- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu SK820-5N Skid Steer Loader Shop Manual CEBM016001

$40.00

- Type Of Manual: Shop Manual

- Manual ID: CEBM016001

- Format: PDF

- Size: 27.8MB

- Number of Pages: 365

Category: Komatsu Shop Manual PDF

-

Model List:

- SK820-5N Skid Steer Loader

- 0.0.0.1. IMPORTANT SAFETY NOTICE

- 0.0.0.2. General Precautions

- 0.0.0.3. Preparations For Work

- 0.0.0.4. Precautions During Work

- 0.1. GENERAL

- 0.2. HOW TO READ THE SHOP MANUAL

- 0.2.1. Volumes

- 0.2.2. Distribution And Updating

- 0.2.3. Filing Method

- 0.2.4. Revised Edition Mark

- 0.2.5. Revisions

- 0.2.6. Symbols

- 0.3. HOISTING INSTRUCTIONS

- 0.3.1. Hoisting

- 0.3.2. Wire Ropes

- 0.4. COATING MATERIALS

- 0.5. STANDARD TIGHTENING TORQUE

- 0.5.1. Bolts And Nuts Standard Tightening Torque

- 0.5.2. Hose Nuts Tightening Torque

- 0.5.3. Split Flange Bolts Tightening Torque

- 0.5.4. Tightening Torque For Flared Nuts

- 0.5.5. Tightening Torque For Flared Nuts

- 0.5.6. Oring Boss Piping Joints Tightening Torque

- 0.5.7. Oring Boss Plugs Tightening Torque

- 0.5.8. Hoses (Taper Seal Type And Face Seal Type) Tightening Torque

- 0.6. SPECIFIC DRIVING TORQUE

- 0.7. ELECTRIC WIRE CODE

- 0.7.1. Classification By Thickness

- 0.7.2. Classification By Color And Code

- 0.8. CONVERSION TABLES

- 0.8.1. Method Of Using The Conversion Table

- 0.9. PUSHPULL TYPE COUPLER

- 1. GENERAL

- 1.1. WEIGHT TABLE

- 1.2. FUEL COOLANT AND LUBRICANTS

- 1.3. SERVICE NOTES

- 1.3.1. Homologated Synthetic Biodegradable Lubricants Type HEES

- 2. STRUCTURE, FUNCTION AND MAINTENANCE STANDARD

- 2.0.1. HST pump LPV40 40 (Standard)

- 2.0.2. HST pump LPV40 40 (High Flow)

- 2.0.3. Suction Safety Valve

- 2.0.4. Charge Safety Valve

- 2.0.5. Charge Pump

- 2.1. ANTIENGINE STALL CONTROL VALVE (AS VALVE)

- 2.2. SHUTTLE VALVE

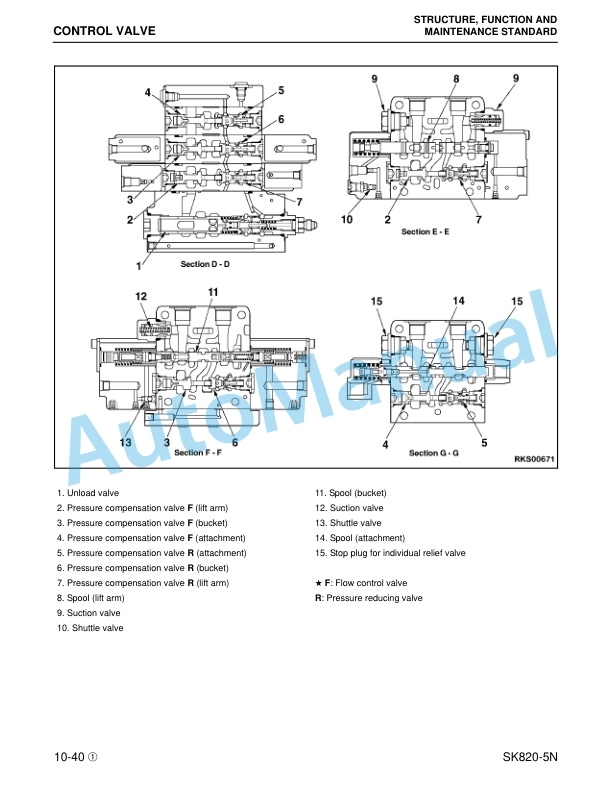

- 2.3. CONTROL VALVE

- 2.3.1. Standard (3Spool)

- 2.3.2. Super Highflow (4Spool)

- 2.4. CLSS

- 2.5. SOLENOID VALVE

- 2.5.1. Solenoid Valve Group ST1

- 2.5.2. Solenoid Valve ST2

- 2.6. ACCUMULATOR

- 2.7. PATTERN CHANGE VALVE

- 2.7.1. Pattern ISO

- 2.7.2. Pattern Optional

- 2.8. PPC VALVE (STANDARD)

- 2.8.1. Equipment Control

- 2.9. PPC VALVE (PATTERN CHANGE)

- 2.9.1. Equipment And Travel Control

- 2.10. PPC VALVE (STANDARD)

- 2.10.1. Travel Control

- 2.11. PPC VALVE (PATTERN CHANGE)

- 2.11.1. Work Equipment and Travel Control

- 2.12. CYLINDER

- 2.12.1. Lift Arm

- 2.12.2. Bucket

- 2.13. WORKING EQUIPMENT

- 3. STANDARD VALUE TABLES

- 3.1. STANDARD TECHNICAL DATA

- 3.1.1. Engine

- 3.1.2. Machine

- 4. TESTING AND ADJUSTING

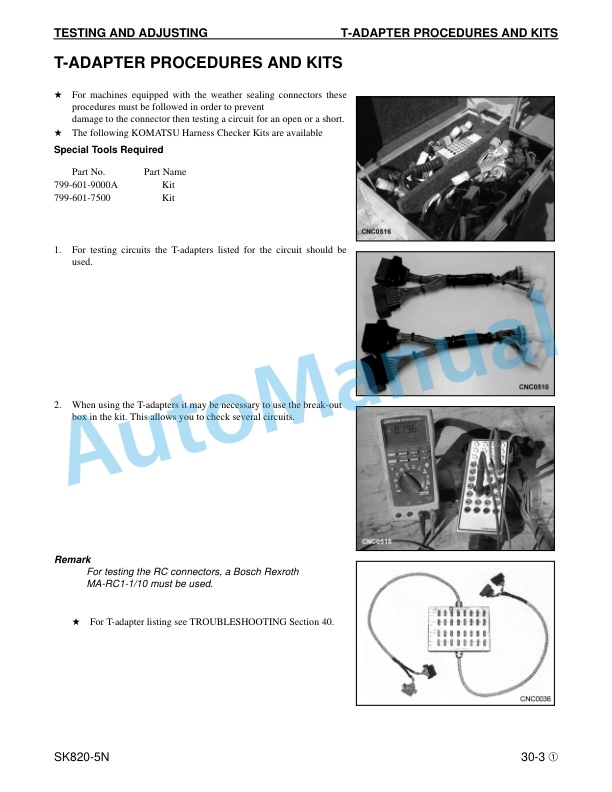

- 4.1. TADAPTER PROCEDURES AND KITS

- 4.2. SPECIAL TOOLS

- 4.3. ENGINE

- 4.3.1. Engine Speed

- 4.3.2. Valve Clearance

- 4.3.3. Compression Pressure

- 4.3.4. Fan Belt

- 4.3.5. Injection Timing

- 4.3.5.1. Checking

- 4.3.5.2. Adjusting

- 4.3.6. Oil Pressure

- 4.4. ACCELERATOR CABLES

- 4.4.1. Adjusting The Stroke

- 4.5. PPC VALVES

- 4.5.1. Drive Pressure

- 4.5.2. Valve Clearance Adjustment

- 4.6. SERVOCONTROL SAFETY SENSOR

- 4.6.1. Adjusting The Engagement Position

- 4.7. GEARING CHAIN

- 4.7.1. Testing And Adjusting Tension

- 4.8. HYDRAULIC CIRCUITS

- 4.8.1. Control And Regulation Of Pressures

- 4.8.2. Hydraulic Pump

- 4.8.3. Valve Calibration

- 4.8.3.1. HST Valve

- 4.8.3.2. AS Valve

- 4.8.4. Travel Deviation

- 4.8.5. Control Valve

- 4.8.6. ServoControl Power Supply

- 4.8.7. Elimination Of Residual Pressures

- 4.8.8. Hydraulic Tank Pressurization

- 4.8.9. Bleeding Air From The Hydraulic Circuits

- 4.8.9.1. Bleeding air from the pump

- 4.8.9.2. Bleeding air from the cylinders

- 4.8.9.3. Bleeding air from any optional equipment

- 5. TROUBLESHOOTING

- 5.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 5.2. SEQUENCE OF EVENTS IN TROUBLESHOOTING

- 5.3. PRECAUTIONS WHEN CARRYING OUT MAINTENANCE

- 5.3.1. Precautions When Handling Electrical Equipment

- 5.3.2. Handling Control Box

- 5.3.3. Points To Remember When Troubleshooting Electrical Circuits

- 5.3.4. Points To Remember When Handling Hydraulic Equipment

- 5.4. CHECKS BEFORE TROUBLESHOOTING

- 5.4.1. Using Troubleshooting Charts

- 5.5. CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

- 5.6. TADAPTER TABLE

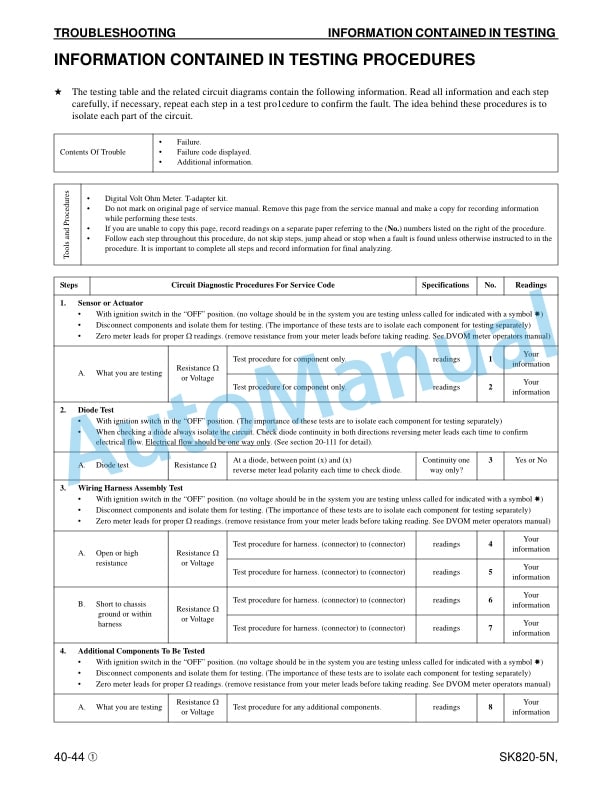

- 5.7. INFORMATION CONTAINED IN TESTING PROCEDURES

- 5.8. BASIC AIR CONDITIONING SYSTEM (TYPICAL)

- 5.8.1. Operator Cab Air Conditioning

- 5.8.2. Principles of Refrigeration

- 5.8.2.1. Air Conditioning

- 5.8.2.2. The Act of Cooling

- 5.8.2.3. The Refrigeration Cycle

- 5.8.3. Air Conditioner System Components

- 5.8.3.1. Compressor (Refrigerant Pump)

- 5.8.3.2. Service Valves

- 5.8.3.3. Condenser

- 5.8.3.4. ReceiverDrier

- 5.8.3.5. Thermostatic Expansion Valve

- 5.8.3.6. Evaporator

- 5.8.4. Electrical Circuit

- 5.8.4.1. Thermostat

- 5.8.4.2. Compressor Clutch

- 5.8.4.3. Safety Switches

- 5.8.5. System Servicing

- 5.8.6. R134A Refrigerant Containers

- 5.8.7. Service Tools And Equipment

- 5.8.7.1. Recovery/Recycle Station

- 5.8.7.2. Leak Detector

- 5.8.7.3. Service Valves

- 5.8.7.4. Vacuum Pump

- 5.8.7.5. Manifold Gauge Set

- 5.8.8. Installing Manifold Gauge Set

- 5.8.9. Purging Air from Service Hoses

- 5.8.10. Adding Refrigerant to the System (Without a Charging Station)

- 5.8.11. Stabilizing the AC System

- 5.8.12. Adding Refrigerant and Stabilizing the System (With a Recovery/Recycling Station)

- 5.8.13. Recovering and Recycling the Refrigerant

- 5.8.13.1. Performing the Recovery Cycle

- 5.8.13.2. Performing the Recycling Procedure

- 5.8.13.3. Evacuating and Charging the AC System

- 5.8.14. System Performance Test

- 5.8.15. System Leak Testing

- 5.8.15.1. Electronic Leak Detector

- 5.8.15.2. Tracer Dyes

- 5.8.15.3. Soap and Water

- 5.8.16. System Repair

- 5.8.16.1. Hoses and Fittings

- 5.8.16.2. Lines

- 5.8.16.3. Expansion Valve

- 5.8.16.4. ReceiverDrier

- 5.8.16.5. Thermostat

- 5.8.16.6. Clutch

- 5.8.16.7. Compressor

- 5.8.17. Checking Compressor Oil Level

- 5.8.18. Evacuating The System

- 5.8.19. Troubleshooting Air Conditioning System

- 5.8.19.1. PreDiagnosis Checks

- 5.8.19.2. Preparing for Diagnosis

- 5.8.19.3. Preliminary Steps

- 5.8.19.4. System Performance Test

- 5.8.19.5. Diagnosis of Gauge Readings and System Performance

- 5.8.19.6. Troubleshooting by Manifold Gauge Set Readings

- 5.8.20. Preventive Maintenance Schedule for A/C System

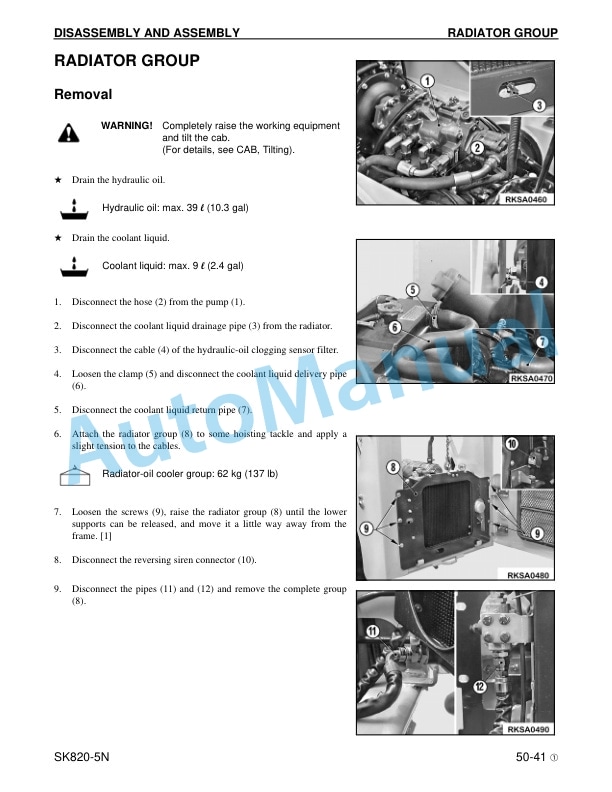

- 6. DISASSEMBLY AND ASSEMBLY

- 6.1. METHOD OF USING MANUAL

- 6.2. PRECAUTIONS DURING OPERATION

- 6.2.1. Precautions When Carrying Out Removal Work

- 6.2.2. Precautions When Carrying Out Installation Work

- 6.2.3. Precautions When Completing The Operations

- 6.2.4. Other Precautions

- 6.3. CONNECTOR REPAIR PROCEDURES

- 6.3.1. Stripping Insulation

- 6.3.2. Wire Inspection

- 6.3.3. Contact Terminal Removal (HD30 Type)

- 6.3.4. Crimping Contact Terminal (HD30 Type)

- 6.3.5. Insertion Of Contact Terminal (HD30 Type)

- 6.3.6. Contact Terminal Removal (DT Type)

- 6.3.7. Crimping Contact Terminal (DT Type)

- 6.3.8. Insertion Of Contact Terminal (DT Type)

- 6.4. AIR INTAKE FILTER

- 6.5. COOLANT LIQUID PUMP

- 6.6. ENGINE PUMP GROUP

- 6.7. ENGINEPUMP COUPLING

- 6.8. WORKING EQUIPMENT

- 6.9. WORKING EQUIPMENT COUPLER

- 6.9.1. Removal

- 6.9.2. Installation

- 7. DIAGRAMS AND SCHEMATICS

- 7.1. ELECTRICAL DIAGRAM

- 7.1.1. ENGINE LINE (1/2)

- 7.1.2. ENGINE LINE (2/2)

- 7.1.3. FRAME LINE STANDARD (1/2)

- 7.1.4. FRAME LINE STANDARD (2/2)

- 7.1.5. FRAME LINE OPTIONAL (1/2)

- 7.1.6. FRAME LINE OPTIONAL (2/2)

- 7.1.7. CABIN LINE STANDARD (1/4)

- 7.1.8. CABIN LINE STANDARD (2/4)

- 7.1.9. CABIN LINE STANDARD (3/4)

- 7.1.10. CABIN LINE STANDARD (4/4)

- 7.1.11. CABIN LINE OPTIONAL (1/6)

- 7.1.12. CABIN LINE OPTIONAL (2/6)

- 7.1.13. CABIN LINE OPTIONAL (3/6)

- 7.1.14. CABIN LINE OPTIONAL (4/6)

- 7.1.15. CABIN LINE OPTIONAL (5/6)

- 7.1.16. CABIN LINE OPTIONAL (6/6)

- 7.1.17. TOPCABIN LIGHT LINE STANDARD (1/2)

- 7.1.18. TOPCABIN LIGHT LINE STANDARD (2/2)

- 7.1.19. TOPCABIN LIGHT LINE HOMOLOGATION (1/2)

- 7.1.20. TOPCABIN LIGHT LINE HOMOLOGATION (2/2)

- 7.1.21. REAR LIGHT LINE (1/2)

- 7.1.22. REAR LIGHT LINE (2/2)

- 7.1.23. HIGH FLOW (1/3)

- 7.1.24. HIGH FLOW (2/3)

- 7.1.25. HIGH FLOW (3/3)

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00

Komatsu Shop Manual PDF

$40.00

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF