- Claas

- Grove

- New Holland

- Komatsu

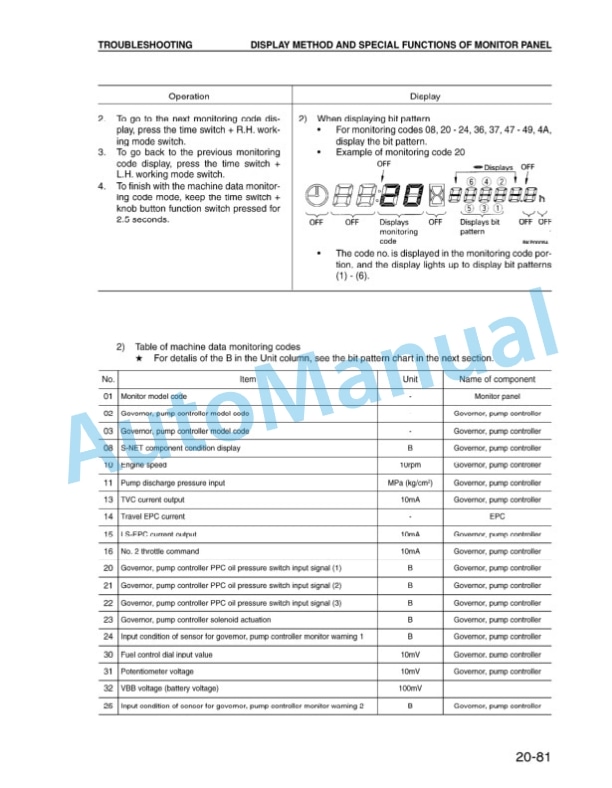

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu PW170ES-6K Hydraulic Excavator Shop Manual UEBM000500

$40.00

- Type Of Manual: Shop Manual

- Manual ID: UEBM000500

- Format: PDF

- Size: 43.7MB

- Number of Pages: 625

Category: Komatsu Shop Manual PDF

-

Model List:

- PW170ES-6K Hydraulic Excavator

- 1. MAIN MENU

- 2. COVER

- 3. STRUCTURE AND FUNCTION

- 3.1. ENGINE RELATED PARTS

- 3.2. RADIATOR OIL COOLER, AFTERCOOLER

- 3.3. POWER TRAIN

- 3.4. SWING CIRCLE

- 3.5. SWING MACHINERY

- 3.6. UNDERCARRIAGE

- 3.7. TRANSMISSION

- 3.8. AXLE

- 3.9. SUSPENSION LOCK CYLINDER

- 3.10. BRAKING TRAIN

- 3.11. BRAKE PEDAL

- 3.12. BRAKE VALVE

- 3.13. ACCUMULATOR FOR BRAKE SYSTEM

- 3.14. STEERING TRAIN

- 3.15. STEERING COLUMN

- 3.16. HYDRAULIC CIRCUIT DIAGRAM

- 3.17. CENTER SWIVEL JOINT

- 3.18. TRAVEL MOTOR (FRONT, REAR)

- 3.19. WORK EQUIPMENT, SWING PPC VALVE

- 3.20. TRAVEL PPC PEDAL

- 3.21. SERVICE PPC VALVE

- 3.22. SAFETY LOCK VALVE

- 3.23. PPC ACCUMULATOR

- 3.24. PPC SHUTTLE VALVE

- 3.25. EPC, SOLENOID VALVE

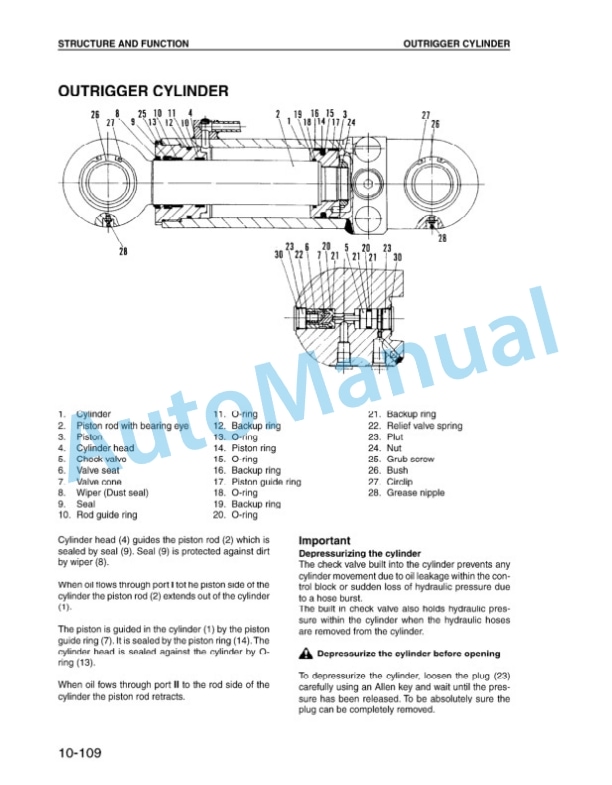

- 3.26. HYDRAULIC CYLINDER

- 3.27. WORK EQUIPMENT

- 3.28. ELECTRICAL WIRING DIAGRAM

- 3.29. ELECTRICAL WIRING DIAGRAM

- 3.30. ELECTRICAL WIRING DIAGRAM

- 3.31. ENGINE CONTROL SYSTEM

- 3.32. ELECTRONIC CONTROL SYSTEM

- 3.33. MACHINE MONITOR SYSTEM

- 4. TESTING AND ADJUSTING

- 4.1. TABLE OF JUDGEMENT STANDARD VALUE

- 4.2. STANDARD VALUE TABLE FOR ELETRICAL PARTS

- 4.3. CHECKING AND ADJUSTING BELT TENSION FOR AIR CONDITIONER COMPRESSOR

- 4.4. ADJUSTING ENGINE SPEED SENSOR

- 4.5. TESTING AND ADJUSTING GOVERNOR MOTOR LEVER STROKE

- 4.6. TESTING CLEARANCE OF SWING CIRCLE BEARING

- 4.7. TESTING AND ADJUSTING HYDRAULIC PRESSURE IN WORK EQUIPMENT, SWING, TRAVEL CIRCUIT

- 4.8. TESTING AND ADJUSTING TVC VALVE OUTPUT PRESSURE (SERVO PISTON INPUT PRESSURE)

- 4.9. TESTING AND ADJUSTING LS VALVE OUTPUT PRESSURE (SERVO PISTON INPUT PRESSURE) AND LS DIFFERENTIAL PRESSURE

- 4.10. TESTING AND ADJUSTING PPC PRESSURE

- 4.11. TESTING EPC VALVE SOLENOID VALVE OUTPUT PRESSURE

- 4.12. MEASURING PPC VALVE OUTPUT PRESSURE AND TESTING PPC SHUTTLE VALVE

- 4.13. ADJUSTING WORK EQUIPMENT SWING PPC VALVE

- 4.14. TESTING LOCATION CAUSING HYDRAULIC DRIFT OF WORK EQUIPMENT

- 4.15. MEASURING OIL LEAKAGE

- 4.16. RELEASING REMAINING PRESSURE IN HYDRAULIC CIRCUIT

- 4.17. BLEEDING AIR

- 4.18. ACCUMULATORS

- 4.19. TROUBLESHOOTING

- 4.19.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 4.19.2. SEQUENCE OF EVENTS IN TROUBLESHOOTING

- 4.19.3. PRECAUTIONS WHEN CARRYING OUT MAINTENANCE

- 4.19.4. CHECKS BEFORE TROUBLESHOOTING

- 4.19.5. CONNECTOR TYPES

- 4.19.6. CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

- 4.19.7. EXPLANATION OF CONTROL MECHANISM OF ELECTRICAL SYSTEM

- 4.19.8. DISPLAY METHOD AND SPECIAL FUNCTIONS OF MONITOR PANEL

- 4.19.9. METHOD OF USING JUDGEMENT TABLE

- 4.19.10. METHOD OF USING TROUBLESHOOTING CHARTS

- 4.19.11. DETAILS OF TROUBLESHOOTING AND TROUBLESHOOTING PROCEDURE

- 4.19.12. SERVICE CODE TABLE

- 4.19.13. TROUBLESHOOTING OF COMMUNICATION ABNORMALITY SYSTEM (N MODE)

- 4.19.14. TROUBLESHOOTING OF GOVERNOR, PUMP CONTROLLER (GOVERNOR CONTROL SYSTEM) (EMODE

- 4.19.15. TROUBLESHOOTING OF ENGINE SYSTEM (SMODE)

- 4.19.16. TROUBLESHOOTING OF GOVERNOR, PUMP CONTROLLER (PUMP CONTROL SYSTEM) (C MODE)

- 4.19.17. TROUBLESHOOTING OF GOVERNOR, PUMP CONTROLLER (INPUT SIGNAL SYSTEM) (F MODE)

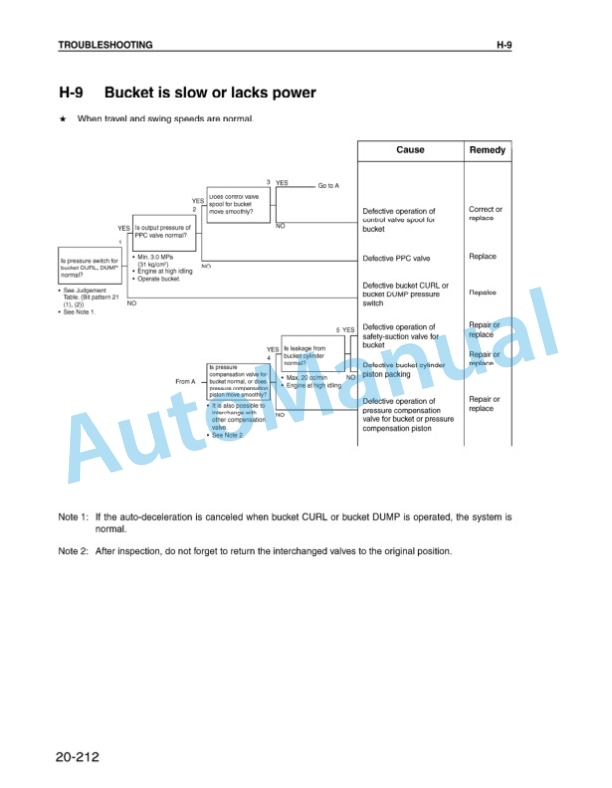

- 4.19.18. TROUBLESHOOTING OF HYDRAULIC, MECHANICAL SYSTEM (HMODE)

- 4.19.19. TROUBLESHOOTING OF MACHINE MONITOR SYSTEM (M MODE)

- 5. DISASSEMBLY AND ASSEMBLY

- 5.1. METHOD OF USING MANUAL

- 5.2. PRECAUTIONS WHEN CARRYING OUT OPERATION

- 5.3. SPECIAL TOOL LIST

- 5.4. GOVERNOR MOTOR ASSEMBLY

- 5.4.1. REMOVAL AND INSTALLATION

- 5.5. HYDRAULIC COOLER ASSEMBLY

- 5.5.1. REMOVAL

- 5.6. RADIATOR, HYDRAULIC COOLER ASSEMBLY

- 5.6.1. REMOVAL

- 5.6.2. INSTALLATION

- 5.7. ENGINE, MAIN PUMP ASSEMBLY

- 5.7.1. REMOVAL

- 5.7.2. INSTALLATION

- 5.8. DAMPER ASSEMBLY

- 5.8.1. REMOVAL AND INSTALLATION

- 5.9. FUEL TANK ASSEMBLY

- 5.9.1. REMOVAL AND INSTALLATION

- 5.10. CENTER SWIVEL JOINT ASSEMBLY

- 5.10.1. REMOVAL AND INSTALLATION

- 5.11. SWING MOTOR ASSEMBLY

- 5.11.1. REMOVAL AND INSTALLATION

- 5.12. SWING MACHINERY ASSEMBLY

- 5.12.1. REMOVAL AND INSTALLATION

- 5.13. SWING MOTOR

- 5.13.1. DISASSEMBLY AND ASSEMBLY

- 5.14. REVOLVING FRAME ASSEMBLY

- 5.14.1. REMOVAL

- 5.14.2. INSTALLATION

- 5.15. SWING CIRCLE ASSEMBLY

- 5.15.1. REMOVAL AND INSTALLATION

- 5.16. HYDRAULIC TANK ASSEMBLY

- 5.16.1. REMOVAL

- 5.16.2. INSTALLATION

- 5.17. MAIN PUMP ASSEMBLY

- 5.17.1. REMOVAL

- 5.17.2. INSTALLATION

- 5.18. CONTROL VALVE ASSEMBLY

- 5.18.1. REMOVAL

- 5.18.2. INSTALLATION

- 5.18.3. DISASSEMBLY AND ASSEMBLY

- 5.19. LS SELECT VALVE ASSEMBLY

- 5.19.1. DISASSEMBLY AND ASSEMBLY

- 5.20. LS SHUTTLE VALVE

- 5.20.1. DISASSEMBLY AND ASSEMBLY

- 5.21. PRESSURE COMPENSATION VALVE

- 5.21.1. DISASSEMBLY AND ASSEMBLY

- 5.22. MAIN RELIEF VALVE ASSEMBLY

- 5.22.1. DISASSEMBLY

- 5.22.2. ASSEMBLY

- 5.23. LS CONTROL EPC VALVE ASSEMBLY

- 5.23.1. REMOVAL AND INSTALLATION

- 5.24. EPC SOLENOID VALVE ASSEMBLY

- 5.24.1. REMOVAL AND INSTALLATION

- 5.25. PPC SHUTTLE VALVE ASSEMBLY

- 5.25.1. REMOVAL

- 5.25.2. INSTALLATION

- 5.25.3. DISASSEMBLY

- 5.25.4. ASSEMBLY

- 5.26. WORK EQUIPMENT PPC VALVE ASSEMBLY

- 5.26.1. REMOVAL AND INSTALLATION

- 5.27. TRAVEL PPC PEDAL ASSEMBLY

- 5.27.1. REMOVAL AND INSTALLATION

- 5.28. BOOM CYLINDER ASSEMBLY

- 5.28.1. REMOVAL

- 5.28.2. INSTALLATION

- 5.29. ARM CYLINDER ASSEMBLY

- 5.29.1. REMOVAL

- 5.29.2. INSTALLATION

- 5.30. BUCKET CYLINDER ASSEMBLY

- 5.30.1. REMOVAL

- 5.30.2. INSTALLATION

- 5.31. HYDRAULIC CYLINDER ASSEMBLY

- 5.31.1. DISASSEMBLY

- 5.31.2. ASSEMBLY

- 5.32. WORK EQUIPMENT ASSEMBLY

- 5.32.1. REMOVAL

- 5.32.2. INSTALLATION

- 5.33. BUCKET ASSEMBLY

- 5.34. BUCKET, ARM ASSEMBLY

- 5.35. OPERATORS CAB ASSEMBLY

- 5.35.1. REMOVAL

- 5.35.2. INSTALLATION

- 5.36. COUNTERWEIGHT ASSEMBLY

- 5.36.1. REMOVAL AND INSTALLATION

- 5.37. GOVERNOR, PUMP CONTROLLER ASSEMBLY

- 5.37.1. REMOVAL AND INSTALLATION

- 5.38. MONITOR PANEL ASSEMBLY

- 5.38.1. REMOVAL AND INSTALLATION

- 5.39. SWING MACHINERY ASSEMBLY

- 5.39.1. DISASSEMBLY

- 5.39.2. ASSEMBLY

- 5.39.3. (SPECIAL TOOLS)

- 5.40. TRANSMISSION

- 5.41. FRONT AXLE

- 5.42. REAR AXLE

- 5.43. BUCKET ADAPTER

- 5.43.1. WELDING INSTRUCTION

- 5.44. OUTRIGGER BLADE CYLINDER

- 6. MAINTENANCE STANDARD

- 6.1. ENGINE MOUNT

- 6.2. SWING MACHINERY

- 6.3. SWING CIRCLE

- 6.4. CONTROL VALVE

- 6.5. SUCTION SAFETY VALVE

- 6.6. SWING MOTOR

- 6.7. WORK EQUIPMENT, SWING PPC VALVE

- 6.8. PPC SHUTTLE VALVE, TRAVEL JUNCTION VALVE

- 6.9. EPC SOLENOID VALVE

- 6.10. CENTER SWIVEL JOINT

- 6.11. BOOM SAFETY VALVE (ARM SAFETY VALVE)

- 6.12. HYDRAULIC CYLINDER

- 6.13. WORK EQUIPMENT

- 6.14. DOZER BLADE, OUTRIGGER CLYINDERS

- 6.15. OUTRIGGER BUSH PINS

- 6.16. TRANSMISSION

- 6.17. FRONT AXLE

- 6.18. REAR AXLE

- 6.19. ARM ROTATION CIRCLE

Rate this product

You may also like

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF