- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu SAA6D107E-1-A, SAA6D107E-1-B Engine Shop Manual SEN06615-01

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEN06615-01

- Format: PDF

- Size: 30.5MB

- Number of Pages: 362

Category: Komatsu Shop Manual PDF

-

Model List:

- SAA6D107E-1-A Engine

- SAA6D107E-1-B Engine

- 1. Cover

- 2. Index and foreword

- 2.1. Table of contents

- 2.2. Safety notice

- 2.3. How to read the shop manual

- 2.4. Explanation of terms for maintenance standard

- 2.5. Handling of electric equipment and hydraulic component

- 2.6. Handling of connectors newly used for engines

- 2.7. How to read electric wire code

- 2.8. Precautions when carrying out operation

- 2.9. Method of disassembling and connecting pushpull type coupler

- 2.10. Standard tightening torque table

- 2.11. Conversion table

- 3. Specification

- 3.1. General

- 3.2. Specifications

- 3.3. General view

- 3.4. Engine performance curve

- 4. Structure, function and maintenance standard

- 4.1. Air intake and exhaust units

- 4.2. Intake system

- 4.3. Exhaust system

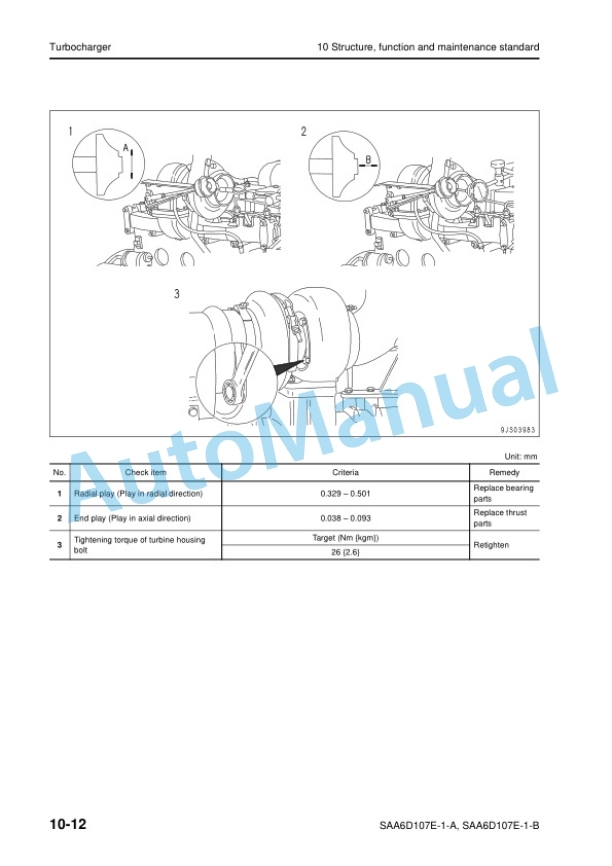

- 4.4. Turbocharger

- 4.5. Lubricating oil system

- 4.6. Cooling system

- 4.7. Fuel system

- 4.8. Main moving parts

- 4.9. Cylinder head

- 4.10. Cylinder block

- 4.11. Crankshaft

- 4.12. Piston, piston ring and piston pin

- 4.13. Connecting rod

- 4.14. Vibration damper

- 4.15. Timing gear

- 4.16. Front cover

- 4.17. Camshaft

- 4.18. Valve system

- 4.19. Valve and valve guide

- 4.20. Rocker arm, shaft and tappet

- 4.21. Oil pump

- 4.22. Oil pan

- 4.23. Flywheel and flywheel housing

- 4.24. Oil filter

- 4.25. Oil cooler

- 4.26. Regulator valve and safety valve

- 4.27. Cylinder block

- 4.28. Fuel system diagram

- 4.29. Fuel supply pump

- 4.30. Fuel filter

- 4.31. Water pump drive and fan drive

- 4.32. Water pump

- 4.33. Alternator

- 4.34. Starting motor

- 4.35. Electric heater

- 5. Standard value table

- 5.1. Standard value table for testing, adjusting and troubleshooting

- 5.2. Runin standard and performance test criteria

- 6. Testing and adjusting

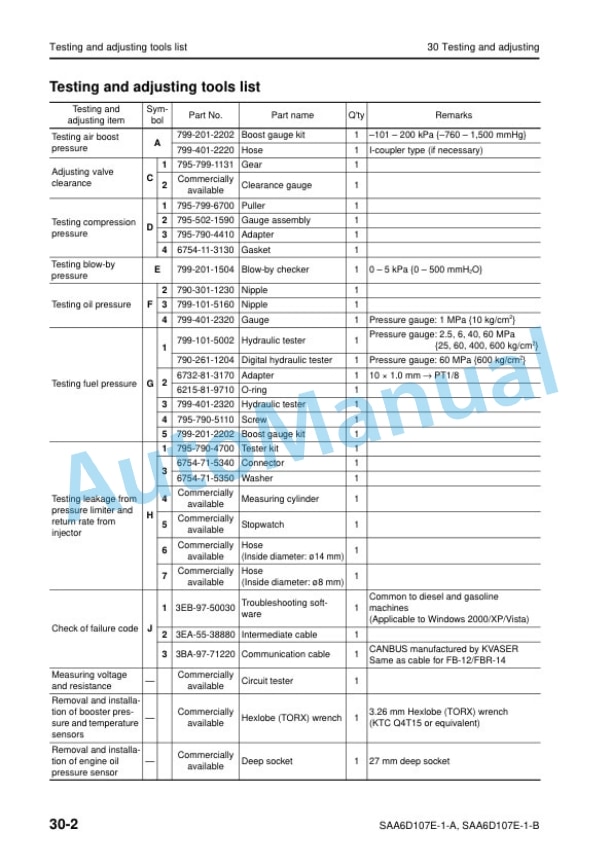

- 6.1. Testing and adjusting tools list

- 6.2. Testing air boost pressure

- 6.3. Adjustment of valve clearance

- 6.4. Testing compression pressure

- 6.5. Testing blowby pressure

- 6.6. Testing engine oil pressure

- 6.7. Handling fuel system parts

- 6.8. Releasing residual pressure in fuel system

- 6.9. Testing fuel pressure

- 6.10. Reduced cylinder mode operation

- 6.11. Noinjection cranking

- 6.12. Testing leakage from pressure limiter and return rate from injector

- 6.13. Bleeding air from fuel circuit

- 6.14. Testing fuel system for leakage

- 6.15. Replacing the fan belt

- 6.16. Handling controller highvoltage circuit

- 6.17. Functions of troubleshooting tool and check of failure code

- 7. Troubleshooting

- 7.1. Failure code table

- 7.2. Information in troubleshooting table

- 7.3. Method of using troubleshooting charts

- 7.4. S1 Starting performance is poor

- 7.5. S2 Engine does not start

- 7.6. S3 Engine does not pick up smoothly

- 7.7. S4 Engine stops during operations

- 7.8. S5 Engine does not rotate smoothly

- 7.9. S6 Engine lacks output (or lacks power)

- 7.10. S7 Exhaust smoke is black (incomplete combustion)

- 7.11. S8 Oil consumption is excessive (or exhaust smoke is blue)

- 7.12. S9 Oil becomes contaminated quickly

- 7.13. S10 Fuel consumption is excessive

- 7.14. S11 Oil is in coolant (or coolant spurts back or coolant level goes down)

- 7.15. S12 Oil pressure drops

- 7.16. S13 Oil level rises (Entry of coolant or fuel)

- 7.17. S14 Coolant temperature becomes too high (overheating)

- 7.18. S15 Abnormal noise is made

- 7.19. S16 Vibration is excessive

- 7.20. E1 Failure code 111 Abnormality in engine controller

- 7.21. E2 Failure code 115 Engine Ne or Bkup speed sensor error

- 7.22. E3 Failure code 122 Abnormally high level in charge pressure sensor

- 7.23. E4 Failure code 123 Abnormally low level in charge pressure sensor

- 7.24. E5 Failure code 131 Throttle sensor high error

- 7.25. E6 Failure code 132 Throttle sensor low error

- 7.26. E7 Failure code 143 (Torque derating by low engine oil pressure)

- 7.27. E8 Failure code 144 Abnormally high level in coolant temperature sensor

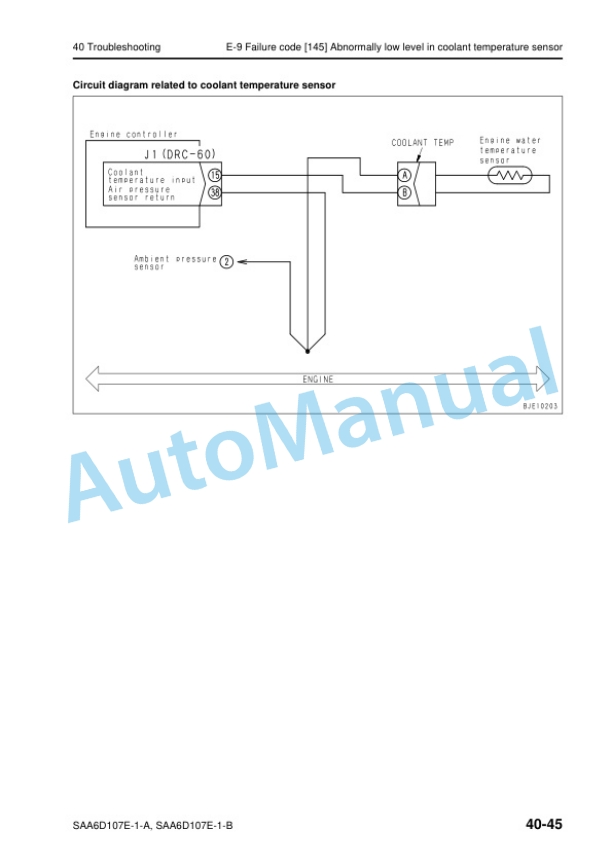

- 7.28. E9 Failure code 145 Abnormally low level in coolant temperature sensor

- 7.29. E10 Failure code 146 (Engine overheating)

- 7.30. E11 Failure code 153 Abnormally high level in charge temperature sensor

- 7.31. E12 Failure code 154 Abnormally low level in charge temperature sensor

- 7.32. E13 Failure code 187 Abnormally low level in sensor power supply 2

- 7.33. E14 Failure code 221 Abnormally high level in atmospheric pressure sensor

- 7.34. E15 Failure code 222 Abnormally low level in atmospheric pressure sensor

- 7.35. E16 Failure code 227 Abnormally high level in sensor power supply 2

- 7.36. E17 Failure code 234 Engine overspeed

- 7.37. E18 Failure code 238 Abnormally level in Ne speed sensor power supply

- 7.38. E19 Failure code 271 Short circuit in IMV

- 7.39. E20 Failure code 272 Disconnection in IMV

- 7.40. E21 Failure code 322 Disconnection, short circuit in injector No. 1 (L/B No. 1)

- 7.41. E22 Failure code 323 Disconnection, short circuit in injector No. 5 (L/B No. 5)

- 7.42. E23 Failure code 324 Disconnection, short circuit in injector No. 3 (L/B No. 3)

- 7.43. E24 Failure code 325 Disconnection, short circuit in injector No. 6 (L/B No. 6)

- 7.44. E25 Failure code 331 Disconnection, short circuit in injector No. 2 (L/B No. 2)

- 7.45. E26 Failure code 332 Disconnection, short circuit in injector No. 4 (L/B No. 4)

- 7.46. E27 Failure code 342 Matching error in engine controller data

- 7.47. E28 Failure code 351 Abnormality in injector drive circuit

- 7.48. E29 Failure code 352 Abnormally low level in sensor power supply 1

- 7.49. E30 Failure code 386 Abnormally high level in sensor power supply 1

- 7.50. E31 Failure code 415 (Rotation derating by low engine oil pressure)

- 7.51. E32 Failure code 418 Water mixed in fuel

- 7.52. E33 Failure code 428 Abnormally high level in water sensor

- 7.53. E34 Failure code 429 Abnormally low level in water sensor

- 7.54. E35 Failure code 431 Idle validation switch error

- 7.55. E36 Failure code 432 Idle validation action error

- 7.56. E37 Failure code 435 Abnormality in engine oil pressure switch

- 7.57. E38 Failure code 441 Abnormally low power supply voltage

- 7.58. E39 Failure code 442 Abnormally high power supply voltage

- 7.59. E40 Failure code 449 Abnormally high common rail pressure 2

- 7.60. E41 Failure code 451 Abnormally high level in common rail pressure sensor

- 7.61. E42 Failure code 452 Abnormally low level in common rail pressure sensor

- 7.62. E43 Failure code 488 Derating of torque by abnormally high charge temperature

- 7.63. E44 Failure code 553 Abnormally high common rail pressure 1

- 7.64. E45 Failure code 559 Nopressure feed by supply pump 1

- 7.65. E46 Failure code 689 Abnormality in engine Ne speed sensor

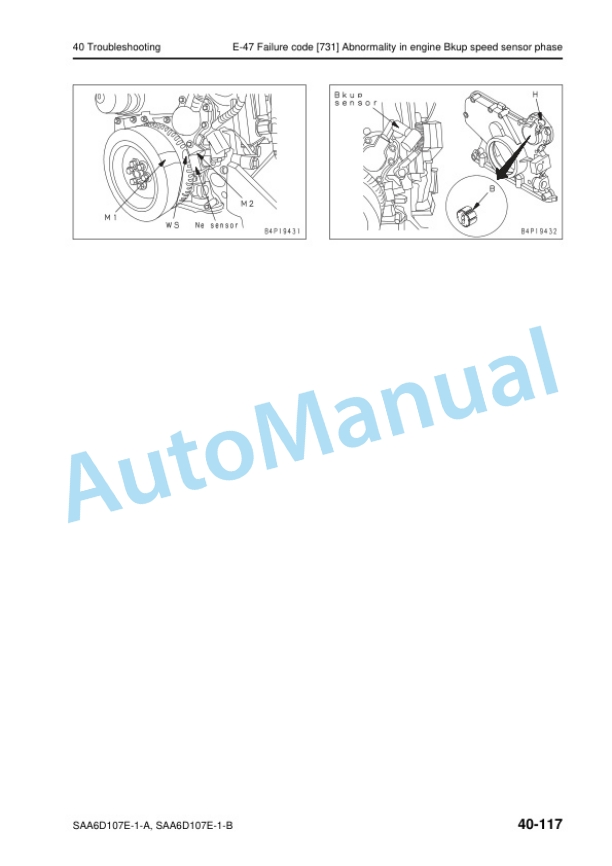

- 7.66. E47 Failure code 731 Abnormality in engine Bkup speed sensor phase

- 7.67. E48 Failure code 757 Loss of all data in engine controller

- 7.68. E49 Failure code 778 Abnormality in engine Bkup speed sensor

- 7.69. E50 Failure code 2185 Throttle sensor supply voltage high error

- 7.70. E51 Failure code 2186 Throttle sensor power supply low error

- 7.71. E52 Failure code 2249 Nopressure feed by supply pump 2

- 7.72. E53 Failure code 2311 Abnormality in IMV solenoid

- 7.73. E54 Failure code 2555 Disconnection in intake air heater relay

- 7.74. E55 Failure code 2556 Short circuit in intake air heater relay

- 8. Disassembly and assembly

- 8.1. How to read this manual

- 8.2. Coating materials list

- 8.3. Special tools list

- 8.4. General disassembly of engine

- 8.5. General assembly of engine

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF