- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu TD-7H, TD-8H, TD-9H Crawler Tractor Operation and Maintenance Manual CEAM002801

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: CEAM002801

- Format: PDF

- Size: 3.9MB

- Number of Pages: 193

-

Model List:

- TD-7H Crawler Tractor

- TD-8H Crawler Tractor

- TD-9H Crawler Tractor

- 1. MAIN MENU

- 2. COVER

- 3. INTRODUCTION

- 3.1. FORWARD

- 3.2. SAFETY INFORMATION

- 3.3. INTRODUCTION

- 3.3.1. INTENDED USE

- 3.3.2. FEATURES

- 3.3.3. BREAKING IN THE MACHINE

- 3.4. LOCATION OF PLATES, TABLES TO ENGIN P.I.N. AND DISTRIBUTOR

- 3.4.1. PLATE LOCATION

- 3.4.2. ENGINE SERIAL NO. PLATE LOCATION

- 3.4.3. TABLE TO ENTER NUMBERS AND DISTRIBUTOR

- 3.5. TABLE OF CONTENTS

- 4. SAFETY

- 4.1. GENERAL PRECAUTIONS

- 4.2. PRECAUTIONS DURING OPERATION

- 4.2.1. BEFORE STARTING ENGINE

- 4.2.2. OPERATING MACHINE

- 4.2.3. TRANSPORTATION

- 4.2.4. BATTERY

- 4.2.5. TOWING

- 4.3. PRECAUTIONS FOR MAINTENANCE

- 4.3.1. BEFORE CARRYING OUT MAINTENANCE

- 4.3.2. DURING MAINTENANCE

- 4.4. POSITION FOR ATTACHING SAFETY LABELS

- 5. OPERATION

- 5.1. GENERAL VIEW

- 5.1.1. GENERAL VIEW OF MACHINES

- 5.1.2. GENERAL VIEW OF CONTROLS AND GAUGES

- 5.1.3. UNIVERSAL SYMBOLS

- 5.2. EXPLANATION OF COMPONENTS

- 5.2.1. GENERAL

- 5.2.2. GAUGES AND WARNING LIGHTS

- 5.2.2.1. HOURMETER

- 5.2.2.2. TRANSMISSION OIL FILTER WARNING LIGHT

- 5.2.2.3. ENGINE COOLANT TEMPERATURE GAUGE

- 5.2.2.4. ENGINE OIL PRESSURE GAUGE

- 5.2.2.5. ILLUMINATION LAMP

- 5.2.2.6. VOLTMETER

- 5.2.2.7. DRIVE TRAIN OIL TEMPERATURE GAUGE

- 5.2.2.8. HYDRAULIC OIL FILTER LIGHT

- 5.2.2.9. AIR CLEANER SERVICE LIGHT

- 5.2.2.10. FUEL GAUGE

- 5.2.3. SWITCHES

- 5.2.3.1. START KEY SWITCH

- 5.2.3.2. WORK LIGHT SWITCH

- 5.2.3.3. HORN SWITCH

- 5.2.3.4. ETHER START SWITCH

- 5.2.3.5. ELECTRICAL SYSTEM MASTER SWITCH

- 5.2.3.6. CAB SWITCHES

- 5.2.4. SEAT, SEAT BELT AND ARM RESTS

- 5.2.4.1. SEAT WITH ADJUSTABLE SEAT BELT

- 5.2.4.2. SEAT WITH RETRACTABLE SEAT BELT

- 5.2.4.3. SEAT BELT

- 5.2.4.4. ARM RESTS

- 5.2.5. CONTROL LEVERS AND PEDALS

- 5.2.5.1. FUEL CONTROL LEVER

- 5.2.5.2. TRANSMISSION SHIFT LEVER

- 5.2.5.3. HAND STEERING LEVERS

- 5.2.5.4. SAFETY LOCK LEVER

- 5.2.5.5. FOOT STEERING PEDALS

- 5.2.5.6. BRAKE AND DECELERATOR PEDAL

- 5.2.5.7. BRAKE PEDAL LOCK

- 5.2.5.8. BLADE CONTROL LEVER

- 5.2.5.9. RIPPER CONTROL LEVER

- 5.2.5.10. CAB CONTROLS

- 5.3. OPERATION

- 5.3.1. CHECKS BEFORE STARTING ENGINE

- 5.3.1.1. WALK AROUND CHECK

- 5.3.1.2. CHECK BEFORE STARTING

- 5.3.1.3. OPERATION AND CHECKS BEFORE STARTING

- 5.3.2. STARTING ENGINE

- 5.3.2.1. NORMAL STARTING

- 5.3.2.2. COLD WEATHER STARTING

- 5.3.3. OPERATIONS AND CHECKS AFTER ENGINE STARTS

- 5.3.4. MOVING MACHINE

- 5.3.5. SHIFTING GEARS

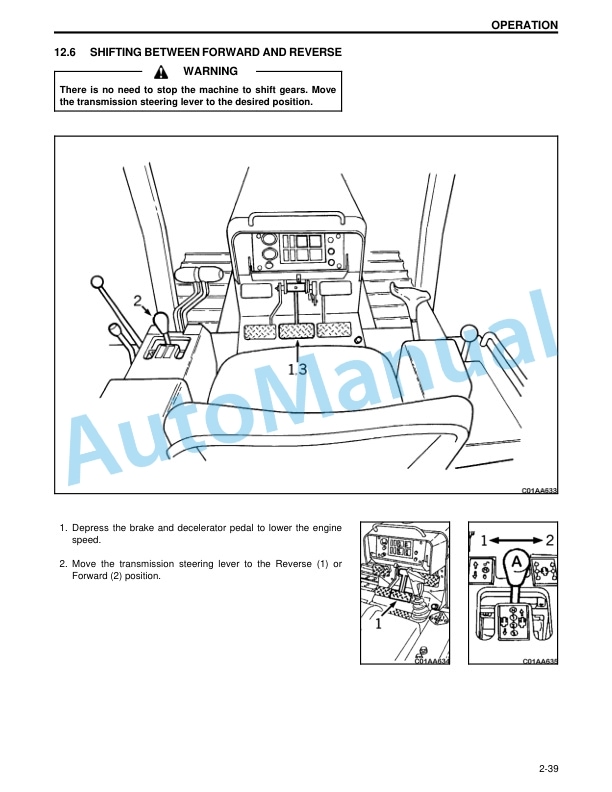

- 5.3.6. SHIFTING BETWEEN FORWARD AND REVERSE

- 5.3.7. STEERING MACHINE

- 5.3.7.1. NORMAL TURNING

- 5.3.7.2. TURNING WHILE DESCENDING A SLOPE

- 5.3.8. STOPPING MACHINE

- 5.3.9. PRECAUTIONS FOR OPERATION

- 5.3.9.1. METHOD FOR USING STEERING CLUTCH

- 5.3.9.2. PERMISSIBLE WATER DEPTH

- 5.3.9.3. PRECAUTIONS WHEN TRAVELING UP OR DOWN HILLS

- 5.3.9.4. PRECAUTIONS ON SLOPES

- 5.3.10. WORK POSSIBLE USING BULLDOZER

- 5.3.10.1. DOZING

- 5.3.10.2. SMOOTHING

- 5.3.10.3. CUTTING INTO HARD/FROZEN GROUND OR DITCHING

- 5.3.11. PARKING MACHINE

- 5.3.12. CHECK AFTER FINISHING WORK

- 5.3.13. STOPPING ENGINE

- 5.3.14. CHECK AFTER STOPPING MACHINE

- 5.3.15. LOCKING

- 5.3.15.1. ROPS CANOPY

- 5.3.15.2. ROPS CAB

- 5.3.16. TIPS FOR LONGER UNDERCARRIAGE LIFE

- 5.3.16.1. OPERATION METHOD

- 5.3.16.2. INSPECTION AND ADJUSTMENT

- 5.3.16.3. INSPECTION AND REPAIR

- 5.4. TRANSPORTATION

- 5.4.1. LOADING, UNLOADING WORK

- 5.4.2. PRECAUTIONS FOR LOADING

- 5.4.3. PRECAUTIONS FOR TRANSPORATION

- 5.5. COLD WEATHER OPERATIONS

- 5.5.1. PRECAUTIONS FOR LOW TEMPERATURE

- 5.5.1.1. FUEL AND LUBRICANTS

- 5.5.1.2. COOLANT

- 5.5.1.3. BATTERY

- 5.5.2. AFTER COMPLETION OF WORK

- 5.5.3. AFTER COLD WEATHER

- 5.6. LONG TERM STORAGE (MORE THAN ONE MONTH)

- 5.6.1. BEFORE STORAGE

- 5.6.2. DURING STORAGE

- 5.6.3. AFTER STORAGE

- 5.7. TROUBLESHOOTING

- 5.7.1. AFTER RUNNING OUT OF FUEL

- 5.7.2. IF BATTERY IS DISCHARGED

- 5.7.2.1. STARTING ENGINE WITH BOOSTER CABLE

- 5.7.3. OTHER TROUBLE

- 5.7.3.1. ELECTRICAL SYSTEM

- 5.7.3.2. CHASSIS

- 5.7.3.3. ENGINE

- 5.7.4. METHODS OF TOWING MACHINE

- 6. MAINTENANCE

- 6.1. GUIDES TO MAINTENANCE

- 6.2. OUTLINES OF SERVICE

- 6.2.1. OUTLINE OF OIL, FUEL, COOLANT

- 6.2.1.2. FUEL

- 6.2.1.3. COOLANT

- 6.2.1.4. GREASE

- 6.2.1.5. STORING OIL AND FUEL

- 6.2.1.6. FILTERS

- 6.2.2. RELATING TO ELECTRICAL SYSTEM

- 6.3. WEAR PARTS LIST

- 6.4. USE OF FUEL COOLANT AND LUBRICANTS ACCORDING TO AMBIENT TEMPERATURE

- 6.4.1. PROPER SELECTION OF FUEL, COOLANT AND LUBRICANT

- 6.4.1.1. TD7H STD, TD7H LGP, TD8H STD OR TD8H LGP

- 6.4.1.2. TD9H STD OR TD9H LGP

- 6.4.1.3. ABBREVIATIONS

- 6.4.2. COOLING SYSTEM

- 6.4.2.1. GENERAL

- 6.4.2.2. WATER

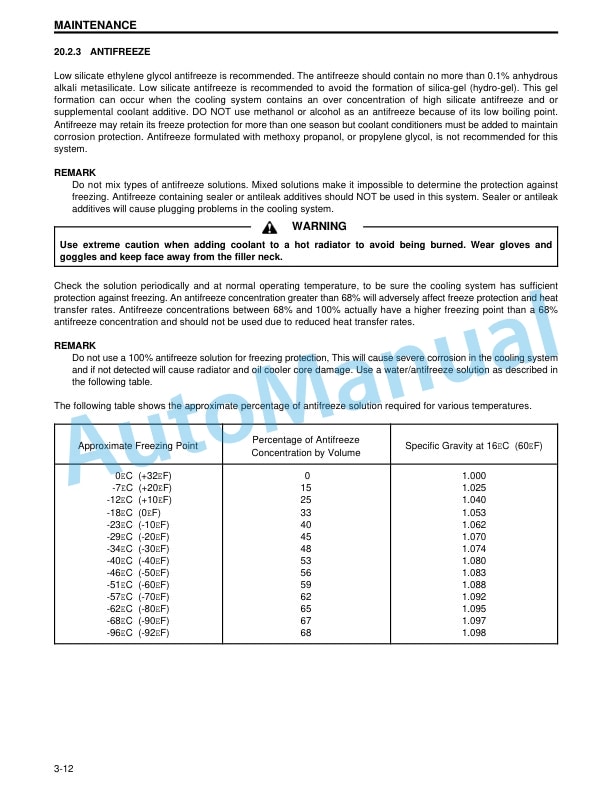

- 6.4.2.3. ANTIFREEZE

- 6.4.2.4. INHIBITORS/CONDITIONERS

- 6.4.3. FUEL SYSTEM

- 6.4.3.1. GENERAL

- 6.4.3.2. DIESEL FUEL SPECIFICATIONS

- 6.4.4. STANDARD TIGHTENING TORQUES

- 6.4.4.1. INTRODUCTION OF NECESSARY TOOLS

- 6.4.4.2. BOLT IDENTIFICATION CHART

- 6.4.4.3. HYDRAULIC TUBES AND FITTINGS

- 6.4.4.4. HOSE CLAMPS

- 6.4.4.5. SPLIT FLANGE CONNECTIONS

- 6.4.5. PERIODIC REPLACEMENT OF CRITICAL PARTS

- 6.4.6. MAINTENANCE SCHEDULE CHART

- 6.4.7. SERVICE PROCEDURE

- 6.4.7.1. INITIAL 10 HOURS SERVICE

- 6.4.7.2. INITIAL 50 HOURS SERVICE

- 6.4.7.3. EVERY 10 HOURS SERVICE (CHECK BEFORE STARTING)

- 6.4.7.4. EVERY 50 HOURS SERVICE

- 6.4.7.5. EVERY 100 HOURS

- 6.4.7.6. EVERY 250 HOURS SERVICE

- 6.4.7.7. EVERY 500 HOURS SERVICE

- 6.4.7.8. EVERY 1000 HOURS SERVICE

- 6.4.7.9. EVERY 2000 HOURS SERVICE

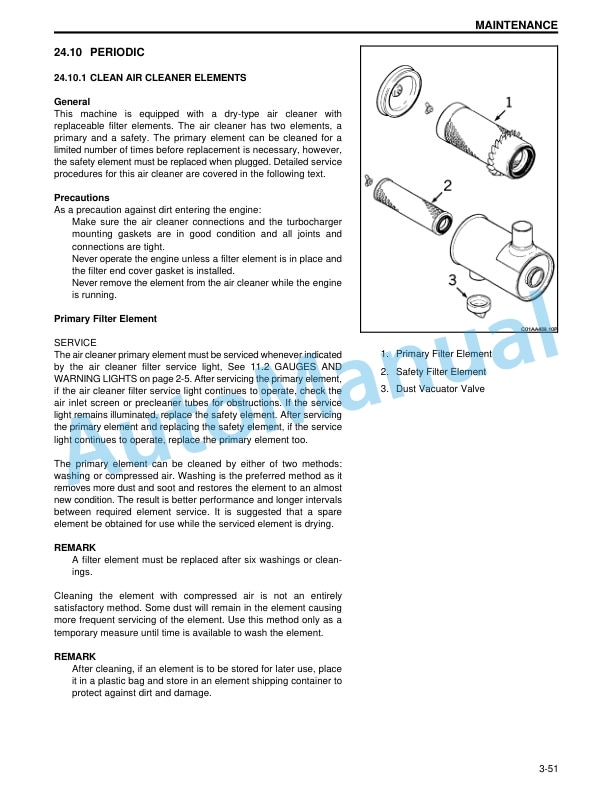

- 6.4.7.10. PERIODIC

- 6.4.7.11. WHEN REQUIRED

- 6.4.7.12. SEASONAL PREPARATION

- 6.4.7.13. TURBOCHARGER TD8H STD LGP, TD9H STD LGP

- 7. SPECIFICATIONS

- 7.1. SPECIFICATIONS

- 7.1.1. TD8H STD, TD7H LGP SPECIFICATIONS

- 7.1.2. TD8H STD, TD8H LGP SPECIFICATIONS

- 7.1.3. TD9H STD, TD9H LGP SPECIFICATIONS

- 7.1.4. TD7H STD DIMENSIONS

- 7.1.5. TD7H LGP DIMENSIONS

- 7.1.6. TD8H STD DIMENSIONS

- 7.1.7. TD8H LGP DIMENSIONS

- 7.1.8. TD9 H STD DIMENSIONS

- 7.1.9. TD9H LGP DIMENSIONS

- 8. OPTIONS, ATTACHEMENTS

- 8.1. PRECAUTIONS RELATED TO SAFETY

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAD014800

Komatsu Operation and Maintenance Manual PDF

Komatsu 630E Dump Truck Operation and Maintenance Manual DG738

Komatsu Operation and Maintenance Manual PDF

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM010301

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM018100

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM014901

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG713

Komatsu Operation and Maintenance Manual PDF

Komatsu 530M Dump Truck Operation and Maintenance Manual DG716

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG725

Komatsu Operation and Maintenance Manual PDF

Komatsu 4D104E, S4D104E Series Diesel Motor Operation and Maintenance Manual WHBMNEF000

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF