- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu WA180-3 Wheel Loader Shop Manual SEBM005802

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM005802

- Format: PDF

- Size: 28.5MB

- Number of Pages: 549

Category: Komatsu Shop Manual PDF

-

Model List:

- WA180-3 Wheel Loader

- 1. MAIN MENU

- 2. CONTENTS

- 3. GENERAL

- 3.1. GENERAL ASSEMBLY DRAWING

- 3.2. SPECIFICATIONS

- 3.3. WEIGHT TABLE

- 3.4. LIST OF LUBRICANT AND WATER

- 4. STRUCTURE AND FUNCTION

- 4.1. POWER TRAIN

- 4.2. POWER TRAIN SYSTEM

- 4.3. TORQUE CONVERTER, TRANSMISSION PIPING

- 4.4. TRANSMISSION HYDRAULIC SYSTEM DIAGRAM

- 4.5. TRANSMISSION HYDRAULIC CIRCUIT DIAGRAM

- 4.6. TORQUE CONVERTER

- 4.7. TORQUE CONVERTER OIL FILTER

- 4.8. TRANSMISSION

- 4.9. TRANSMISSION CONTROL VALVE

- 4.10. TRANSMISSION CONTROL

- 4.11. DRIVE SHAFT

- 4.12. AXLE

- 4.13. FINAL DRIVE

- 4.14. AXLE MOUNT

- 4.15. CENTER HINGE PIN

- 4.16. STEERING PIPING

- 4.17. STEERING COLUMN

- 4.18. PRIORITY VALVE

- 4.19. CUSHION VALVE

- 4.20. STEERING VALVE (ORBITROLL)

- 4.21. BRAKE PIPING

- 4.22. BRAKE CONTROL

- 4.23. BRAKE BOOSTER

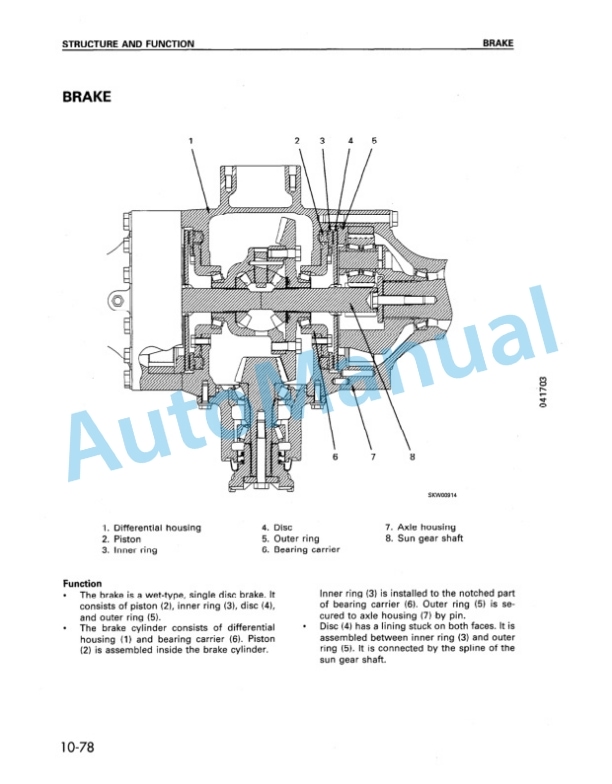

- 4.24. BRAKE

- 4.25. PARKING BRAKE CONTROL

- 4.26. PARKING BRAKE

- 4.27. HYDRAULIC PIPING

- 4.28. WORK EQUIPMENT HYDRAULIC SYSTEM DIAGRAM

- 4.29. WORK EQUIPMENT HYDRAULIC CIRCUIT DIAGRAM

- 4.30. HYDRAULIC TANK

- 4.31. MAIN CONTROL VALVE

- 4.32. WORK EQUIPMENT LEVER LINKAGE

- 4.33. WORK EQUIPMENT LINKAGE

- 4.34. BUCKET

- 4.35. BUCKET POSITIONER AND BOOM KICKOUT

- 4.36. PROXIMITY SWITCH

- 4.37. CANOPY

- 4.38. ROPS CAB

- 4.39. AIR CONDITIONER

- 4.40. TRAVEL DAMPER SYSTEM

- 4.41. ELECTRICAL WIRING DIAGRAM

- 4.42. ELECTRICAL CIRCUIT DIAGRAM (1/2)

- 4.43. AIR CONDITIONER ELECTRICAL CIRCUIT DIAGRAM (2/2)

- 4.44. CENTRAL PANEL (CLUSTER GUAGE)

- 4.45. SENSOR

- 4.46. ENGINE STARTING CIRCUIT

- 4.47. ENGINE STOP CIRCUIT

- 4.48. AUTOMATIC PREHEATING CIRCUIT (Q.G.S. CIRCUIT)

- 4.49. AUTOMATIC AIR BLEED MECHANISM

- 4.50. ELECTRICAL TRANSMISSION CONTROL

- 4.51. COMBINATION SWITCH

- 4.52. TRANSMISSION CUTOFF FUNCTION

- 4.53. PARKING BRAKE FUNCTION

- 4.54. KICKDOWN SWITCH

- 5. TESTING AND ADJUSTING

- 5.1. STANDARD VALUE TABLE FOR ENGINE

- 5.2. STANDARD VALUE TABLE FOR CHASSIS

- 5.3. TOOLS FOR TESTING, ADJUSTING, AND TROUBLESHOOTING

- 5.4. ADJUSTING VALVE CLEARANCE

- 5.5. MEASURING COMPRESSION PRESSURE

- 5.6. TESTING AND ADJUSTING FUEL INJECTION TIMING

- 5.7. MEASURING EXHAUST COLOR

- 5.8. MEASURING BLOWBY PRESSURE

- 5.9. MEASURING INTAKE AIR PRESSURE (BOOST PRESSURE)

- 5.10. MEASURING ENGINE OIL PRESSURE

- 5.11. TESTING AND ADJUSTING FAN BELT TENSION

- 5.12. MEASURING ENGINE SPEED

- 5.13. METHOD FOR ADJUSTING ENGINE STOP MOTOR CABLE

- 5.14. MEASURING ACCELERATOR PEDAL

- 5.15. MEASURING OPERATING FORCE, TRAVEL OF SPEED LEVER

- 5.16. MEASURING STALL SPEED

- 5.17. MEASURING TORQUE CONVERTER, TRANSMISSION OIL PRESSURE

- 5.18. METHOD OF OPERATING EMERGENCY MANUAL SPOOL

- 5.19. TESTING AND ADJUSTING STEERING WHEEL

- 5.20. MEASURING STEERING OIL PRESSURE

- 5.21. MEASURING OPERATING FORCE, TRAVEL OF BRAKE PEDAL

- 5.22. TESTING AND ADJUSTING BRAKE PEDAL LINKAGE

- 5.23. MEASURING BRAKE PERFORMANCE

- 5.24. MEASURING BRAKE OIL PRESSURE

- 5.25. TESTING FOR BRAKE DISC WEAR

- 5.26. BLEEDING AIR FROM BRAKE SYSTEM

- 5.27. MEASURING PARKING BRAKE PERFORMANCE

- 5.28. TESTING AND ADJUSTING PARKING BRAKE LINKAGE

- 5.29. TESTING PARKING BRAKE DISC WEAR

- 5.30. MEASURING PARKING BRAKE DISC WEAR

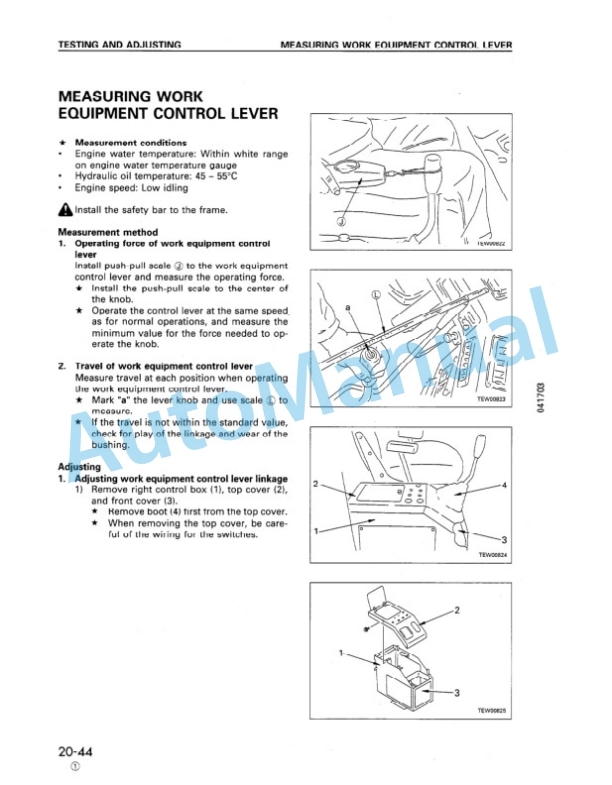

- 5.31. MEASURING WORK EQUIPMENT CONTROL LEVER

- 5.32. MEASURING STROKE OF WORK EQUIPMENT VALVE SPOOL

- 5.33. MEASURING WORK EQUIPMENT HYDRAULIC PRESSURE

- 5.34. MEASURING WORK EQUIPMENT

- 5.35. TESTING AND ADJUSTING BUCKET POSITIONER

- 5.36. TESTING AND ADJUSTING BOOM KICKOUT

- 5.37. TROUBLESHOOTING

- 5.37.1. TROUBLESHOOTING OF ENGINE SYSTEM

- 5.37.1.1. USING TROUBLESHOOTING CHARTS FOR ENGINERELATED FAILURE

- 5.37.1.2. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 5.37.1.3. S1 Starting performance is poor (Starting always takes time)

- 5.37.1.4. S2 Engine does not start

- 5.37.1.5. S3 Engine does not pick up smoothly (Followup is poor)

- 5.37.1.6. S4 Engine stops during operations

- 5.37.1.7. S5 Engine does not rotate smoothly (hunting)

- 5.37.1.8. S6 Engine lacks output (no power)

- 5.37.1.9. S7 Exhaust gas is black (incomplete combustion)

- 5.37.1.10. S8 Oil consumption is excessive (or exhaust gas is blue)

- 5.37.1.11. S9 Oil becomes contaminated quickly

- 5.37.1.12. S10 Fuel consumption is excessive

- 5.37.1.13. S11 Oil is in cooling water, or water spurts back, or water level goes down

- 5.37.1.14. S12 Oil pressure lamp lights up (drop in oil pressure)

- 5.37.1.15. S13 Oil level rises

- 5.37.1.16. S14 Water temperature becomes too high (overheating)

- 5.37.1.17. S15 Abnormal noise is made

- 5.37.1.18. S16 Vibration is excessive

- 5.37.2. TROUBLESHOOTING OF HYDRAULIC AND MECHANICAL SYSTEM (CHASSIS RELATED)

- 5.37.2.1. POWER TRAIN

- 5.37.2.2. STEERING SYSTEM

- 5.37.2.3. BRAKE SYSTEM

- 5.37.2.4. WORK EQUIPMENT

- 6. DISASSEMBLY AND ASSEMBLY

- 6.1. METHOD OF USING MANUAL

- 6.2. PRECAUTIONS WHEN CARRYING OUT OPERATION

- 6.3. SPECIAL TOOL LIST

- 6.4. STARTING MOTOR

- 6.4.1. REMOVAL AND INSTALLATION

- 6.5. ALTERNATOR

- 6.5.1. REMOVAL AND INSTALLATION

- 6.6. FUEL INJECTION PUMP

- 6.6.1. REMOVAL

- 6.6.2. INSTALLATION

- 6.7. ENGINE OIL COOLER

- 6.7.1. REMOVAL AND INSTALLATION

- 6.8. WATER PUMP

- 6.8.1. REMOVAL AND INSTALLATION

- 6.9. NOZZLE HOLDER

- 6.9.1. REMOVAL AND INSTALLATION

- 6.10. THERMOSTAT

- 6.10.1. REMOVAL AND INSTALLATION

- 6.11. TURBOCHARGER

- 6.11.1. REMOVAL AND INSTALLATION

- 6.12. TORQUE CONVERTER CHARGING PUMP

- 6.12.1. REMOVAL AND INSTALLATION

- 6.13. TORQUE CONVERTER, TRANSMISSION

- 6.13.1. REMOVAL

- 6.13.2. INSTALLATION

- 6.14. TORQUE CONVERTER

- 6.15. TRANSMISSION CONTROL VALVE

- 6.15.1. REMOVAL

- 6.15.2. INSTALLATION

- 6.15.3. DISASSEMBLY

- 6.15.4. ASSEMBLY

- 6.16. TRANSMISSION SOLENOID VALVE

- 6.16.1. DISASSEMBLY AND ASSEMBLY

- 6.17. TRANSMISSION ACCUMULATOR VALVE

- 6.18. CENTER HINGE PIN

- 6.18.1. REMOVAL

- 6.18.2. INSTALLATION

- 6.19. PRIORITY VALVE

- 6.19.1. REMOVAL

- 6.19.2. INSTALLATION

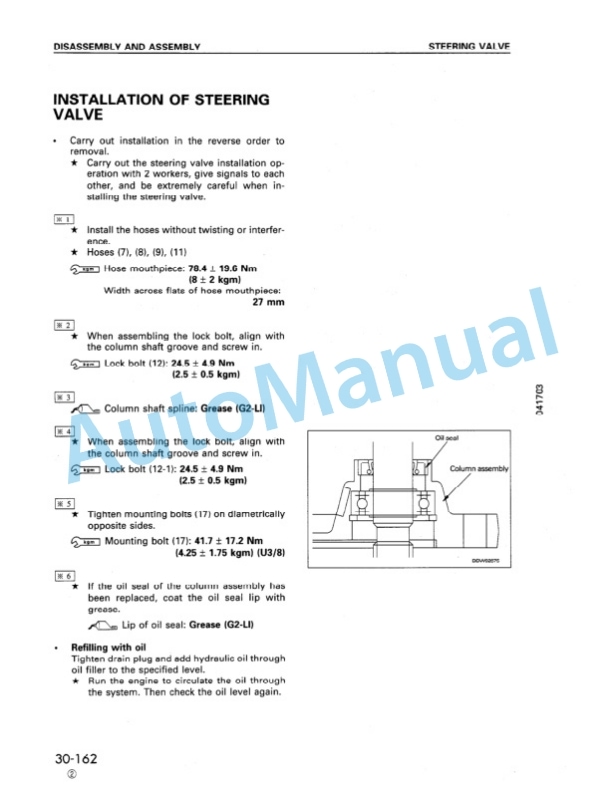

- 6.20. STEERING VALVE

- 6.20.1. REMOVAL

- 6.20.2. INSTALLATION

- 6.20.3. DISASSEMBLY

- 6.20.4. ASSEMBLY

- 6.21. STEERING CYLINDER

- 6.22. HYDRAULIC TANK

- 6.22.1. REMOVAL

- 6.22.2. INSTALLATION

- 6.23. HYDRAULIC FILTER

- 6.23.1. REMOVAL AND INSTALLATION

- 6.24. HYDRAULIC, STEERING PUMP

- 6.24.1. REMOVAL

- 6.24.2. INSTALLATION

- 6.25. MAIN CONTROL VALVE

- 6.25.1. REMOVAL

- 6.25.2. INSTALLATION

- 6.25.3. DISASSEMBLY

- 6.25.4. ASSEMBLY

- 6.26. BUCKET CYLINDER

- 6.27. HYDRAULIC CYLINDER

- 6.27.1. DISASSEMBLY

- 6.27.2. ASSEMBLY

- 6.28. WORK EQUIPMENT

- 6.28.1. REMOVAL AND INSTALLATION

- 6.29. INSTRUMENT PANEL

- 6.29.1. REMOVAL AND INSTALLATION

- 7. MAINTENANCE STANDARD

- 7.1. ENGINE MOUNT, TRANSMISSION MOUNT

- 7.2. TORQUE CONVERTER CHARGING PUMP

- 7.3. TORQUE CONVERTER

- 7.4. TRANSMISSION

- 7.5. TRANSMISSION CONTROL VALVE

- 7.6. ACCUMULATOR VALVE

- 7.7. DRIVE SHAFT

- 7.8. DIFFERENTIAL

- 7.9. FINAL DRIVE

- 7.10. AXLE MOUNT

- 7.11. CENTER HINGE PIN

- 7.12. STEERING COLUMN

- 7.13. PRIORITY VALVE

- 7.14. STEERING CYLINDER MOUNT

- 7.15. BRAKE BOOSTER

- 7.16. BRAKE

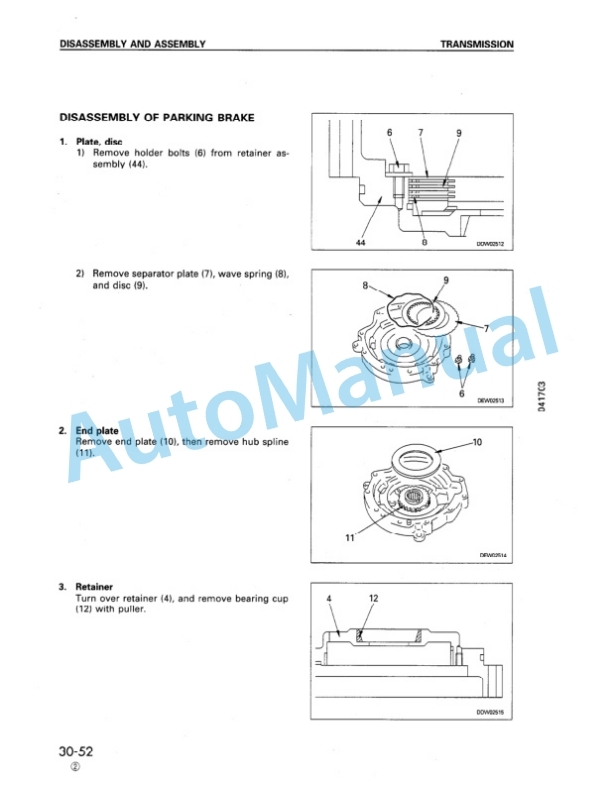

- 7.17. PARKING BRAKE

- 7.18. HYDRAULIC PUMP

- 7.19. MAIN CONTROL VALVE

- 7.20. HYDRAULIC CYLINDER

- 7.21. WORK EQUIPMENT LINKAGE

- 7.22. BUCKET

- 7.23. BUCKET POSITIONER AND BOOM KICKOUT

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF