- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu PW170ES-6K Hydraulic Excavator Shop Manual UEBM001001

$40.00

- Type Of Manual: Shop Manual

- Manual ID: UEBM001001

- Format: PDF

- Size: 12.9MB

- Number of Pages: 667

Category: Komatsu Shop Manual PDF

-

Model List:

- PW170ES-6K Hydraulic Excavator

- 0.1. HOW TO READ THE SHOP MANUAL

- 0.2. HOISTING INSTRUCTIONS

- 0.3. COATING MATERIALS

- 0.4. STANDARD TIGHTENING TORQUE

- 0.5. ELECTRIC WIRE CODE

- 0.6. CONVERSION TABLE

- 1. STRUCTURE AND FUNCTION

- 1.1. ENGINE RELATED PARTS

- 1.2. RADIATOR, OIL COOLER, AFTERCOOLER

- 1.3. POWER TRAIN

- 1.4. SWING CIRCLE

- 1.5. SWING MACHINERY

- 1.6. UNDERCARRIAGE

- 1.7. TRANSMISSION

- 1.8. AXLE

- 1.9. SUSPENSION LOCK CYLINDER

- 1.10. BRAKING TRAIN

- 1.11. BRAKE PEDAL

- 1.12. BRAKE VALVE

- 1.13. ACCUMULATOR FOR BRAKE SYSTEM

- 1.14. STEERING TRAIN

- 1.15. STEERING COLUMN

- 1.16. HYDRAULIC CIRCUIT DIAGRAM

- 1.17. CENTER SWIVEL JOINT

- 1.18. TRAVEL MOTOR (FRONT, REAR)

- 1.19. WORK EQUIPMENT, SWING PPC VALVE

- 1.20. TRAVEL PPC PEDAL

- 1.21. SERVICE PPC VALVE

- 1.22. SAFETY LOCK VALVE

- 1.23. PPC ACCUMULATOR

- 1.24. PPC SHUTTLE VALVE, TRAVEL JOINT VALVE

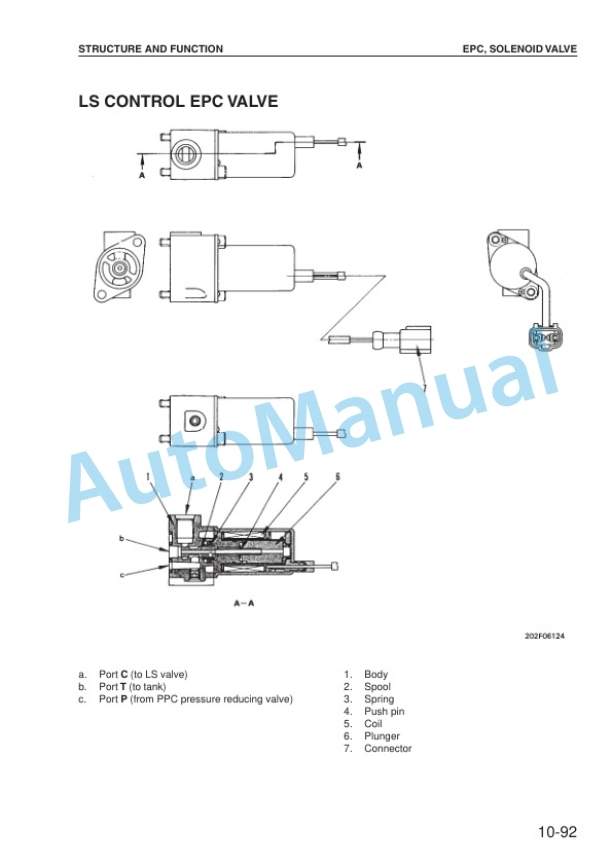

- 1.25. EPC, SOLENOID VALVE

- 1.26. BOOM HOLDING VALVE

- 1.27. HYDRAULIC CYLINDERS

- 1.28. WORK EQUIPMENT

- 1.29. ELECTRICAL WIRING DIAGRAM

- 1.30. ELECTRICAL WIRING DIAGRAM

- 1.31. ELECTRICAL WIRING DIAGRAM

- 1.32. EUROPEAN SPECIFICATIONS

- 1.33. TRAVEL ALARM FOR USA SPECIFICATIONS

- 1.34. ENGINE CONTROL SYSTEM

- 1.35. ELECTRONIC CONTROL SYSTEM

- 1.36. MACHINE MONITOR SYSTEM

- 1.37. REVERSE ALARM

- 1.38. BREAKER MODE HYDRAULIC PERFORMANCE

- 2. TESTING AND ADJUSTING

- 2.1. TABLE OF JUDGEMENT STANDARD VALUE

- 2.2. STANDARD VALUE TABLE FOR ELECTRICAL PARTS

- 2.3. CHECKING AND ADJUSTING BELT TENSION FOR AIR CONDITIONER COMPRESSION

- 2.4. ADJUSTING ENGINE SPEED SENSOR

- 2.5. TESTING AND ADJUSTING GOVERNOR MOTOR LEVER STROKE

- 2.6. TESTING CLEARANCE OF SWING CIRCLE BEARING

- 2.7. TESTING AND ADJUSTING HYDRAULIC PRESSURE IN WORK EQUIPMENT, SWING, TRAVEL CIRCUIT

- 2.8. TESTING AND ADJUSTING TVC VALVE OUTPUT PRESSURE (SERVO PISTON INPUT PRESSURE)

- 2.9. TESTING AND ADJUSTING LS VALVE OUTPUT PRESSURE (SERVO PISTON INPUT PRESSURE) AND LS DIFFERENTIAL PRESSURE

- 2.10. TESTING AND ADJUSTING PPC PRESSURE

- 2.11. TESTING EPC VALVE, SOLENOID VALVE OUTPUT PRESSURE

- 2.12. MEASURING PPC VALVE OUTPUT PRESSURE AND TESTING PPC SHUTTLE VALVE

- 2.13. ADJUSTING WORK EQUIPMENT, SWING PPC VALVE

- 2.14. TESTING LOCATION CAUSING HYDRAULIC DRIFT OF WORK EQUIPMENT

- 2.15. MEASURING OIL LEAKAGE

- 2.16. RELEASING REMAINING PRESSURE IN HYDRAULIC CIRCUIT

- 2.17. BLEEDING AIR

- 2.18. ACCUMULATORS

- 2.19. TROUBLESHOOTING

- 2.19.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 2.19.2. SEQUENCE OF EVENTS IN TROUBLESHOOTING

- 2.19.3. PRECAUTIONS WHEN CARRYING OUT MAINTENANCE

- 2.19.4. CHECKS BEFORE TROUBLESHOOTING

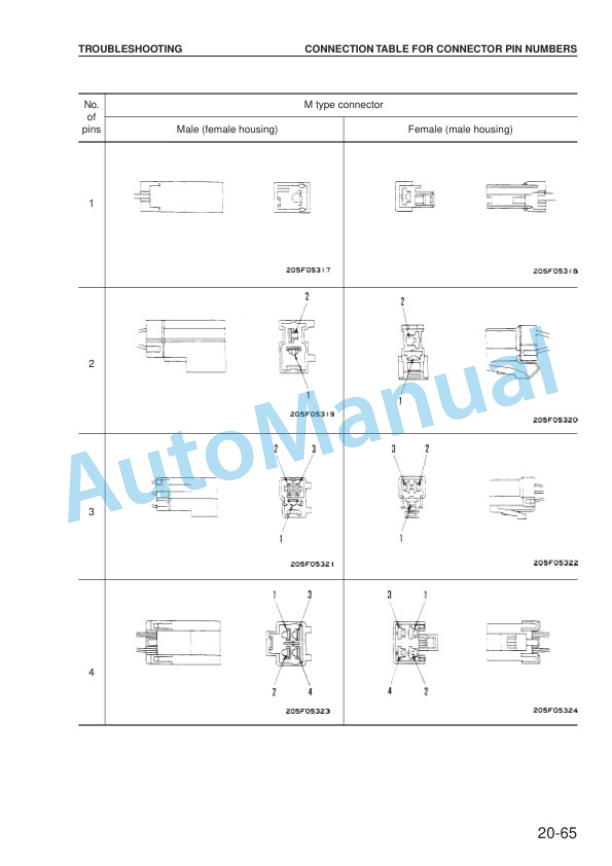

- 2.19.5. CONNECTOR TYPES

- 2.19.6. CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

- 2.19.7. EXPLANATION OF CONTROL MECHANISM OF ELECTRICAL SYSTEM

- 2.19.8. DISPLAY METHOD AND SPECIAL FUNCTIONS OF MONITOR PANEL

- 2.19.9. METHOD OF USING JUDGEMENT TABLE

- 2.19.10. METHOD OF USING TROUBLESHOOTING CHARTS

- 2.19.11. DETAILS OF TROUBLESHOOTING AND TROUBLESHOOTING PROCEDURE

- 2.19.12. SERVICE CODE TABLE

- 2.19.13. TROUBLESHOOTING OF COMMUNICATION ABNORMALITY SYSTEM (N MODE)

- 2.19.14. TROUBLESHOOTING OF GOVERNOR, PUMP CONTROLLER (GOVERNOR CONTROL SYSTEM)(E MODE)

- 2.19.15. TROUBLESHOOTING OF ENGINE (S MODE)

- 2.19.16. TROUBLESHOOTING OF GOVERNOR, PUMP CONTROLLER SYSTEM (PUMP CONTROL SYSTEM) (C MODE)

- 2.19.17. TROUBLESHOOTING OF GOVERNOR, PUMP CONTROLLER (INPUT SIGNAL SYSTEM) (F MODE)

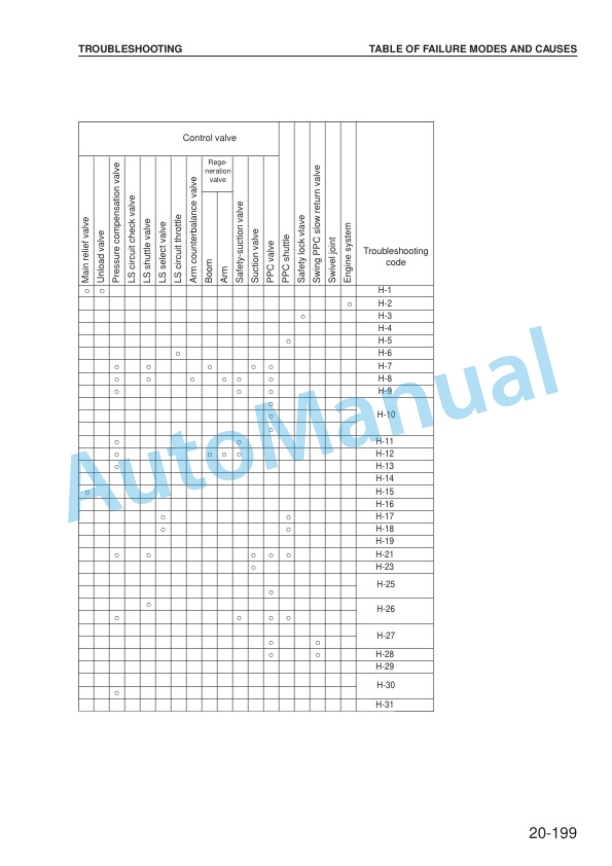

- 2.19.18. TROUBLESHOOTING OF HYDRAULIC, MECHANICAL SYSTEM (H MODE)

- 2.19.19. TROUBLESHOOTING OF MACHINE PANEL SYSTEM (M MODE)

- 3. DISASSEMBLY AND ASSEMBLY

- 3.1. METHOD OF USING MANUAL

- 3.2. PRECAUTIONS WHEN CARRYING OUT OPERATION

- 3.3. SPECIAL TOOL LIST

- 3.4. GOVERNOR MOTOR ASSEMBLY

- 3.4.1. REMOVAL AND INSTALLATION

- 3.5. HYDRAULIC COOLER ASSEMBLY

- 3.5.1. REMOVAL

- 3.6. RADIATOR, HYDRAULIC COOLER ASSEMBLY

- 3.6.1. REMOVAL

- 3.6.2. INSTALLATION

- 3.7. ENGINE, MAIN PUMP ASSEMBLY

- 3.7.1. REMOVAL

- 3.7.2. INSTALLATION

- 3.8. DAMPER ASSEMBLY

- 3.8.1. REMOVAL AND INSTALLATION

- 3.9. FUEL TANK ASSEMBLY

- 3.9.1. REMOVAL AND INSTALLATION

- 3.10. CENTER SWIVEL JOINT ASSEMBLY

- 3.10.1. REMOVAL AND INSTALLATION

- 3.11. SWING MOTOR ASSEMBLY

- 3.11.1. REMOVAL AND INSTALLATION

- 3.12. SWING MACHINERY ASSEMBLY

- 3.12.1. REMOVAL AND INSTALLATION

- 3.13. SWING MOTOR

- 3.13.1. DISASSEMBLY AND ASSEMBLY

- 3.14. REVOLVING FRAME ASSEMBLY

- 3.14.1. REMOVAL

- 3.14.2. INSTALLATION

- 3.15. SWING CIRCLE ASSEMBLY

- 3.15.1. REMOVAL AND INSTALLATION

- 3.16. HYDRAULIC TANK ASSEMBLY

- 3.16.1. REMOVAL

- 3.16.2. INSTALLATION

- 3.17. MAIN PUMP ASSEMBLY

- 3.17.1. REMOVAL

- 3.17.2. INSTALLATION

- 3.18. CONTROL VALVE ASSEMBLY

- 3.18.1. REMOVAL

- 3.18.2. INSTALLATION

- 3.18.3. DISASSEMBLY AND ASSEMBLY

- 3.19. LS SELECT VALVE ASSEMBLY

- 3.19.1. DISASSEMBLY AND ASSEMBLY

- 3.20. LS SHUTTLE VALVE

- 3.20.1. DISASSEMBLY AND ASSEMBLY

- 3.21. PRESSURE COMPENSATION VALVE ASSEMBLY

- 3.21.1. DISASSEMBLY AND ASSEMBLY

- 3.22. MAIN RELIEF VALVE ASSEMBLY

- 3.22.1. DISASSEMBLY

- 3.22.2. ASSEMBLY

- 3.23. LS CONTROL EPC VALVE ASSEMBLY

- 3.23.1. REMOVAL AND INSTALLATION

- 3.24. EPC SOLENOID VALVE ASSEMBLY

- 3.24.1. REMOVAL AND INSTALLATION

- 3.25. PPC SHUTTLE VALVE ASSEMBLY

- 3.25.1. REMOVAL

- 3.25.2. INSTALLATION

- 3.25.3. DISASSEMBLY

- 3.25.4. ASSEMBLY

- 3.26. WORK EQUIPMENT PPC VALVE ASSEMBLY

- 3.26.1. REMOVAL AND INSTALLATION

- 3.27. TRAVEL PPC VALVE ASSEMBLY

- 3.27.1. REMOVAL AND INSTALLATION

- 3.28. BOOM CYLINDER ASSEMBLY

- 3.28.1. REMOVAL

- 3.28.2. INSTALLATION

- 3.29. ARM CYLINDER ASSEMBLY

- 3.29.1. REMOVAL

- 3.29.2. INSTALLATION

- 3.30. BUCKET CYLINDER ASSEMBLY

- 3.30.1. REMOVAL

- 3.30.2. INSTALLATION

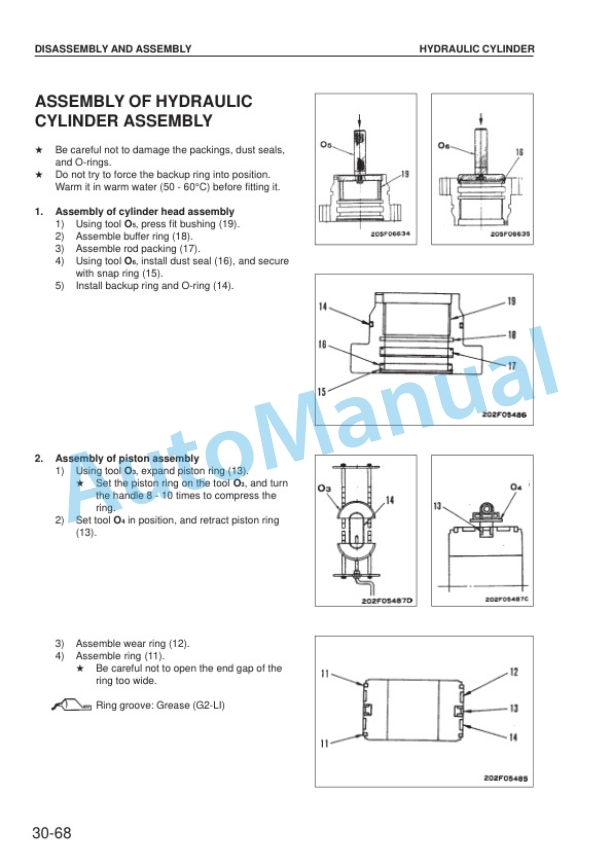

- 3.31. HYDRAULIC CYLINDER ASSEMBLY

- 3.31.1. DISASSEMBLY

- 3.31.2. ASSEMBLY

- 3.32. WORK EQUIPMENT ASSEMBLY

- 3.32.1. REMOVAL

- 3.32.2. INSTALLATION

- 3.33. BUCKET ASSEMBLY

- 3.34. BUCKET, ARM ASSEMBLY

- 3.35. OPERATORS CAB ASSEMBLY

- 3.35.1. REMOVAL

- 3.35.2. INSTALLATION

- 3.36. COUNTERWEIGHT ASSEMBLY

- 3.36.1. REMOVAL AND INSTALLATION

- 3.37. GOVERNOR, PUMP CONTROLLER ASSEMBLY

- 3.37.1. REMOVAL AND INSTALLATION

- 3.38. MONITOR PANEL ASSEMBLY

- 3.38.1. REMOVAL AND INSTALLATION

- 3.39. SWING MACHINERY ASSEMBLY

- 3.39.1. DISASSEMBLY

- 3.39.2. ASSEMBLY

- 3.39.3. (SPECIAL TOOLS FOR SWING MACHINERY)

- 3.40. TRANSMISSION

- 3.41. FRONT AXLE

- 3.42. REAR AXLE

- 3.43. BUCKET ADAPTOR

- 3.43.1. WELDING INSTRUCTIONS

- 3.44. OUT RIGGER BLADE CYLINDER

- 4. MAINTENANCE STANDARD

- 4.1. ENGINE MOUNT

- 4.2. SWING MACHINERY

- 4.3. SWING CIRCLE

- 4.4. CONTROL VALVE

- 4.5. SUCTIONSAFETY VALVE

- 4.6. SWING MOTOR

- 4.7. WORK EQUIPMENT, SWING PPC VALVE

- 4.8. PPC SHUTTLE VALVE, TRAVEL JUNCTION VALVE

- 4.9. EPC SOLENOID VALVE

- 4.10. CENTER SWIVEL JOINT

- 4.11. BOOM SAFETY VALVE (ARM SAFETY VALVE)

- 4.12. HYDRAULIC CYLINDER

- 4.13. WORK EQUIPMENT

- 4.14. DOZER BLADE, OUTRIGGER CYLINDERS

- 4.15. OUTRIGGER BUSH PINS

- 4.16. TRANSMISSION

- 4.17. FRONT AXLE

- 4.18. REAR AXLE

- 4.19. ARM ROTATION CIRCLE

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF