- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu SAA4D94LE-3 Engine Shop Manual VENBM07100

$40.00

- Type Of Manual: Shop Manual

- Manual ID: VENBM07100

- Format: PDF

- Size: 113.5MB

- Number of Pages: 1206

Category: Komatsu Shop Manual PDF

-

Model List:

- SAA4D94LE-3 Engine

- 1. VENBM07100 SHOP MANUAL ENGINE

- 2. Table of Contents

- 3. Introduction

- 4. Safety

- 4.1. Safety Statements

- 4.2. Safety Precautions

- 5. General Service Information

- 5.1. Component Identification

- 5.2. Location of Labels

- 5.3. Emission Control Regulations

- 5.4. Emission Control Labels

- 5.5. ENGINE FAMILY

- 5.6. Function of Major Engine Components

- 5.7. Function of Cooling System Components

- 5.8. Main Electronic Control Components and Features

- 5.9. Installation Position of Sensors

- 5.10. Diesel Fuel

- 5.11. Engine Oil

- 5.12. Engine Coolant

- 5.13. Aqueous urea

- 5.14. Specifications

- 5.15. Principal Engine Specifications

- 5.16. Engine Service Standards

- 5.17. Tightening Torques for Standard Bolts and Nuts

- 5.18. Abbreviations and Symbols

- 5.19. Unit Conversions

- 6. Periodic Maintenance

- 6.1. Before You Begin Servicing

- 6.2. Introduction

- 6.3. Periodic Maintenance Schedule

- 6.4. Periodic Maintenance Procedures

- 7. Engine

- 7.1. Before You Begin Servicing

- 7.2. Introduction

- 7.3. Cylinder Head Specifications

- 7.4. Camshaft and Timing Gear Train Specifications

- 7.5. Crankshaft and Piston Specifications

- 7.6. Cylinder Block Specifications

- 7.7. Special Torque Chart

- 7.8. Special Service Tools

- 7.9. Measuring Instruments

- 7.10. Cylinder Head

- 7.11. Measuring and Adjusting Valve Clearance

- 7.12. Crankshaft and Camshaft Components

- 8. Fuel System

- 8.1. Before You Begin Servicing

- 8.2. System Structure

- 8.3. Fuel System Specifications

- 8.4. Fuel System Diagram

- 8.5. Fuel System Components

- 9. Cooling System

- 9.1. Before You Begin Servicing

- 9.2. Cooling System Diagram

- 9.3. Engine Coolant Pump Components

- 9.4. Engine Coolant System Check

- 9.5. Engine Coolant Pump

- 10. Lubrication System

- 10.1. Before You Begin Servicing

- 10.2. Introduction

- 10.3. Oil Pump Service Information

- 10.4. Lubrication System Diagram

- 10.5. Checking Engine Oil Pressure

- 10.6. Trochoid Oil Pump

- 11. Exhaust System

- 11.1. EGR System

- 11.2. Turbocharger

- 11.3. Diesel Particulate Filter (DPF)

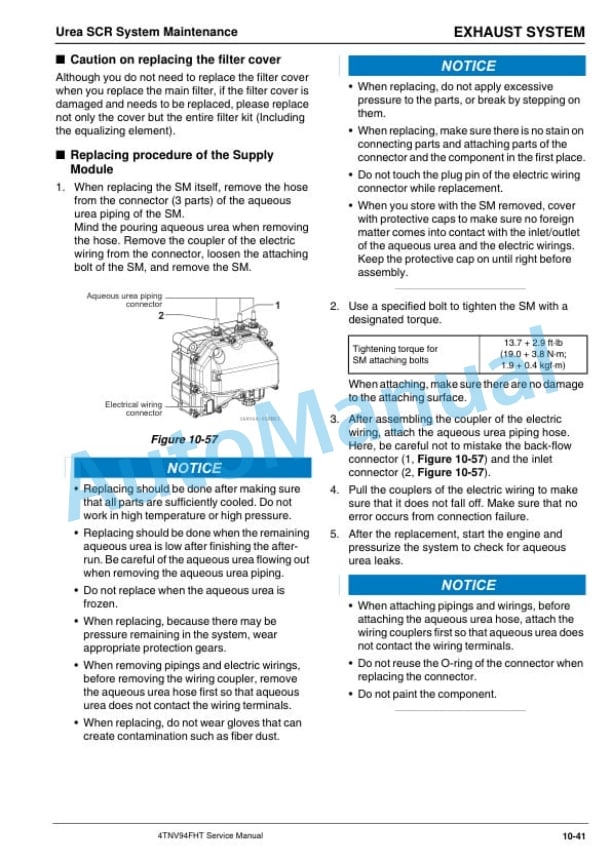

- 11.4. Urea SCR System

- 11.5. Maintenance service for After Treatment Device

- 11.6. Urea SCR System Maintenance

- 12. Starter Motor

- 12.1. Before You Begin Servicing

- 12.2. Introduction

- 12.3. Starter Motor Information

- 12.4. Starter Motor Specifications

- 12.5. Starter Motor Troubleshooting

- 12.6. Starter Motor Components

- 12.7. Starter Motor

- 13. Alternator

- 13.1. Before You Begin Servicing

- 13.2. Introduction

- 13.3. Alternator Specifications

- 13.4. Alternator Troubleshooting

- 13.5. Alternator Components

- 13.6. Alternator Wiring Diagram

- 13.7. Alternator Standard Output

- 13.8. Alternator

- 14. Electronic Control System

- 14.1. Before You Begin Servicing

- 14.2. Introduction

- 14.3. Electronic Control System

- 14.4. Troubleshooting of Electronic Control System

- 14.5. Replacement of Components

- 14.6. Electronic Control Harness Connections

- 15. Electric Wiring

- 15.1. Electric Wiring Precautions

- 15.2. Electrical Wire Resistance

- 15.3. Battery Cable Resistance

- 15.4. Electrical Wire Sizes Voltage Drop

- 15.5. Conversion of AWG to European Standards

- 16. Failure Diagnosis

- 16.1. Special Service Tools

- 16.2. Troubleshooting by Measuring Compression Pressure

- 16.3. Measured Value and Troubleshooting

- 16.4. Quick Reference Table for Troubleshooting

- 17. Trouble Shooting

- 17.1. CONTENTS

- 17.2. GENERAL DESCRIPTION OF ENGINE ELECTRONIC CONTROL SYSTEM

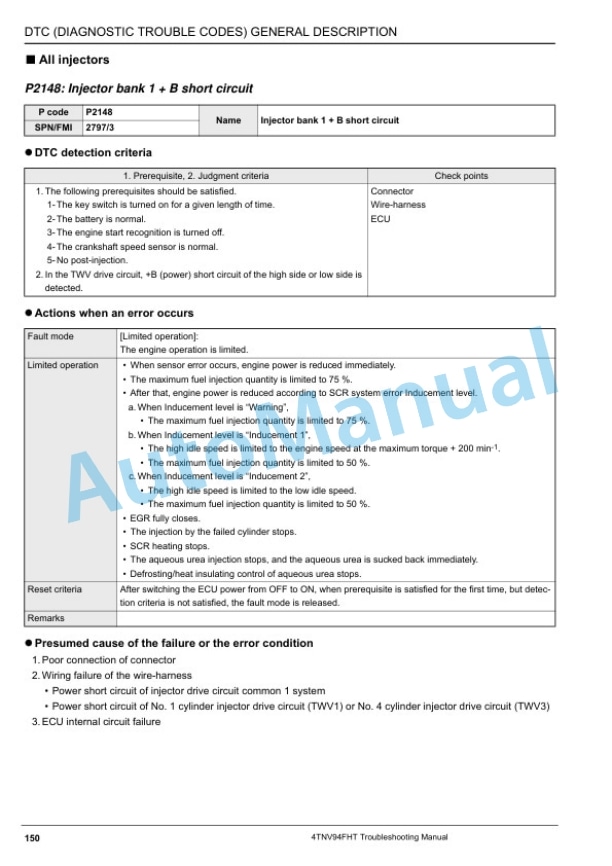

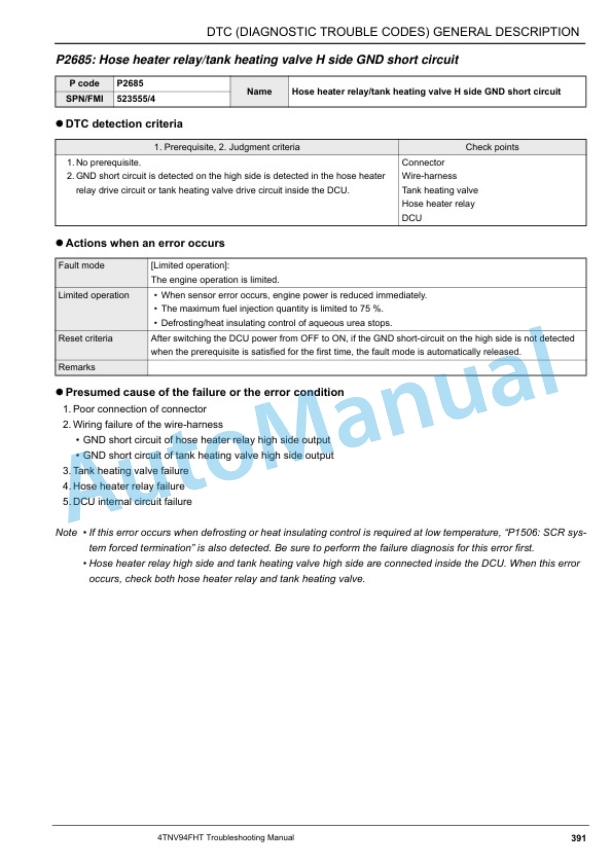

- 17.3. DTC (DIAGNOSTIC TROUBLE CODES) GENERAL DESCRIPTION

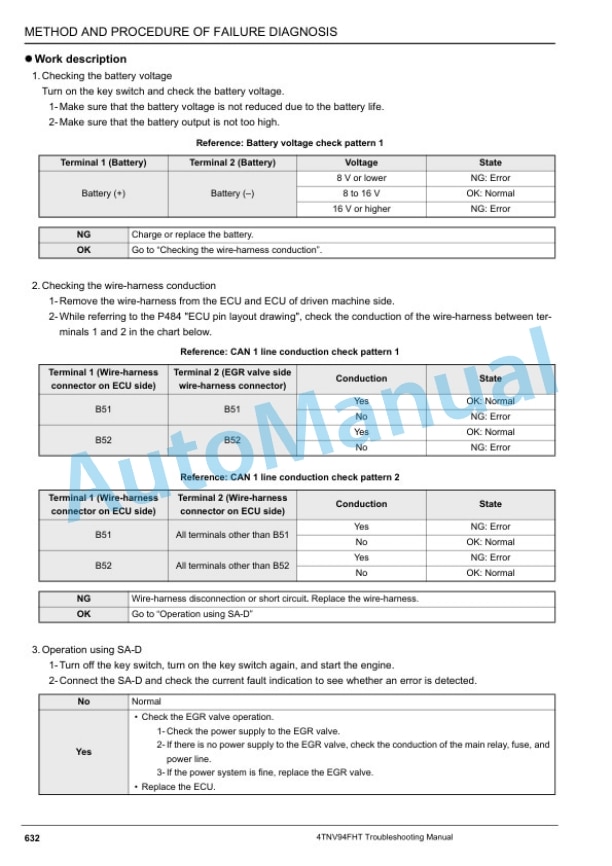

- 17.4. METHOD AND PROCEDURE OF FAILURE DIAGNOSIS

Rate this product

You may also like

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF