- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu WA100M-8E0 Wheel Loader Shop Manual VENBM07001

$40.00

- Type Of Manual: Shop Manual

- Manual ID: VENBM07001

- Format: PDF

- Size: 94.5MB

- Number of Pages: 928

Category: Komatsu Shop Manual PDF

-

Model List:

- WA100M-8E0 Wheel Loader

- 1. INDEX AND FOREWORD

- 1.1. ABBREVIATION LIST

- 1.2. FOREWORD, SAFETY, BASIC INFORMATION

- 1.3. PRECAUTIONS TO PREVENT FIRE

- 1.4. ACTIONS IF FIRE OCCURS

- 1.5. PRECAUTIONS FOR DISPOSING OF WASTE MATERIALS

- 1.6. ACTIONS TAKEN TO MEET EXHAUST GAS REGULATIONS

- 1.7. PRECAUTIONS FOR DEF

- 1.8. STORE AdBlue/DEF

- 1.9. PRECAUTIONS FOR HANDLING HYDRAULIC EQUIPMENT

- 1.10. PRECAUTIONS FOR DISCONNECTION AND CONNECTION OF PIPINGS

- 1.11. PRECAUTIONS FOR HANDLING ELECTRICAL EQUIPMENT

- 1.12. HOW TO READ ELECTRICAL WIRE CODE

- 1.13. EXPLANATION OF TERMS FOR MAINTENANCE STANDARD

- 1.14. STANDARD TIGHTENING TORQUE TABLE

- 1.15. CONVERSION TABLE

- 2. SPECIFICATIONS

- 2.1. DIMENSIONS, WEIGHTS AND OPERATING DATA

- 2.2. SPECIFICATIONS

- 2.3. WEIGHT TABLES

- 2.4. LUBRICANTS AND OPERATING MEDIUMS

- 2.5. BASIC PROCEDURES OF MAINTENANCE

- 2.6. TIGHTENING TORQUE LIST METRIC SCREWS AND NUTS

- 3. STRUCTURE AND FUNCTION

- 3.1. ABBREVIATION LIST

- 3.2. UREA SCR SYSTEM

- 3.3. UREA SCR SYSTEM DIAGRAM

- 3.4. FUNCTION OF UREA SCR SYSTEM

- 3.5. COMPONENT PARTS OF UREA SCR SYSTEM

- 3.6. ELECTRICAL SYSTEM

- 3.7. BOOTUP SYSTEM

- 3.8. BATTERY DISCONNECT SWITCH

- 3.9. PREHEATING SYSTEM

- 3.10. ENGINE SYSTEM

- 3.11. COOLING SYSTEM

- 3.12. COOLING FAN CONTROL SYSTEM

- 3.13. COMPONENT PARTS OF COOLING SYSTEM

- 3.14. CONTROL SYSTEM

- 3.15. MACHINE MONITOR SYSTEM

- 3.16. KOMTRAX SYSTEM

- 3.17. COMPONENT PARTS OF CONTROL SYSTEM

- 3.18. HYDRAULIC SYSTEM

- 3.19. POWER TRAIN SYSTEM

- 3.20. FUNCTION OF THE CLOSED CIRCUIT SYSTEM

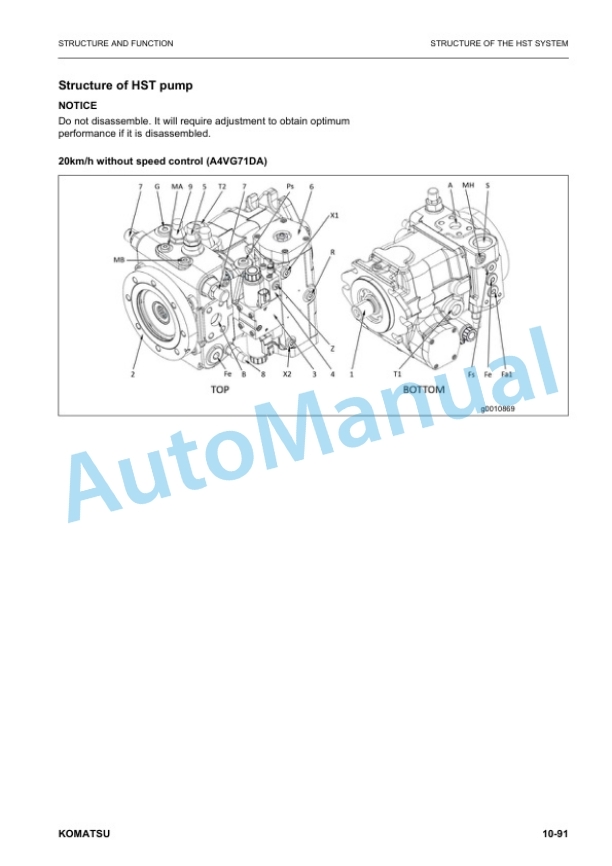

- 3.21. STRUCTURE OF THE HST SYSTEM

- 3.22. WORK EQUIPMENT SYSTEM

- 3.23. Loader Linkage with quickcoupler

- 3.24. STEERING SYSTEM

- 3.25. BRAKE SYSTEM

- 3.26. UNDERCARRIAGE AND FRAME

- 3.27. WORK EQUIPMENT

- 3.28. CAB AND ITS ATTACHMENTS

- 4. STANDARD VALUE TABLE

- 4.1. ABBREVIATION LIST

- 4.2. STANDARD VALUE TABLE

- 4.3. TEST CERTIFICATE

- 5. TESTING AND ADJUSTING

- 5.1. ABBREVIATION LIST

- 5.2. TEST ENGINE WITH SOFTWARE TOOL

- 5.3. ENGINE AND COOLING SYSTEM

- 5.4. TEST EXHAUST GAS COLOUR

- 5.5. TEST AND ADJUST VALVE CLEARANCE

- 5.6. TEST COMPRESSION PRESSURE

- 5.7. TEST ENGINE OIL PRESSURE

- 5.8. METHOD FOR BLEEDING AIR FROM FUEL SYSTEM

- 5.9. TEST FUEL CIRCUIT FOR LEAKAGE

- 5.10. HANDLE NOINJECTION CRANKING OPERATION

- 5.11. TEST DOC, SCR AND MUFFLER STACK FOR LOOSENESS AND DAMAGE

- 5.12. TEST INSTALLED CONDITION OF CYLINDER HEADS AND MANIFOLDS

- 5.13. TEST ENGINE PIPING FOR DAMAGE AND LOOSENESS

- 5.14. TEST AND ADJUST AIR CONDITIONER COMPRESSOR BELT TENSION

- 5.15. TEST ALTERNATOR BELT

- 5.16. CLEAN AdBlue/DEF TANK

- 5.17. POWER TRAIN

- 5.18. TEST DRIVE SHAFT FOR LOOSENESS, BACKLASH, AND DAMAGE

- 5.19. STEERING SYSTEM

- 5.20. TEST AND ADJUST STEERING CIRCUIT OIL PRESSURE

- 5.21. BLEED AIR FROM STEERING CYLINDER CIRCUIT

- 5.22. BLEED AIR FROM BRAKE CIRCUIT

- 5.23. TEST BRAKING PERFORMANCE

- 5.24. TEST PARKING BRAKE PERFORMANCE

- 5.25. HYDRAULIC SYSTEM

- 5.26. TEST AND ADJUST WORK EQUIPMENT PRESSURE

- 5.27. TEST WORK EQUIPMENT PPC PRESSURE

- 5.28. BLEED AIR FROM WORK EQUIPMENT PPC CIRCUIT

- 5.29. TESTING AND ADJUSTING COOLING FAN SPEED

- 5.30. TEST ECSS ACCUMULATOR NITROGEN GAS PRESSURE

- 5.31. ELECTRICAL SYSTEM

- 6. TROUBLESHOOTING

- 6.1. ABBREVIATION LIST

- 6.2. RELATED INFORMATION ON TROUBLESHOOTING

- 6.3. SEQUENCE OF EVENTS IN TROUBLESHOOTING

- 6.4. CHECKS BEFORE TROUBLESHOOTING

- 6.5. INSPECTION PROCEDURE BEFORE TROUBLESHOOTING

- 6.6. PROCEDURE FOR TESTING AND TROUBLESHOOTING

- 6.7. INFORMATION DESCRIBED IN TROUBLESHOOTING TABLE

- 6.8. CONNECTOR LOCATION LIST

- 6.9. CONNECTOR CONTACT IDENTIFICATION

- 6.10. SPARE FUSES AND RELAY

- 6.11. FAILURE CODES TABLE

- 6.12. TROUBLESHOOTING FOR HYDRAULIC AND MECHANICAL SYSTEMS (H MODE)

- 6.13. TROUBLESHOOTING OF ENGINE (SMODE)

- 7. DISASSEMBLY AND ASSEMBLY

- 7.1. ABBREVIATION LIST

- 7.2. RELATED INFORMATION ON DISASSEMBLY AND ASSEMBLY

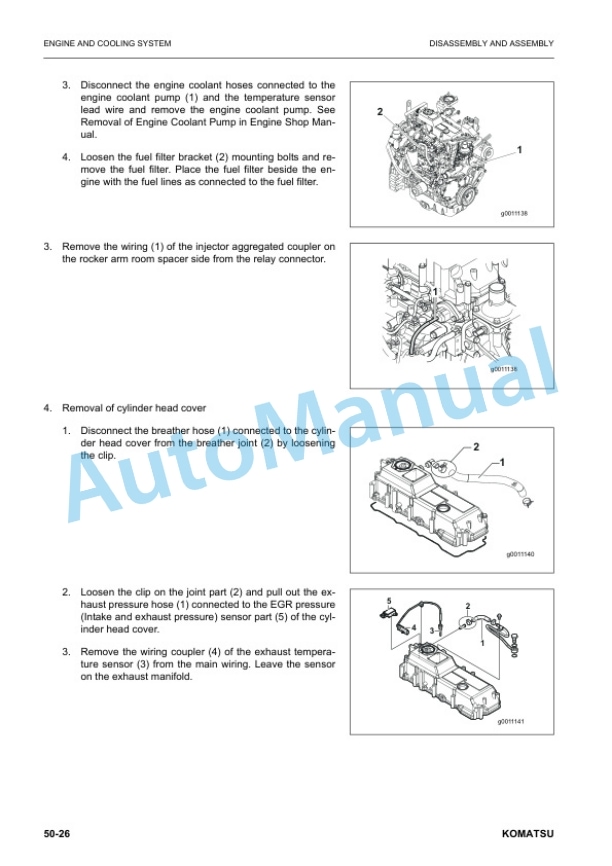

- 7.3. ENGINE AND COOLING SYSTEM

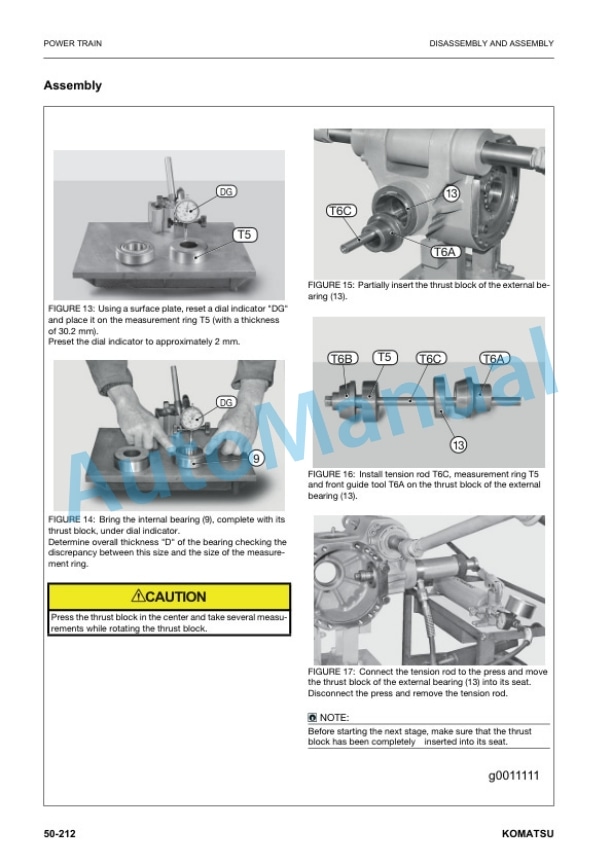

- 7.4. POWER TRAIN

- 7.5. WORK EQUIPMENT SYSTEM

- 7.6. ELECTRICAL SYSTEM

- 8. MAINTENANCE STANDARD

- 8.1. ABBREVIATION LIST

- 8.2. ENGINE AND COOLING

- 8.3. HYDRAULIC SYSTEM

- 8.4. CAB AND ITS ATTACHMENTS

- 9. APPENDIX

- 9.1. ABBREVIATION LIST

- 9.2. AIR CONDITIONER SYSTEM

- 9.3. AIR CONDITIONER COMPONENT

- 9.4. CONFIGURATION AND FUNCTION OF REFRIGERATION CYCLE

- 9.5. AIR CONDITIONER TROUBLESHOOTING CHART

- 9.6. CONNECTION OF SERVICE TOOL

- 9.7. PRECAUTIONS FOR DISCONNECTING AND CONNECTING HOSES AND TUBES IN AIR CONDITIONER PIPINGS

- 9.8. HANDLE COMPRESSOR OIL

- 10. OTHER

- 10.1. HYDRAULIC CIRCUIT DIAGRAM (SERIAL NUMBERS H11201 AND UP)

- 10.2. WIRING DIAGRAMS (SERIAL NUMBERS H11201 AND UP)

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF