- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu TD-7H, TD-8H, TD-9H Crawler Tractor Shop Manual CEBM003200

$40.00

- Type Of Manual: Shop Manual

- Manual ID: CEBM003200

- Format: PDF

- Size: 24.9MB

- Number of Pages: 650

Category: Komatsu Shop Manual PDF

-

Model List:

- TD-7H Crawler Tractor

- TD-8H Crawler Tractor

- TD-9H Crawler Tractor

- 1. MAIN MENU

- 2. COVER

- 3. INDEX TO SECTIONS

- 4. SECTION 1 INTRODUCTION

- 4.1. SAFETY PRECAUTIONS

- 4.1.1. GENERAL

- 4.1.2. BEFORE STARTING THE ENGINE

- 4.1.3. OPERATION

- 4.1.4. MAINTENANCE

- 4.1.5. SHUTDOWN

- 4.1.6. SAFETY PRODUCT GRAPHICS AND LOCATION

- 4.2. SERVICE INFORMATION

- 4.2.1. GENERAL

- 4.2.2. PIN AND SERIAL NUMBERS

- 4.2.3. SERVICE TOOLS AND PARTS

- 4.2.4. INSPECTION AND REPAIR

- 4.3. LOCTITE USAGE

- 4.3.1. SURFACE PREPARATION

- 4.3.2. APPLICATION

- 4.3.3. SETTING TIME

- 4.3.4. REMOVAL

- 4.3.5. APPLICATIONS AT LOW TEMPERATURES

- 5. SECTION 2 MISCELLANEOUS

- 5.1. DIMENSIONS

- 5.1.1. TD7H STD DIMENSIONS

- 5.1.2. TD7H LGP DIMENSIONS

- 5.1.3. TD8H STD DIMENSIONS

- 5.1.4. TD8H LGP DIMENSIONS

- 5.1.5. TD9H STD DIMENSIONS

- 5.1.6. TD9H LGP DIMENSIONS

- 5.2. SPECIFICATIONS

- 5.2.1. TD7H STD, TD7H LGP SPECIFICATIONS

- 5.2.2. TD8H STD, TD8H LGP SPECIFICATIONS

- 5.2.3. TD9H STD, TD9H LGP SPECIFICATIONS

- 5.3. CAPACITIES AND LUBRICANTS

- 5.4. SPECIAL TORQUES

- 5.5. STANDARD TORQUES

- 5.5.1. INTRODUCTION OF NECESSARY TOOLS

- 5.5.2. BOLT IDENTIFICATION CHART

- 5.5.3. GRADE 5 AND 8 NONPHOSPATE COATED HARDWARE

- 5.5.4. GRADE 8 PHOSPATE COATED HARDWARE

- 5.5.5. STANDARD METRIC FASTENERS

- 5.5.6. HOSE CLAMPS

- 5.5.7. SPLIT FLANGE CONNECTIONS

- 6. SECTION 4 BRAKES

- 6.1. BRAKE SUPPORT BRACKET

- 7. SECTION 6 COOLING

- 7.1. GENERAL

- 7.1.1. DESCRIPTION

- 7.1.2. OPERATION

- 7.1.3. SPECIFICATIONS

- 7.2. SERVICE DIAGNOSIS

- 8. SECTION 7 DRIVE TRAIN

- 8.1. TORQUE CONVERTER

- 8.1.1. SPECIFICATIONS

- 8.1.2. DRIVE TRAIN SCHEMATIC

- 8.1.3. DESCRIPTION

- 8.1.4. OPERATON

- 8.1.5. CHECKING DRIVE TRAIN PRESSURES

- 8.1.6. CONVERTER STALL SPEED

- 8.1.7. TRANSMISSION CLUTCH TEST

- 8.2. DIRECT DRIVE

- 8.2.1. SPECIFICATIONS

- 8.2.2. CHECKING DRIVE TRAIN PRESSURES

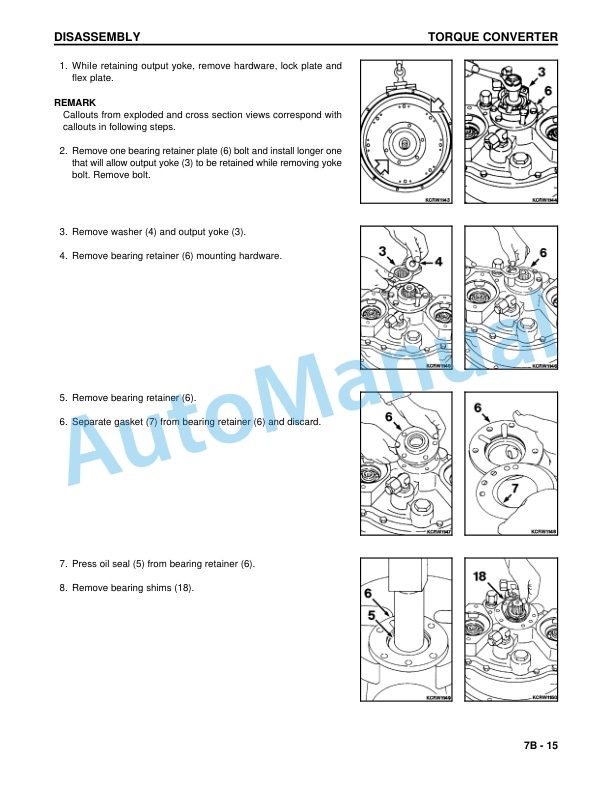

- 9. SECTION 7B TORQUE CONVERTER

- 9.0.1. SERVICE DIAGNOSIS

- 9.1. REMOVAL

- 9.2. DISASSEMBLY TWOPIECE HOUSING

- 9.2.1. COMPLETE ASSEMBLY

- 9.2.2. CONVERTER ASSEMBLY

- 9.2.3. REAR HOUSING

- 9.3. DISASSEMBLY ONE PIECE HOUSING

- 9.3.1. COMPLETE ASSEMBLY

- 9.3.2. THRUST BEARING REPLACEMENT

- 9.3.3. OIL LEAKING IN FLYWHEEL

- 9.4. REASSEMBLY TWOPIECE HOUSING

- 9.4.1. REAR HOUSING

- 9.4.2. CONVERTER ASSEMBLY

- 9.4.3. COMPLETE ASSEMBLY

- 9.5. REASSEMBLY ONE PIECE HOUSING

- 9.5.1. OIL LEAKING IN FLY WHEEL

- 9.5.2. THRUST BEARING REPLACEMENT

- 9.5.3. COMPLETE ASSEMBLY

- 9.6. INSTALLATION

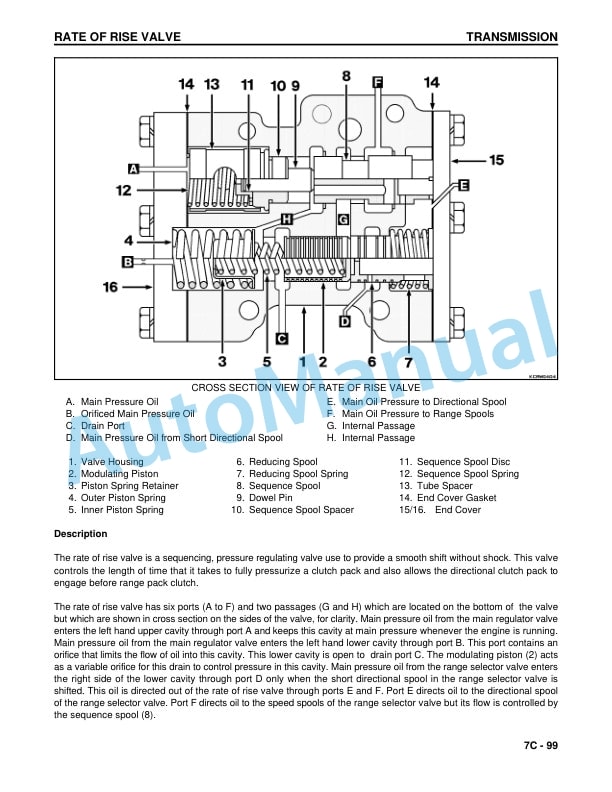

- 10. SECTION 7C TRANSMISSION

- 10.1. COMPLETE ASSEMBLY

- 10.1.1. DISASSEMBLY

- 10.1.2. REASSEMBLY

- 10.2. DIRECTIONAL (INPUT) SHAFT

- 10.2.1. GENERAL

- 10.2.2. PISTION RETURN SPRING CRITERION

- 10.3. RANGE (OUTPUT) SHAFT

- 10.3.1. GENERAL

- 10.3.2. PISTION RETURN SPRING CRITERION

- 10.3.3. DISASSEMBLY

- 10.3.4. REASSEMBLY

- 10.4. REVERSE IDLER SHAFT

- 10.4.1. GENERAL

- 10.4.2. DISASSEMBLY

- 10.4.3. REASSEMBLY

- 10.5. MAIN REGULATOR VALVE

- 10.5.1. DESCRIPTION

- 10.5.2. THEORY OF OPERATION

- 10.5.3. SPECIFICATIONS

- 10.5.4. DISASSEMBLY

- 10.5.5. REASSEMBLY

- 10.6. RANGE SELECTOR VALVE

- 10.6.1. DESCRIPTION

- 10.6.2. THEORY OF OPERATION

- 10.6.3. SPECIFICATIONS

- 10.6.4. DISASSEMBLY

- 10.6.5. REASSEMBLY

- 10.7. RATE OF RISE VALVE

- 10.8. PILOT CONTROL VALVE

- 10.8.1. DESCRIPTION

- 10.8.2. THEORY OF OPERATION

- 10.9. TRANSMISSION CONTROLS

- 11. SECTION 7E STEERING DRIVE

- 11.1. STEERING CYLINDER

- 11.2. BRAKE/STEERING SHOES

- 11.2.1. SPECIFICATIONS

- 11.2.2. SERVICE

- 11.3. BEARING CARRIER

- 11.3.1. SERVICE

- 11.4. PLANET GEAR CARRIER

- 11.4.1. SERVICE

- 11.5. REASSEMBLY

- 11.6. INSTALLATION

- 11.7. BRAKE ADJUSTMENT

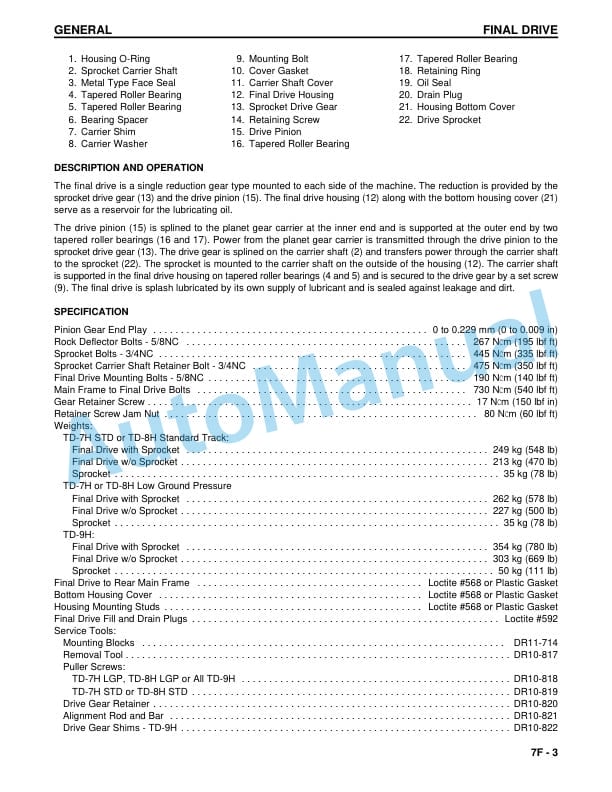

- 12. SECTION 7F FINAL DRIVE

- 12.1. GENERAL

- 12.1.1. DESCRIPTION

- 12.1.2. OPERATION

- 12.1.3. SPECIFICATION

- 12.1.4. SERVICE DIAGNOSIS

- 12.2. METAL TYPE FACE SEALS

- 12.2.1. SEAL INSPECTION

- 12.2.2. SEAL INSTALLATION

- 12.3. INSTALLATION

- 13. SECTION 8 ELECTRICAL

- 14. SECTION 10 HYDRAULICS

- 14.0.1. BLADE EQUIPMENT LEVER

- 14.0.2. REAR EQUIPMENT LEVER

- 15. SECTION 10A PUMPS

- 15.1. CHARGE AND SCAVENGE PUMP

- 16. SECTION 10B CONTROL VALVE

- 16.1. REMOVAL

- 16.2. COMPLETE ASSEMBLY

- 16.2.1. DISASSEMBLY

- 16.2.2. REASSEMBLY

- 16.3. SYSTEM RELIEF VALVE

- 16.3.1. DISASSEMBLY

- 16.3.2. REASSEMBLY

- 16.4. BLADE LIFT SECTION

- 16.4.1. DISASSEMBLY

- 16.4.2. REASSEMBLY

- 16.5. BLADE TILT SECTION

- 16.5.1. DISASSEMBLY

- 16.5.2. REASSEMBLY

- 16.6. BLADE ANGLE OR RIPPER SECTION

- 16.6.1. DISASSEMBLY

- 16.6.2. REASSEMBLY

- 16.7. INSTALLATION

- 17. SECTION 10C CYLINDERS

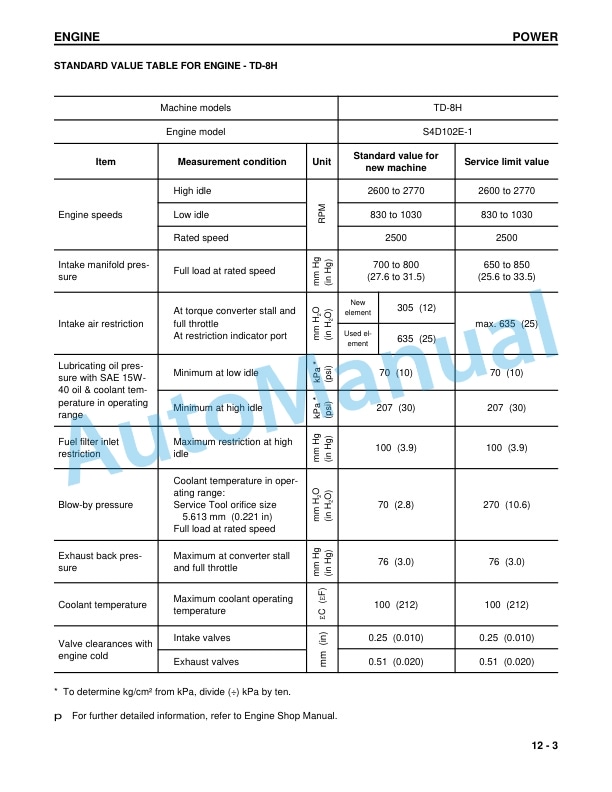

- 17.1. BLADE EQUIPMENT

- 18. SECTION 12 POWER

- 18.1. ENGINE

- 18.1.1. STANDARD VALUE TABLE

- 19. SECTION 14 UNDERCARRIAGE

- 19.0.1. TRACK TOP IDLER

- 19.0.2. TRACK ROLLER

- 19.0.3. FRONT CROSSBAR

- 19.0.4. REAR RIGID BAR

- 19.0.5. MAINTENANCE

- 19.1. SERVICE DIAGNOSIS

- 19.2. WEAR LIMIT CHECKS

- 19.2.1. SPECIFICATIONS

- 19.2.2. GENERAL

- 19.2.3. TRACK SHOE GROUSER HEIGHT

- 19.2.4. LINK HEIGHT

- 19.2.5. BUSHING OUTSIDE DIAMETER

- 19.2.6. INTERNAL PIN AND BUSHING WEAR (PITCH)

- 19.2.7. FRONT IDLER FLANGE HEIGHT

- 19.2.8. TRACK ROLLER ROLLING DIAMETER

- 19.2.9. TOP IDLER ROLLING DIAMETER

- 19.3. METAL TYPE FACE SEALS

- 19.3.1. SEAL INSPECTION

- 19.3.2. SEAL INSTALLATION

- 19.4. TRACK FRAME ALIGHNMENT

- 20. SECTION 15 TRACK CHAIN

- 20.1. MASTER PIN TYPE CHAINS

- 20.1.1. DESCRIPTION

- 20.1.2. SPECIFICATIONS

- 20.1.3. MAINTENANCE

- 20.1.4. REMOVAL

- 20.1.5. TRACK CHAIN REPAIR

- 20.1.6. INSTALLATION

- 20.2. SPLIT LINK TYPE CHAINS

- 20.2.1. COMPLETE CHAIN REBUILD

- 20.2.2. SINGLE TRACK CHAIN JOINT REBUILD

- 21. SECTION 17 MOUNTED EQUIPMENT

- 21.1. C FRAME RUB BARS

- 21.1.1. MOUNTING

- 21.2. ANGLING FRAME

- 21.2.1. BUSHING REPLACEMENT

- 21.2.2. BUSHING REPLACEMENT

- 21.3. BLADE BUSHINGS

- 21.3.1. BUSHING REPLACEMENT

Rate this product

You may also like

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF