- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu SAA4D95LE-5, S4D95LE-3 Diesel Engine Shop Manual 4D95LE-BE4

$40.00

- Type Of Manual: Shop Manual

- Manual ID: 4D95LE-BE4

- Format: PDF

- Size: 62.4MB

- Number of Pages: 613

Category: Komatsu Shop Manual PDF

-

Model List:

- SAA4D95LE-5 Diesel Engine

- S4D95LE-3 Diesel Engine

- 1. EBE4

- 1.1. Index and foreword

- 1.1.1. Index and foreword

- 1.1.1.1. Composition of shop manual

- 1.1.1.2. Table of contents

- 1.1.1.3. Safety notice

- 1.1.1.4. How to read the shop manual

- 1.1.1.5. Explanation of terms for maintenance standard

- 1.1.1.6. Handling of electric equipment and hydraulic component

- 1.1.1.7. Handling of connectors newly used for engines

- 1.1.1.8. How to read electric wire code

- 1.1.1.9. Precautions when carrying out operation

- 1.1.1.10. Method of disassembling and connecting pushpull type coupler

- 1.1.1.11. Standard tightening torque table

- 1.1.1.12. Conversion table

- 1.2. Specification

- 1.2.1. Specification

- 1.2.1.1. Outline

- 1.2.1.2. Specifications

- 1.2.1.3. General view

- 1.2.1.4. Weight table

- 1.2.1.5. Engine performance curves

- 1.3. Structure,function and maintenance standard

- 1.3.1. Structure,function and maintenance standard

- 1.3.1.1. General structure

- 1.3.1.2. Air intake and exhaust system

- 1.3.1.3. Engine unit

- 1.3.1.4. Lubrication system

- 1.3.1.5. Fuel system

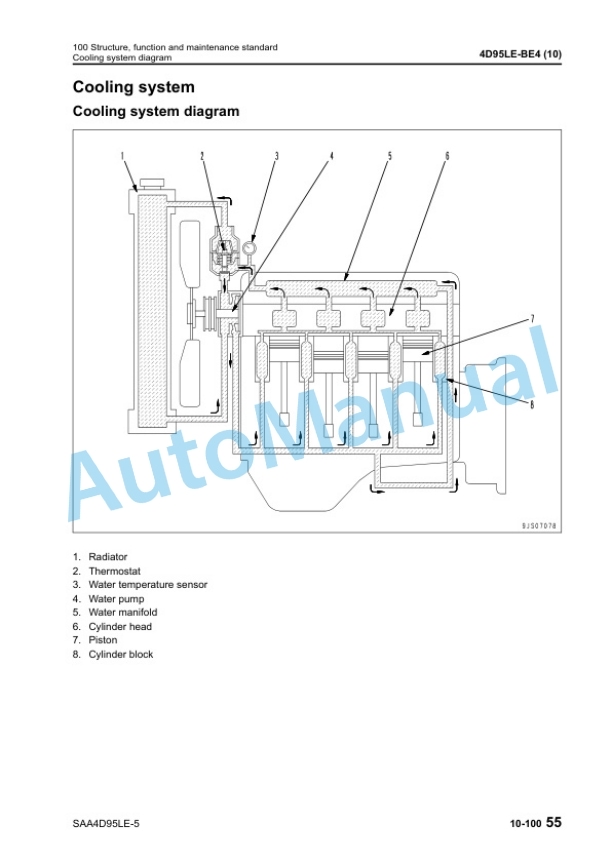

- 1.3.1.6. Cooling system

- 1.3.1.7. Electrical equipment

- 1.4. Standard value table

- 1.4.1. Standard value table

- 1.4.1.1. Standard service value table for testing, adjusting, and troubleshooting

- 1.4.1.2. Runningin standard and performance test standard

- 1.5. Testing and adjusting

- 1.5.1. Testing and adjusting

- 1.5.1.1. Testing and adjusting tools list

- 1.5.1.2. Testing exhaust temperature

- 1.5.1.3. Adjusting valve clearance

- 1.5.1.4. Testing compression pressure

- 1.5.1.5. Testing blowby pressure

- 1.5.1.6. Testing oil pressure

- 1.5.1.7. Handling fuel system parts

- 1.5.1.8. Releasing residual pressure in fuel system

- 1.5.1.9. Testing fuel pressure

- 1.5.1.10. Reduced cylinder mode operation

- 1.5.1.11. Noinjection cranking

- 1.5.1.12. Testing leakage from pressure limiter and return rate from injector

- 1.5.1.13. Bleeding air from fuel circuit

- 1.5.1.14. Testing fuel system for leakage

- 1.5.1.15. Testing and adjusting alternator belt tension

- 1.5.1.16. Handling controller voltage circuit

- 1.5.1.17. Functions of troubleshooting tool and check of failure code

- 1.6. Troubleshooting

- 1.6.1. Troubleshooting

- 1.6.1.1. General information on troubleshooting

- 1.6.1.2. Troubleshooting for mechanical system (Smode)

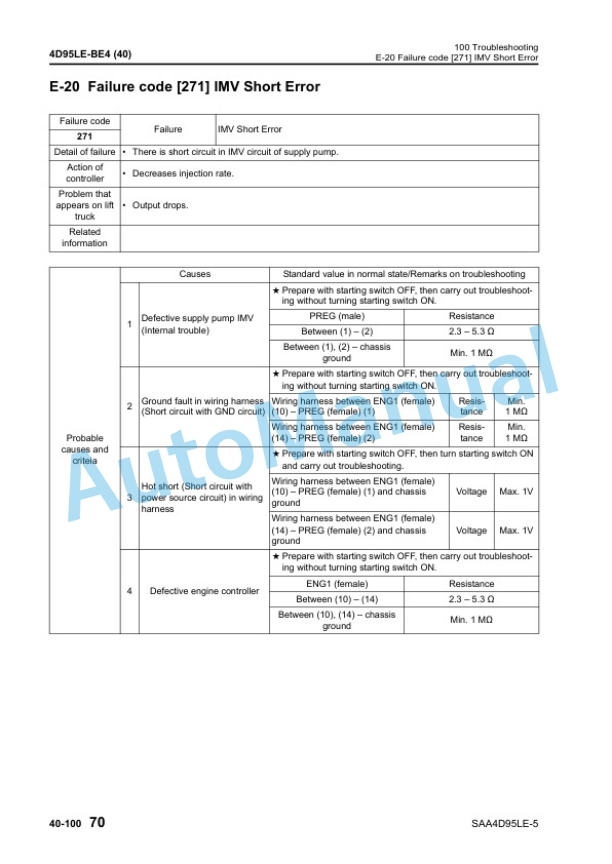

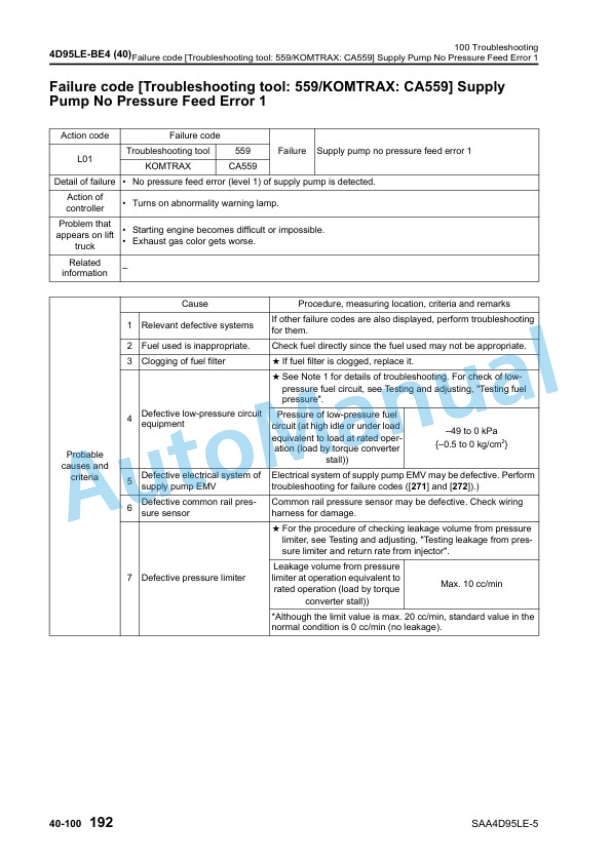

- 1.6.1.3. Troubleshooting for electrical system (Emode)

- 1.7. Disassembly and assembly

- 1.7.1. Disassembly and assembly

- 1.7.1.1. How to read this manual

- 1.7.1.2. Coating materials list

- 1.7.1.3. Special tools list

- 1.7.1.4. General disassembly of engine

- 1.7.1.5. General assembly of engine

- 1.7.1.6. Disassembly and assembly procedure for fuel supply pump unit

- 1.7.1.7. Disassembly and assembly procedure for oil seal units

- 1.7.2. OVERALL DRAWING

- 1.7.3. ENGINE PERFORMANCE CURVE

- 1.8. STRUCTURE, FUNCTION AND MAINTENANCE STANDARD

- 1.8.1. GENERAL STRUCTURE

- 1.8.1.1. General structure

- 1.8.2. INTAKE AND EXHAUST SYSTEM

- 1.8.2.1. Intake and exhaust system

- 1.8.2.2. Main revolving system

- 1.8.2.3. Crankshaft

- 1.8.2.4. Piston,piston ring and piston pin

- 1.8.2.5. Connecting rod

- 1.8.2.6. Flywheel and flywheel housing

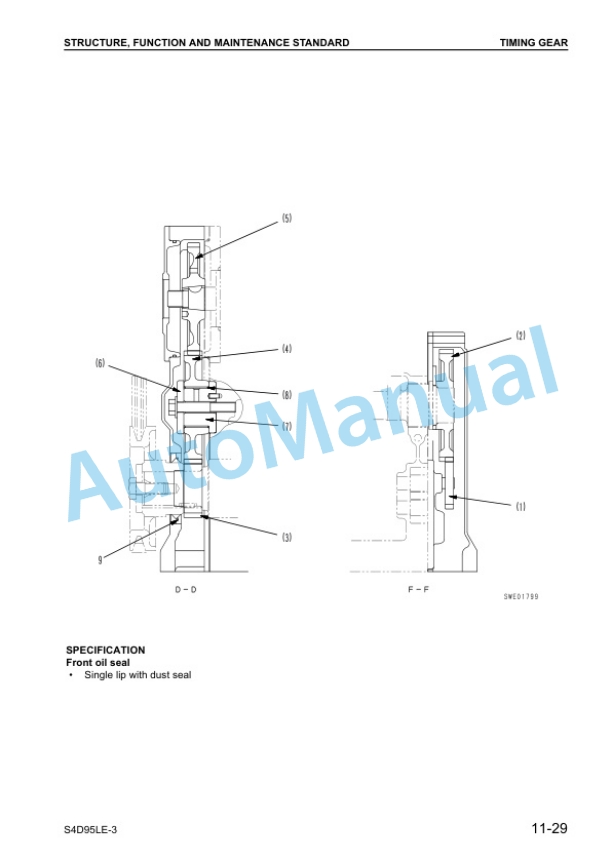

- 1.8.2.7. Timing gear

- 1.8.2.8. Valve system

- 1.8.2.9. Camshaft

- 1.8.2.10. Rocker arm shaft,push rod and tappet

- 1.8.2.11. Valve,valve guide

- 1.8.3. LUBRICATION SYSTEM

- 1.8.3.1. Lubrication system chart

- 1.8.3.2. Oil pump

- 1.8.3.3. Regulator valve

- 1.8.3.4. Oil filter mount

- 1.8.3.5. Oil filter

- 1.8.4. FUEL SYSTEM

- 1.8.4.1. Fuel system chart

- 1.8.4.2. Fuel injection pump

- 1.8.4.3. Fuel injection nozzle

- 1.8.4.4. Fuel filter

- 1.8.5. COOLING SYSTEM

- 1.8.5.1. Cooling system chart

- 1.8.5.2. Water pump

- 1.8.5.3. Fan drive and thermostat

- 1.8.6. ELECTRICAL SYSTEM

- 1.8.6.1. Starting and charging system electrical circuit diagram

- 1.8.6.2. Alternator

- 1.8.6.3. Starting motor

- 1.8.6.4. Engine starting device

- 1.9. TESTING AND ADJUSTING

- 1.9.1. TESTING AND ADJUSTING

- 1.9.1.1. Adjusting valve clearance

- 1.9.1.2. Measuring compression pressure

- 1.9.1.3. Adjusting fuel injection pressure (Cracking pressure)

- 1.9.1.4. Testing and adjusting fuel injection timing

- 1.9.2. FUEL INJECTION PUMP CALIBRATION DATA

- 1.9.3. PERFORMANCE TEST

- 1.9.3.1. Runin standard

- 1.9.3.2. Performance test criteria

- 1.9.4. TROUBLESHOOTING

- 1.9.4.1. Method of using troubleshooting charts

- 1.9.4.2. Points to remember when troubleshooting

- 1.9.4.3. S 1 Starting performance is poor (starting always takes time)

- 1.9.4.4. S 2 Engine does not start

- 1.9.4.5. S 3 Engine does not pick up smoothly (followup is poor)

- 1.9.4.6. S 4 Engine stops during operations

- 1.9.4.7. S 5 Engine does not rotate smoothly (hunting)

- 1.9.4.8. S 6 Engine lacks output (no power)

- 1.9.4.9. S 7 Exhaust smoke is black (incomplete combustion)

- 1.9.4.10. S 8 Oil consumption is excessive or exhaust smoke is blue

- 1.9.4.11. S 9 Oil becomes contaminated quickly

- 1.9.4.12. S10 Fuel consumption is excessive

- 1.9.4.13. S11 Oil is in coolant, or coolant spurts back,or coolant level goes down

- 1.9.4.14. S12 Oil pressure caution lamp lights up (drop in oil pressure)

- 1.9.4.15. S13 Oil level rises (water,fuel in oil)

- 1.9.4.16. S14 Coolant temperature becomes too high (overheating)

- 1.9.4.17. S15 Abnormal noise is made

- 1.9.4.18. S16 Vibration is excessive

- 1.9.5. TESTING AND ADJUSTING TOOL LIST

- 1.9.6. TESTING AND ADJUSTING DATA

- 1.10. DISASSEMBLY AND ASSEMBLY

- 1.10.1. SPECIAL TOOL LIST

- 1.10.2. OVERALL DISASSEMBLY,ASSEMBLY

- 1.10.3. DISASSEMBLY

- 1.10.4. ASSEMBLY

- 1.11. REPAIR AND REPLACEMENT OF PARTS

- 1.11.1. CYLINDER HEAD SECTION

- 1.11.1.1. Grinding cylinder head mounting surface

- 1.11.1.2. Replacing valve guide

- 1.11.1.3. Grinding valve

- 1.11.2. CYLINDER BLOCK SECTION

- 1.11.2.1. Replacing camshaft bushing

- 1.11.2.2. Replacing crankshaft gear

- 1.11.2.3. Replacing cam gear

- 1.11.2.4. Replacing flywheel ring gear

- 1.11.2.5. Procedure for pressure test

- 1.11.2.6. Cylinder liner (special restoration part)

- 1.11.2.7. Machining drawing for cylinder block bore

- 1.11.2.8. Additional machining of cam journal

- 1.11.2.9. Grinding crankshaft

- 1.11.2.10. Replacing connecting rod small end bushing

- 1.12. BACK COVER

Rate this product

You may also like

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF