- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu TD-7H Crawler Tractor Operation and Maintenance Manual CEAM470010

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: CEAM470010

- Format: PDF

- Size: 2.5MB

- Number of Pages: 108

-

Model List:

- TD-7H Crawler Tractor

- 1. MAIN MENU

- 2. COVER

- 3. CONTENTS

- 4. SECTION 1 SAFETY PRECAUTIONS

- 4.1. SAFETY PRECAUTIONS

- 4.1.1. GENERAL

- 4.1.2. BEFORE STARTING THE ENGINE

- 4.1.3. OPERATION

- 4.1.4. MAINTENANCE

- 4.1.5. PRESSURIZED HYDRAULIC RESERVOIR

- 4.1.6. SHUT DOWN

- 4.2. SAFETY PRODUCT GRAPHICS AND LOCATION

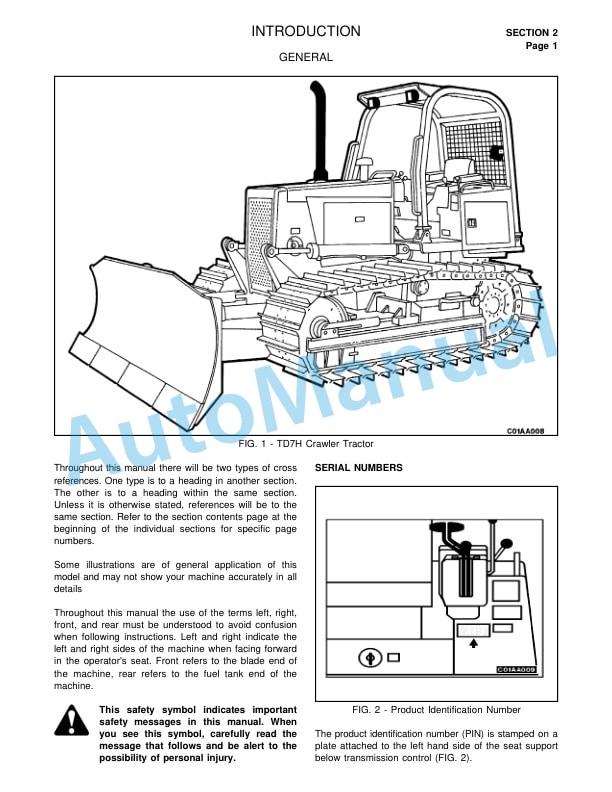

- 5. SECTION 2 INTRODUCTION

- 5.1. GENERAL

- 5.1.1. SERIAL NUMBERS

- 5.2. MACHINE TRANSPORT

- 5.2.1. SHIPPING INSTRUCTIONS

- 5.2.1.1. GENERAL

- 5.2.1.2. TRUCK

- 5.2.1.3. RAILROAD FLATCAR

- 5.2.1.4. MOVING A DISABLED MACHINE

- 5.3. MACHINE STORAGE

- 5.3.1. PREPARING FOR STORAGE

- 5.3.2. SERVICING ENGINE DURING STORAGE

- 5.3.2.1. ONEMONTH REPETITIVE SERVICE PERIOD

- 5.3.2.2. SIXMONTH REPETITIVE SERVICE PERIOD

- 5.3.3. PREPARING FOR OPERATION

- 5.3.4. THEFT DETERRENT PRACTICES

- 5.3.4.1. ACTION TO DISCOURAGE THEFT AND VANDALISM

- 5.3.4.2. ACTIONS TO AIR IN RECOVERY OF STOLEN MACHINES

- 6. SECTION 3 OPERATING

- 6.1. MACHINE PRECAUTIONS

- 6.2. UNIVERSAL SYMBOLS

- 6.3. INSTRUMENT PANEL

- 6.3.1. GENERAL

- 6.3.2. HOURMETER

- 6.3.3. TRANSMISSION OIL FILTER WARNING LIGHT

- 6.3.4. ENGINE COOLANT TEMPERATURE GAUGE

- 6.3.5. ENGINE OIL PRESSURE GAUGE

- 6.3.6. ILLUMINATION LAMP

- 6.3.7. ETHER START SWITCH

- 6.3.8. VOLTMETER

- 6.3.9. DRIVE TRAIN OIL TEMPERATURE GAUGE

- 6.3.10. HYDRAULIC OIL FILTER WARNING LIGHT

- 6.3.11. AIR CLEANER SERVICE LIGHT

- 6.3.12. WORK LIGHT SWITCH

- 6.3.13. HORN BUTTON

- 6.3.14. WARNING LIGHT BULB CHECK

- 6.4. CONTROLS

- 6.4.1. STATIC SEAT

- 6.4.2. SUSPENSION SEAT

- 6.4.3. SEAT BELT

- 6.4.4. ARM RESTS

- 6.4.5. ENGINE SPEED AND SHUT DOWN LEVER

- 6.4.6. TRANSMISSION NEUTRAL LOCK LEVER

- 6.4.7. TRANSMISSION SHIFT LEVER

- 6.4.8. HAND STEERING LEVERS

- 6.4.9. FOOT STEERING PEDALS

- 6.4.10. BRAKE AND DECELERATOR PEDAL

- 6.4.11. BRAKE PEDAL LOCK

- 6.4.12. ELECTRICAL SYSTEM MASTER SWITCH

- 6.4.13. BLADE CONTROL LEVER

- 6.4.14. REAR EQUIPMENT CONTROL LEVER

- 6.5. STARTING THE ENGINE

- 6.6. STOPPING THE ENGINE

- 6.7. DRIVING THE MACHINE

- 6.7.1. SHIFTING THE TRANSMISSION

- 6.7.2. CONVERTER OVERHEATING

- 6.7.3. STEERING THE MACHINE

- 6.7.4. LOCKING BOTH TRACKS

- 6.7.5. DOWNGRADE OPERATION

- 6.7.6. OPERATING OVER AN OBSTRUCTION

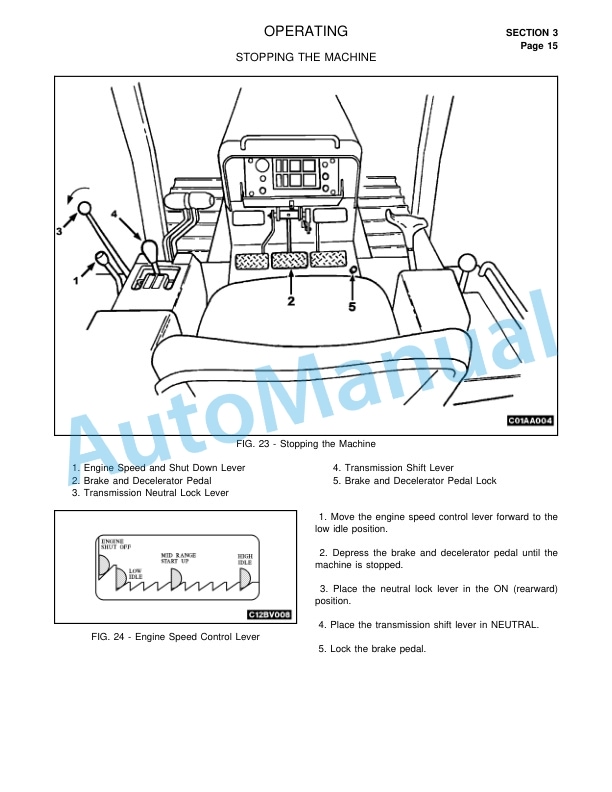

- 6.8. STOPPING THE MACHINE

- 6.9. PARKING THE MACHINE

- 6.10. MOUNTED EQUIPMENT

- 6.10.1. BLADE LEFT TILT

- 6.10.2. BLADE RIGHT TILT

- 6.10.3. BLADE LEFT ANGLE

- 6.10.4. BLADE RIGHT ANGLE

- 6.10.5. RIPPER CONTROL LEVER

- 6.10.5.1. LOWER

- 6.10.5.2. HOLD

- 6.10.5.3. RAISE

- 6.11. OPERATING TEQHNIQUES

- 6.11.1. GENERAL

- 6.11.2. DIGGING AND CLEARING

- 6.11.3. TRANSPORTING, LOADING OR PILING

- 6.11.4. BREAKING PILES AND SPREADING

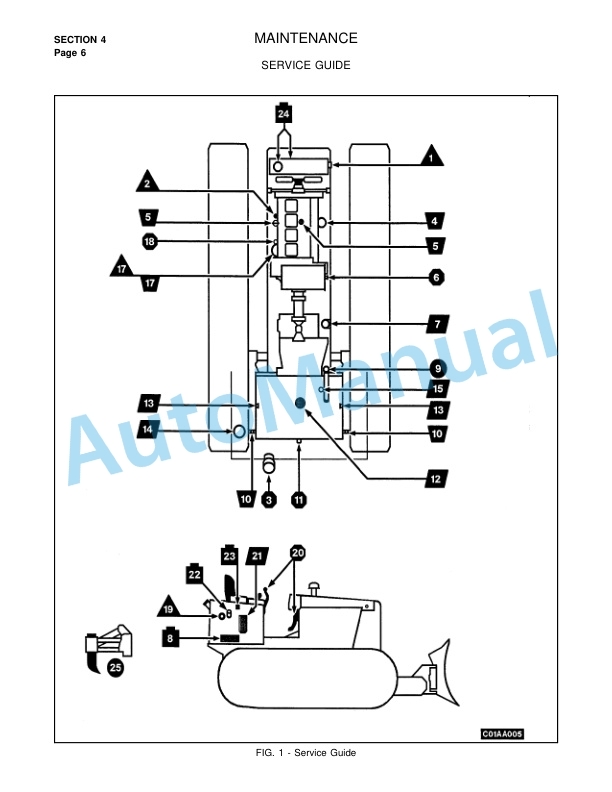

- 7. SECTION 4 MAINTENANCE

- 7.1. WORK SAFELY FOLLOW THESE RULES

- 7.2. SERVICE PRECAUTIONS

- 7.3. SCHEDULED MAINTENANCE GUIDE

- 7.4. REFILL SPECIFICATION AND CAPACITIES

- 7.5. SEASONAL PREPARATION

- 7.5.1. GENERAL

- 7.5.2. OUTSIDE SOURCE OF HEAT

- 7.5.3. LUBRICATION

- 7.5.4. FUEL SYSTEM

- 7.5.5. COOLING SYSTEM

- 7.5.6. ELECTRICAL SYSTEM

- 7.6. AIR CLEANING SYSTEM

- 7.6.1. AIR CLEANER

- 7.6.2. PRECUATIONS

- 7.6.3. PRIMARY FILTER ELEMENT

- 7.6.4. SAFETY FILTER ELEMENT

- 7.6.4.1. SERVICE

- 7.6.4.2. REMOVAL

- 7.6.5. PRECLEANER

- 7.6.6. DUST VACUATOR VALVE

- 7.7. BELTS

- 7.7.1. GENERAL

- 7.7.2. ALTERNATOR AND FAN BELT

- 7.7.2.1. CHECKING TENSION

- 7.7.3. INHIBITORS/CONDITIONERS

- 7.7.3.1. MAINTENANCE OF COOLING SYSTEM INHIBITORS

- 7.7.3.2. COOLANT TESTINGFOR CONDITIONER CONCENTRATION

- 7.7.3.3. REPLENISHING THE COOLANT CONDITIONER

- 7.7.4. RADIATOR CAP

- 7.7.4.1. GENERAL

- 7.7.4.2. REMOVAL

- 7.7.4.3. INSTALLATION

- 7.7.5. CHECKING COOLANT LEVEL

- 7.7.6. DRAINING THE SYSTEM

- 7.7.7. CLEANING THE SYSTEM

- 7.7.8. FILLING THE SYSTEM

- 7.7.9. REFILLING AN OVERHEATED SYSTEM

- 7.7.10. CLEANING THE RADIATOR

- 7.7.11. THERMOSTAT

- 7.7.12. REVERSIBLE FAN (IF EQUIPPED)

- 7.7.13. CIRCUIT BREAKERS

- 7.7.14. BATTERIES

- 7.7.14.1. GENERAL

- 7.7.14.2. MAINTENANCE

- 7.7.14.3. CLEANING THE BATTERIES

- 7.7.14.4. LIQUID LEVEL CONVENTIONAL BATTERY

- 7.7.14.5. CHARGING FULLY DISCHARGE MAINTENANCE FREE BATTERY

- 7.7.15. ENGINE

- 7.7.15.1. CHECKING THE CRANKCASE OIL LEVEL

- 7.7.15.2. CHANGING THE CRANKCASE OIL

- 7.7.15.3. CHANGING THE LUBRICATING OIL FILTERS

- 7.7.16. ETHER START

- 7.7.16.1. PRECAUTIONS

- 7.7.16.2. INSPECTIONS AND CLEANING

- 7.7.16.3. CHANGING THE FLUID CONTAINER

- 7.7.17. FUEL SYSTEM

- 7.7.17.1. GENERAL

- 7.7.17.2. DIESEL FUEL SPECIFICATIONS

- 7.7.17.3. FUEL INJECTION PUMP

- 7.7.17.4. FUEL LEVEL GAUGE

- 7.7.17.5. FUEL TANK FILLER STRAINER

- 7.7.17.6. FUEL TANK SHUTOFF VALVE

- 7.7.17.7. IN LINE FUEL STRAINER

- 7.7.17.8. FUEL FILTER

- 7.7.17.8.1. GENERAL

- 7.7.17.8.2. FUEL FILTER WATER DRAIN

- 7.7.17.8.3. WHEN TO REPLACE THE FILTER

- 7.7.17.8.4. REPLACING THE FUEL FILTER

- 7.7.17.9. DRAINING FUEL TANK

- 7.7.17.10. VENTING SYSTEM

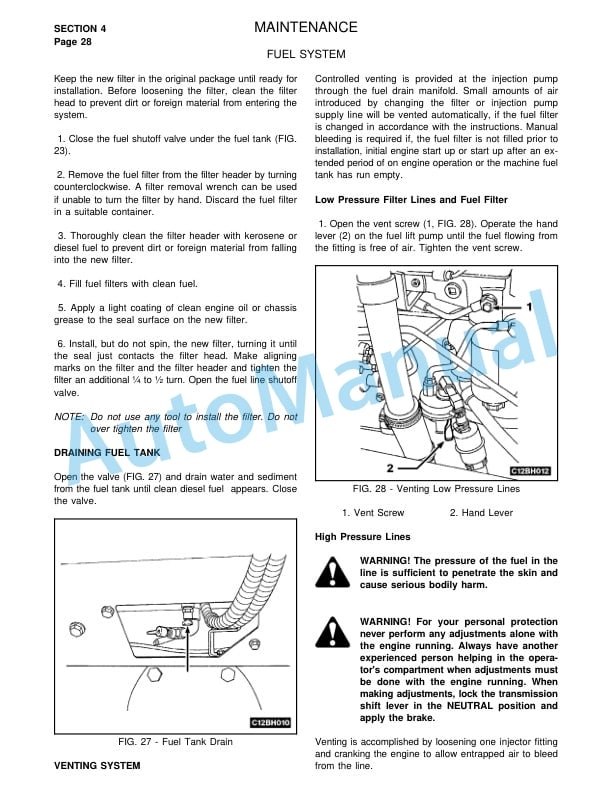

- 7.7.17.10.1. LOW PRESSURE FILTER LINES AND FUEL FILTER

- 7.7.17.10.2. HIGH PRESSURE LINES

- 7.7.18. HYDRAULIC SYSTEM

- 7.7.18.1. GENERAL

- 7.7.18.2. CHECKING OIL LEVEL

- 7.7.18.3. CHANGING HYDRAULIC OIL

- 7.7.18.4. SERVICING THE RETURN FILTER

- 7.7.18.5. SERVICING THE SUCTION STRAINER

- 7.7.18.6. SERVICING THE RESERVOIR BREATHER

- 7.7.18.7. VENTING

- 7.7.19. LUBRICATION FITTINGS

- 7.7.19.1. GENERAL

- 7.7.19.2. BRAKE AND THROTTLE LINKAGE

- 7.7.19.3. HAND STEERING LEVERS

- 7.7.19.4. FOOT STEERING PEDALS

- 7.7.19.5. HYDRAULIC CONTROLS

- 7.7.19.6. EQUIPMENT

- 7.7.19.6.1. BLADE

- 7.7.19.6.2. RIPPER

- 7.7.20. MACHINE EQUIPMENT

- 7.7.20.1. ANGLING FRAME TO BLADE

- 7.7.21. SEAT BELT

- 7.7.22. SPROCKET DRIVE

- 7.7.22.1. GENERAL

- 7.7.22.2. CHECKING THE LUBRICANT LEVEL

- 7.7.22.3. CHANGING THE LUBRICANT

- 7.7.23. TRANSMISSION SYSTEM

- 7.7.23.1. GENERAL

- 7.7.23.2. CHECKING THE OIL LEVEL

- 7.7.23.3. CHANGING TRANSMISSION SYSTEM OIL

- 7.7.23.4. SERVICING THE PRESSURE FILTER

- 7.7.23.5. SERVICING THE SUCTION STRAINER

- 7.7.23.6. SERVICING THE BREATHER

- 7.7.24. UNDERCARRIAGE

- 7.7.24.1. GENERAL

- 7.7.24.2. TRACK SHOE BOLTS

- 7.7.24.3. PROPER ADJUSTMENT

- 7.7.24.4. CHECKING THE TENSION

- 7.7.24.5. ADJUSTING TENSION

- 8. SECTION 5 SPECIFICATION

- 8.1. DIMENSION, CAPACITIES AND WEIGHTS

- 8.1.1. DIMENSIONS

- 8.1.2. CAPACITIES

- 8.1.3. ELECTRICAL SYSTEM

- 8.1.4. ENGINE

- 8.1.5. TORQUE CONVERTER

- 8.1.6. TRANSMISSION

- 8.1.7. TRAVEL SPEEDS

- 8.1.8. WEIGHT

- 8.2. SPECIAL TORQUES

- 8.3. TORQUES

- 8.3.1. BOLT IDENTIFICATION CHART

- 8.3.2. GRADE 5 AND 8 NONPHOSPATE COATED HARDWARE

- 8.3.3. GRADE 8 PHOSPATE COATED HARDWARE

- 8.3.4. STANDARD METRIC FASTENERS

- 8.3.5. SPLIT FLANGE CONNECTIONS

- 8.3.6. HYDRAULIC TUBES AND FITTINGS

- 8.3.7. HOSE CLAMPS

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM011200

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG725

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Field Assembly Instruction CEAW004103

Komatsu Operation and Maintenance Manual PDF

Komatsu 450FXL-1 Crawler Feller Buncher Operation and Maintenance Manual CEAM023802

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG615

Komatsu Operation and Maintenance Manual PDF

Komatsu 430FX-1, 430FXL-1, 445FXL-1 Operation and Maintenance Manual CEAM023702

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM006700

Komatsu Operation and Maintenance Manual PDF

Komatsu 503 Motor Grader Operation and Maintenance Manual 2079A-H45

Komatsu Operation and Maintenance Manual PDF

Komatsu 101 Basics Forklift Truck Operation and Maintenance Manual

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM018100

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF