- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu WA120-3CS Avance Wheel Loader Shop Manual SEBM012402

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM012402

- Format: PDF

- Size: 27.0MB

- Number of Pages: 421

Category: Komatsu Shop Manual PDF

-

Model List:

- WA120-3CS Avance Wheel Loader

- 1. COVER

- 2. CONTENTS

- 3. GENERAL

- 3.1. GENERAL ASSEMBLY DRAWING

- 3.2. SPECIFCATIONS

- 3.3. WEIGHT TABLE

- 3.4. LIST OF LUBRICANT AND WATER

- 4. STRUCTURE AND FUNCTION

- 4.1. OUTLINE

- 4.2. POWER TRAIN SYSTEM

- 4.3. DAMPER

- 4.4. HST PIPING

- 4.5. HYDRAULIC CIRCUIT DIAGRAM FOR HYDROSTATIC TRANSMISSION(HST)

- 4.6. MAIN PISTON PUMP

- 4.7. HIGHPRESSURE RELIEF VALVE

- 4.8. LOWPRESSURE RELIEF VALVE

- 4.9. HST CHARGE PUMP

- 4.10. CHARGE PUMP OIL FILTER

- 4.11. SPEED RELATED VALVE(DA VALVE)

- 4.12. HIGHPRESSURE CUTOFF VALVE

- 4.13. PISTON MOTOR

- 4.14. DIRECTIONAL SHUTTLE VALVE

- 4.15. SERVO VALVE

- 4.16. INTERMEDIATE FIXED CONTROL OF ANGLE

- 4.17. CENTER HINGE PIN

- 4.18. STEERING PIPING

- 4.19. STEERING COLUMN

- 4.20. PRIORITY VALVE

- 4.21. STEERING VALVE(ORBITROLL)

- 4.22. BRAKE PIPING

- 4.23. BRAKE CONTROL

- 4.24. BRAKE

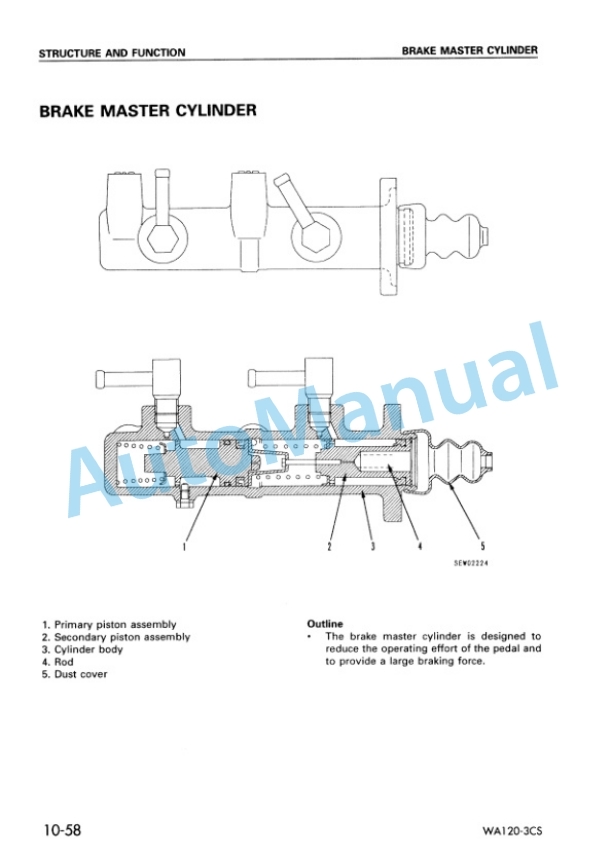

- 4.25. BRAKE MASTER CYLINDER

- 4.26. PARKING BRAKE CONTROL

- 4.27. PARKING BRAKE

- 4.28. HYDRAULIC PIPING

- 4.29. WORK EQUIPMENT HYDRAULIC CIRCUIT DIAGRAM

- 4.30. WORK EQUIPMENT LEVER LINKAGE

- 4.31. HYDRAUIC TANK

- 4.32. HYDRAULIC FILTER

- 4.33. MAIN CONTROL VALVE

- 4.34. WORK EQUIPMENT LINKAGE

- 4.35. BUCKET

- 4.36. BUCKET POSITIONER

- 4.37. PROXIMITY SWITCH

- 4.38. CANOPY

- 4.39. ELECTRIC CIRCUIT DIAGRAM

- 4.40. CENTRAL PANEL(CLUSTER GAUGE)

- 4.41. SENSOR

- 4.42. ENGINE STARTING CIRCUIT

- 4.43. ENGINE STOP CIRCUIT

- 4.44. PARKING BRAKE CIRCUIT

- 5. TESTING AND ADJUSTING

- 5.1. STANDARD VALUE TABLE FOR ENGINE

- 5.2. STANDARD VALUE TABLE FOR CHASSIS

- 5.3. STANDARD VALUE TABLE FOR ELECTRICAL PARTS

- 5.4. TABLE OF TOOLS FOR TESTING,ADJUSTING,AND TROUBLESHOOTING

- 5.5. MEASURING ENGINE SPEED

- 5.6. MEASURING EXHAUST COLOR

- 5.7. ADJUSTING VALVE CLEARANCE

- 5.8. MEASURING COMPRESSION PRESSURE

- 5.9. MEASURING BLOWBY PRESSURE

- 5.10. TESTING AND ADJUSTING FUEL INJECTION TIMING

- 5.11. MEASURING ENGINE OIL PRESSURE

- 5.12. TESTING AND ADJUSTING FAN BELT TENSION

- 5.13. METHOD FOR ADJUSTING ENGINE STOP MOTOR CABLE

- 5.14. TESTING AND ADJUSTING HST OIL PRESSURE

- 5.15. TESTING AND ADJUSTING STEERING OIL PRESSURE

- 5.16. BLEEDING AIR FROM STEERING CIRCUIT

- 5.17. MEASURING BRAKE PERFORMANCE

- 5.18. TESTING DROP IN WHEEL BRAKE OIL PRESSURE

- 5.19. MEASURING WHEEL BRAKE DISC WEAR

- 5.20. BLEEDING AIR FROM WHEEL BRAKE CIRCUIT

- 5.21. ADJUSTING WHEEL BRAKE LINKAGE

- 5.22. MEASURING PARKING BRAKE PERFORMANCE

- 5.23. TESTING AND ADJUSTING PARKING BRAKE LINKAGE

- 5.24. MEASURING WORK EQUIPMENT HYDRAULIC PRESSURE

- 5.25. BLEEDING AIR FROM WORK EQUIPMENT CIRCUIT

- 5.26. ADJUSTING WORK EQUIPMENT LEVER LINKAGE

- 5.27. TESTING AND ADJUSTING BUCKET POSITIONER

- 5.28. TROUBLESHOOTING

- 5.28.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 5.28.2. SEQUENCE OF EVENTS IN TROUBLESHOOTING

- 5.28.3. POINTS TO REMEMBER WHEN CARRYING OUT MAINTENANCE

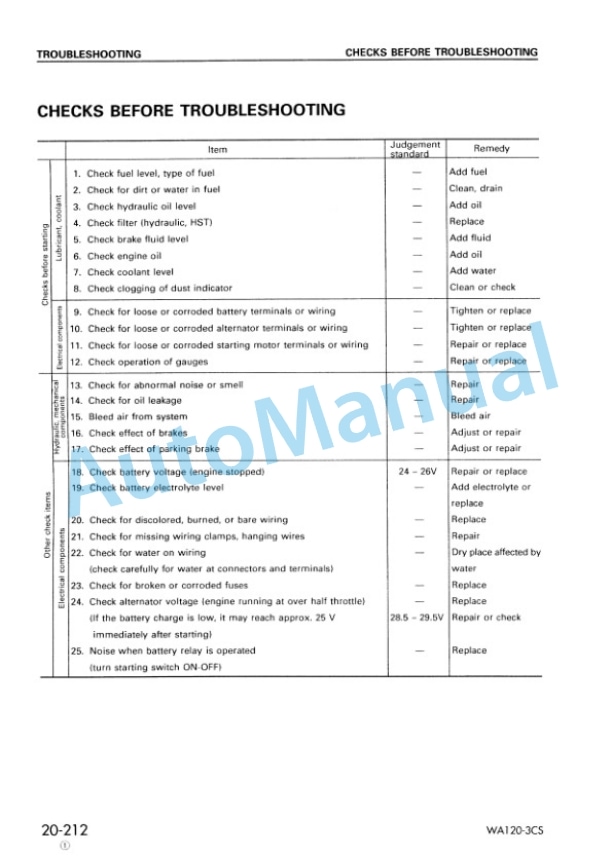

- 5.28.4. CHECKS BEFORE TROUBLESHOOTING

- 5.28.5. CONNECTOR TYPES AND MOUNTING LOCATIONS

- 5.28.6. CONNECTOR PIN ARRANGEMENT DIAGRAM

- 5.28.7. CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

- 5.28.8. METHOD OF USING FAILURE MODE AND JUDGEMENT TABLE

- 5.28.9. FAILURE MODES AND JUDGEMENT TABLE

- 5.28.10. METHOD OF USING TROUBLESHOOTING CHARTS

- 5.28.11. TROUBLESHOOTING OF ENGINE SYSTEM(S MODE)

- 5.28.12. TROUBLESHOOTING OF ELECTRICAL SYSTEM(E MODE)

- 5.28.13. TROUBLESHOOTING OF HYDRAULIC AND MECHANICAL SYSTEM(H MODE)

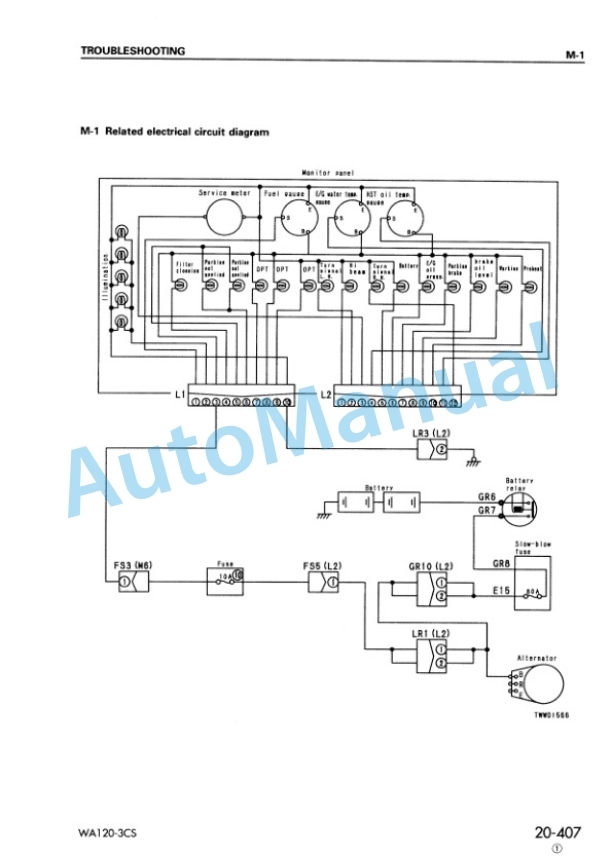

- 5.28.14. TROUBLESHOOTING OF MONITOR PANEL SYSTEM(M MODE)

- 6. DISASSEMBLY AND ASSEMBLY

- 6.1. METHOD OF USING MANUAL

- 6.2. PRECAUTIONS WHEN CARRYING OUT OPERATION

- 6.3. SPECIAL TOOL LIST

- 6.4. SKETCHES OF SPECIAL TOOLS

- 6.5. STARTING MOTOR

- 6.5.1. REMOVAL AND INSTALLATION

- 6.6. ALTERNATOR

- 6.6.1. REMOVAL AND INSTALLATION

- 6.7. FUEL INJECTION PUMP

- 6.7.1. REMOVAL

- 6.7.2. INSTALLATION

- 6.8. NOZZLE HOLDER

- 6.8.1. REMOVAL AND INSTALLATION

- 6.9. WATER PUMP

- 6.9.1. REMOVAL AND INSTALLATION

- 6.10. THERMOSTAT

- 6.10.1. REMOVAL AND INSTALLATION

- 6.11. ENGINE OIL COOLER

- 6.11.1. REMOVAL AND INSTALLATION

- 6.12. ENGINE,HYDRAULIC PUMP

- 6.12.1. REMOVAL

- 6.12.2. INSTALLATION

- 6.13. FUEL TANK

- 6.13.1. REMOVAL AND INSTALLATION

- 6.14. CENTER HINGE PIN

- 6.14.1. REMOVAL

- 6.14.2. INSTALLATION

- 6.15. STEERING,HYDRAULIC PUMP

- 6.15.1. REMOVAL AND INSTALLATION

- 6.16. STEERING VALVE

- 6.16.1. REMOVAL

- 6.16.2. INSTALLATION

- 6.17. STEERING CYLINDER

- 6.17.1. REMOVAL

- 6.17.2. INSTALLATION

- 6.17.3. DISASSEMBLY

- 6.17.4. ASSEMBLY

- 6.18. BRAKE MASTER CYLINDER

- 6.18.1. REMOVAL AND INSTALLATION

- 6.19. INCHING VALVE

- 6.19.1. REMOVAL AND INSTALLATION

- 6.20. HYDRAULIC TANK

- 6.20.1. REMOVAL AND INSTALLATION

- 6.21. MAIN CONTROL VALVE

- 6.21.1. REMOVAL AND INSTALLATION

- 6.22. BOOM CYLINDER

- 6.22.1. REMOVAL

- 6.22.2. INSTALLATION

- 6.23. BUCKET CYLINDER

- 6.23.1. REMOVAL

- 6.23.2. INSTALLATION

- 6.24. BOOM,BUCKET CYLINDER

- 6.24.1. DISASSEMBLY

- 6.24.2. ASSEMBLY

- 6.25. BUCKET

- 6.25.1. REMOVAL AND INSTALLATION

- 6.26. BOOM

- 6.26.1. REMOVAL

- 6.26.2. INSTALLATION

- 6.27. ENGINE HOOD

- 6.27.1. REMOVAL AND INSTALLATION

- 6.28. CANOPY

- 6.28.1. REMOVAL AND INSTALLATION

- 6.29. FLOOR FRAME

- 6.29.1. REMOVAL

- 6.29.2. INSTALLATION

- 6.30. COUNTERWEIGHT(REAR END)

- 6.30.1. REMOVAL AND INSTALLATION

- 6.31. COUNTERWEIGHT(LOWER PORTION)

- 6.31.1. REMOVAL AND INSTALLATION

- 6.32. MONITOR PANEL

- 6.32.1. REMOVAL AND INSTALLATION

- 7. MAINTENANCE STANDARD

- 7.1. ENGINE MOUNT

- 7.2. TRANSFER MOUNT

- 7.3. TRANSFER

- 7.4. HST INCHING VALVE

- 7.5. DRIVE SHAFT

- 7.6. DIFFERENTIAL

- 7.7. FINAL DRIVE

- 7.8. AXLE MOUNT

- 7.9. CENTER HINGE PIN

- 7.10. STEERING COLUMN

- 7.11. PRIORITY VALVE

- 7.12. STEERING CYLINDER MOUNT

- 7.13. PARKING BRAKE

- 7.14. HYDRAULIC AND STEERING PUMP

- 7.15. HYDRAULIC CYLINDER

- 7.16. WORK EQUIPMENT LINKAGE

- 7.17. BUCKET

- 7.18. BUCKET POSITIONER

- 8. OTHERS

- 8.1. ELECTRIC CIRCUIT DIAGRAM(1/2)

- 8.2. ELECTRIC CIRCUIT DIAGRAM(2/2)

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF