- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu SA6D140-H-1 Diesel Engine Shop Manual SEBM036200

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM036200

- Format: PDF

- Size: 19.7MB

- Number of Pages: 290

Category: Komatsu Shop Manual PDF

-

Model List:

- SA6D140-H-1 Diesel Engine

- 1. COVER

- 2. CONTENTS

- 3. GENERAL

- 3.1. APPLICABLE MACHINE

- 3.2. SPECIFICATIONS

- 3.3. GENERAL ASSEMBLY DRAWING

- 3.4. WEIGHT TABLE

- 3.5. ENGINE PERFORMANCE CURVE

- 4. STRUCTURE AND FUNCTION

- 4.1. GENERAL STRUCTURE

- 4.1.1. GENERAL STRUCTURE

- 4.2. INTAKE AND EXHAUST SYSTEM

- 4.2.1. INTAKE AND EXHAUST SYSTEM

- 4.2.2. AIR CLEANER (IF EQUIPPED)

- 4.2.3. TURBOCHARGER

- 4.3. ENGINE BODY

- 4.3.1. CYLINDER HEAD

- 4.3.2. CYLINDER BLOCK

- 4.3.3. MAIN CIRCULATION SYSTEM

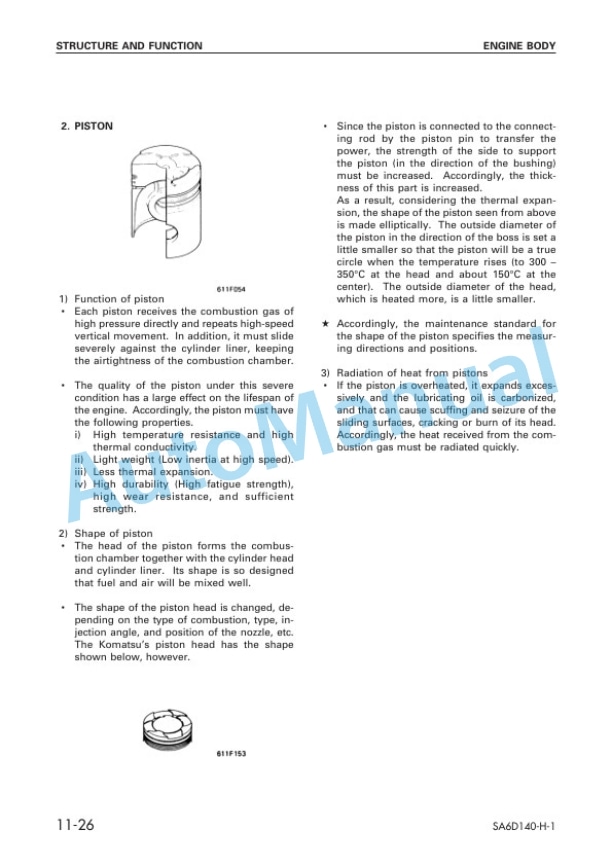

- 4.3.4. PISTON AND CONNECTING ROD

- 4.3.5. MAIN CIRCULATION SYSTEM

- 4.3.6. TIMING GEAR

- 4.3.7. VALVE MECHANISM

- 4.3.8. FLYWHEEL, FLYWHEEL HOUSING

- 4.4. LUBRICATION SYSTEM

- 4.4.1. LUBRICATION SYSTEM

- 4.4.2. LUBRICATION SYSTEM CHART

- 4.4.3. OIL PUMP

- 4.4.4. REGULATOR VALVE, PISTON COOLING VALVE

- 4.4.5. OIL FILTER (FULLFLOW OIL FILTER)

- 4.4.6. BYPASS FILTER

- 4.4.7. OIL COOLER

- 4.5. FUEL SYSTEM

- 4.5.1. FUEL SYSTEM

- 4.5.2. FUEL SYSTEM CHART

- 4.5.3. FUEL INJECTION PUMP

- 4.5.4. ELECTRONIC GOVERNOR (RED)

