Komatsu PC78MR-6 Hydraulic Excavator Shop Manual SEBM030604

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM030604

- Format: PDF

- Size: 36.1MB

- Number of Pages: 589

Category: Komatsu Shop Manual PDF

-

Model List:

- PC78MR-6 Hydraulic Excavator

- 0.1. HOW TO READ THE SHOP MANUAL

- 0.2. HOISTING INSTRUCTIONS

- 0.3. METHOD OF DISASSEMBLING, CONNECTING PUSHPULL TYPE COUPLER

- 0.4. COATING MATERIALS

- 0.5. STANDARD TIGHTENING TORQUE

- 0.6. ELECTRIC WIRE CODE

- 0.7. CONVERSION TABLE

- 0.8. UNITS

- 1. GENERAL

- 1.1. SPECIFICATION DIMENSIONS DRAWING

- 1.2. WORKING RANGE DRAWING

- 1.3. SPECIFICATIONS

- 1.4. WEIGHT TABLE

- 1.5. LIST OF LUBRICANTS AND COOLANT

- 2. STRUCTURE, FUNCTION AND MAINTENANCE STANDARD

- 2.2. COOLING SYSTEM

- 2.3. POWER TRAIN SYSTEM

- 2.4. SWING CIRCLE

- 2.5. SWING MACHINERY

- 2.6. TRACK FRAME AND IDLER CUSHION

- 2.7. ARRANGEMENT OF HYDRAULIC COMPONENTS

- 2.8. HYDRAULIC TANK AND OIL FILTER

- 2.9. CENTER SWIVEL JOINT

- 2.10. TRAVEL MOTOR

- 2.11. WORK EQUIPMENT CYLINDER

- 2.12. SOLENOID VALVE

- 2.13. SOLENOID VALVE (FOR EU SPEC.)

- 2.14. ACCUMULATOR FOR PPC

- 2.15. MULTICONTROL VALVE

- 2.16. ACCUMULATOR FOR BRAKER

- 2.17. HYDRAULIC PUMP

- 2.18. CONTROL VALVE

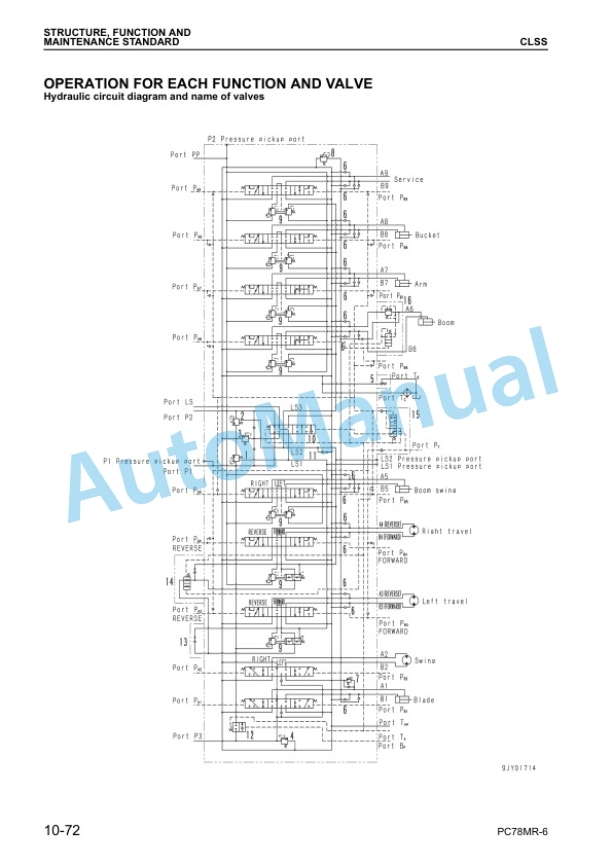

- 2.19. CLSS

- 2.20. SWING MOTOR

- 2.21. WORK EQUIPMENT AND SWING PPC VALVE

- 2.22. TRAVEL PPC VALVE

- 2.23. BOOM SWING PPC VALVE, BLADE PPC VALVE

- 2.24. BOOM HYDRAULIC ANTIBURST VALVE (FOR EU SPEC)

- 2.25. WORK EQUIPMENT

- 2.26. DIMENSIONS OF EACH PART OF WORK EQUIPMENT

- 2.27. AIR CONDITIONER PIPING (OPTIONAL)

- 2.28. ELECTRIC CONTROL SYSTEM

- 2.29. SYSTEM COMPONENTS

- 2.30. MONITOR SYSTEM

- 2.31. SENSORS

- 3. TESTING AND ADJUSTING

- 3.1. STANDARD VALUE TABLE FOR ENGINE

- 3.2. STANARD VALUE TABLE FOR CHASSIS

- 3.3. STANDARD VALUE TABLE FOR ELECTRIC PARTS

- 3.4. TESTING AND ADJUSTING

- 3.4.1. LIST OF DEVICES FOR TESTING, ADJUSTING, AND TROUBLESHOOTING

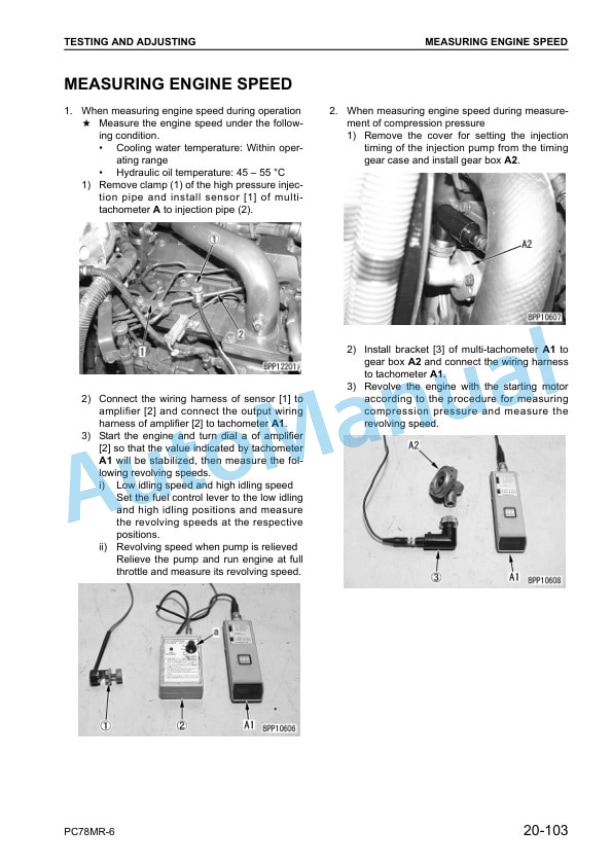

- 3.4.2. MEASURING ENGINE SPEED

- 3.4.3. MEASURING EXHAUST GAS COLOR

- 3.4.4. ADJUSTING VALVE CLEARANCE

- 3.4.5. MEASURING COMPRESSION PRESSURE

- 3.4.6. MEASURING BLOWBY PRESSURE

- 3.4.7. TESTING AND ADJUSTING FUEL INJECTION TIMING

- 3.4.8. MEASURING ENGINE OIL PRESSURE

- 3.4.9. ADJUSTING ENGINE STOP SOLENOID

- 3.4.10. ADJUSTING FUEL CONTROL LINKAGE

- 3.4.11. ADJUSTING ENGINE SPEED SENSOR

- 3.4.12. TESTING AND ADJUSTING HYDRAULIC PRESSURE IN WORK EQUIPMENT, SWING, AND TRAVEL CIRCUITS

- 3.4.13. MEASURING LS DIFFERENTIAL PRESSURE AND ADJUSTING LS VALVE

- 3.4.14. ADJUSTING PC VALVE

- 3.4.15. TESTING TVCEPC SOLENOID OUTPUT PRESSURE

- 3.4.16. MEASURING CONTROL CIRCUIT PRESSURE

- 3.4.17. MEASURING PPC VALVE OUTPUT PRESSURE

- 3.4.18. TESTING SOLENOID VALVE OUTPUT PRESSURE

- 3.4.19. ADJUSTING WORK EQUIPMENT VALVE AND SWING PPC VALVE

- 3.4.20. TESTING TRAVEL DEVIATION

- 3.4.21. TESTING PARTS WHICH CAN CAUSE HYDRAULIC DRIFT OF WORK EQUIPMENT

- 3.4.22. MEASURING OIL LEAKAGE FROM SWING AND TRAVEL MOTORS

- 3.4.23. RELEASING RESIDUAL PRESSURE FROM HYDRAULIC CIRCUIT

- 3.4.24. TESTING CLEARANCE OF SWING CIRCLE BEARING

- 3.4.25. TESTING AND ADJUSTING TRACK SHOE TENSION

- 3.4.26. BLEEDING AIR FROM HYDRAULIC CIRCUIT

- 3.4.27. REPLACEMENT PROCEDURE OF POTENTIOMETERS

- 3.4.28. PROCEDURE FOR TESTING DIODE

- 3.5. TROUBLESHOOTING

- 3.5.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 3.5.2. SEQUENCE OF EVENTS IN TROUBLESHOOTING

- 3.5.3. POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE

- 3.5.4. CHECKS BEFORE TROUBLESHOOTING

- 3.5.5. TYPE AND LOCATION OF CONNECTORS

- 3.5.6. CONNECTOR ARRANGEMENT DIAGRAM

- 3.5.7. CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

- 3.5.8. EXPLANATION OF FUNCTIONS OF ELECTRIC SYSTEM CONTROL MECHANISM

- 3.5.9. DISPLAY AND SPECIAL FUNCTIONS OF MONITOR PANEL

- 3.5.10. TVC VALVE CURRENT ADJUSTMENT TABLE

- 3.5.11. METHOD OF USING JUDGEMENT TABLE

- 3.5.12. HOW TO READ FLOW OF TROUBLESHOOTING

- 3.5.13. CONTENTS AND PROCEDURE OF TROUBLESHOOTING

- 3.5.14. TROUBLESHOOTING OF ENGINE (S MODE)

- 3.5.15. TROUBLESHOOTING OF COMMUNICATION SYSTEM (N MODE)

- 3.5.16. TROUBLESHOOTING FOR CONTROLLER (GOVERNOR CONTROL SYSTEM) (E MODE)

- 3.5.17. TROUBLESHOOTING FOR CONTROLLER PUMP CONTROL SYSTEM (C MODE)

- 3.5.18. TROUBLESHOOTING FOR CONTROLLER (INPUT SIGNAL SYSTEM) (F MODE)

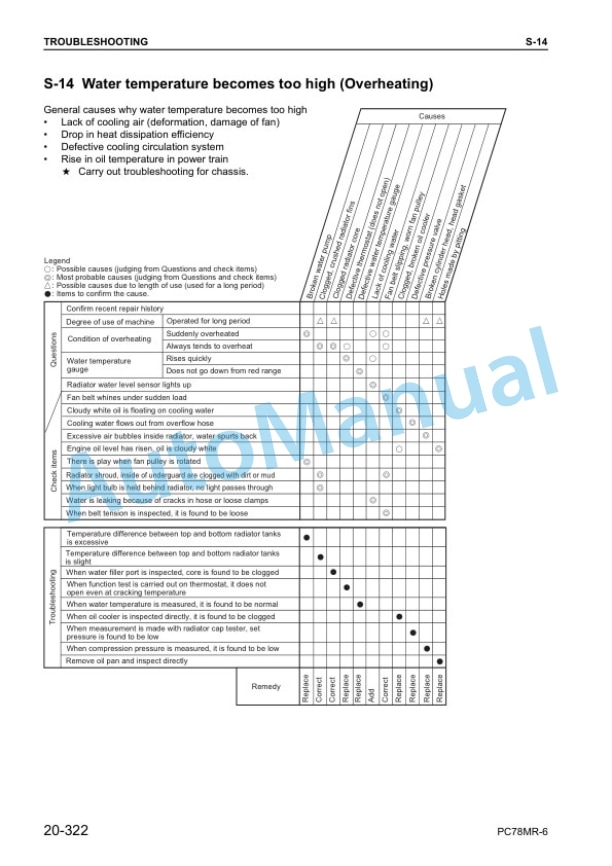

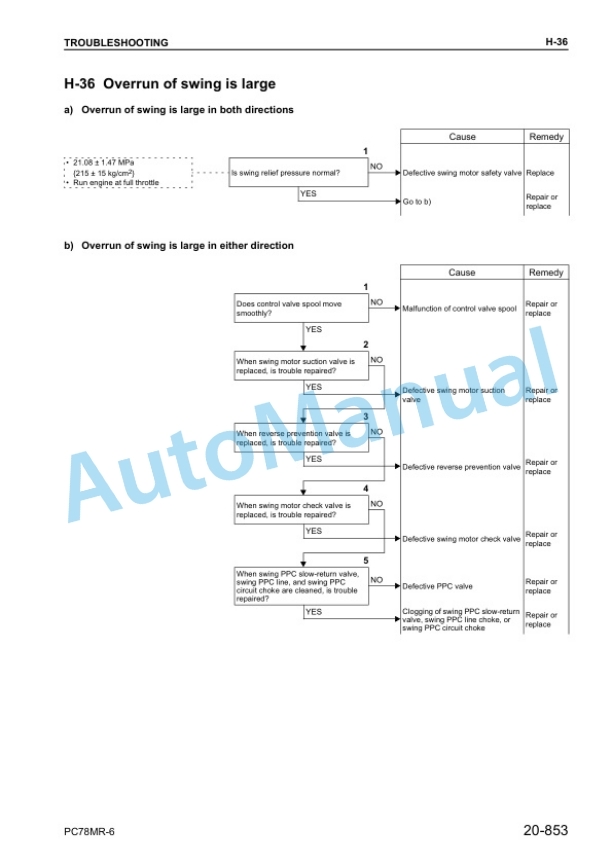

- 3.5.19. TROUBLESHOOTING FOR HYDRAULIC AND MECHANICAL SYSTEMS (H MODE)

- 3.5.20. TROUBLESHOOTING FOR MACHINE MONITOR SYSTEM (M MODE)

- 4. DISASSEMBLY AND ASSEMBLY

- 4.1. METHOD OF USING MANUAL

- 4.2. PRECAUTIONS WHEN CARRYING OUT OPERATION

- 4.3. SPECIAL TOOL LIST

- 4.4. COUNTERWEIGHT

- 4.4.1. REMOVAL AND INSTALLATION

- 4.5. INJECTION PUMP

- 4.5.1. REMOVAL AND INSTALLATION

- 4.6. ENGINE AND MAIN PUMP

- 4.6.1. REMOVAL

- 4.6.2. INSTALLATION

- 4.7. HYDRAULIC OIL COOLER

- 4.7.1. REMOVAL AND INSTALLATION

- 4.8. RADIATOR

- 4.8.1. REMOVAL

- 4.8.2. INSTALLATION

- 4.9. SWING MOTOR AND SWING MACHINERY

- 4.9.1. REMOVAL AND INSTALLATION

- 4.10. SWING MACHINERY

- 4.10.1. DISASSEMBLY

- 4.10.2. ASSEMBLY

- 4.11. SWING MOTOR

- 4.11.1. REMOVAL AND INSTALLATION

- 4.12. CENTER SWIVEL JOINT

- 4.12.1. REMOVAL

- 4.12.2. INSTALLATION

- 4.12.3. DISASSEMBLY AND ASSEMBLY

- 4.13. CONTROL VALVE

- 4.13.1. REMOVAL AND INSTALLATION

- 4.13.2. ASSEMBLY

- 4.14. WORK EQUIPMENT PPC VALVE

- 4.14.1. ASSEMBLY

- 4.15. TRAVEL PPC VALVE

- 4.15.1. ASSEMBLY

- 4.16. HYDRAULIC TANK

- 4.16.1. REMOVAL AND INSTALLATION

- 4.17. FUEL TANK

- 4.17.1. REMOVAL

- 4.17.2. INSTALLATION

- 4.18. CONTROLLER

- 4.18.1. REMOVAL AND INSTALLATION

- 4.19. MONITOR PANEL

- 4.19.1. REMOVAL AND INSTALLATION

- 4.20. AIR CONDITIONER UNIT

- 4.20.1. REMOVAL

- 4.20.2. INSTALLATION

- 4.21. OPERATORS CAB

- 4.21.1. REMOVAL AND INSTALLATION

- 4.22. FLOOR FRAME

- 4.22.1. REMOVAL

- 4.22.2. INSTALLATION

- 4.23. REVOLVING FRAME

- 4.23.1. REMOVAL AND INSTALLATION

- 4.24. SWING CIRCLE

- 4.24.1. REMOVAL AND INSTALLATION

- 4.25. WORK EQUIPMENT

- 4.26. STEEL SHOE, RUBBER PAD SHOE, ROAD LINER

- 4.26.1. EXPANSION AND INSTALLATION

- 4.27. RUBBER SHOE

- 4.27.1. REMOVAL AND INSTALLATION

- 4.28. HYDRAULIC CYLINDER

- 4.28.1. DISASSEMBLY

- 4.28.2. ASSEMBLY

- 5. OTHERS

- 5.1. HYDRAULIC CIRCUIT DIAGRAM (FOR STD SPEC)

- 5.2. HYDRAULIC CIRCUIT DIAGRAM (FOR EU SPEC)

- 5.3. ELECTRICAL CIRCUIT DIAGRAM (FOR STD SPEC) (1/2)

- 5.4. ELECTRICAL CIRCUIT DIAGRAM (FOR STD SPEC) (2/2)

- 5.5. ELECTRICAL CIRCUIT DIAGRAM (FOR EU SPEC) (1/2)

- 5.6. ELECTRICAL CIRCUIT DIAGRAM (FOR EU SPEC) (2/2)

- 5.7. ELECTRICAL CIRCUIT DIAGRAM (FOR NORWAY SPEC.) (1/2)

- 5.8. ELECTRICAL CIRCUIT DIAGRAM (FOR NORWAY SPEC.) (2/2)

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00