- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu WA150-5 Galeo Wheel Loader Shop Manual VEBM934100

$40.00

- Type Of Manual: Shop Manual

- Manual ID: VEBM934100

- Format: PDF

- Size: 38.7MB

- Number of Pages: 776

Category: Komatsu Shop Manual PDF

-

Model List:

- WA150-5 Galeo Wheel Loader

- 1. MAIN MENU

- 2. COVER

- 3. CONTENTS

- 4. GENERAL

- 4.1. GENERAL ASSEMBLY DRAWINGS

- 4.2. SPECIFICATIONS

- 4.3. WEIGHT TABLE

- 4.4. LIST OF LUBRICANT AND COOLANT

- 5. STRUCTURE, FUNCTION AND MAINTENANCE STANDARD

- 5.1. Engine mount and transfer mount

- 5.2. Damper

- 5.3. Cooling system

- 5.4. Power train

- 5.5. Power train system diagram

- 5.6. Drive shaft

- 5.7. HST hydraulic piping diagram

- 5.8. HST pump

- 5.9. Highpressure relief valve

- 5.10. Lowpressure relief valve

- 5.11. HST charge pump

- 5.12. Speedrelated valve (DA valve)

- 5.13. Highpressure cutoff valve

- 5.14. HST motor

- 5.15. EP servo valve

- 5.16. HA servo valve

- 5.17. Forwardreverse shuttle valve

- 5.18. Transfer

- 5.19. Clutch solenoid valve

- 5.20. Axle

- 5.21. Differential

- 5.22. Limitedslip differential

- 5.23. Final drive

- 5.24. Axle mounting and center hinge pin

- 5.25. Steering piping

- 5.26. Steering column

- 5.27. Priority valve

- 5.28. Orbitroll valve

- 5.29. Steering cylinder

- 5.30. Emergency steering piping

- 5.31. Emergency steering valve

- 5.32. Brake piping

- 5.33. Brake valve

- 5.34. Inching valve

- 5.35. Charge valve

- 5.36. Accumulator (for brake)

- 5.37. Slack adjuster

- 5.38. Brake

- 5.39. Parking brake control

- 5.40. Parking brake

- 5.41. Hydraulic piping

- 5.42. Work equipment lever linkage

- 5.43. Hydraulic tank

- 5.44. gear pump unit

- 5.45. Accumulator (for ppc circuit)

- 5.46. Lock valve

- 5.47. valve

- 5.48. Accumulator (for E.C.S.S.)

- 5.49. Hydraulic piping of coolingsystem

- 5.50. Cooling fan motor

- 5.51. Work equipment control valve

- 5.52. Work equipment PPC valve

- 5.53. Work equipment linkage

- 5.54. Bucket

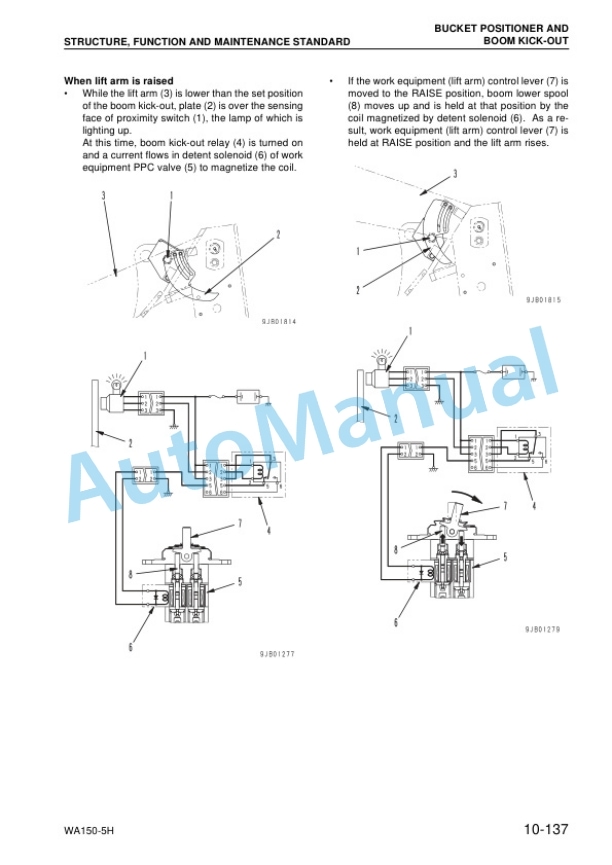

- 5.55. Bucket positioner and boom kickout

- 5.56. Work equipment cylinder

- 5.57. Air conditioner

- 5.58. Machine monitoring system

- 5.59. Machine monitor

- 5.60. List of items displayed onmonitor

- 5.61. Electrical system (HSTcontroller system)

- 5.62. HST controller

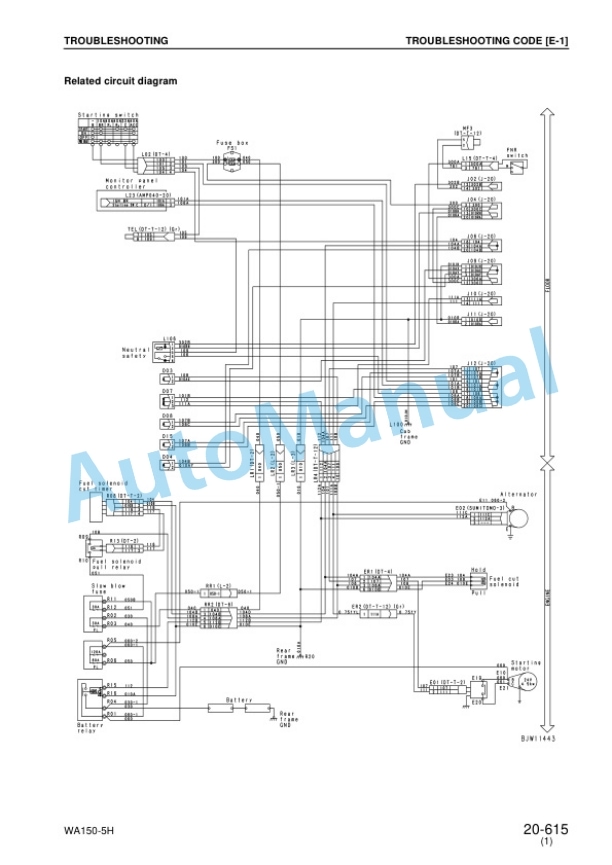

- 5.63. Engine start circuit

- 5.64. Engine stop circuit

- 5.65. Preheating circuit

- 5.66. Parking brake circuit

- 5.67. Electronically controlled suspension system

- 5.68. Sensors

- 6. TESTING AND ADJUSTING

- 6.1. STANDARD VALUE TABLE FOR ENGINE

- 6.2. STANDARD VALUE TABLE FOR CHASSIS

- 6.3. TESTING AND ADJUSTING

- 6.4. TROUBLESHOOTING

- 6.5. TROUBLESHOOTING OF HST CONTROLLER SYSTEM (HST MODE)

- 6.6. TROUBLESHOOTING OF TRAVEL DAMPER SYSTEM (ECSS MODE)

- 6.7. TROUBLSHOOTING OF MONITOR SYSTEM (MON MODE)

- 6.8. TROUBLESHOOTING OF ELECTRICAL SYSTEM (E MODE)

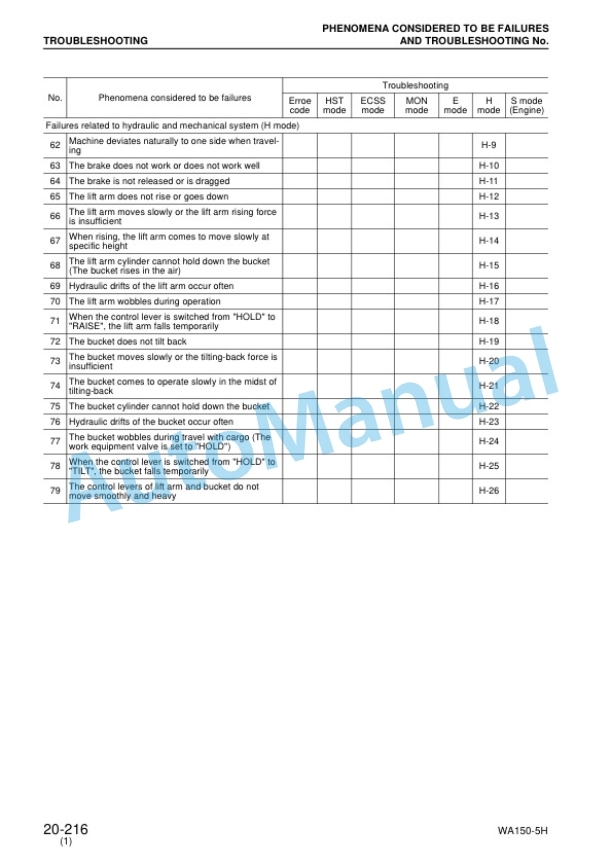

- 6.9. TROUBLESHOOTING OF HYDRAULIC, MECHANICAL SYSTEM (H MODE)

- 6.10. TROUBLESHOOTING OF ENGINE (S MODE)

- 7. DISASSEMBLY AND ASSEMBLY

- 7.1. HOW TO READ THIS MANUAL

- 7.2. PRECAUTIONS WHEN PERFORMING OPERATION

- 7.3. SPECIAL TOOL LIST

- 7.4. SKETCHES OF SPECIAL TOOLS

- 7.5. REMOVAL AND INSTALLATION OF FUEL INJECTION PUMP ASSEMBLY

- 7.6. REMOVAL AND INSTALLATION OF NOZZLE HOLDER

- 7.7. REMOVAL AND INSTALLATION OF CYLINDER HEAD ASSEMBLY

- 7.8. REMOVAL AND INSTALLATION OF ENGINE ASSEMBLY

- 7.9. REMOVAL AND INSTALLATION OF RADIATOR ASSEMBLY

- 7.10. REMOVAL AND INSTALLATION OF AIR AFTERCOOLER

- 7.11. REMOVAL AND INSTALLATION OF HYDRAULIC OIL COOLER ASSEMBLY

- 7.12. REMOVAL AND INSTALLATION OF COOLING FAN AND FAN MOTOR ASSEMBLY

- 7.13. REMOVAL AND INSTALLATION OF FUEL TANK ASSEMBLY

- 7.14. REMOVAL AND INSTALLATION OF TRANSFER ASSEMBLY

- 7.15. DISASSEMBLY AND ASSEMBLY OF TRANSFER ASSEMBLY

- 7.16. REMOVAL AND INSTALLATION OF PARKING BRAKE ASSEMBLY

- 7.17. DISASSEMBLY AND ASSEMBLY OF PARKING BRAKE ASSEMBLY

- 7.18. REMOVAL AND INSTALLATION OF FRONT AXEL ASSEMBLY

- 7.19. REMOVAL AND INSTALLATION OF REAR AXEL ASSEMBLY

- 7.20. DISASSEMBLY AND ASSEMBLY OF AXLE HOUSING ASSEMBLY

- 7.21. DISASSEMBLY AND ASSEMBLY OF DIFFERENTIAL ASSEMBLY

- 7.22. REMOVAL AND INSTALLATION OF HST PUMP AND 3GEAR PUMP ASSEMBLY

- 7.23. REMOVAL AND INSTALLATION OF HST MOTOR 1 ASSEMBLY

- 7.24. REMOVAL AND INSTALLATION OF HST MOTOR 2 ASSEMBLY

- 7.25. REMOVAL AND INSTALLATION OF WORK EQUIPMENT CONTROL VALVE ASSEMBLY

- 7.26. REMOVAL AND INSTALLATION OF TRAVEL DAMPER VALVE ASSEMBLY

- 7.27. REMOVAL AND INSTALLATION OF HYDRAULIC TANK

- 7.28. REMOVAL AND INSTALLATION OF WORK EQUIPMENT ASSEMBLY

- 7.29. DISASSMBLY AND ASSEMBLY OF HYDRAULIC CYLINDER ASSEMBLY

- 7.30. REMOVAL AND INSTALLATION OF OPERATORS CAB ASSEMBLY

- 7.31. REMOVAL AND INSTALLATION OF OPERATORS CAB GLASS (STUCK GLASS)

- 7.32. REMOVAL AND INSTALLATION OF CENTER HINGE PIN

- 7.33. REMOVAL AND INSTALLATION OF COUNTERWEIGHT

- 7.34. REMOVAL AND INSTALLATION OF AIR CONDITIONER UNIT ASSEMBLY

- 7.35. REMOVAL AND INSTALLATION OF AIR CONDITIONER COMPRESSOR ASSEMBLY

- 7.36. REMOVAL AND INSTALLATION OF MONITOR PANEL

- 8. OTHERS

- 8.1. Hydraulic circuit diagram

- 8.2. Electrical circuit diagram 1/4 (1/4)

- 8.3. Electrical circuit diagram 1/4 (2/4)

- 8.4. Electrical circuit diagram 1/4 (3/4)

- 8.5. Electrical circuit diagram 1/4 (4/4)

- 8.6. Electrical circuit diagram 2/4

- 8.7. Electrical circuit diagram 3/4

- 8.8. Electrical circuit diagram 4/4

- 8.9. Electrical circuit diagram 1/4 (1/4)

- 8.10. Electrical circuit diagram 1/4 (2/4)

- 8.11. Electrical circuit diagram 1/4 (3/4)

- 8.12. Electrical circuit diagram 1/4 (4/4)

- 8.13. Electrical circuit diagram 2/4

- 8.14. Electrical circuit diagram 3/4

- 8.15. Electrical circuit diagram 4/4

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF