- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu PC8000-6 Diesel Hydraulic Mining Shovel Shop Manual 12071-upD-GB-01

$40.00

- Type Of Manual: Shop Manual

- Manual ID: 12071-upD-GB-01

- Format: PDF

- Size: 103.0MB

- Number of Pages: 1802

Category: Komatsu Shop Manual PDF

-

Model List:

- PC8000-6 Diesel Hydraulic Mining Shovel

- 1. SHOP MANUAL COVER

- 2. FOREWORD SAFETY

- 2.1. FOREWORD

- 2.1.1. BEFORE READING THIS MANUAL

- 2.1.2. DIRECTIONS OF THE MACHINE

- 2.1.3. SPECIFICATION AND SERIAL PLATE

- 2.1.4. DIVISION OF THE BINDER

- 2.1.5. DESIGNATED USE OF THE SHOVEL

- 2.1.6. DELIVERY OF THE SHOVEL

- 2.1.7. EXPLANATION OF ABBREVIATIONS

- 2.1.8. CONTENTS

- 2.2. SAFETY

- 2.2.1. SAFETY INFORMATION

- 2.2.2. OVERVIEW

- 2.2.3. SOUND PRESSURE LEVEL IN THE OPERATORS CAB.

- 2.2.4. GENERAL PRECAUTIONS COMMON TO OPERATION ON THE EXCAVATOR

- 2.2.5. PRECAUTION FOR MAINTENANCE

- 2.2.6. ADDITIONAL SAFETY INFORMATION FOR TROUBLESHOOTING AND ADJUSTMENTS

- 2.2.7. SPECIAL SAFETY EQUIPMENT

- 2.2.8. SAFETY WARNING SIGNS

- 3. Specification

- 4. Structure Function

- 4.1. Introduction

- 4.1.1. Contents of the binder

- 4.1.2. Foreword

- 4.1.3. Recommendations for environmentally friendly operation and maintenance of hydraulic mining shovels

- 4.1.4. Explanation of abbreviations

- 4.1.5. Diagrams and illustrations in this manual

- 4.2. Specifications

- 4.2.1. Lifting Gears

- 4.2.2. Safety hints for sling accessory

- 4.2.3. Standard Tightening Torque Chart

- 4.2.4. Conversion Table

- 4.2.5. Blind plugs

- 4.2.6. Classification of threads to the nominal width

- 4.2.7. Plugs and fittings according to ISO 84341 / DIN 2353

- 4.2.8. Sensor Limit Values

- 4.3. Main assembly groups

- 4.3.1. General layout

- 4.3.2. Superstructure

- 4.3.3. Machine house

- 4.3.4. Hydraulic oil tank

- 4.3.5. Hydraulic oil cooler

- 4.3.6. Fuel tank

- 4.3.7. Cab support

- 4.3.8. Operators cab

- 4.3.9. Control blocks

- 4.3.10. Swing machinery

- 4.3.11. Undercarriage

- 4.3.12. Attachments

- 4.4. Drive

- 4.4.1. Prime drive assembly

- 4.4.2. Engine mounts

- 4.4.3. Drive shaft

- 4.4.4. Flexible coupling

- 4.4.5. Fan drive and radiator assembly

- 4.4.6. Pump distributor gearbox (PTO)

- 4.4.7. Air filter

- 4.5. Hydraulic oil tank

- 4.5.1. General layout

- 4.5.2. Location of the electric equipment

- 4.5.3. Suction oil tank with strainers

- 4.5.4. Return oil collector pipe with strainer

- 4.5.5. Back pressure valve

- 4.5.6. Transfer pump

- 4.5.7. Return and leak oil filter

- 4.5.8. Breather filter

- 4.6. Hydraulic oil cooling

- 4.6.1. Overall view of the hydraulic oil cooling

- 4.6.2. Function of the hydraulic oil cooling circuit

- 4.6.3. Adjustment of the back pressure valve

- 4.6.4. Fan drive standard oil cooler

- 4.6.5. Adjustment of the cooler fan drive speed

- 4.6.6. Fan drive additional oil cooler

- 4.7. Controlling

- 4.7.1. General layout

- 4.7.2. Control and filter panels location of components

- 4.7.3. Pilot pressure supply and adjustments

- 4.7.4. Function of the electrohydraulic control system

- 4.7.5. Hand lever (joystick) control

- 4.7.6. Foot pedal control

- 4.7.7. Proportional amplifier module, type A

- 4.7.8. Proportional amplifier module, type B

- 4.7.9. Ramp time module

- 4.7.10. Adjustment of amplifier modules

- 4.7.11. Adjusting the ramp time module

- 4.8. Components

- 4.8.1. Main control blocks and high pressure filters (FSA)

- 4.8.2. Distributor manifold location of restrictor blocks and anticavitation valves

- 4.8.3. Restrictor block with secondary relief valve

- 4.8.4. Anticavitation valve (ACV) block

- 4.8.5. Remote control valves

- 4.8.6. Directional solenoid valves

- 4.8.7. Proportional solenoid valves

- 4.8.8. Highpressure filter (screen)

- 4.8.9. CONTROL blocks and valves

- 4.8.10. Travel brake valve

- 4.8.11. Pressure reducing valve

- 4.8.12. Directional valves

- 4.8.13. Pressure double stage valve

- 4.8.14. Hydraulic cylinder

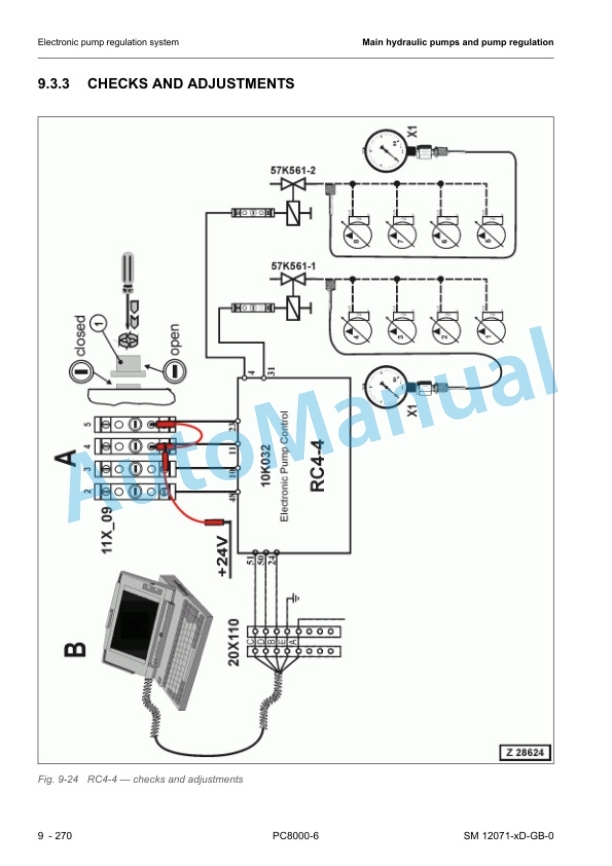

- 4.9. Main hydraulic pumps and pump regulation

- 4.9.1. General

- 4.9.2. Main pumps

- 4.9.3. Electronic pump regulation system

- 4.9.4. Hydraulic constant regulation system

- 4.9.5. Power check (engine performance)

- 4.9.6. Engine speed sensor (pickup)

- 4.9.7. Energy efficiency

- 4.10. Operating hydraulics

- 4.10.1. General

- 4.10.2. Hydraulics for the attachment cylinders FSA

- 4.10.3. Hydraulics for the slew circuit

- 4.10.4. Hydraulics for the travel circuit

- 4.11. Hydraulic track tensioning system

- 4.11.1. General

- 4.11.2. Functional description

- 4.11.3. Doublestage valve

- 4.11.4. Tensioning cylinder

- 4.11.5. Adjustments / checks

- 4.12. Access ladder, hydraulically operated

- 4.12.1. General

- 4.12.2. Function of the hydraulically operated access ladder

- 4.12.3. Adjustments / checks

- 4.13. Central refilling system (service arm)

- 4.13.1. General

- 4.13.2. Function

- 4.14. Hints for reading the hydraulic diagram

- 4.14.1. General

- 4.14.2. Hydraulic symbols

- 4.15. Hints for reading the electric wiring diagram

- 4.15.1. General

- 4.15.2. Reference designation of the electrical components

- 4.15.3. Graphical symbols

- 4.15.4. Drawing concept

- 4.15.5. Cable marking

- 4.15.6. Table of new and old component designations

- 4.16. KOMTRAX Plus

- 4.16.1. General

- 4.16.2. Specifications for Operators

- 4.16.3. Tables of all Provided Messages

- 4.16.4. Flow Charts (14) VHMS Main Screens

- 4.16.5. VHMS Service Level

- 4.16.6. InterfaceConnection VHMSController

- 4.16.7. Wiring of the VHMSController

- 4.16.8. Global Layout of the MTC Control System

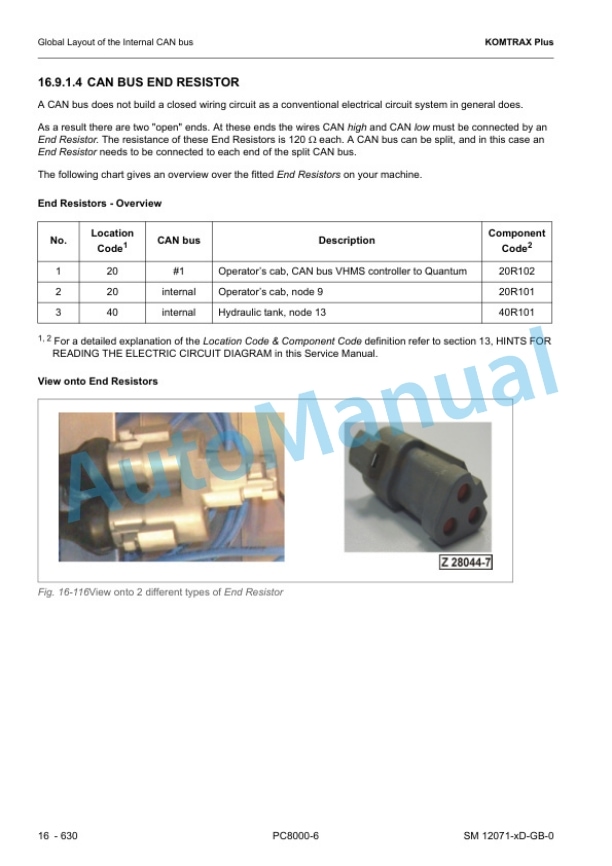

- 4.16.9. Global Layout of the Internal CAN bus

- 4.16.10. The Nodes in the CAN bus System

- 4.17. Lubrication system

- 4.17.1. General overview (SLS CLS 1 / 2)

- 4.17.2. Basic function of the lubrication systems

- 4.17.3. Central lubrication system (CLS 1 2)

- 4.17.4. Slew ring lubrication system (SLS)

- 4.17.5. Lubrication cycle

- 4.17.6. Hydraulically driven lube pump

- 4.17.7. Lubricant injectors

- 4.17.8. Vent valve

- 4.17.9. Endline switch

- 4.17.10. Inline filter

- 4.17.11. Lubricant level sensor

- 4.17.12. Commissioning

- 5. Troubleshooting

- 5.1. Introduction General Information for Troubleshooting

- 5.1.1. Overview

- 5.1.2. General Precautions

- 5.1.3. Preparations For Work

- 5.1.4. Precautions During Work

- 5.1.5. Precautions When Carrying Out Any Operation

- 5.1.6. Fundamental Requirements for Troubleshooting

- 5.1.7. Points To Remember When Trouble shooting

- 5.1.8. Sequence Of Events In Troubleshooting

- 5.1.9. Checks Before Troubleshooting

- 5.1.10. Handling Of Electric Equipment And Hydraulic Components

- 5.1.11. General working procedures

- 5.1.12. Cylinder bypass test

- 5.1.13. Information about MTC Nodes

- 5.1.14. Basics about How to crimp

- 5.1.15. Cable Shielding

- 5.1.16. KOMTRAX Plus vs. VHMS

- 5.1.17. Mounting Locations and Connector Types

- 5.1.18. Standard Value Table for Electrical Components

- 5.1.19. References for Troubleshooting (CAN Bus Node Outputs)

- 5.1.20. Tables for Testing and Troubleshooting

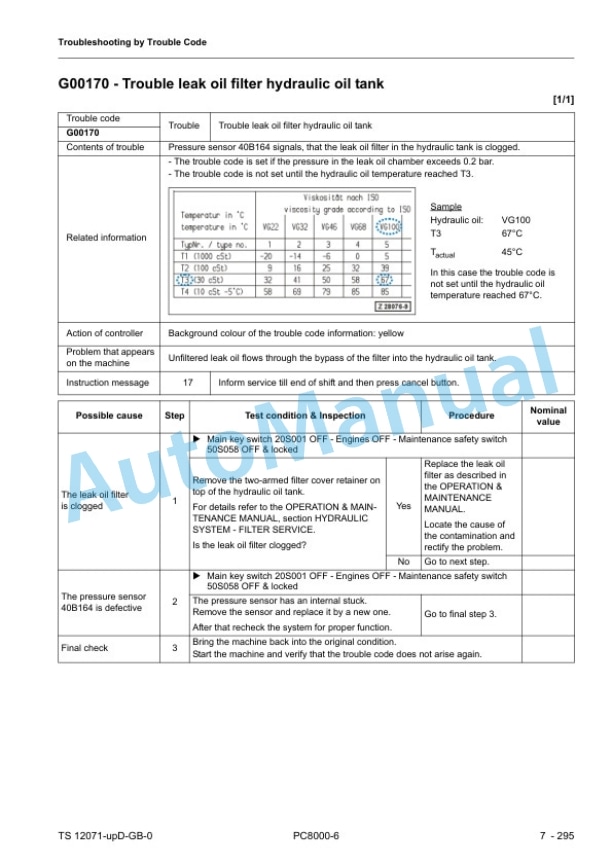

- 5.1.21. Troubleshooting by Trouble Code

- 5.1.22. Troubleshooting by Symptoms

- 6. Assembly Disassembly

- 6.1. Introduction

- 6.1.1. Contents of the binder

- 6.1.2. Foreword

- 6.2. Safety and standards

- 6.2.1. Safety instructions

- 6.2.2. Torque charts according to DIN

- 6.2.3. Blind plugs

- 6.2.4. Conversion table

- 6.2.5. Tools

- 6.2.6. Explanation of Abbreviations

- 6.3. Superstructure

- 6.3.1. Superstructure overview

- 6.3.2. Special preparatory work

- 6.3.3. Diesel engine

- 6.3.4. Radiators (engine coolant)

- 6.3.5. Torsion type coupling

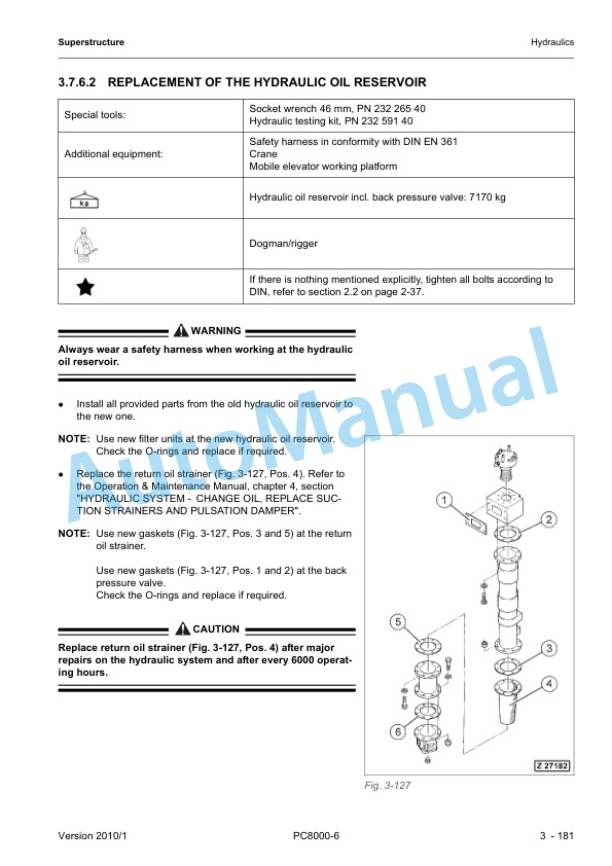

- 6.3.7. Hydraulics

- 6.3.8. Slew system

- 6.3.9. Lubrication system

- 6.3.10. Operators cab

- 6.3.11. Cab base

- 6.3.12. Access ladder

- 6.3.13. Counterweight

- 6.3.14. Superstructure lifting

- 6.3.15. Fuel tank

- 6.4. Undercarriage

- 6.4.1. Travel system

- 6.4.2. Car body

- 6.5. Attachment

- 6.5.1. Face Shovel (FSA)

- 6.5.2. Metering valves (grease injectors) at the attachment

- 6.5.3. Cylinder bypass test

- 6.6. Service information

- 6.6.1. Fluids and lubricants

- 6.6.2. Filling capacities

- 6.6.3. Work Instructions

- 6.6.4. Used special tools (overview)

- 6.7. Tools catalogue

- 6.8. Parts Service News

Rate this product

You may also like

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF