- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu SK1020-5NA, SK1020-5N Skid Steer Loader Shop Manual CEBM013902

$40.00

- Type Of Manual: Shop Manual

- Manual ID: CEBM013902

- Format: PDF

- Size: 57.3MB

- Number of Pages: 370

Category: Komatsu Shop Manual PDF

-

Model List:

- SK1020-5NA Skid Steer Loader

- SK1020-5N Skid Steer Loader

- 1. COVER

- 1.1. CONTENTS

- 1.2. SAFETY

- 1.3. GENERAL

- 1.4. HOW TO READ THE SHOP MANUAL

- 1.5. HOISTING INSTRUCTIONS

- 1.6. MAINTENANCE STANDARD TERMINOLOGY

- 1.7. HANDLING ELECTRIC EQUIPMENT AND HYDRAULIC COMPONENTS

- 1.8. PUSH PULL COUPLER

- 1.9. COATING MATERIALS

- 1.10. STANDARD TIGHTENING TORQUE

- 1.11. SPECIFIC DRIVING TORQUE

- 1.12. ELECTRIC WIRE CODE

- 1.13. CONVERSION TABLES

- 2. FOREWORD

- 2.1. CONTENTS

- 2.2. SAFETY

- 2.3. GENERAL

- 2.4. HOW TO READ THE SHOP MANUAL

- 2.5. HOISTING INSTRUCTIONS

- 2.6. MAINTENANCE STANDARD TERMINOLOGY

- 2.7. HANDLING ELECTRIC EQUIPMENT AND HYDRAULIC COMPONENTS

- 2.8. PUSH PULL COUPLER

- 2.9. COATING MATERIALS

- 2.10. STANDARD TIGHTENING TORQUE

- 2.11. SPECIFIC DRIVING TORQUE

- 2.12. ELECTRIC WIRE CODE

- 2.13. CONVERSION TABLES

- 3. GENERAL

- 3.1. DIMENSION DRAWINGS

- 3.2. SPECIFICATIONS

- 3.3. WEIGHT TABLE

- 3.4. FUEL COOLANT AND LUBRICANTS

- 3.5. SERVICE NOTES

- 4. STRUCTURE, FUNCTION AND MAINTENANCE STANDARD

- 4.1. WORK EQUIPMENT PIVOT POINT CLEARANCES

- 4.2. WHEEL DRIVE SYSTEM

- 4.3. DRIVE MOTOR SYSTEM

- 4.4. HYDRAULIC PUMPS

- 4.5. SAFETY VALVES

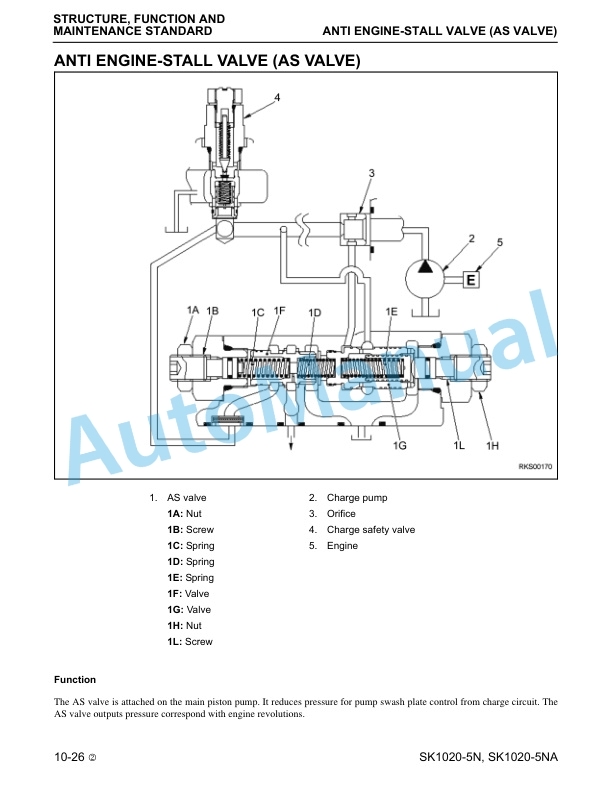

- 4.6. ANTI ENGINESTALL VALVE (AS VALVE)

- 4.7. CONTROL VALVES

- 4.8. CLOSED CENTER LOAD SENSING SYSTEM

- 4.9. SOLENOID VALVE

- 4.10. ACCUMULATOR

- 4.11. PATTERN CHANGE VALVE

- 4.12. PPC VALVE (STANDARD)

- 4.13. PPC VALVE (PATTERN CHANGE)

- 4.14. PPC VALVE (STANDARD)

- 4.15. PPC VALVE (PATTERN CHANGE)

- 4.16. CYLINDERS

- 5. STANDARD VALUE TABLES

- 5.1. STANDARD SERVICE VALUE TABLE

- 5.2. Standard Service Value Table for Engine

- 5.3. Standard Value Table for Chassis

- 6. TESTING AND ADJUSTING

- 6.1. SPECIAL TOOLS

- 6.2. TADAPTER PROCEDURES AND KITS

- 6.3. ENGINE COMPONENTS

- 6.4. ADJUSTING PPC VALVE PRESSURES

- 6.5. ADJUSTING SERVOCONTROL SAFETY SENSOR

- 6.6. CHAIN TENSION

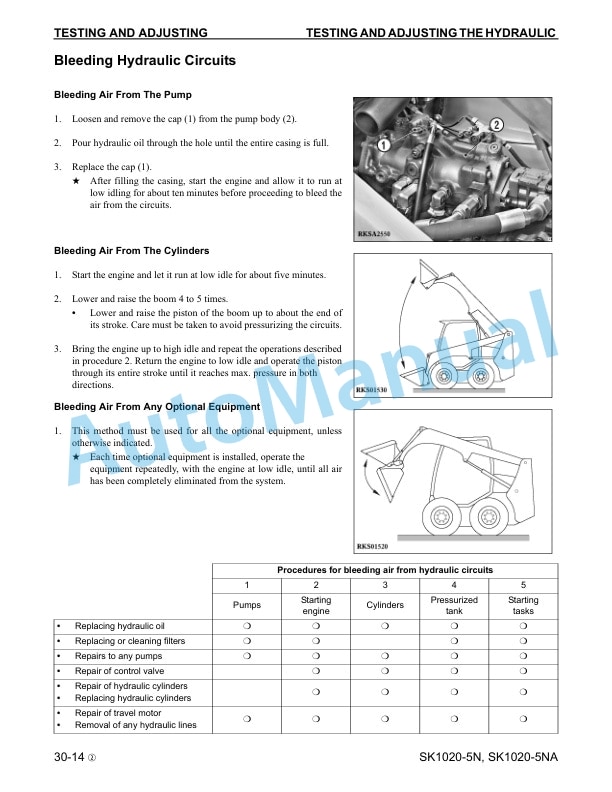

- 6.7. TESTING AND ADJUSTING THE HYDRAULIC SYSTEM

- 6.8. HYDRAULIC PUMP

- 6.9. CONTROL VALVE

- 6.10. AIR CONDITIONING SYSTEM

- 7. TROUBLESHOOTING

- 7.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 7.2. SEQUENCE OF EVENTS IN TROUBLESHOOTING

- 7.3. CHECKS BEFORE TROUBLESHOOTING

- 7.4. CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

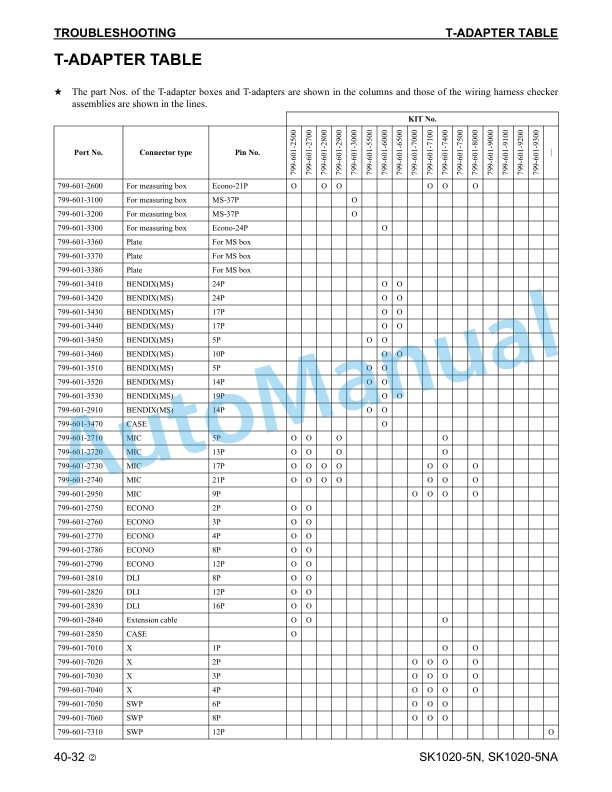

- 7.5. TADAPTER TABLE

- 7.6. ENGINE COOLANT TEMPERATURE SENSOR FAILURE

- 7.7. ABNORMAL ENGINE OIL PRESSURE INDICATED

- 7.8. AIR CLEANER CLOG INDICATED

- 7.9. ENGINE PREHEAT SYSTEM INOPERABLE

- 7.10. FUEL LEVEL INDICATION IS INCORRECT

- 7.11. FUEL PUMP MOTOR INOPERATIVE

- 7.12. ENGINE DOES NOT SHUT DOWN OR WILL NOT START

- 7.13. ALTERNATOR NOT CHARGING BATTERY

- 7.14. ENGINE WILL NOT CRANK

- 7.15. BACKUP ALARM WILL NOT FUNCTION

- 7.16. HYDRAULIC FILTER SENSOR WARNING

- 7.17. PPC SYSTEM ELECTRICAL MALFUNCTION

- 7.18. SEAT SAFETY SWITCH MALFUNCTION

- 7.19. SAFETY BAR SWITCH MALFUNCTION

- 7.20. TRAVEL SPEEDS CANNOT BE CHANGED

- 7.21. FLOAT CONTROL MALFUNCTION

- 7.22. PARKING BRAKE SYSTEM MALFUNCTION

- 7.23. PATTERN CHANGE MALFUNCTION

- 7.24. STABALIZER SYSTEM MALFUNCTION

- 7.25. LOW OR WEAK TRAVEL, WEAK BRAKEOUT FORCE

- 7.26. WEAK TRAVEL, WEAK BREAKOUT FORCE IN REVERSE

- 7.27. ROTATING BEACON INOPERABLE

- 7.28. REAR WORK LIGHTS WILL NOT OPERATE

- 7.29. HORN DOES NOT SOUND

- 7.30. POSSIBLE DEFECTIVE SAFETY RELAY UNIT

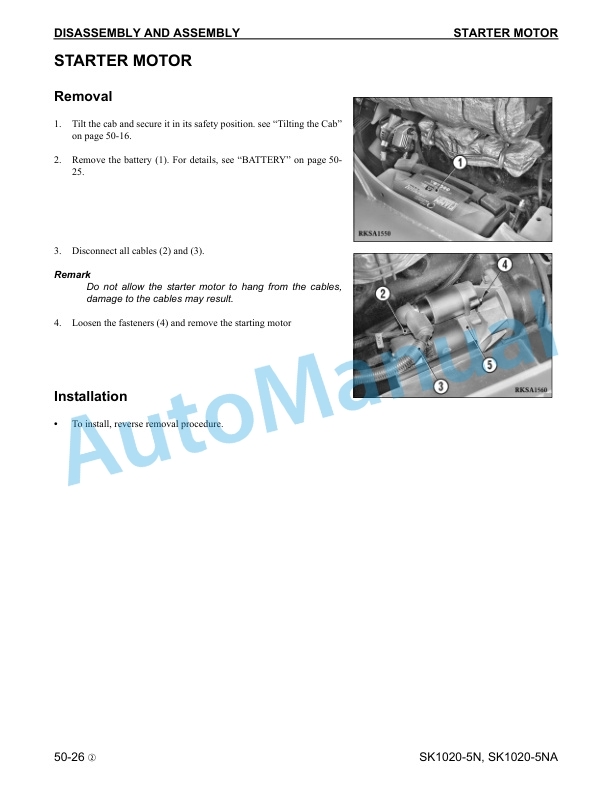

- 8. DISASSEMBLY AND ASSEMBLY

- 8.1. HOW TO READ THIS MANUAL

- 8.2. CONNECTOR REPAIR PROCEDURES

- 8.3. ENGINE

- 8.4. ENGINE HOOD ASSEMBLY

- 8.5. OPERATORS CAB ASSEMBLY

- 8.6. WORK EQUIPMENT SYSTEM

- 8.7. REMOVING EQUIPMENT SUPPORT FRAME

- 8.8. AIR FILTER ASSEMBLY

- 8.9. MUFFLER ASSEMBLY (SK10205N)

- 8.10. MUFFLER ASSEMBLY (SK10205N TURBO)

- 8.11. RADIATOR ASSEMBLY

- 8.12. FUEL TANK ASSEMBLY

- 8.13. ENGINEPUMP ASSEMBLY

- 8.14. HYDRAULIC PUMP ASSEMBLY

- 8.15. GEAR PUMP ASSEMBLY

- 8.16. ENGINEPUMP COUPLING

- 8.17. CAB HEATER ASSEMBLY

- 8.18. WHEEL HUB ASSEMBLY

- 8.19. FINAL DRIVE ASSEMBLY

- 8.20. LIFT AND BUCKET CYLINDERS

- 8.21. WORK EQUIPMENT CYLINDER OVERHAUL

- 8.22. MONITOR PANEL REPLACEMENT

- 9. OTHERS

- 9.1. ENGINE ELECTRICAL

- 9.2. FRAME LINE ELECTRICAL

- 9.3. FRAME LINE ELECTRICAL (OPTIONAL)

- 9.4. OPERATOR COMPARTMENT ELECTRICAL

- 9.5. OPERATOR COMPARTMENT ELECTRICAL (OPTIONAL)

- 9.6. TOP OPERATOR CAB ELECTRICAL

- 9.7. HYDRAULIC CIRCUIT

- 9.8. AIR CONDITIONER

Rate this product

You may also like

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF