Komatsu PC600-7, PC600LC-7 Shop Manual SEBM031206

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM031206

- Format: PDF

- Size: 68.5MB

- Number of Pages: 854

Category: Komatsu Shop Manual PDF

-

Model List:

- PC600-7

- PC600LC-7

- 1. COVER

- 2. CONTENTS

- 3. GENERAL

- 3.1. SPECIFICATION DRAWINGS

- 3.2. SPECIFICATIONS

- 3.3. WEIGHT TABLE

- 3.4. FUEL, COOLANT AND LUBRICANTS

- 4. STRUCTURE, FUNCTION AND MAINTENANCE STANDARD

- 4.1. PARTS RELATED TO ENGINE

- 4.3. CONTROL AND PTO LUBRICATION PUMP

- 4.4. RADIATOR, OIL COOLER

- 4.5. POWER TRAIN

- 4.6. FINAL DRIVE

- 4.7. SPROCKET

- 4.8. SWING CIRCLE

- 4.9. SWING MACHINERY

- 4.10. TRACK FRAME, RECOIL SPRING

- 4.11. IDLER

- 4.12. CARRIER ROLLER

- 4.13. TRACK ROLLER

- 4.14. TRACK SHOE

- 4.15. HYDRAULIC PIPING DRAWING

- 4.16. HYDRAULIC TANK, HYDRAULIC FILTER

- 4.17. HYDRAULIC PUMP (PISTON PUMP)

- 4.18. LINE OIL FILTER

- 4.19. CONTROL VALVE

- 4.20. SWING MOTOR

- 4.21. CENTER SWIVEL JOINT

- 4.22. TRAVEL MOTOR

- 4.23. VALVE CONTROL

- 4.24. WORK EQUIPMENT, SWING PPC VALVE

- 4.25. TRAVEL PPC VALVE

- 4.26. SERVICE PPC VALVE

- 4.27. PPC ACCUMULATOR

- 4.28. PPC SHUTTLE VALVE

- 4.29. SOLENOID VALVE

- 4.30. BOOM HOLDING VALVE

- 4.31. BOOM LOWER REGENERATION VALVE

- 4.32. HYDRAULIC CYLINDER

- 4.33. WORK EQUIPMENT

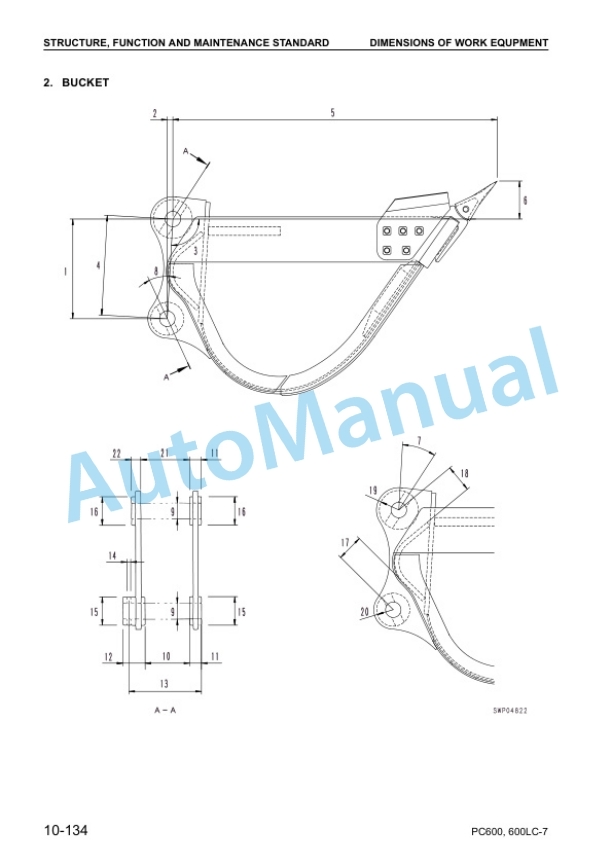

- 4.34. DIMENSIONS OF WORK EQUPMENT

- 4.35. COUNTERWEIGHT REMOVER

- 4.36. AIR CONDITIONER

- 4.37. ENGINE CONTROL

- 4.38. MACHINE CONTROL SYSTEM

- 4.39. MONITOR SYSTEM

- 4.40. SENSORS

- 5. TESTING AND ADJUSTING

- 5.1. STANDARD VALUE TABLE FOR ENGINE

- 5.2. STANDARD VALUE TABLE FOR CHASSIS

- 5.3. TESTING AND ADJUSTING

- 5.3.1. TOOLS FOR TESTING, ADJUSTING AND TROUBLESHOOTING

- 5.3.2. MEASURING ENGINE SPEED

- 5.3.3. MEASURING INTAKE AIR PRESSURE (BOOST PRESSURE)

- 5.3.4. MEASURING EXHAUST GAS TEMPERATURE

- 5.3.5. MEASURING EXHAUST GAS COLOR

- 5.3.6. ADJUSTING VALVE CLEARANCE

- 5.3.7. MEASURING COMPRESSION PRESSURE

- 5.3.8. MEASURING BLOWBY PRESSURE

- 5.3.9. MEASURING ENGINE OIL PRESSURE

- 5.3.10. HANDLING EQUIPMENT IN FUEL CIRCUIT

- 5.3.11. RELEASING REMAINING PRESSURE IN FUEL SYSTEM

- 5.3.12. MEASURING FUEL PRESSURE

- 5.3.13. BLEEDING AIR FROM FUEL CIRCUIT

- 5.3.14. CHECK FOR LEAKAGE IN FUEL SYSTEM

- 5.3.15. ADJUSTING ENGINE SPEED SENSOR

- 5.3.16. TESTING AND ADJUSTING FAN BELT TENSION

- 5.3.17. TESTING AND ADJUSTING ALTERNATOR BELT TENSION

- 5.3.18. TESTING AND ADJUSTING AIR CONDITIONER COMPRESSOR BELT TENSION

- 5.3.19. TESTING CLEARANCE OF SWING CIRCLE BEARING

- 5.3.20. TESTING AND ADJUSTING TRACK SHOE TENSION

- 5.3.21. TESTING AND ADJUSTING WORK EQUIPMENT, SWING, AND TRAVEL CIRCUIT OIL PRESSURES

- 5.3.22. TESTING AND ADJUSTING CONTROL CIRCUIT OIL PRESSURE

- 5.3.23. TESTING AND ADJUSTING PISTON PUMP CONTROL OIL PRESSURE

- 5.3.24. TESTING SERVO PISTON STROKE

- 5.3.25. MEASURING PPC VALVE OUTPUT PRESSURE

- 5.3.26. MEASURING OUTLET PRESSURES OF SOLENOID VALVE AND PPC SHUTTLE VALVE

- 5.3.27. ADJUSTING WORK EQUIPMENTSWING PPC VALVE

- 5.3.28. TESTING AND ADJUSTING TRAVEL DEVIATION

- 5.3.29. INSPECTION OF LOCATIONS OF HYDRAULIC DRIFT OF WORK EQUIPMENT

- 5.3.30. MEASURING OIL LEAKAGE

- 5.3.31. RELEASING REMAINING PRESSURE IN HYDRAULIC CIRCUIT

- 5.3.32. BLEEDING AIR FROM EACH PART

- 5.3.33. INSPECTION PROCEDURES FOR DIODE

- 5.3.34. SPECIAL FUNCTION OF MONITOR PANEL

- 5.3.35. HANDLING ENGINE CONTROLLER HIGH VOLTAGE CIRCUIT

- 5.3.36. PREPARATION WORK FOR TROUBLESHOOTING ELECTRICAL SYSTEM

- 5.3.37. PMCLINIC SERVICE

- 5.3.38. UNDERCARRIAGE INSPECTION

- 5.4. TROUBLESHOOTING

- 5.4.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 5.4.2. SEQUENCE OF EVENTS IN TROUBLESHOOTING

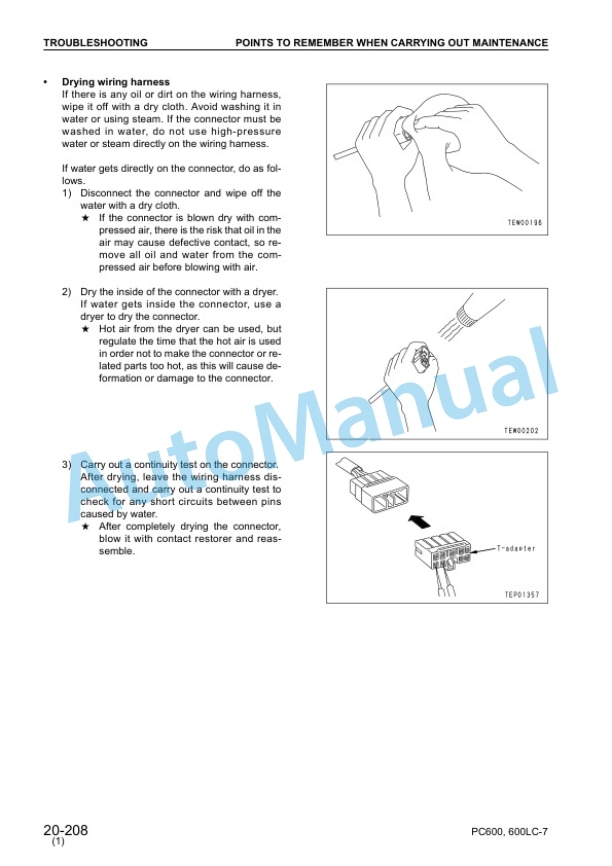

- 5.4.3. POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE

- 5.4.4. CHECKS BEFORE TROUBLESHOOTING

- 5.4.5. CLASSIFICATION AND STEPS FOR TROUBLESHOOTING

- 5.4.6. CONNECTOR LOCATION CHART AND ELECTRICAL CIRCUIT DIAGRAM BY SYSTEM

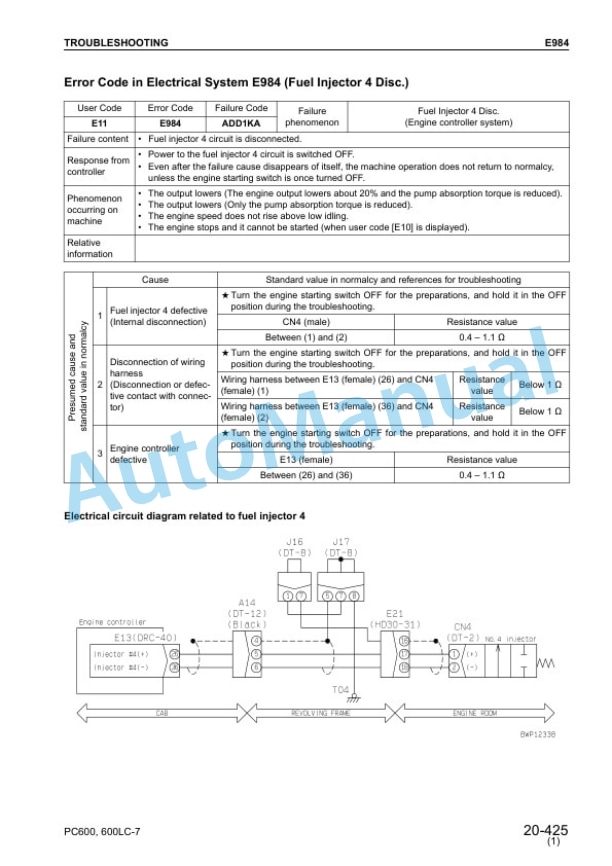

- 5.4.7. TROUBLESHOOTING WHEN ERROR CODE (ELECTRICAL SYSTEM) AND FAILURE CODE (MECHANICAL SYSTEM) ARE DISPLAYED (DISPLAYED CODE)

- 5.4.8. TROUBLESHOOTING OF ELECTRICAL SYSTEM (E MODE)

- 5.4.9. TROUBLESHOOTING OF HYDRAULIC AND MECHANICAL SYSTEM (H MODE)

- 5.4.10. TROUBLESHOOTING OF ENGINE (S MODE)

- 6. DISASSEMBLY AND ASSEMBLY

- 6.1. METHOD OF USING MANUAL

- 6.2. PRECAUTIONS WHEN CARRYING OUT OPERATION

- 6.3. SPECIAL TOOL LIST

- 6.4. REMOVAL AND INSTALLATION OF FUEL SUPPLY PUMP ASSEMBLY

- 6.5. REMOVAL AND INSTALLATION OF FUEL INJECTOR ASSEMBLY

- 6.6. REMOVAL AND INSTALLATION OF NOZZLE TIP

- 6.7. REMOVAL AND INSTALLATION OF ENGINE FRONT SEAL

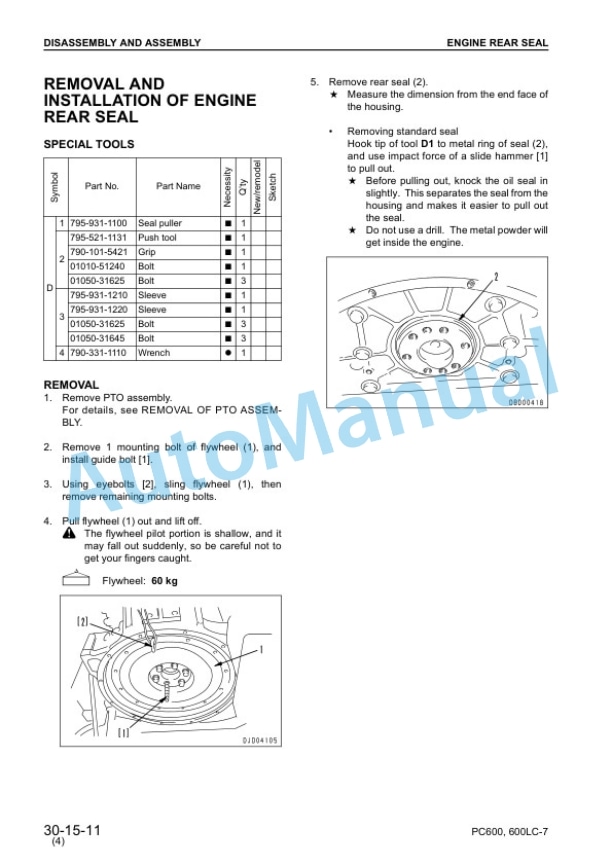

- 6.8. REMOVAL AND INSTALLATION OF ENGINE REAR SEAL

- 6.9. REMOVAL AND INSTALLATION OF CYLINDER HEAD ASSEMBLY

- 6.10. REMOVAL AND INSTALLATION OF RADIATOR, HYDRAULIC COOLER ASSEMBLY

- 6.11. REMOVAL AND INSTALLATION OF ENGINE, PTO, HYDRAULIC PUMP ASSEMBLY

- 6.12. REMOVAL AND INSTALLATION OF PTO ASSEMBLY

- 6.13. DISASSEMBLY AND ASSEMBLY OF PTO ASSEMBLY

- 6.14. REMOVAL AND INSTALLATION OF FUEL TANK ASSEMBLY

- 6.15. DISASSEMBLY AND ASSEMBLY OF FINAL DRIVE ASSEMBLY

- 6.16. DISASSEMBLY AND ASSEMBLY OF TRAVEL MOTOR ASSEMBLY

- 6.17. REMOVAL AND INSTALLATION OF REVOLVING FRAME ASSEMBLY

- 6.18. REMOVAL AND INSTALLATION OF SWING MOTOR ASSEMBLY

- 6.19. DISASSEMBLY AND ASSEMBLY OF SWING MOTOR ASSEMBLY

- 6.20. REMOVAL AND INSTALLATION OF SWING MACHINERY ASSEMBLY

- 6.21. DISASSEMBLY AND ASSEMBLY OF SWING MACHINERY ASSEMBLY

- 6.22. REMOVAL AND INSTALLATION OF SWING CIRCLE ASSEMBLY

- 6.23. REMOVAL AND INSTALLATION OF TRACK SHOE ASSEMBLY

- 6.24. DISASSEMBLY AND ASSEMBLY OF ONE LINK IN FIELD

- 6.25. REMOVAL AND INSTALLATION OF IDLER, RECOIL SPRING ASSEMBLY

- 6.26. DISASSEMBLY AND ASSEMBLY OF IDLER ASSEMBLY

- 6.27. DISASSEMBLY AND ASSEMBLY OF RECOIL SPRING ASSEMBLY

- 6.28. REMOVAL AND INSTALLATION OF TRACK ROLLER ASSEMBLY

- 6.29. DISASSEMBLY AND ASSEMBLY OF TRACK ROLLER ASSEMBLY

- 6.30. REMOVAL AND INSTALLATION OF CARRIER ROLLER ASSEMBLY

- 6.31. DISASSEMBLY AND ASSEMBLY OF CARRIER ROLLER ASSEMBLY

- 6.32. REMOVAL AND INSTALLATION OF HYDRAULIC TANK ASSEMBLY

- 6.33. DISASSEMBLY AND ASSEMBLY OF MAIN RELIEF VALVE ASSEMBLY

- 6.34. REMOVAL AND INSTALLATION OF MAIN CONTROL VALVE, SOLENOID VALVE ASSEMBLY

- 6.35. DISASSEMBLY AND ASSEMBLY OF MAIN CONTROL VALVE ASSEMBLY

- 6.36. REMOVAL AND INSTALLATION OF NO.1 AND NO.2 PUMP ASSEMBLY

- 6.37. DISASSEMBLY AND ASSEMBLY OF HYDRAULIC PUMP ASSEMBLY

- 6.38. REMOVAL AND INSTALLATION OF CONTROL, PTO LUBRICATION PUMP ASSEMBLY

- 6.39. REMOVAL AND INSTALLATION OF CENTER SWIVEL JOINT ASSEMBLY

- 6.40. DISASSEMBLY AND ASSEMBLY OF CENTER SWIVEL JOINT ASSEMBLY

- 6.41. DISASSEMBLY AND ASSEMBLY OF WORK EQUIPMENT PPC VALVE ASSEMBLY

- 6.42. DISASSEMBLY AND ASSEMBLY OF TRAVEL PPC VALVE ASSEMBLY

- 6.43. REMOVAL AND INSTALLATION OF BUCKET CYLINDER ASSEMBLY

- 6.44. REMOVAL AND INSTALLATION OF ARM CYLINDER ASSEMBLY

- 6.45. REMOVAL AND INSTALLATION OF BOOM CYLINDER ASSEMBLY

- 6.46. DISASSEMBLY AND ASSEMBLY OF HYDRAULIC CYLINDER ASSEMBLY

- 6.47. REMOVAL AND INSTALLATION OF BUCKET ASSEMBLY

- 6.48. REMOVAL AND INSTALLATION OF ARM ASSEMBLY

- 6.49. REMOVAL AND INSTALLATION OF BOOM ASSEMBLY

- 6.50. REMOVAL AND INSTALLATION OF OPERATORS CAB ASSEMBLY

- 6.51. REMOVAL AND INSTALLATION OF COUNTERWEIGHT ASSEMBLY

- 6.52. REMOVAL AND INSTALLATION OF OPERATORS CAB GLASS (STUCK GLASS)

- 6.53. REMOVAL AND INSTALLATION OF FRONT WINDOW ASSEMBLY

- 6.54. REMOVAL AND INSTALLATION OF COUNTERWEIGHT ASSEMBLY

- 7. OTHERS

- 7.1. HYDRAULIC CIRCUIT DIAGRAM

- 7.2. ELECTRICAL CIRCUIT DIAGRAM (1/5)

- 7.3. ELECTRICAL CIRCUIT DIAGRAM (2/5)

- 7.4. ELECTRICAL CIRCUIT DIAGRAM (3/5)

- 7.5. ELECTRICAL CIRCUIT DIAGRAM (4/5)

- 7.6. ELECTRICAL CIRCUIT DIAGRAM (5/5)

- 7.7. ELECTRICAL CIRCUIT FOR AIR CONDITIONER

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00