Komatsu PC7000-6 Hydraulic Mining Shovel Shop Manual 35001-xD-GB-0

$40.00

- Type Of Manual: Shop Manual

- Manual ID: 35001-xD-GB-0

- Format: PDF

- Size: 38.5MB

- Number of Pages: 756

Category: Komatsu Shop Manual PDF

-

Model List:

- PC7000-6 Hydraulic Mining Shovel

- 1. SHOP MANUAL Cover

- 2. FOREWORD SAFETY

- 2.1. Foreword

- 2.1.1. Before reading this manual

- 2.1.2. Contents of this binder

- 2.1.3. Division of the binder

- 2.2. SAFETY

- 2.2.1. SAFETY INFORMATION

- 2.2.2. OVERVIEW

- 2.2.3. SOUND PRESSURE AND VIBRATION LEVELs IN THE OPERATORS CAB.

- 2.2.4. GENERAL PRECAUTIONS COMMON TO OPERATION ON THE EXCAVATOR

- 2.2.5. PRECAUTION FOR MAINTENANCE

- 2.2.6. ADDITIONAL SAFETY INFORMATION FOR TROUBLESHOOTING AND ADJUSTMENTS

- 2.2.7. SPECIAL SAFETY EQUIPMENT

- 3. SPECIFICATION

- 3.1. PC70006

- 4. STRUCTURE FUNCTION

- 4.2. Introduction

- 4.2.1. Foreword

- 4.2.2. Recommendations for environmentally friendly operation and maintenance of hydraulic mining shovels

- 4.2.3. Explanation of abbreviations

- 4.2.4. Diagrams and illustrations in this manual

- 4.3. Specifications

- 4.3.1. Lifting Gears

- 4.3.2. Safety hints for sling accessory

- 4.3.3. Standard Tightening Torque Chart

- 4.3.4. Conversion Table

- 4.3.5. Blind plugs

- 4.3.6. Classification of threads to the nominal width

- 4.3.7. Plugs and fittings according to ISO 84341 / DIN 2353

- 4.4. Main assembly groups

- 4.4.1. General layout

- 4.4.2. Superstructure

- 4.4.3. Machine house

- 4.4.4. Hydraulic oil tank

- 4.4.5. Hydraulic oil cooler

- 4.4.6. Fuel tank

- 4.4.7. Cab support

- 4.4.8. Operators cab

- 4.4.9. Main control blocks (FSA)

- 4.4.10. Slew gear

- 4.4.11. Undercarriage

- 4.4.12. Slew ring

- 4.4.13. Attachment

- 4.5. Drive

- 4.5.1. Prime drive assembly

- 4.5.2. Engine and PTO mounts

- 4.5.3. Flexible coupling

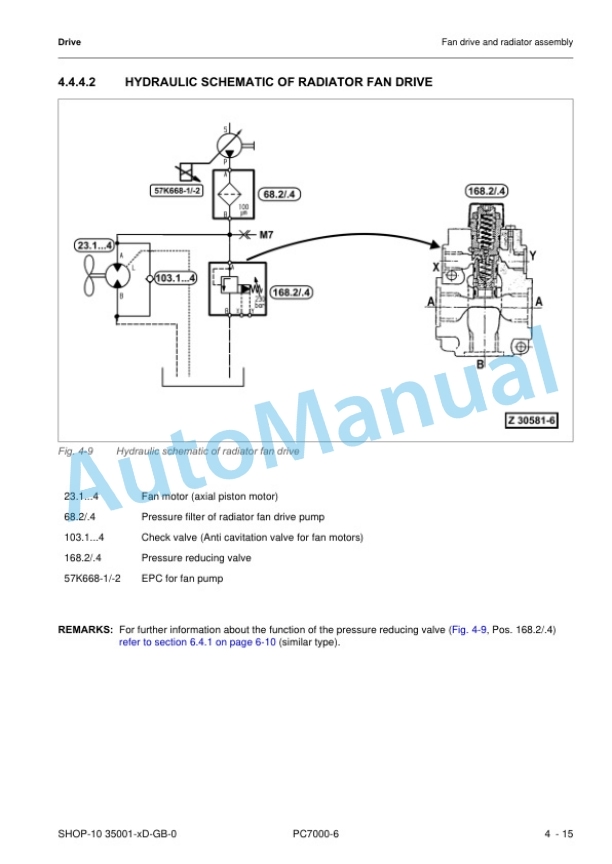

- 4.5.4. Fan drive and radiator assembly

- 4.5.5. Pump distributor gearbox (PTO)

- 4.5.6. Hydraulic pumps location, drive speed and flow rates

- 4.5.7. Air cleaner

- 4.6. Hydraulic oil tank

- 4.6.1. General layout

- 4.6.2. Hydraulic oil tank, location of the electric equipment

- 4.6.3. Suction oil tank with strainers

- 4.6.4. Return oil collector pipe with strainer

- 4.6.5. Back pressure valve

- 4.6.6. Transfer pump

- 4.6.7. Return and leak oil filter

- 4.6.8. Breather filter

- 4.7. Hydraulic oil cooling

- 4.7.1. Overall view of the hydraulic oil cooling

- 4.7.2. Function of the hydraulic oil cooling circuit

- 4.7.3. Adjustment of the back pressure valve

- 4.7.4. Stepless cooler fan RPM control

- 4.7.5. Oil cooler fan speed testing/adjustment

- 4.8. Controlling

- 4.8.1. General layout

- 4.8.2. Control and filter panels location of components

- 4.8.3. Pilot pressure supply and adjustments

- 4.8.4. Function of the electro hydraulic control system

- 4.8.5. Hand lever (joystick) control

- 4.8.6. Foot pedal control

- 4.8.7. Hand lever foot pedal monitoring

- 4.8.8. Valve solenoid adjustment

- 4.8.9. ACCEL DECEL time adjustment

- 4.9. Components

- 4.9.1. Main control blocks and high pressure screens (FSA)

- 4.9.2. Main control blocks with valves (FSA)

- 4.9.3. Main control blocks with valves (BHA)

- 4.9.4. Distributor manifold location of restrictor blocks and anti cavitation valves (FSA)

- 4.9.5. Distributor manifold location of restrictor blocks and anti cavitation valves (BHA)

- 4.9.6. Restrictor block with secondary relief valve

- 4.9.7. Anticavitation valve (ACV) block

- 4.9.8. Remote control valves

- 4.9.9. Directional solenoid valves

- 4.9.10. Proportional solenoid valves

- 4.9.11. Highpressure screen

- 4.9.12. Control blocks and valves

- 4.9.13. Travel brake valve

- 4.9.14. Pressure reducing valve

- 4.9.15. Directional valves

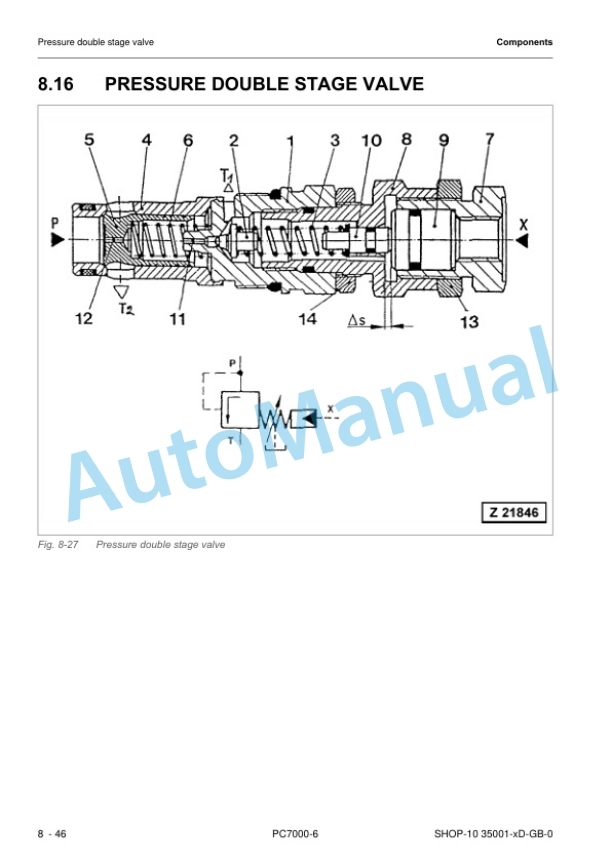

- 4.9.16. Pressure double stage valve

- 4.9.17. Hydraulic cylinder

- 4.10. Main hydraulic pumps, pump regulation, valve control monitoring system

- 4.10.1. General

- 4.10.2. Main pumps

- 4.10.3. Electronic pump regulation system

- 4.10.4. Pump valve controllers

- 4.10.5. Multimonitor

- 4.10.6. Service menu 01 Monitoring

- 4.10.7. Using Multimonitor functions for monitoring

- 4.10.8. Service menu 02 Abnormality Record

- 4.10.9. Service menu 03 Default

- 4.10.10. Service menu 04 Adjustment

- 4.10.11. Service menu 05 Display Setup

- 4.10.12. Checks and adjustments

- 4.10.13. Engine speed sensors (pickup)

- 4.11. Operating hydraulics

- 4.11.1. General

- 4.11.2. Spool functions (FSA)

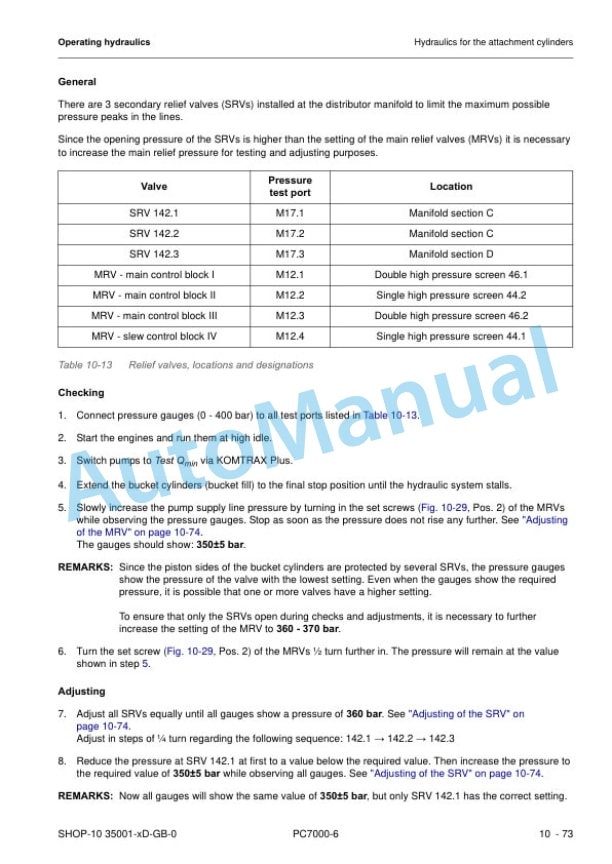

- 4.11.3. Hydraulics for the attachment cylinders

- 4.11.4. Hydraulics for the slew circuit

- 4.11.5. Hydraulics for the travel circuit

- 4.12. Hydraulic track tensioning system

- 4.12.1. General

- 4.12.2. Functional description

- 4.12.3. Double stage valve

- 4.12.4. Tensioning cylinder

- 4.12.5. Adjustments / checks

- 4.13. Access ladder, hydraulically operated

- 4.13.1. Overview

- 4.13.2. Function of the hydraulically operated access ladder

- 4.13.3. Adjustments / checks

- 4.14. Central refilling system (Service arm)

- 4.14.1. Refilling arm location

- 4.14.2. Function

- 4.15. Hints for reading the hydraulic diagram

- 4.15.1. General

- 4.15.2. Hydraulic symbols

- 4.16. Hints for reading the electric wiring diagram

- 4.16.1. General

- 4.16.2. Reference code of the electrical components

- 4.16.3. Graphical symbols

- 4.16.4. Drawing concept

- 4.16.5. Cable marking

- 4.17. KOMTRAX Plus MTC control system

- 4.17.1. General

- 4.17.2. Specifications for operators

- 4.17.3. Tables of all provided messages

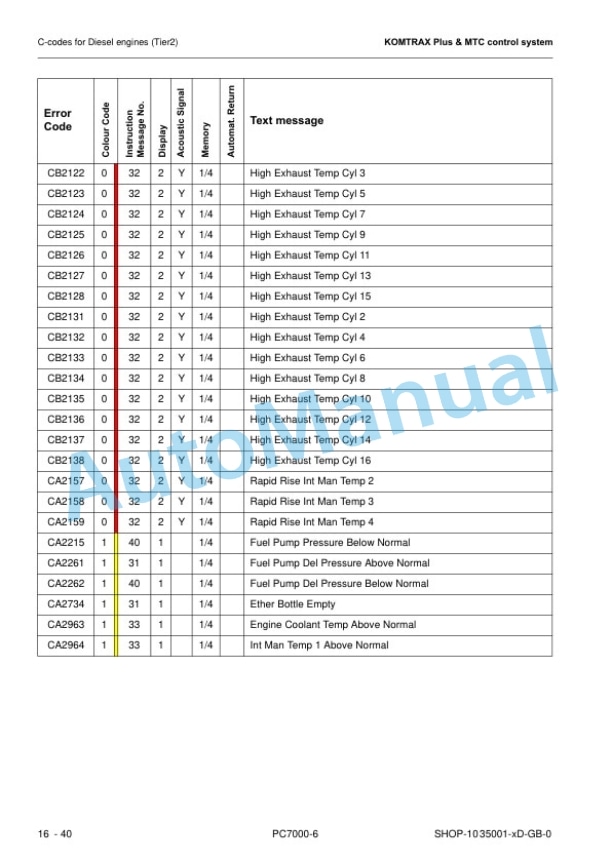

- 4.17.4. Ccodes for Diesel engines (Tier2)

- 4.17.5. Flow charts (14) of KOMTRAX Plus main screens

- 4.17.6. KOMTRAX Plus service level

- 4.17.7. InterfaceConnection KOMTRAX Plus controller MTC

- 4.17.8. segment error code indication

- 4.17.9. Wiring of the KOMTRAX Plus controller

- 4.17.10. MTC control system global layout

- 4.17.11. Global layout of the internal CAN BUS

- 4.17.12. The nodes in the CAN BUS system

- 4.18. Lubrication system

- 4.18.1. General overview SLS CLS1/2

- 4.18.2. Basic function of the lubrication systems

- 4.18.3. Lubrication systems (SLS CLS1/2)

- 4.18.4. Lubrication cycle

- 4.18.5. Hydraulically driven lube pump

- 4.18.6. Lubricant injectors

- 4.18.7. Vent valve and grease outlet filter

- 4.18.8. Endline switch

- 4.18.9. Lubricant level sensors

- 4.18.10. Commissioning

- 4.19. Deep temperature equipment (option)

- 4.19.1. General information

- 4.19.2. Preheating procedure

- 4.19.3. Constant heating of travel motors (TTT equipment below40C only)

- 4.19.4. Component location

- 4.19.5. Components of TT equipment

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00