- 4.5.5. STRUCTURAL DRAWING

- 4.5.6. CONTROLLER I/O PORT

- 4.5.7. CONTROL OF ELECTRONIC GOVERNOR

- 4.5.8. CONTROL BOX

- 4.5.9. FEED PUMP

- 4.5.10. PRIMING PUMP

- 4.5.11. FUEL INJECTION NOZZLE

- 4.5.12. FUEL FILTER

- 4.6. COOLING SYSTEM

- 4.6.1. COOLING SYSTEM

- 4.6.2. COOLING SYSTEM CHART

- 4.6.3. WATER PUMP

- 4.6.4. THERMOSTAT

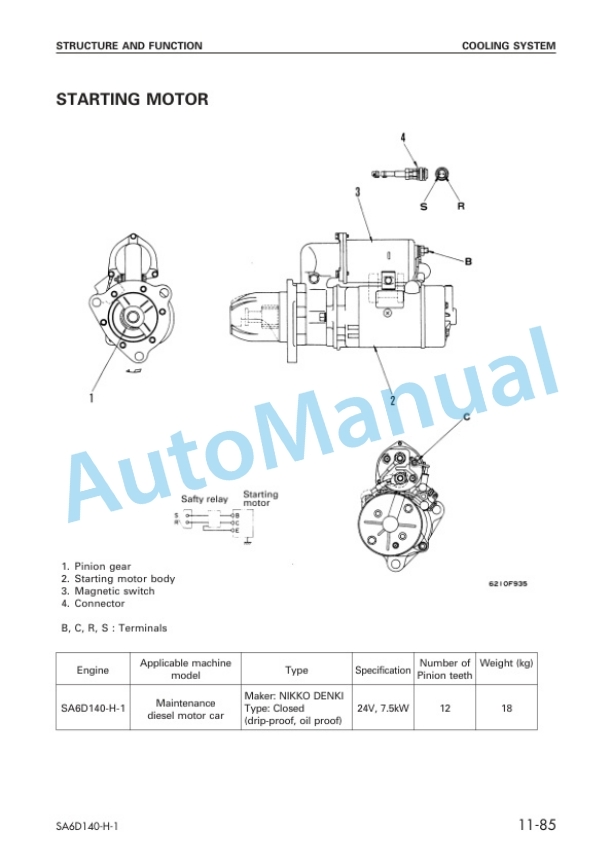

- 4.6.5. STARTING MOTOR

- 5. TESTING AND ADJUSTING

- 5.1. TESTING AND ADJUSTING

- 5.1.1. MOUNTING (ADJUSTING) METHOD OF ENGINE SPEED SENSOR

- 5.2. INTAKE AND EXHAUST SYSTEM

- 5.2.1. SUCTION RESISTANCE

- 5.2.2. MEASURING INTAKE AIR PRESSURE (BOOST PRESSURE)

- 5.2.3. ADJUSTING VALVE CLEARANCE

- 5.2.4. MEASURING EXHAUST GAS COLOR

- 5.3. ENGINE BODY

- 5.3.1. MEASURING COMPRESSION PRESSURE

- 5.3.2. MEASURING BLOWBY PRESSURE

- 5.4. LUBRICATION SYSTEM

- 5.4.1. MEASURING OIL PRESSURE

- 5.5. FUEL SYSTEM

- 5.5.1. TESTING AND ADJUSTING FULE INJECTION TIMING

- 5.5.2. ADJUSTING FUEL INJECTION PRESSURE

- 5.5.3. ADJUSTING FUEL INJECTION PUMP

- 5.5.4. FUEL INJECTION VOLUME STANDARD (WITH ELECTRONIC GOVERNOR)

- 5.5.5. ADJUSTING GOVERNOR

- 5.5.6. ADJUSTING OUTPUT

- 5.6. COOLING SYSTEM

- 5.6.1. CHECKING COOLING SYSTEM (RADIATOR) FOR COOLANT LEAKAGE

- 5.6.2. METHOD OF MEASURING CORROSION PREVENTIVE CONTENT IN COOLANT

- 5.7. PERFORMANCE TEST

- 5.7.1. RUNIN STANDARD

- 5.7.2. PERFORMANCE TEST STANDARDS

- 5.8. TROUBLESHOOTING

- 5.8.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 5.8.2. METHOD OF USING TROUBLESHOOTING CHARTS

- 5.8.3. S1 STARTING PERFORMANCE IS POOR (STARTING ALWAYS TAKES TIME)

- 5.8.4. S2 ENGING DOES NOT START

- 5.8.5. S3 ENGINE DOES NOT PICK UP SMOOTHLY(FOLLOWUP IS POOR)

- 5.8.6. S4 ENGINE STOPS DURING OPERATIONS

- 5.8.7. S5 ENGINE DOES NOT ROTATE SMOOTHLY (HUNTING)

- 5.8.8. S6 ENGINE LACKS OUTPUT (NO POWER)

- 5.8.9. S7 EXHAUST SMOKE IS BLACK (INCOMPLETE COMBUSTION)

- 5.8.10. S8 OIL CONSUMPTION IS EXCESSIVE (OR EXHAUST SMOKE IS BLUE)

- 5.8.11. S9 OIL BECOMES CONTAMINATED QUICKLY

- 5.8.12. S10 FUEL CONSUMPTION IS EXCESSIVE

- 5.8.13. S11 OIL IS IN COOLING WATER, OR WATER SPURTS BACK, OR WATER LEVEL GOES DOWN

- 5.8.14. S12 OIL PRESSURE CAUTION LAMP LIGHTS UP (DROP IN OIL PRESSURE)

- 5.8.15. S13 OIL LEVEL RISES (WATER, FUEL IN OIL)

- 5.8.16. S14 WATER TEMPERATURE BECOMES TOO HIGH (OVERHEATING)

- 5.8.17. S15 ABNORMAL NOISE IS MADE

- 5.8.18. S16 VIBRATION IS EXCESSIVE

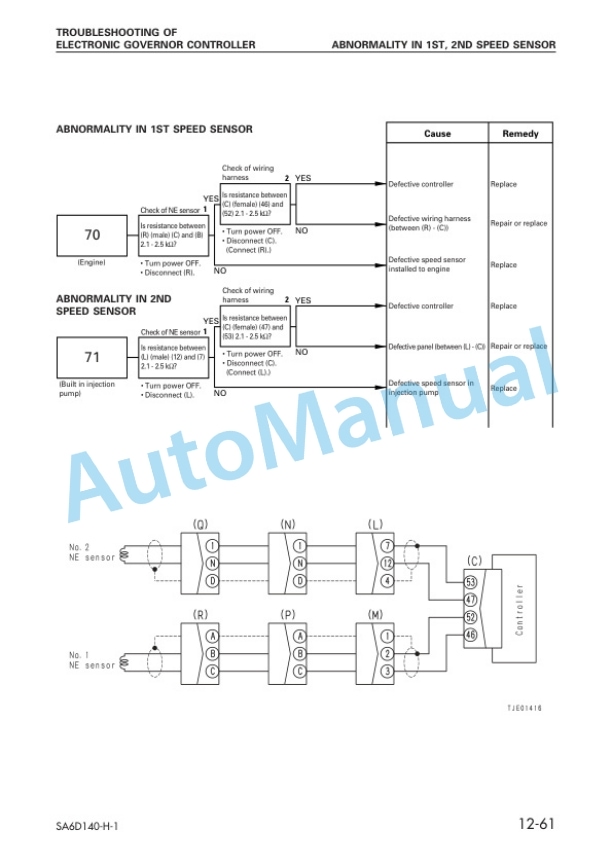

- 5.8.19. S17 DIAGNOSIS USING ELECTRONIC GOVERNOR DIAGNOSIS SYSTEM DISPLAY

- 5.9. TESTING AND ADJUSTING DATA

- 6. DISASSEMBLY AND ASSEMBLY

- 6.1. GENERAL DISASSEMBLY

- 6.1.1. STARTING MOTOR

- 6.1.2. TURBOCHARGER DRAIN TUBE

- 6.1.3. SETTING ENGINE IN ENGINE OVERHAUL STAND

- 6.1.4. CONNECTOR

- 6.1.5. DIPSTICK GUIDE, AIR COMPRESSOR

- 6.1.6. FUEL HOSE

- 6.1.7. TURBOCHARGER

- 6.1.8. EXHAUST MANIFOLD

- 6.1.9. AFTERCOOLER ASSEMBLY

- 6.1.10. FUEL INJECTION TUBE

- 6.1.11. FUEL INJECTION PUMP ASSEMBLY

- 6.1.12. TUBE, BRACKET, PTO CASE

- 6.1.13. FUEL FILTER

- 6.1.14. OIL FILTER

- 6.1.15. BRACKET, COVER

- 6.1.16. OIL PAN

- 6.1.17. SUCTION PIPE, UNDER FRAME

- 6.1.18. FLYWHEEL

- 6.1.19. FLYWHEEL HOUSING

- 6.1.20. AIR VENT TUBE, SPILL PIPE, ROCKER ARM HOUSING COVER

- 6.1.21. NOZZLE HOLDER, INLET CONNECTOR

- 6.1.22. ROCKER ARM

- 6.1.23. PUSH ROD

- 6.1.24. CROSSHEAD

- 6.1.25. ROCKET ARM HOUSING

- 6.1.26. CYLINDER HEAD ASSEMBLY

- 6.1.27. VIBRATION DAMPERCRANKSHAFT PULLEY ASSEMBLY

- 6.1.28. FRONT SUPPORT

- 6.1.29. THERMOSTAT HOUSING

- 6.1.30. WATER PUMP ASSEMBLY

- 6.1.31. OIL COOLER ASSEMBLY

- 6.1.32. CAM FOLLOWER

- 6.1.33. GEAR CASE COVER

- 6.1.34. INJECTION PUMP DRIVE GEAR

- 6.1.35. CAMSHAFT

- 6.1.36. OIL PUMP ASSEMBLY, OIL PUMP IDLER GEAR

- 6.1.37. MAIN IDLER GEAR, INJECTION PUMP DRIVE SHAFT

- 6.1.38. PISTON COOLING NOZZLE

- 6.1.39. PISTON AND CONNECTING ROD ASSEMBLY

- 6.1.40. CRANKSHAFT

- 6.1.41. CYLINDER LINER

- 6.2. GENERAL ASSEMBLY

- 6.2.1. GENERAL ASSEMBLY

- 7. MAINTENANCE STANDARD

- 7.1. INTAKE AND EXHAUST SYSTEM

- 7.1.1. TURBOCHARGER

- 7.2. ENGINE BODY

- 7.2.1. CYLINDER HEAD

- 7.2.2. VALVE, VALVE GUIDE

- 7.2.3. ROCKER ARM AND SHAFT

- 7.2.4. CROSSHEAD AND GUIDE

- 7.2.5. CYLINDER BLOCK

- 7.2.6. CYLINDER LINER

- 7.2.7. CRANKSHAFT

- 7.2.8. CAMSHAFT

- 7.2.9. CAM FOLLOWER AND PUSH ROD

- 7.2.10. TIMING GEAR

- 7.2.11. PISTON

- 7.2.12. CONNECTING ROD

- 7.2.13. FLYWHEEL AND FLYWHEEL HOUSING

- 7.3. LUBRICATION SYSTEM

- 7.3.1. OIL PUMP

- 7.3.2. REGULATOR VALVE, PISTON COOLING VALVE AND SAFETY VALVE

- 7.3.3. OIL COOLER

- 7.4. COOLING SYSTEM

- 7.4.1. WATER PUMP

- 7.4.2. THERMOSTAT

- 8. REPAIR AND REPLACEMENT OF PARTS

- 8.1. CYLINDER HEAD

- 8.1.1. GRINDING CYLINDER HEAD MOUNTING FACE

- 8.1.2. REPLACING VALVE SEAT INSERT

- 8.1.3. REPLACING CROSSHEAD GUIDE

- 8.1.4. REPLACING VALVE GUIDE

- 8.1.5. GRINDING VALVE

- 8.1.6. PRESSURE TEST

- 8.2. CYLINDER BLOCK

- 8.2.1. REPLACING CAM BUSHING

- 8.2.2. REPLACING CRANKSHAFT GEAR

- 8.2.3. REPLACING CAM GEAR

- 8.2.4. REPLACING FLYWHEEL RING GEAR

- 8.2.5. REPLACING CONNECTING ROD SMALL END BUSHING

- 8.3. RECLAMATION AND REPLACEMENT

- 8.3.1. CYLINDER BLOCK

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF