- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu SK12SR-3 Shop Manual S5PA0013E01

$40.00

- Type Of Manual: Shop Manual

- Manual ID: S5PA0013E01

- Format: PDF

- Size: 46.2MB

- Number of Pages: 384

Category: Komatsu Shop Manual PDF

-

Model List:

- SK12SR-3

- 1. Cover

- 2. CONTENTS

- 3. General Cautions for Maintenance Work

- 3.1. Correct Work

- 3.2. Safety Precautions

- 3.3. Preparations

- 3.4. Cautions for Disassembly and Reassembly

- 3.5. Cautions for Removal and Installation of Hydraulic Equipment

- 3.6. Cautions for Removal and Installation of Hydraulic Piping

- 3.7. Cautions for Handling Seals

- 3.8. Correct Installation of Hydraulic Hose

- 3.9. Specifications of Hydraulic Hose

- 3.10. Air Release of Hydraulic Equipment

- 4. Technical Data

- 4.1. Specifications

- 4.2. Outline Drawing and Working Area

- 4.3. Weight List of Main Parts

- 4.4. Lifting Capacity List

- 5. Service Standards

- 5.1. Machine Performance

- 5.2. Engine

- 5.3. Undercarriage

- 5.3.1. Rubber Crawler Specifications

- 5.4. Controls

- 5.5. Hydraulic Equipment

- 5.5.1. Hydraulic Cylinders

- 5.6. Implement

- 5.6.1. Front Attachments

- 5.6.2. Blade Moving Device

- 5.6.3. Bucket Teeth

- 5.7. List of Tightening Torque

- 5.7.1. Machine

- 5.7.2. Engine

- 5.7.3. Tightening Torque for General Bolts and Nuts

- 6. Engine

- 6.1. Exploded View (General layouts of major engine components)

- 6.2. Measurement, Inspection and Adjustment

- 6.2.1. Measuring the Compression Pressure

- 6.2.2. Adjusting the Valve Clearance

- 6.2.3. Checking the Vbelt Tension

- 6.2.4. Checking the Fuel Injection Valve

- 6.2.5. Checking and Adjusting Fuel Injection Timing

- 6.2.6. Adjusting the Maximum (or Minimum) Idling Speed

- 6.2.7. Checking the Cooling Water System and Radiator for Water Leakage

- 6.2.8. Checking the Sensors

- 6.3. Measurement Procedure, Service Data and Corrective Action

- 6.3.1. Cylinder Head

- 6.3.2. Cylinder Block

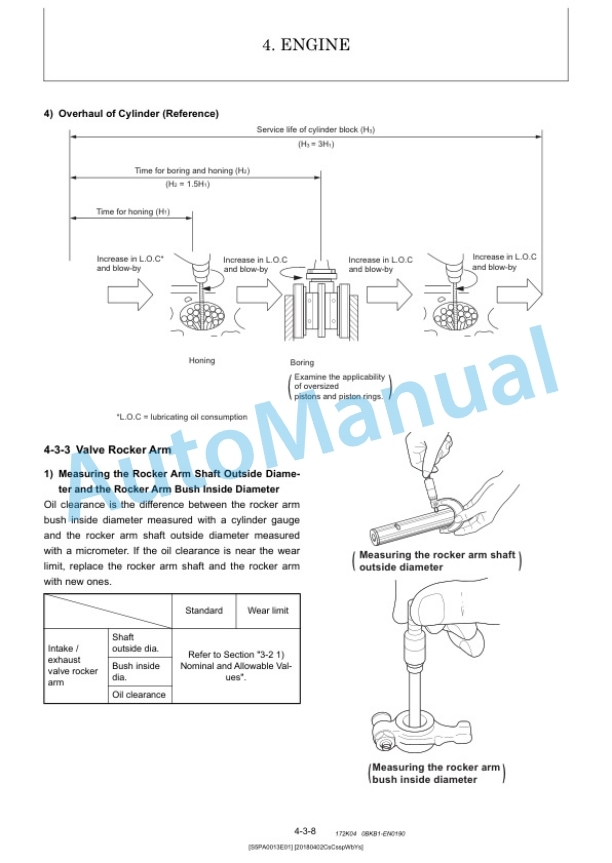

- 6.3.3. Valve Rocker Arm

- 6.3.4. Piston and Piston Rings

- 6.3.5. Connecting Rod

- 6.3.6. Cam shaft

- 6.3.7. Crank shaft

- 6.3.8. Gears

- 6.3.9. Trochoid Pump

- 6.4. Precautions for Reassembly

- 6.5. Electrical Equipment

- 6.5.1. Starter Motor

- 6.5.2. Alternator

- 7. Hydraulic System

- 7.1. Outline

- 7.1.1. Control Valve Operation

- 7.2. Hydraulic Circuit Schematic

- 7.3. Circuit Operation

- 7.3.1. Boom

- 7.3.3. Bucket

- 7.3.4. Swing

- 7.3.5. Boom Swing

- 7.3.6. Blade

- 7.3.7. Travel

- 7.3.8. Track Gauge Change

- 7.3.9. Simultaneous Operation of Travel and Blade

- 7.3.10. Simultaneous Operation of Boom Up and Bucket

- 7.3.11. Hydraulic P.T.O.

- 7.3.12. Safety Lock

- 7.4. Pressure Adjustment

- 7.4.1. System Relief Valves

- 7.4.2. Circuit Relief Valves

- 7.4.3. Swing Brake Valve

- 7.4.4. CutOff Valve

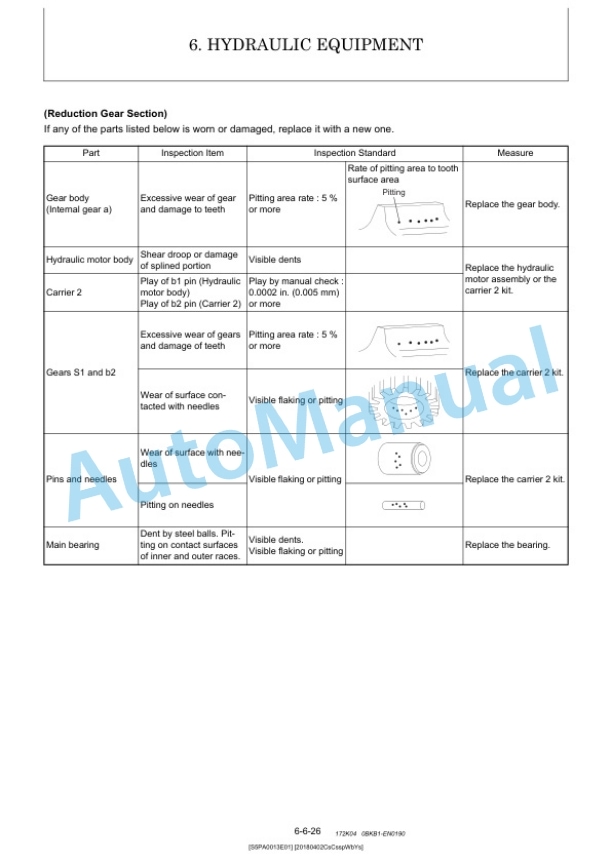

- 8. Hydraulic Equipment

- 8.1. Hydraulic Pump

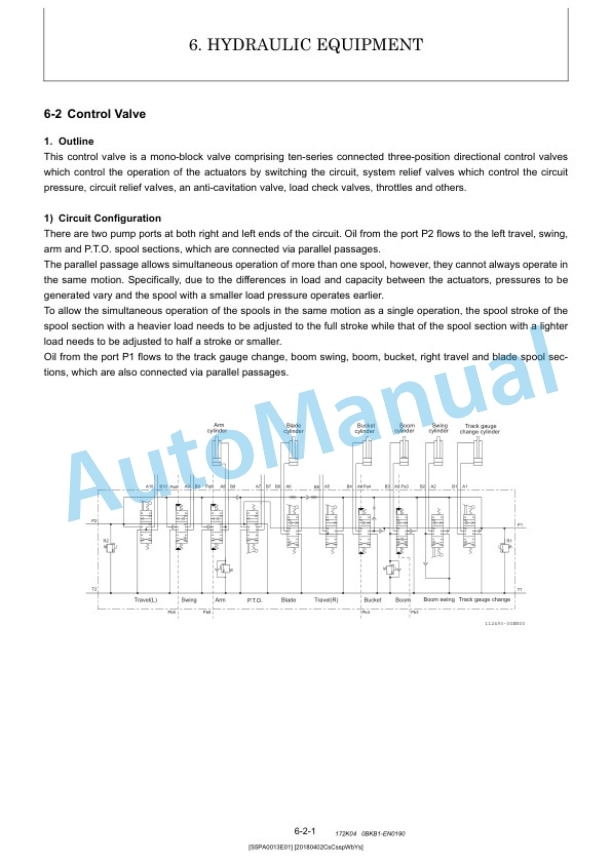

- 8.2. Control Valve

- 8.3. Pilot Valve

- 8.4. Cutoff Valve

- 8.5. Swing Motor

- 8.6. Travel Motor

- 8.7. Solenoid Valve

- 9. Adjustment and Repair

- 9.1. Electrical Equipment and Engine of Machine

- 9.1.1. Parts Layout of Electrical Equipment

- 9.1.2. Monitor and Alarm Systems

- 9.1.3. Wiring Diagram

- 9.1.4. Circuit Description of Engine Start and Stop

- 9.1.5. Removal and Reinstallation of Engine

- 9.1.6. Removal and Reinstallation of Starter Motor

- 9.1.7. Removal and Reinstallation of Fuel Injection Pump

- 9.1.8. Removal and Reinstallation of Fuel Tank

- 9.1.9. Removal and Reinstallation of Radiator

- 9.2. Undercarriage

- 9.2.1. Outline

- 9.2.2. Points of Reassembly

- 9.2.3. Removal and Reinstallation of Crawler

- 9.2.4. Disassembly and Reassembly of Idler

- 9.2.5. Disassembly and Reassembly of Track Roller

- 9.2.6. Removal and Reinstallation of Track Gauge Change Cylinder

- 9.3. Controls

- 9.3.1. Control Train

- 9.3.2. Mechanical Control Linkage

- 9.3.3. Adjustment of Travel and Blade Levers

- 9.3.4. Adjustment of Boom Swing and P.T.O. Pedals and P.T.O. Pedal Lock

- 9.3.5. Lock Lever Switches

- 9.3.6. Adjustment of Travel Lever Lock

- 9.3.7. Adjustment of Accelerator Lever

- 9.4. Swing Bearing

- 9.4.1. Removal and Reinstallation of Swing Bearing

- 9.5. Hydraulic Equipment

- 9.5.1. Removal and Reinstallation of Hydraulic Oil Pump

- 9.5.2. Removal and Reinstallation of Control Valve

- 9.5.3. Removal and Reinstallation of Swing Motor

- 9.5.4. Removal and Reinstallation of Swivel Joint

- 9.5.5. Disassembly and Reassembly of Swivel Joint

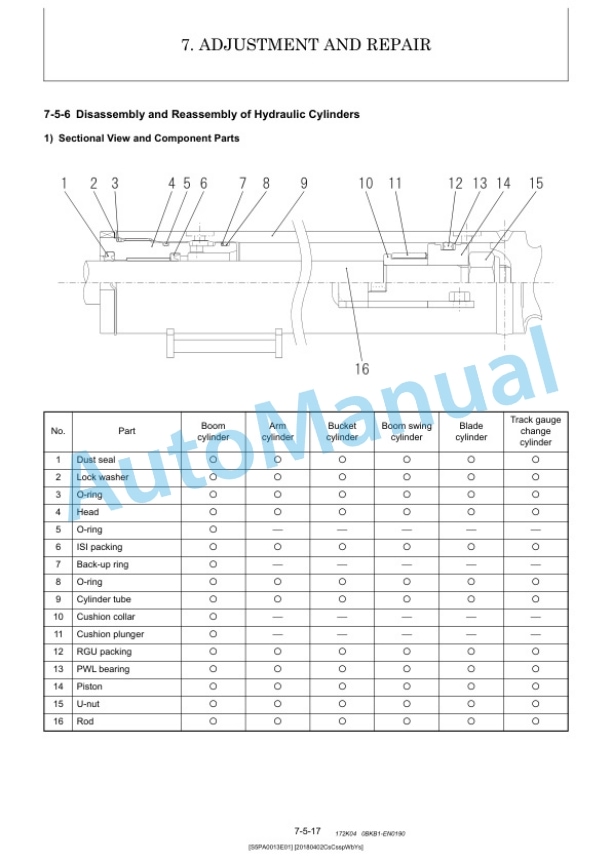

- 9.5.6. Disassembly and Reassembly of Hydraulic Cylinders

- 9.5.7. Removal and Reinstallation of Boom Swing Cylinder

- 9.5.8. Removal and Reinstallation of Hydraulic Oil Tank

- 9.5.9. Piping Layout

- 9.6. Implement

- 9.6.1. Removal and Reinstallation of Implement

- 10. Periodic Inspection and Servicing

- 10.1. List of Periodic Inspection and Servicing

- 11. Fuel, Lube Oil and Grease Recommended

- 12. Troubleshooting

- 12.1. NonBreakdowns

- 12.1.1. Natural Release of Bucket

- 12.1.2. Discontinuous Arm Movement

- 12.1.3. Drifting of Upperstructure on Quick Travel Operation

- 12.1.4. Thermal Shock of Travel Motor

- 12.1.5. Change of Blade Speed in Loaded Condition

- 12.1.6. Time Lag on Travel Speed Switching

- 12.1.7. Fluctuation in Oil Level of Hydraulic Oil Tank Due to Temperature Change

- 12.2. Troubleshooting

- 12.2.1. Machine and Engine

- 12.2.2. Electrical Equipment on Panel

- 13. Reference Data

- 13.1. Specifications for Attachment

Rate this product

You may also like

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF