- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu PW200-7H, PW220-7H Shop Manual VEBM370100

$40.00

- Type Of Manual: Shop Manual

- Manual ID: VEBM370100

- Format: PDF

- Size: 38.3MB

- Number of Pages: 890

Category: Komatsu Shop Manual PDF

-

Model List:

- PW200-7H

- PW220-7H

- 1. VEBM370100_PW2007HPW2207H

- 1.1. SPECIFICATION DIMENSION DRAWINGS

- 1.2. DIMENSIONS

- 1.2.1. PIECE BOOM

- 1.3. SPECIFICATIONS

- 1.3.1. PW2007, PW2207

- 1.4. WEIGHT TABLE

- 1.4.1. pW2007, PW2207

- 1.4.2. PIECE boom

- 1.4.3. PIECE boom

- 1.5. FUEL, COOLANT AND LUBRICANTS

- 2. Section 10

- 2.1. ENGINE RELATED PARTS

- 2.2. RADIATOR . OIL COOLER . charge air cooler

- 2.3. POWER TRAIN

- 2.4. SWING CIRCLE

- 2.5. SWING MACHINERY motor

- 2.6. SWING MOTOR

- 2.6.1. Operation of swing lock

- 2.6.2. RELIEF VALVE PORTION

- 2.6.3. Operation

- 2.7. UNDERCARRIAGE

- 2.8. TRANSMISSION

- 2.9. TRAVEL MOTOR

- 2.9.1. oPERATION OF TRAVEL MOTOR

- 2.10. CLUTCH CONTROL CIRCUIT

- 2.11. AXLE

- 2.12. sUSPENSION LOCK CYLINDER

- 2.13. Braking System

- 2.14. brake/steer pump

- 2.15. PRIORITY VALVE

- 2.15.1. SPECIFICATIONS

- 2.15.2. FUNCTION

- 2.16. ACCUMULATOR for brake system

- 2.17. STEERING sYSTEM

- 2.18. STEERING COLUMN

- 2.19. ORBITROL VALVE

- 2.20. hydraulic equipment layout drawingS

- 2.21. hydraulic CIRCUIT dIAgRAM

- 2.22. HYDRAULIC TANK

- 2.23. HYDRAULIC PUMP

- 2.23.1. HPV95 95 (PW2007H)

- 2.23.2. LS VALVE

- 2.23.3. PC VALVE

- 2.23.4. LS valve

- 2.23.5. PC Valve

- 2.24. PILOT PRESSURE CONTROL (PPC) SYSTEM

- 2.25. CONTROL VALVE

- 2.25.1. PW200 2207H

- 2.26. CLSS

- 2.26.1. OUTLINE OF CLSS

- 2.26.2. MAIN RELIEF VALVE

- 2.26.2.1. Function

- 2.26.3. Variable pressure compensation valve

- 2.27. CENTre SWIVEL JOINT

- 2.28. TRAVEL PPC PEDAL

- 2.29. WORK EQUIPMENT . SWING PPC VALVE

- 2.30. SERVICE PPC VALVE

- 2.31. SOLENOID VALVES

- 2.31.1. SOLENOID VALVE BLOCK

- 2.31.1.1. Position 3 way valve

- 2.31.1.2. Position 4 way valve

- 2.31.2. LS (PC)EPC VALVE

- 2.31.3. attachment epc valve

- 2.32. Boom safety valve

- 2.33. HYDRAULIC CYLINDER

- 2.33.1. pw2007, pw2207

- 2.33.1.1. BOOM CYLINDER

- 2.33.1.2. ARM CYLINDER

- 2.33.1.3. BUCKET CYLINDER

- 2.33.1.4. ADJUST CYLINDER

- 2.34. Outrigger CYLINDER

- 2.35. dozer CYLINDER

- 2.36. work equipment

- 2.36.1. Pw200/2207

- 2.36.1.1. Work Equipment

- 2.36.2. DIMENSION OF ARM

- 2.36.3. Dimension of bucket

- 2.37. air conditioner

- 2.37.1. air conditioner piping

- 2.38. electrical wiring diagram

- 2.39. engine control system

- 2.39.1. Governor motor

- 2.39.2. Engine throttle and pump controller

- 2.40. ELECTRONIC CONTROL SYSTEM

- 2.40.1. machine control system diagram

- 2.41. machine MONITOR SYSTEM

- 2.41.1. Monitor panel

- 2.41.2. LIQUID CRYSTAL MONITOR ADJUSTMENT SWITCH

- 2.42. OVERLOAD WARNING DEVICE

- 2.42.1. OUTLINE

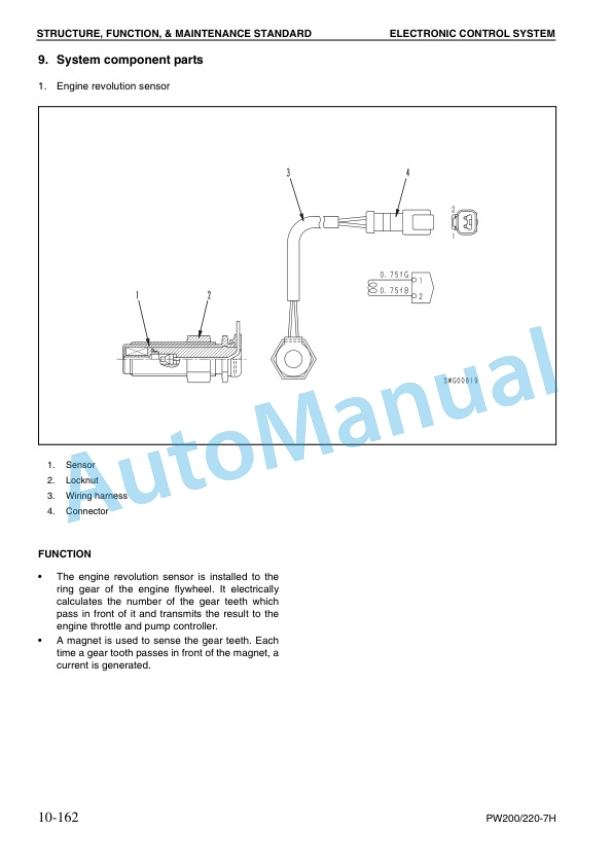

- 2.43. SENSOR

- 2.44. t attachment circuit hydraulic performance (main valve bypassed)

- 2.44.1. TRAVEL CIRCUIT

- 2.44.2. oPERATIONAL AND CONTROL FEATURES

- 2.45. SteeRING system

- 2.45.1. Operating principles

- 2.46. SERVICE BRAKE AND SUSPENSION SYSTEM

- 2.46.1. bRAKING SYSTEM

- 2.46.2. operation

- 3. Section 20

- 3.1. INSPECTION AND ADJUSTMENT OF ENGINE RPM

- 3.2. MEASUREMENT OF EXHAUST GAS COLOR

- 3.3. ADJUSTMENT OF VALVE CLEARANCE

- 3.4. EASUREMENT OF COMPRESSION PRESSURE

- 3.5. MEASUREMENT OF BLOWBY PRESSURE

- 3.6. INSPECTION AND ADJUSTMENT OF FUEL INJECTION TIMING

- 3.7. MEASUREMENT OF ENGINE OIL PRESSURE

- 3.8. EMERGENcy sEtting iF FAILURE occurs IN ENGINE CONTROL SYSTEM

- 3.9. MEASUREMENT OF CLEARANCE IN SWING CIRCLE BEARINGS

- 3.10. INSPECTION AND ADJUSTMENT OF HYDRAULIC OIL PRESSURE IN HYDRAULIC CIRCUIT FOR WORK EQUIPMENT, SWING AND TRAVEL

- 3.11. INSPECTION AND ADJUSTMENT OF CONTROL CIRCUIT OIL PRESSURE

- 3.12. INSPECTION AND ADJUSTMENT OF PUMP PC (Valve INLET) CONTROL OIL PRESSURE(PW200/220)

- 3.13. INSPECTION AND ADJUSTMENT OF PUMP LS valve CONTROL OIL PRESSURE(pW200/220)

- 3.14. MEASUREMENT OF SOLENOID VALVE OUTPUT PRESSURE

- 3.14.1. Stage solenoid block

- 3.14.2. Stage solenoid block

- 3.14.3. Stage solenoid block

- 3.15. MEASUREMENT OF PPC VALVE OUTPUT PRESSURE

- 3.16. ADJUSTMENT OF WORK EQUIPMENT AND SWING PPC VALVE

- 3.17. testing travel motor relief pressure

- 3.18. adjusting travel motor relief pressure

- 3.19. Testing propshaft speed

- 3.20. TESTING TRANSMISSION CLUTCH CONTROL CIRCUIT

- 3.21. INSPECTION OF LOCATIONS OF HYDRAULIC DRIFT OF WORK EQUIPMENT

- 3.21.1. RELEASE OF REMAINING PRESSURE IN HYDRAULIC CIRCUIT

- 3.22. MEASUREMENT OF OIL LEAKAGE AMOUNT

- 3.23. INSPECTION PROCEDURES FOR DIODE

- 3.24. SPECIAL FUNCTION OF MONITOR PANEL

- 3.24.1. OPERATION OF OPERATORS MENU AND DISPLAY (OUTLINE)

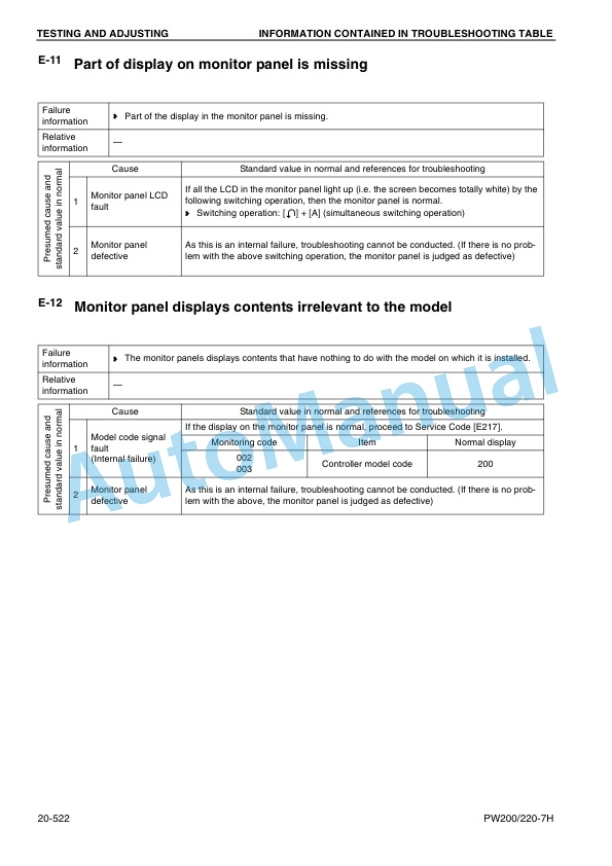

- 3.24.2. TABLE FOR ERROR AND FAILURE CODE NO.

- 3.24.3. OPERATION AND DISPLAY OF SERVICE MENU

- 3.24.3.1. Way of switching to Service Menu

- 3.24.3.2. Table for Monitoring Items

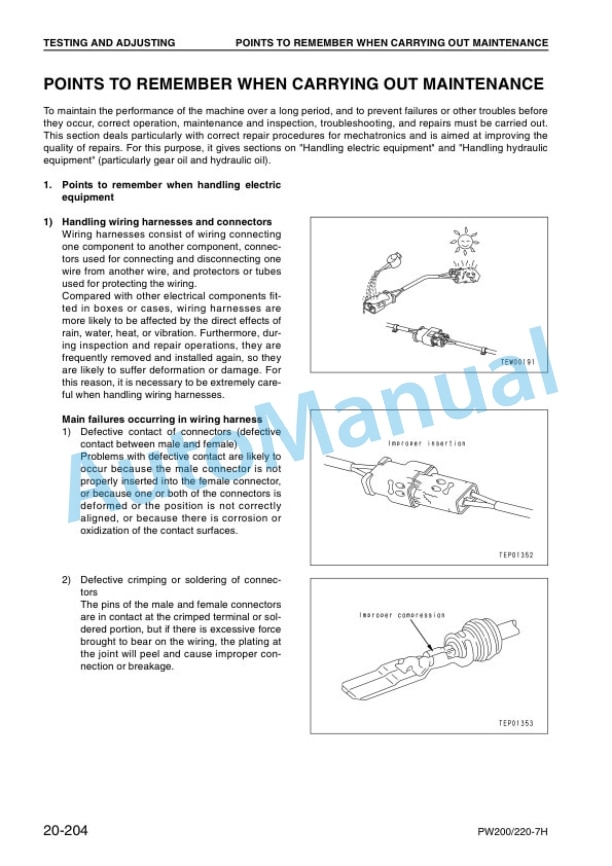

- 3.25. PREPARATIONS FOR TROUBLESHOOTING ELECTRICAL SYSTEM

- 4. Section 30

- 4.1. HOW TO READ THIS MANUAL

- 4.1.1. REMOVAL AND INSTALLATION OF ASSEMBLIES

- 4.1.2. DISASSEMBLY AND ASEMBLY OF ASSEMBLIES

- 4.2. SPECIAL TOOLS

- 4.2.1. SKETCHES

- 4.2.2. LIST OF TOOLS

- 4.3. PRECAUTIONS WHEN PERFORMING OPERATION

- 4.4. GOVERNOR MOTOR ASSEMBLY

- 4.4.1. REMOVAL

- 4.5. STARTING MOTOR ASSEMBLY

- 4.5.1. REMOVAL

- 4.5.2. INSTALLATION

- 4.6. FUEL INJECTION PUMP ASSEMBLY

- 4.7. ENGINE FRONT SEAL

- 4.8. ENGINE REAR SEAL

- 4.9. CYLINDER HEAD ASSEMBLY

- 4.10. COMBINATION COOLER

- 4.11. ENGINE AND HYDRAULIC PUMP ASSEMBLIES

- 4.12. TRANSMISSION AND TRAVEL MOTOR ASSEMBLY

- 4.13. TRANSMISSION ASSEMBLY

- 4.14. TRAVEL MOTOR ASSEMBLY

- 4.15. SWING MOTOR AND SWING MACHINERY ASSEMBLY

- 4.16. SWING MOTOR AND SWING MACHINERY ASSEMBLY

- 4.17. FRONT AXLE ASSEMBLY

- 4.18. FRONT AXLE ASSEMBLY

- 4.19. REAR AXLE ASSEMBLY

- 4.20. REAR AXLE ASSEMBLY

- 4.21. PROPSHAFT ASSEMBLY

- 4.22. WHEEL ASSEMBLY

- 4.23. SUSPENSION LOCK CYLINDER ASSEMBLY

- 4.24. SUSPENSION LOCK ASSEMBLY

- 4.25. OUTRIGGER ASSEMBLY

- 4.26. OUTRIGGER ASSEMBLY

- 4.27. DOZER BLADE ASSEMBLY

- 4.28. DOZER BLADE ASSEMBLY

- 4.29. SWING CIRCLE

- 4.30. ASSEMBLY

- 4.31. REVOLVING FRAME ASSEMBLY

- 4.32. CENTRE SWIVEL JOINT ASSEMBLY

- 4.33. CENTRE SWIVEL JOINT ASSEMBLY

- 4.34. HYDRAULIC TANK ASSEMBLY

- 4.35. FUEL TANK ASSEMBLY

- 4.36. CONTROL VALVE ASSEMBLY

- 4.37. LS SELECT VALVE ASSEMBLY

- 4.38. LS SHUTTLE VALVE ASSEMBLY

- 4.39. PRESSURE COMPENSATION VALVE ASSEMBLY

- 4.40. MAIN RELIEF VALVE ASSEMBLY

- 4.41. LS CONTROL EPC VALVE ASSEMBLY

- 4.42. EPC SOLENOID VALVE ASSEMBLY

- 4.43. PPC VALVE BLOCK ASSEMBLY

- 4.44. MANIFOLD BLOCK ASSEMBLY

- 4.45. OIL SEAL IN HYDRAULIC PUMP INPUT SHAFT

- 4.46. WORK EQUIPMENT PPC VALVE ASSEMBLY

- 4.47. HYDRAULIC CYLINDER ASSEMBLY

- 4.48. MONOBOOM WORK EQUIPMENT ASSEMBLY

- 4.49. PIECE BOOM WORK EQUIPMENT ASSEMBLY

- 4.50. AIR CONDITIONER UNIT ASSEMBLY

- 4.51. COUNTERWEIGHT ASSEMBLY

- 4.52. OPERATOR CAB ASSEMBLY

- 4.53. MONITOR ASSEMBLY

- 4.54. GOVERNOR / PUMP CONTROLLER ASSEMBLY

- 5. Section 90

- 5.1. OTHERS

- 5.2. HYDRAULIC CIRCUIT DIAGRAM 1/3

- 5.3. HYDRAULIC CIRCUIT DIAGRAM 2/3

- 5.4. HYDRAULIC CIRCUIT DIAGRAM 3/3

- 5.5. ELECTRICAL CIRCUIT DIAGRAM 1/5

- 5.6. ELECTRICAL CIRCUIT DIAGRAM 2/5

- 5.7. ELECTRICAL CIRCUIT DIAGRAM 3/5

- 5.8. ELECTRICAL CIRCUIT DIAGRAM 4/5

- 5.9. ELECTRICAL CIRCUIT DIAGRAM 5/5

Rate this product

You may also like

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF