- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu PW148-11 Wheeled Excavator Shop Manual VENBM68001

$40.00

- Type Of Manual: Shop Manual

- Manual ID: VENBM68001

- Format: PDF

- Size: 141.5MB

- Number of Pages: 1896

Category: Komatsu Shop Manual PDF

-

Model List:

- PW148-11 Wheeled Excavator

- 1. VENBM68001 PW14811

- 2. CONTENTS

- 3. FOREWORD

- 3.1. Safety

- 3.2. General

- 3.3. How to read the shop manual

- 3.4. Hoisting instructions

- 3.5. Coating materials

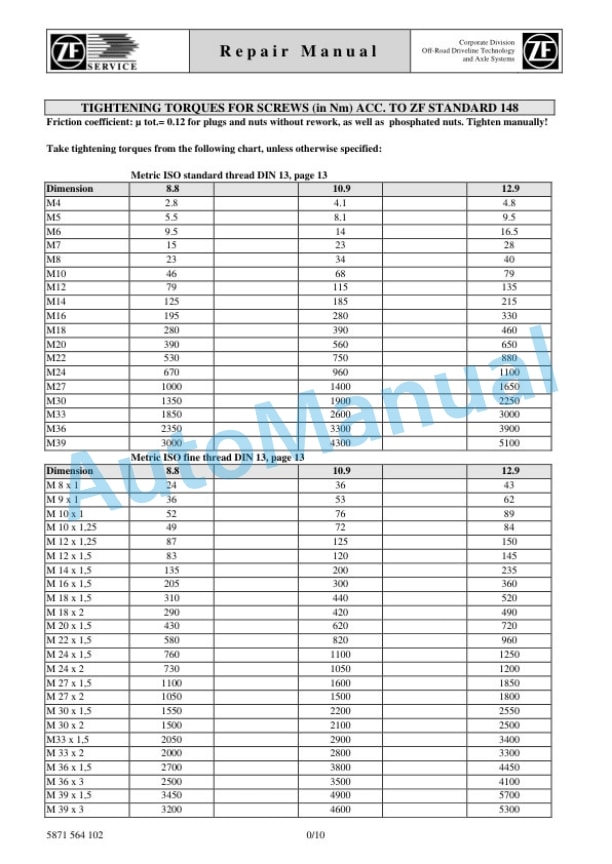

- 3.6. Standard tightening torque

- 3.7. Electric wire code

- 3.8. Conversion tables

- 3.9. Units

- 4. GENERAL

- 4.1. Specification dimension drawings

- 4.2. Working ranges

- 4.3. Weight table

- 4.4. Fuel, coolant and lubricants

- 5. STRUCTURE AND FUNCTION

- 5.1. Abbreviation list

- 5.2. UREA SCR system

- 5.3. BOOTUP system

- 5.4. Engine system

- 5.5. Cooling system

- 5.6. Power train

- 5.7. Swing machinery motor

- 5.8. d Auxiliary circuit in the undercarriage

- 5.9. Hydraulic quick coupler

- 5.10. Full hydraulic quick coupler

- 5.11. Travel motor

- 5.12. Clutch control circuit

- 5.13. Axle

- 5.14. Suspension lock cylinder

- 5.15. Braking system

- 5.16. Power brake valve

- 5.17. Accumulator for brake valve

- 5.18. Steering system

- 5.19. Joystick steering system

- 5.20. Steering column STD

- 5.21. Steering column JSS

- 5.22. Orbitrol valve STD

- 5.23. Orbitrol valve JSS

- 5.24. Hydraulic equipment layout drawings

- 5.25. Hydraulic circuit diagram

- 5.26. Pilot pressure control (PPC) system

- 5.27. Control main valve

- 5.28. CLSS

- 5.29. Centre swivel joint

- 5.30. Travel PPC pedal

- 5.31. Work equipment Swing PPC valve

- 5.32. Solenoid valve block with integrated ATT EPC

- 5.33. Bucket to 2ATT

- 5.34. Boom safety valve

- 5.35. Boom floating

- 5.36. Hydraulic cylinder

- 5.37. Work equipment

- 5.38. Tool control

- 5.39. ECSS

- 5.40. Breaker return valve

- 5.41. Air conditioner

- 5.42. Electrical wiring diagram

- 5.43. Electrical system

- 5.44. Engine controller

- 5.45. Machine control system diagram

- 5.46. Machine monitor system

- 5.47. KOMTRAX system

- 5.48. KomVision system

- 5.49. KomVision controller

- 5.50. Overload warning device

- 5.51. Sensor

- 5.52. PPC levers

- 5.53. t attachment circuit hydraulic performance (main valve bypassed)

- 5.54. Travel system

- 5.55. Lubrication diagrams

- 6. STANDARD VALUE TABLE

- 6.1. Engine and cooling system

- 6.2. Replacing the fan belt

- 6.3. Measurement of clearance in swing circle bearing

- 6.4. Inspection and adjustment of hydraulic oil pressure in hydraulic circuit for work equipment, swing and travel

- 6.5. Inspection and adjustment of control circuit oil pressure

- 6.6. Inspection and adjustment of pump PC (valve inlet) control oil pressure

- 6.7. Inspection and adjustment of pump LS differential pressure

- 6.8. Measurement of solenoid valve output pressure

- 6.9. Adjustment of work equipment and swing PPC valve

- 6.10. Measuring and adjusting quick coupler control valve output pressure

- 6.11. Testing travel motor relief pressure

- 6.12. Testing propshaft speed

- 6.13. Testing transmission clutch control circuit

- 6.14. Inspection of locations of hydraulic drift of work equipment

- 6.15. Release of remaining pressure in hydraulic circuit

- 6.16. Measurement of oil leakage

- 6.17. Air bleeding of various parts

- 6.18. Inspection procedures for diode

- 6.19. Electrical system

- 6.20. Inspection and adjustment of ECSS (ACCU pressure)

- 6.21. Inspection and adjustment of Tool control

- 6.22. Changing the lubrication interval times

- 6.23. Adjust rearview camera angle

- 6.24. Adjust KomVision camera angle

- 6.25. Method for adjusting KomVision camera angle

- 6.26. Adjust KomVision related items

- 7. TESTING AND ADJUSTING

- 8. TROUBLESHOOTING

- 8.1. Abbreviation list

- 8.2. Related information on troubleshooting

- 8.3. TBranch box and TBranch adapter table

- 8.4. Fuse location table

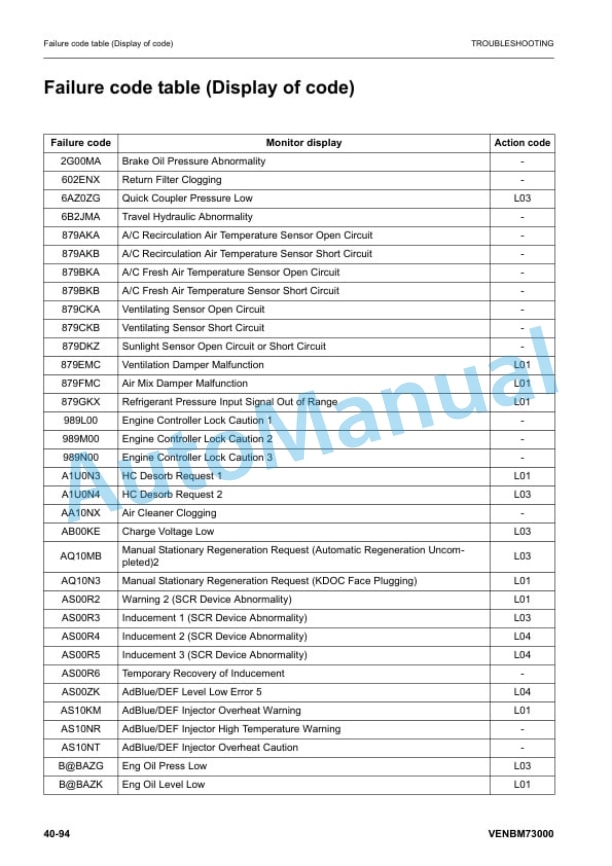

- 8.5. Failure code table (Display of code)

- 8.6. Contents

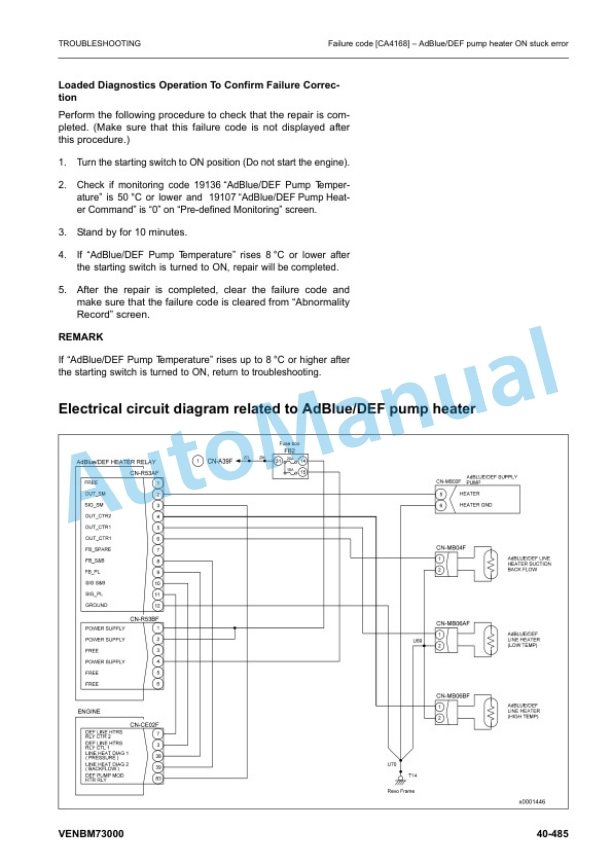

- 8.7. Troubleshooting by failure code (Display of code)

- 8.8. Troubleshooting of central lubrication system (CLS)

- 8.9. Troubleshooting of engine (Smode)

- 9. MAINTENANCE STANDARD

- 9.1. Abbreviation list

- 9.2. Engine and cooling system

- 9.3. Power train

- 9.4. Hydraulic system

- 9.5. Work equipment

- 9.6. Hydraulic cylinder

- 10. DISASSEMBLY AND ASSEMBLY (preliminary version)

- 10.1. FRONT AXLE

- 10.2. REAR AXLE

- 10.3. TRANSMISSION

- 11. OTHER

- 11.1. Hydraulic circuit diagram

- 11.2. Wiring circuit diagram

- 11.3. Connector diagram

Rate this product

You may also like

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF