- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu PW160-7H Wheel Excavator Shop Manual VEBM390100

$40.00

- Type Of Manual: Shop Manual

- Manual ID: VEBM390100

- Format: PDF

- Size: 40.3MB

- Number of Pages: 956

Category: Komatsu Shop Manual PDF

-

Model List:

- PW160-7H Wheel Excavator

- 1. VEBM390100 SHOP MANUAL

- 1.1. TITLE

- 1.2. GENERAL

- 1.3. SAFETY

- 1.3.1. SAFETY NOTICE

- 1.4. SECTION 10

- 1.4.1. H50051 AND UP

- 1.4.2. HOW TO READ THE SHOP MANUAL

- 1.4.3. HOISTING INSTRUCTIONS

- 1.4.4. PUSHPULL TYPE COUPLERS

- 1.4.5. COATING MATERIALS

- 1.4.6. STANDARD TIGHTENING TORQUE

- 1.4.7. ELECTRIC WIRE CODE

- 1.4.8. CONVERSION TABLES

- 1.4.9. UNITS

- 1.4.10. WORKING RANGES

- 1.4.11. SPECIFICATION DIMENSION DRAWINGS

- 1.4.12. FUEL, COOLANT AND LUBRICANTS

- 1.4.13. ENGINE RELATED PARTS

- 1.4.14. RADIATOR . OIL COOLER . charge air cooler

- 1.4.15. POWER TRAIN

- 1.4.16. SWING CIRCLE

- 1.4.17. SWING MACHINERY motor

- 1.4.18. SWING MOTOR

- 1.4.19. UNDERCARRIAGE

- 1.4.20. TRANSMISSION

- 1.4.21. TRAVEL MOTOR

- 1.4.22. CLUTCH CONTROL CIRCUIT

- 1.4.23. AXLE

- 1.4.24. sUSPENSION LOCK CYLINDER

- 1.4.25. Braking System

- 1.4.26. brake/steer pump

- 1.4.27. PRIORITY VALVE

- 1.4.28. POWER BRAKE VALVE

- 1.4.29. ACCUMULATOR for brake system

- 1.4.30. STEERING SYSTEM

- 1.4.31. STEERING COLUMN

- 1.4.32. ORBITROL VALVE

- 1.4.33. hydraulic equipment layout drawingS

- 1.4.34. hydraulic CIRCUIT dIAgRAM

- 1.4.35. PILOT PRESSURE CONTROL (PPC) SYSTEM

- 1.4.36. CONTROL VALVE

- 1.4.37. CLSS

- 1.4.38. Unload valve

- 1.4.39. Introduction of LS pressure

- 1.4.40. LS Bypass plug

- 1.4.41. Pressure compensation valve

- 1.4.42. Area ratio of pressure compensation valve

- 1.4.43. Boom regeneration circuit

- 1.4.44. Arm regeneration circuit

- 1.4.45. Swing bleeding valve

- 1.4.46. Variable type pressure compensation valve (for service)

- 1.4.47. LS select valve

- 1.5. SECTION 20

- 1.5.1. INSPECTION AND ADJUSTMENT OF ENGINE RPM

- 1.5.2. MEASUREMENT OF EXHAUST GAS COLOUR

- 1.5.3. ADJUSTMENT OF VALVE CLEARANCE

- 1.5.4. MEASUREMENT OF COMPRESSION PRESSURE

- 1.5.5. MEASUREMENT OF BLOWBY PRESSURE

- 1.5.6. INSPECTION AND ADJUSTMENT OF FUEL INJECTION TIMING

- 1.5.7. MEASUREMENT OF ENGINE OIL PRESSURE

- 1.5.8. EMERGENcy sEtting iF FAILURE occurs IN ENGINE CONTROL SYSTEM

- 1.5.9. MEASUREMENT OF CLEARANCE IN SWING CIRCLE BEARINGS

- 1.5.10. INSPECTION AND ADJUSTMENT OF HYDRAULIC OIL PRESSURE IN HYDRAULIC CIRCUIT FOR WORK EQUIPMENT, SWING AND TRAVEL

- 1.5.11. INSPECTION AND ADJUSTMENT OF CONTROL CIRCUIT OIL PRESSURE

- 1.5.12. INSPECTION AND ADJUSTMENT OF PUMP PC (Valve INLET) CONTROL OIL PRESSURE

- 1.5.13. INSPECTION AND ADJUSTMENT OF PUMP LS valve CONTROL OIL PRESSURE

- 1.5.14. MEASUREMENT OF SOLENOID VALVE OUTPUT PRESSURE

- 1.5.15. MEASUREMENT OF PPC VALVE OUTPUT PRESSURE

- 1.5.16. ADJUSTMENT OF WORK EQUIPMENT AND SWING PPC VALVE

- 1.5.17. testing travel motor relief pressure

- 1.5.18. adjusting travel motor relief pressure

- 1.5.19. Testing propshaft speed

- 1.5.20. tESTING TRANSMISSION CLUTCH CONTROL CIRCUIT

- 1.5.21. INSPECTION OF LOCATIONS OF HYDRAULIC DRIFT OF WORK EQUIPMENT

- 1.5.22. MEASUREMENT OF OIL LEAKAGE AMOUNT

- 1.5.23. AIR BLEEDING OF VARIOUS PARTS

- 1.5.24. INSPECTION PROCEDURES FOR DIODE

- 1.5.25. SPECIAL FUNCTION OF MONITOR PANEL

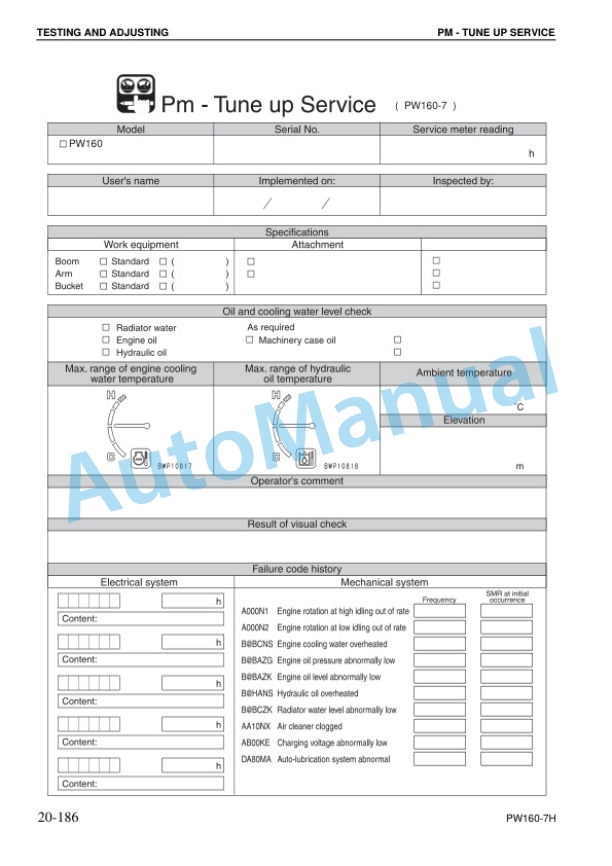

- 1.5.26. PM Tune up service

- 1.5.27. PREPARATIONS FOR TROUBLESHOOTING ELECTRICAL SYSTEM

- 1.5.28. TROUBLESHOOTING

- 1.5.29. TROUBLESHOOTING OF ELECTRICAL SYSTEM (EMODE)

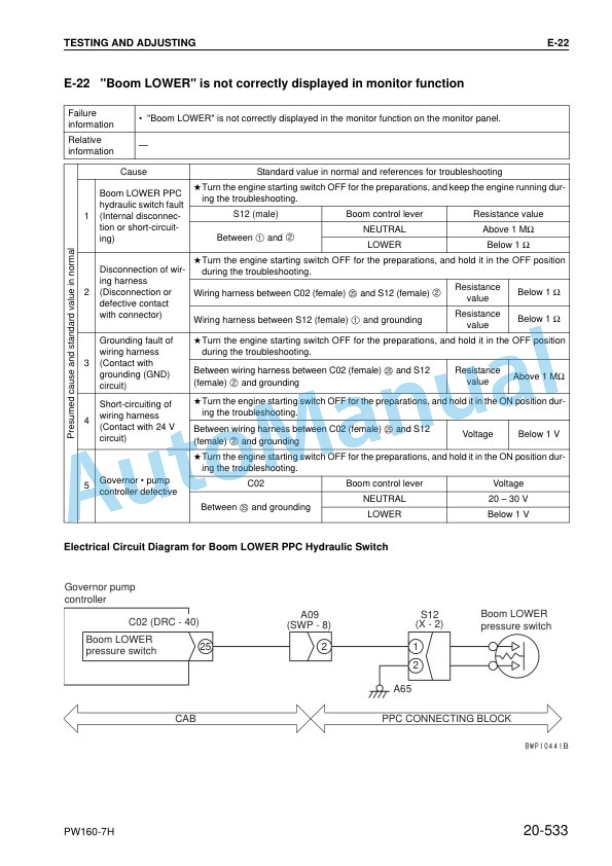

- 1.5.30. TROUBLESHOOTING OF ELECTRICAL SYSTEM

- 1.5.31. (Error checking of items without Monitor codes)

- 1.5.32. TROUBLESHOOTING OF HYDRAULIC AND MECHANICAL SYSTEM (HMODE)

- 1.6. SECTION 30

- 1.6.1. HOW TO READ THIS MANUAL

- 1.6.2. SPECIAL TOOLS

- 1.6.3. PRECAUTIONS WHEN PERFORMING OPERATION

- 1.6.4. GOVERNOR MOTOR ASSEMBLY

- 1.6.5. REMOVAL AND INSTALLATION OF Assembly

- 1.6.6. STARTING MOTOR ASSEMBLY

- 1.6.7. REMOVAL AND INSTALLATION OF Assembly

- 1.6.8. FUEL INJECTION PUMP ASSEMBLY

- 1.6.9. ENGINE FRONT SEAL

- 1.6.10. ENGINE REAR SEAL

- 1.6.11. CYLINDER HEAD ASSEMBLY

- 1.6.12. COMBINATION COOLER

- 1.6.13. ENGINE AND HYDRAULIC PUMP ASSEMBLIES

- 1.6.14. TRAVEL MOTOR ASSEMBLY

- 1.6.15. TRAVEL MOTOR ASSEMBLY

- 1.6.16. REMOVAL AND INSTALLATION OF

- 1.6.17. SWING MOTOR AND SWING MACHINERY ASSEMBLY

- 1.6.18. SWING MACHINERY ASSEMBLY

- 1.6.19. SWING MOTOR ASSEMBLY

- 1.6.20. FRONT AXLE ASSEMBLY

- 1.6.21. FRONT AXLE ASSEMBLY

- 1.6.22. REAR AXLE AND TRANSMISSION ASSEMBLY

- 1.6.23. REAR AXLE ASSEMBLY

- 1.6.24. TRANSMISSION ASSEMBLY

- 1.6.25. PROPSHAFT ASSEMBLY

- 1.6.26. WHEEL ASSEMBLY

- 1.6.27. SUSPENSION LOCK CYLINDER ASSEMBLY

- 1.6.28. SUSPENSION LOCK ASSEMBLY

- 1.6.29. OUTRIGGER ASSEMBLY

- 1.6.30. OUTRIGGER ASSEMBLY

- 1.6.31. DOZER BLADE ASSEMBLY

- 1.6.32. DOZER BLADE ASSEMBLY

- 1.6.33. SWING CIRCLE

- 1.6.34. ASSEMBLY

- 1.6.35. REVOLVING FRAME ASSEMBLY

- 1.6.36. CENTRE SWIVEL JOINT ASSEMBLY

- 1.6.37. CENTRE SWIVEL JOINT ASSEMBLY

- 1.6.38. HYDRAULIC TANK ASSEMBLY

- 1.6.39. FUEL TANK ASSEMBLY

- 1.6.40. CONTROL VALVE ASSEMBLY

- 1.6.41. LS SEPARATION VALVE ASSEMBLY

- 1.6.42. PRESSURE COMPENSATION VALVE ASSEMBLY

- 1.6.43. MAIN RELIEF VALVE ASSEMBLY

- 1.6.44. LS CONTROL EPC VALVE ASSEMBLY

- 1.6.45. EPC SOLENOID VALVE ASSEMBLY

- 1.6.46. PPC SOLENOID VALVE BLOCK ASSEMBLY

- 1.6.47. MANIFOLD BLOCK ASSEMBLY

- 1.6.48. OIL SEAL IN HYDRAULIC PUMP INPUT SHAFT

- 1.6.49. WORK EQUIPMENT PPC VALVE ASSEMBLY

- 1.6.50. HYDRAULIC CYLINDER ASSEMBLY

- 1.6.51. MONOBOOM WORK EQUIPMENT ASSEMBLY

- 1.6.52. PIECE BOOM WORK EQUIPMENT ASSEMBLY

- 1.6.53. AIR CONDITIONER UNIT ASSEMBLY

- 1.6.54. COUNTERWEIGHT ASSEMBLY

- 1.6.55. OPERATOR CAB ASSEMBLY

- 1.6.56. MONITOR ASSEMBLY

- 1.6.57. GOVERNOR / PUMP CONTROLLER ASSEMBLY

- 1.7. OTHERS

- 1.7.1. Hydraulic circuit diagram 1/3

- 1.7.2. Hydraulic circuit diagram 2/3

- 1.7.3. Hydraulic circuit diagram 3/3

- 1.7.4. Electrical circuit diagram 1/5

- 1.7.5. Electrical circuit diagram 2/5

- 1.7.6. Electrical circuit diagram 3/5

- 1.7.7. Electrical circuit diagram 4/5

- 1.7.8. Electrical circuit diagram 5/5

Rate this product

You may also like

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF