- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

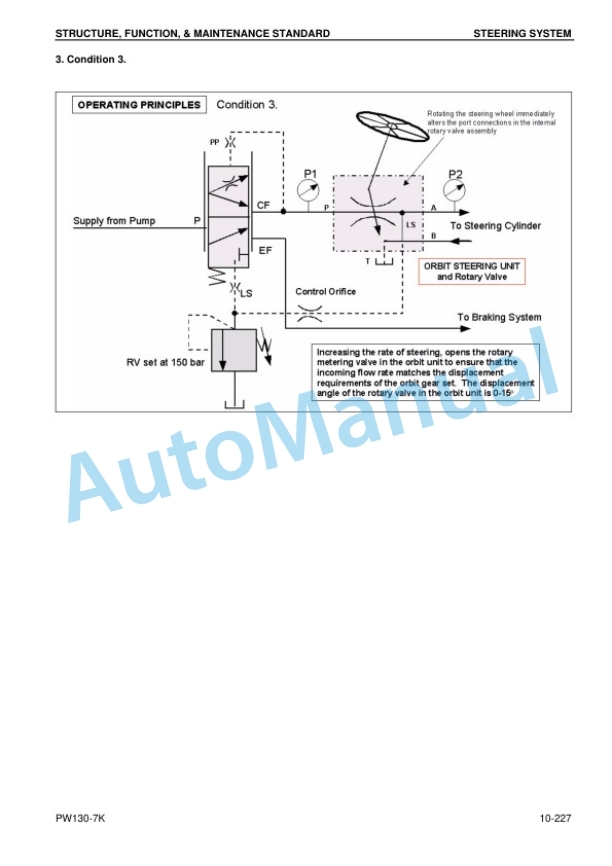

Komatsu PW130-7K Wheeled Excavator Shop Manual UEBM002800

$40.00

- Type Of Manual: Shop Manual

- Manual ID: UEBM002800

- Format: PDF

- Size: 33.4MB

- Number of Pages: 435

Category: Komatsu Shop Manual PDF

-

Model List:

- PW130-7K Wheeled Excavator

- 1. Sec 00.pdf

- 1.1. SAFETY

- 1.1.1. SAFETY NOTICE

- 1.1.1.1. IMPORTANT SAFETY NOTICE

- 1.1.1.2. GENERAL PRECAUTIONS

- 1.1.1.3. PRECAUTIONS DURING WORK

- 1.2. GENERAL

- 1.3. HOW TO READ THE SHOP MANUAL

- 1.3.1. VOLUMES

- 1.3.2. DISTRIBUTION AND UPDATING

- 1.3.3. FILING METHOD

- 1.3.4. REVISED EDITION MARK

- 1.3.5. REVISIONS

- 1.3.6. SYMBOLS

- 1.4. HOISTING INSTRUCTIONS

- 1.4.1. HOISTING

- 1.4.2. WIRE ROPES

- 1.5. PUSHPULL TYPE COUPLERS

- 1.6. COATING MATERIALS

- 1.7. STANDARD TIGHTENING TORQUE

- 1.7.1. STANDARD TIGHTENING TORQUE OF BOLTS AND NUTS

- 1.7.2. TIGHTENING TORQUE OF HOSE NUTS

- 1.7.3. TIGHTENING TORQUE OF SPLIT FLANGE BOLTS

- 1.7.4. TIGHTENING TORQUE FOR FLARED NUTS

- 1.7.5. Tightening torque for 102 engine series (bolts and nuts)

- 1.7.6. Tightening torque for 102 engine series (eye joints)

- 1.7.7. Tightening torque for 102 engine series (tapered screws)

- 1.8. ELECTRIC WIRE CODE

- 1.8.1. CLASSIFICATION BY THICKNESS

- 1.8.2. CLASSIFICATION BY COLOR AND CODE

- 1.9. CONVERSION TABLES

- 1.9.1. METHOD OF USING THE CONVERSION TABLE

- 1.10. SPECIFICATION DIMENSION DRAWINGS

- 1.11. FUEL, COOLANT AND LUBRICANTS

- 2.1. ENGINE RELATED PARTS

- 2.2. PTO (COUPLING)

- 2.3. RADIATOR . OIL COOLER . CHARGE AIR COOLER

- 2.4. POWER TRAIN

- 2.5. SWING CIRCLE

- 2.6. SWING MACHINERY MOTOR

- 2.7. UNDERCARRIAGE

- 2.8. TRANSMISSION

- 2.9. TRAVEL MOTOR

- 2.9.1. OPERATION OF TRAVEL MOTOR

- 2.10. CLUTCH CONTROL CIRCUIT

- 2.11. AXLE

- 2.12. SUSPENSION LOCK CYLINDER

- 2.13. BRAKING SYSTEM

- 2.14. BRAKE/STEER PUMP

- 2.15. PRIORITY VALVE

- 2.16. POWER BRAKE VALVE

- 2.17. ACCUMULATOR FOR BRAKE SYSTEM

- 2.18. STEERING TRAIN

- 2.19. STEERING COLUMN

- 2.20. ORBITROL VALVE

- 2.21. HYDRAULIC EQUIPMENT LAYOUT DRAWINGS

- 2.22. HYDRAULIC CIRCUIT DIAGRAM

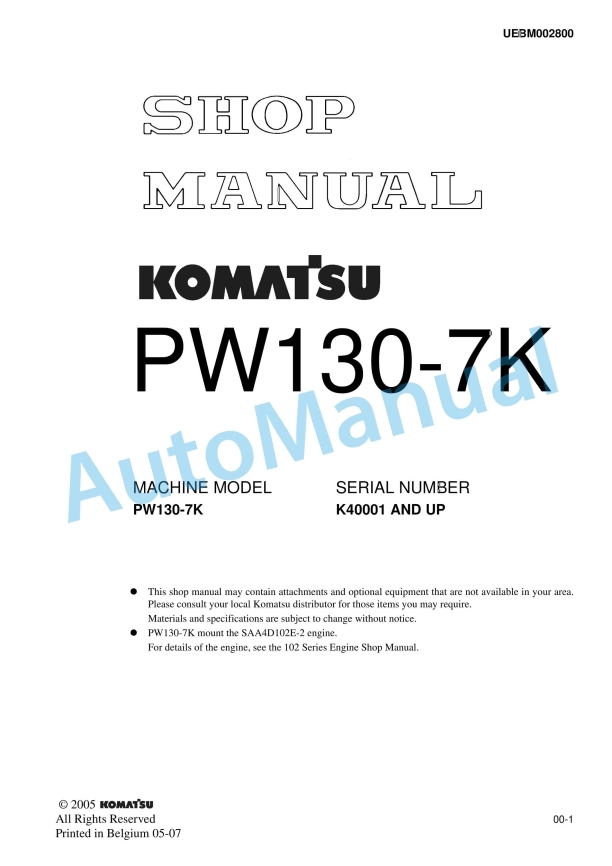

- 2.22.1. FIXED THROTTLE VALVE

- 2.23. PILOT PRESSURE CONTROL (PPC) SYSTEM

- 2.24. CONTROL VALVE

- 2.25. CLSS

- 2.26. SWING MOTOR

- 2.27. CENTRE SWIVEL JOINT

- 2.28. TRAVEL PPC PEDAL

- 2.29. WORK EQUIPMENT . SWING PPC VALVE

- 2.30. SERVICE PPC VALVE

- 2.31. SOLENOID VALVE MANIFOLD

- 2.31.1. Solenoid valve (2, 4 6stage solenoid)

- 2.31.2. ATTACHMENT EPC VALVE

- 2.32. BOOM SAFETY VALVE

- 2.33. HYDRAULIC CYLINDER

- 2.33.1. BOOM CYLINDER

- 2.33.2. ARM CYLINDER

- 2.33.3. BUCKET CYLINDER

- 2.33.4. ADJUST CYLINDER

- 2.34. OUTRIGGER CYLINDER

- 2.35. DOZER CYLINDER

- 2.36. WORK EQUIPMENT

- 2.37. AIR CONDITIONER

- 2.37.1. Air Conditioner Piping

- 2.38. ELECTRICAL WIRING DIAGRAM

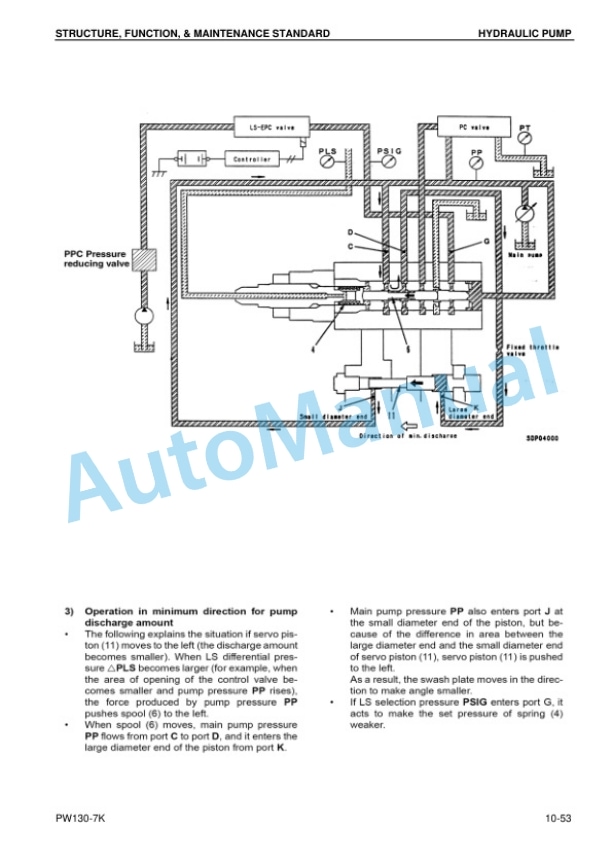

- 2.39. ENGINE CONTROL SYSTEM

- 2.39.1. Governor motor

- 2.39.2. Engine throttle and pump controller

- 2.40. ELECTRONIC CONTROL SYSTEM

- 2.40.1. MACHINE CONTROL SYSTEM DIAGRAM

- 2.41. MACHINE MONITOR SYSTEM

- 2.41.1. MONITOR PANEL

- 2.41.2. LIQUID CRYSTAL MONITOR ADJUSTMENT SWITCH

- 2.42. OVERLOAD WARNING DEVICE

- 2.42.1. OUTLINE

- 2.43. SENSOR

- 2.44. BREAKER MODE HYDRAULIC PERFORMANCE (MAIN VALVE BYPASSED)

- 2.45. BREAKER MODE HYDRAULIC PERFORMANCE (VIA MAIN VALVE)

- 2.46. TRAVEL SYSTEM

- 2.46.1. TRAVEL CIRCUIT

- 2.46.2. OPERATIONAL AND CONTROL FEATURES

- 2.46.2.1. Operators Input via travel mode switch

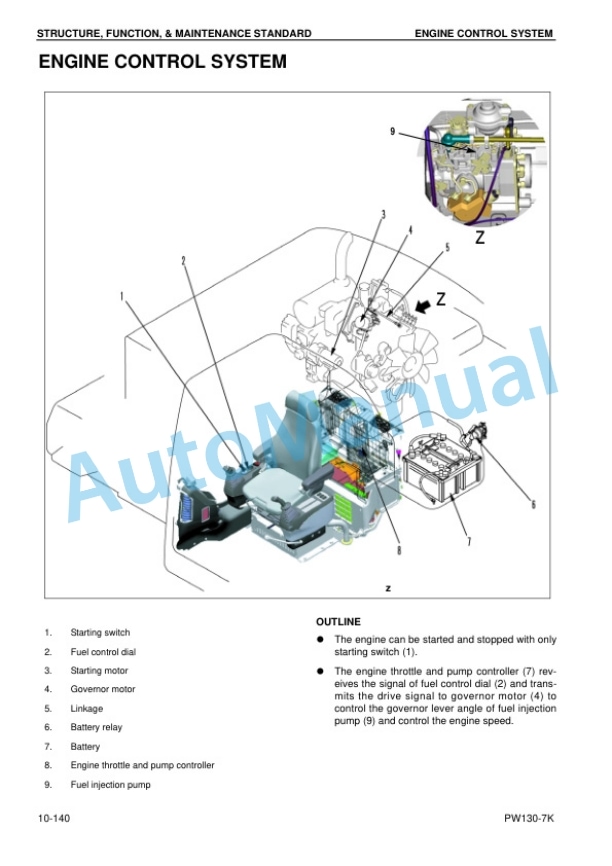

- 2.47. STEERING SYSTEM

- 2.47.1. Operating principles

- 2.47.2. Dynamic Steering

- 2.47.3. stage principle

- 2.48. SERVICE BRAKE AND SUSPENSION SYSTEM

- 2.48.1. BRAKING SYSTEM

- 2.48.2. OPERATION

- 3. _001.pdf

- 3.1. STANDARD VALUE TABLE FOR ENGINE RELATED PARTS

- 3.2. STANDARD VALUE TABLE FOR CHASSIS RELATED PARTS

- 3.2.1. Flow control characteristic of PCEPC valve (STD)

- 4. _101.pdf

- 4.1. INSPECTION AND ADJUSTMENT OF AIR COMPRESSOR BELT TENSION

- 4.2. ADJUSTMENT OF ENGINE SPEED SENSOR

- 4.3. TESTING AND ADJUSTING GOVERNOR MOTOR LEVER STROKE

- 4.4. MEASUREMENT OF CLEARANCE IN SWING CIRCLE BEARINGS

- 4.5. TESTING AND ADJUSTING HYDRAULIC PRESSURE IN WORK EQUIPMENT, SWING AND TRAVEL CIRCUIT

- 4.6. TESTING AND ADJUSTING PC VALVE OUTPUT PRESSURE (SERVO PISTON INPUT PRESSURE)

- 4.7. TESTING AND ADJUSTING LS VALVE OUTPUT PRESSURE (SERVO PISTON INPUT PRESSURE) AND LS DIFFERENTIAL PRESSURE

- 4.8. INSPECTION AND ADJUSTMENT OF CONTROL CIRCUIT OIL PRESSURE

- 4.9. MEASUREMENT OF SOLENOID VALVE OUTPUT PRESSURE

- 4.9.1. Stage solenoid block

- 4.9.2. Stage solenoid block

- 4.9.3. Stage solenoid block

- 4.10. TESTING TRAVEL MOTOR RELIEF PRESSURE

- 4.11. ADJUSTING TRAVEL MOTOR RELIEF PRESSURE

- 4.12. TESTING LOCATIONS CAUSING HYDRAULIC DRIFT OF WORK EQUIPMENT

- 4.13. MEASURING OIL LEAKAGE

- 4.14. RELEASE OF REMAINING PRESSURE IN HYDRAULIC CIRCUIT

- 4.15. BLEEDING AIR

- 4.15.1. ORDER FOR OPERATIONS AND PROCEDURE FOR BLEEDING AIR

- 4.16. INSPECTION PROCEDURES FOR DIODE

- 4.17. MEASURING ROTATING SPEED OF PROPSHAFT

- 4.18. TESTING TRANSMISSION CLUTCH CONTROL CIRCUIT

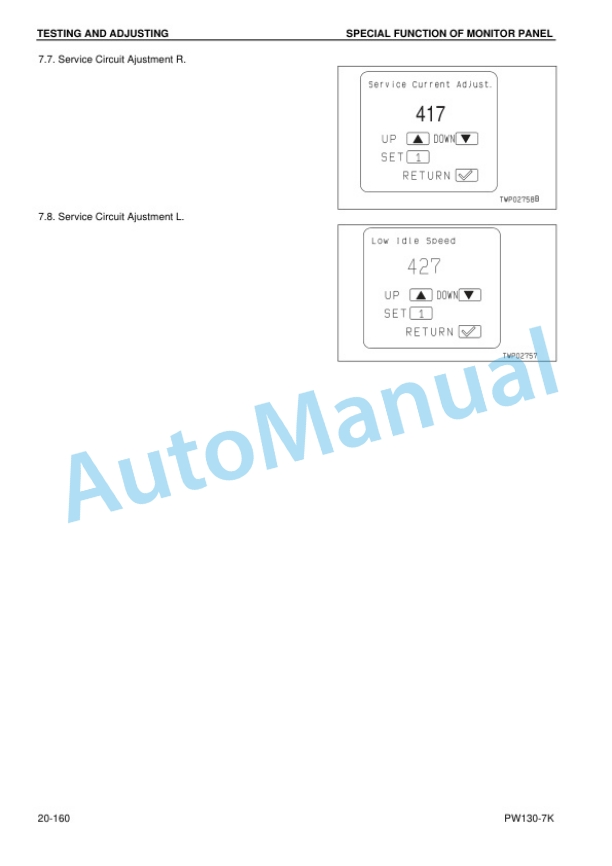

- 4.19. SPECIAL FUNCTION OF MONITOR PANEL

- 4.19.1. OPERATION OF OPERATORS MENU AND DISPLAY (OUTLINE)

- 4.19.2. TABLE FOR SERVICE AND FAILURE CODE NO.

- 4.19.3. OPERATION AND DISPLAY OF SERVICE MENU

- 4.19.3.1. Way of switching to Service Menu

- 4.19.3.2. Table for Monitoring Items

- 4.20. PREPARATIONS FOR TROUBLESHOOTING ELECTRICAL SYSTEM

- 5. _201.pdf

- 5.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 5.2. SEQUENCE OF EVENTS IN TROUBLESHOOTING

- 5.3. POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE

- 5.4. CHECKS BEFORE TROUBLESHOOTING

- 5.5. CLASSIFICATION AND STEPS FOR TROUBLESHOOTING

- 5.5.1. Classification of troubleshooting

- 5.5.1.1. Steps for troubleshooting

- 5.5.2. Failurelooking Phenomenon and Troubleshooting No.

- 5.6. CONNECTOR LOCATION CHART AND ELECTRICAL CIRCUIT DIAGRAM BY SYSTEM

- 5.6.1. CONNECTOR LOCATION

- 5.7. CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

- 6. UEBM002800_A2.pdf

- 6.1. HYDRAULIC CIRCUIT DIAGRAM (1/3)

- 6.2. HYDRAULIC CIRCUIT DIAGRAM (2/3)

- 6.3. HYDRAULIC CIRCUIT DIAGRAM (3/3)

- 6.4. ELECTRICAL CIRCUIT DIAGRAM (1/5)

- 6.4.1. FOR MULTI MONITOR

- 6.5. ELECTRICAL CIRCUIT DIAGRAM (2/5)

- 6.5.1. FOR MULTI MONITOR

- 6.6. ELECTRICAL CIRCUIT DIAGRAM (3/5)

- 6.6.1. FOR MULTI MONITOR

- 6.7. ELECTRICAL CIRCUIT DIAGRAM (4/5)

- 6.7.1. FOR MULTI MONITOR

- 6.8. ELECTRICAL CIRCUIT DIAGRAM (5/5)

- 6.8.1. FOR MULTI MONITOR

Rate this product

You may also like

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF