- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu PC88MR-8 Hydraulic Excavator Shop Manual CEBM007301

$40.00

- Type Of Manual: Shop Manual

- Manual ID: CEBM007301

- Format: PDF

- Size: 88.4MB

- Number of Pages: 1001

Category: Komatsu Shop Manual PDF

-

Model List:

- PC88MR-8 Hydraulic Excavator

- 1. CEBM007301 PC88MR8 sn A90001up

- 1.1. CONTENTS

- 1.2. REVISED PAGES

- 1.3. SAFETY

- 1.4. GENERAL

- 1.5. HOW TO READ THE SHOP MANUAL

- 1.6. HOISTING INSTRUCTIONS

- 1.7. PUSH PULL COUPLER

- 1.8. EXPLANATION OF MAINTENANCE STANDARD TERMS

- 1.9. STANDARD TIGHTENING TORQUE

- 1.10. ELECTRIC WIRE CODE

- 1.11. CONVERSION TABLES

- 1.12. COATING MATERIALS

- 2. GENERAL

- 2.1. SPECIFICATIONS DIMENSION DRAWING

- 2.2. TABLE FOR FUEL, COOLANT AND LUBRICANTS

- 3. STRUCTURE, FUNCTION AND MAINTENANCE STANDARD

- 3.1. ENGINE AND COOLING SYSTEM

- 3.2. POWER TRAIN

- 3.3. UNDERCARRIAGE AND FRAME

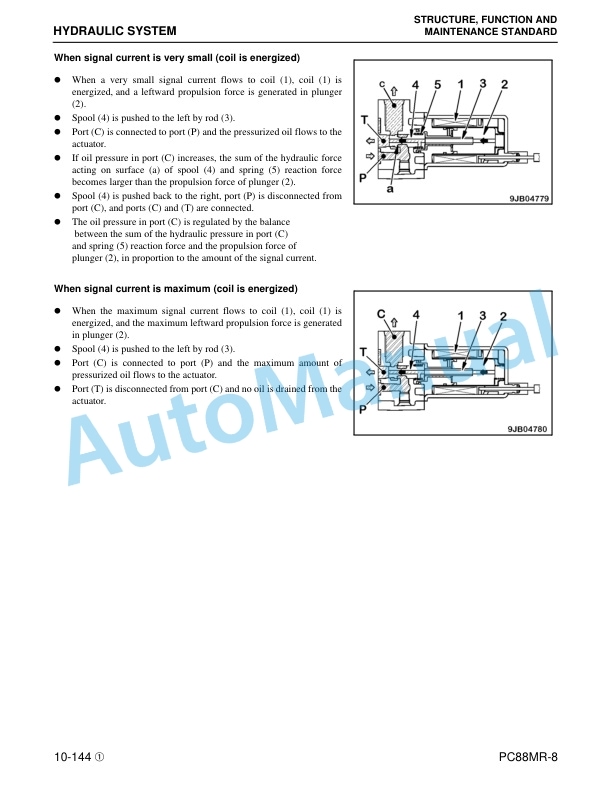

- 3.4. HYDRAULIC SYSTEM

- 3.5. WORK EQUIPMENT

- 3.6. AIR CONDITIONER

- 3.7. ELECTRICAL SYSTEM

- 4. STANDARD VALUE TABLES

- 4.1. STANDARD VALUE TABLE FOR ENGINE RELATED PARTS

- 4.2. STANDARD VALUE TABLE FOR CHASSIS

- 5. TESTING AND ADJUSTING

- 5.1. TOOLS FOR TESTING, ADJUSTING, AND TROUBLESHOOTING

- 5.2. ENGINE SPEED

- 5.3. EXHAUST TEMPERATURE

- 5.4. EXHAUST GAS COLOR

- 5.5. VALVE CLEARANCE

- 5.6. COMPRESSION PRESSURE

- 5.7. BLOWBY PRESSURE

- 5.8. ENGINE OIL PRESSURE

- 5.9. HANDLING FUEL SYSTEM PARTS

- 5.10. ALTERNATOR BELT TENSION

- 5.11. AIR CONDITIONER COMPRESSOR BELT TENSION

- 5.12. SWING CIRCLE BEARING CLEARANCE

- 5.13. TRACK SHOE TENSION

- 5.14. OIL PRESSURE IN WORK EQUIPMENT AND TRAVEL CIRCUITS

- 5.15. SWING AND BLADE CIRCUIT OIL PRESSURE

- 5.16. CONTROL CIRCUIT BASIC PRESSURE

- 5.17. OIL PRESSURE IN PUMP PC CONTROL CIRCUIT

- 5.18. PCEPC SOLENOID OUTPUT PRESSURE

- 5.19. LS DIFFERENTIAL PRESSURE AND LS VALVE

- 5.20. SOLENOID VALVE OUTPUT PRESSURE

- 5.21. PPC VALVE OUTPUT PRESSURE

- 5.22. PLAY OF WORK EQUIPMENT AND SWING PPC VALVES

- 5.23. PARTS WHICH CAUSE HYDRAULIC DRIFT OF WORK EQUIPMENT

- 5.24. TRAVEL DEVIATION

- 5.25. RELEASING RESIDUAL PRESSURE FROM HYDRAULIC CIRCUIT

- 5.26. OIL LEAKAGE

- 5.27. MIRRORS

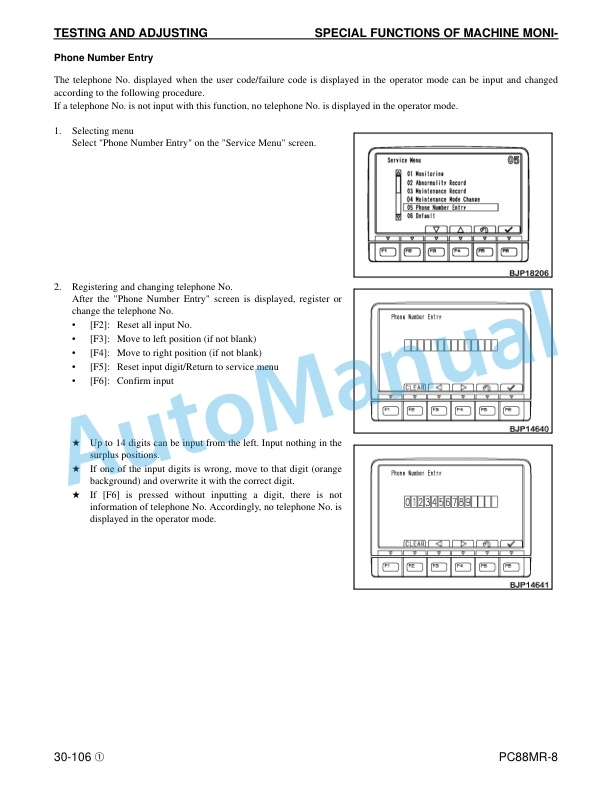

- 5.28. SPECIAL FUNCTIONS OF MACHINE MONITOR

- 5.29. HANDLING VOLTAGE CIRCUIT OF ENGINE CONTROLLER

- 5.30. PREPARATION WORK FOR TROUBLESHOOTING OF ELECTRICAL SYSTEM

- 5.31. PROCEDURE FOR TESTING DIODES

- 5.32. PM CLINIC SERVICE

- 6. TROUBLESHOOTING

- 6.1. GENERAL INFORMATION ON TROUBLESHOOTING

- 6.2. CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

- 6.3. TADAPTER TABLE

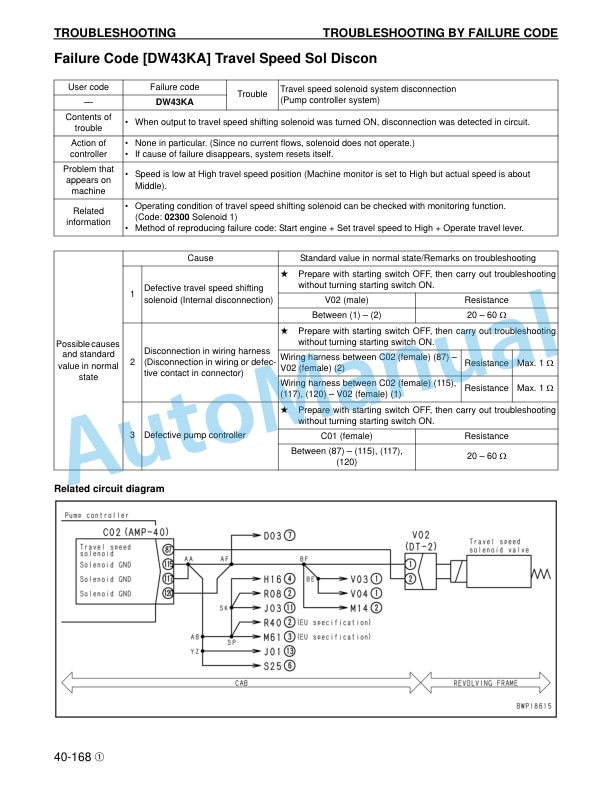

- 6.4. FAILURE CODE TABLE

- 6.5. FUSE LOCATIONS

- 6.6. TROUBLESHOOTING BY FAILURE CODE

- 6.7. TROUBLESHOOTING OF ELECTRICAL SYSTEM (EMODE)

- 6.8. TROUBLESHOOTING OF HYDRAULIC AND MECHANICAL SYSTEM (HMODE)

- 7. DISASSEMBLY AND ASSEMBLY

- 7.1. HOW TO READ THIS MANUAL

- 7.2. COATING MATERIALS LIST

- 7.3. SPECIAL TOOLS LIST

- 7.4. SKETCHES OF SPECIAL TOOLS

- 7.5. CONNECTOR REPAIR PROCEDURES

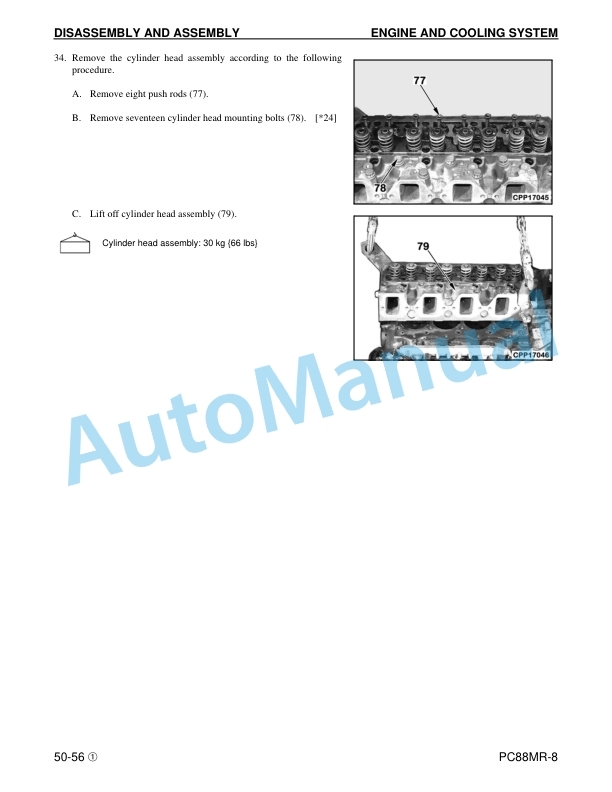

- 7.6. ENGINE AND COOLING SYSTEM

- 7.7. POWER TRAIN

- 7.8. UNDERCARRIAGE AND FRAME

- 7.9. HYDRAULIC SYSTEM

- 7.10. WORK EQUIPMENT

- 7.11. CAB AND ITS ATTACHMENTS

- 7.12. ELECTRICAL SYSTEM

- 8. DIAGRAMS AND SCHEMATICS

- 8.1. HYDRAULIC SYSTEM

- 8.2. ELECTRICAL SYSTEM

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF