.1. SAFETY

- 3.18.2. SECTIONAL DRAWING, SINGLE VIEW DRAWING, AND PARTS LIST

- 3.18.3. TOOLS

- 3.18.4. TIGHENING TORQUE

- 3.18.5. WEIGHT TABLE

- 3.18.6. DISASSEMBLY

- 3.18.7. MAINTENANCE STANDARD TABLE

- 3.18.8. ASSEMBLY

- 3.18.9. DIMENSIONS TABLE OF CLEARENCE ADJUSTMENT PARTS

- 3.18.10. PERFORMANCE CONFIRMATION TEST

- 3.19. SWING MOTOR, SWING MACHINERY

- 3.19.1. REMOVAL AND INSTALLATION

- 3.20. SWING MOTOR

- 3.20.1. DISASSEMBLY

- 3.20.2. ASSEMBLY

- 3.21. SWING MACHINERY

- 3.21.1. DISASSEMBLY

- 3.21.2. ASSEMBLY

- 3.22. REVOLVING FRAME

- 3.22.1. REMOVAL

- 3.22.2. INSTALLATION

- 3.23. SWING CIRCLE

- 3.23.1. REMOVAL AND INSTALLATION

- 3.24. IDLER, RECOIL SPRING

- 3.24.1. REMOVAL AND INSTALLATION

- 3.24.2. REMOVAL AND INSTALLATION

- 3.24.3. DISASSEMBLY

- 3.24.4. ASSEMBLY

- 3.25. CARRIER ROLLER

- 3.25.1. REMOVAL AND INSTALLATION

- 3.26. TRACK SHOE

- 3.26.1. REMOVAL AND INSTALLATION

- 3.27. HYDRAULIC TANK

- 3.28. MAIN PUMP INPUT SHAFT OIL SEAL

- 3.28.1. REMOVAL AND INSTALLATION

- 3.29. MAIN RELIEF VALVE

- 3.29.1. DISASSEMBLY AND ASSEMBLY

- 3.30. SOLENOID VALVE

- 3.30.1. REMOVAL AND INSTALLATION

- 3.31. WORK EQUIPMENT LEFT SIDE PPC VALVE (FOR ARM, SWING CONTROL) REMOVAL AND INSTALLATION

- 3.32. WORK EQUIPMENT RIGHT SIDE PPC VALVE (FOR BOOM, BUCKET CONTROL) REMOVAL AND INSTALLATION

- 3.33. WORK EQUIPMENT PPC VALVE (FOR BOOM, ARM, BUCKET, SWING CONTROL PPC VALUE)

- 3.33.1. DISASSEMBLY

- 3.33.2. ASSEMBLY

- 3.34. TRAVEL PPC VALVE

- 3.34.1. REMOVAL AND INSTALLATION

- 3.34.2. DISASSEMBLY AND ASSEMBLY

- 3.35. BUCKET CYLINDER

- 3.35.1. REMOVAL

- 3.35.2. INSTALLATION

- 3.36. BLADE CYCLINDER

- 3.36.1. REMOVAL

- 3.36.2. INSTALLATION

- 3.37. HYDRAULIC CYCLINDER

- 3.37.1. REMOVAL AND INSTALLATION

- 3.38. OPERATORS CAB

- 3.38.1. REMOVAL AND INSTALLATION

- 3.39. COUNTERWEIGHT

- 3.39.1. REMOVAL AND INSTALLATION

- 3.40. MONITOR

- 3.40.1. REMOVAL AND INSTALLATION

- 3.41. SWING CONTROLLER

- 3.41.1. REMOVAL AND INSTALLATION

- 3.42. AUTOGREASING CONTROLLER

- 3.42.1. REMOVAL AND INSTALLATION

- 3.43. AUTOGREASING PUMP

- 3.43.1. REMOVAL AND INSTALLATION

- 4. MAINTENANCE STANDARD

- 4.1. SWING MACHINERY

- 4.2. SELFPRESSURE REDUCING VALVE

- 4.3. SWING MOTOR

- 4.4. CENTER SWIVEL JOINT

- 4.5. WORK EQUIPMENT, SWING PPC VALVE

- 4.6. TRAVEL PPC VALVE

- 4.7. SERVICE PPC VALVE

- 4.8. WORK EQUIPMENT

- 4.9. HYDRAULIC CYCLINDER

- 5. OTHER SPECIFICATION (PC607 (FOR NORWAY)

- 5.1. PC607 (FOR NORWAY)

- 5.1.1. STRUCTURE AND FUNCTION

- 5.1.2. TESTING AND ADJUSTING

- 5.1.3. TROUBLESHOOTING

- 5.1.4. DISASSEMBLY AND ASSEMBLY

- 6. OTHERS

- 6.1. HYDRAULIC PIPING DRAWING

- 6.2. HYDRAULIC CIRCUIT DIAGRAM

- 6.3. OVERALL SYSTEM DIAGRAM (1/5)

- 6.4. OVERALL SYSTEM DIAGRAM (2/5)

- 6.5. OVERALL SYSTEM DIAGRAM (3/5)

- 6.6. OVERALL SYSTEM DIAGRAM (4/5)

- 6.7. OVERALL SYSTEM DIAGRAM (5/5)

- 6.8. ELECTRICAL ALLOCATION DIAGRAM

- 6.8.1. SERIAL NO. 52374 57999

- 6.8.2. SERIAL NO. 58001 AND UP

- 6.9. ELECTRIC CIRCUIT DIAGRAM

- 6.9.1. C607 SERIAL NO. 55720 AND UP FOR NORWAY)

- 6.10. CONNECTOR TYPES AND MOUNTING LOCATIONS

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00