- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu WA200-1, WA250-1 Wheel Loader Shop Manual SEBM04180110

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEBM04180110

- Format: PDF

- Size: 61.1MB

- Number of Pages: 844

Category: Komatsu Shop Manual PDF

-

Model List:

- WA200-1 Wheel Loader

- WA250-1 Wheel Loader

- 1. COVER

- 2. CONTENTS

- 3. ENGINE

- 3.1. STRUCTURE AND FUNCTION

- 3.1.1. ENGINE MOUNT

- 3.1.2. RADIATOR AND COOLER

- 3.1.3. RADIATOR AND COOLER

- 3.1.4. ENGINE CONTROL

- 3.2. TESTING AND ADJUSTING

- 3.2.1. TABLE OF JUDGEMENT STANDARD

- 3.2.2. TESTING AND ADJUSTING TOOL LIST

- 3.2.3. ADJUSTING VALVE CLEARANCE

- 3.2.4. MEASURING COMPRESSION PRESSURE

- 3.2.5. TESTING AND ADJUSTING FUEL INJECTION TIMING

- 3.2.6. MEASURING ENGINE OIL PRESSURE AND TEMPERATURE

- 3.2.7. MEASURING BLOWBY PRESSURE

- 3.2.8. TESTING AND ADJUSTING FAN BELT TENSION

- 3.2.9. MEASURING EXHAUST GAS COLOR

- 3.2.10. ADJUSTING FUEL CUT SOLENOID

- 3.2.11. MEASURING OPERATING FORCE AND OPERATING ANGLE OF ACCELERATOR PEDAL

- 3.3. DISASSEMBLY AND ASSEMBLY

- 3.3.1. STARTING MOTOR

- 3.3.2. ALTERNATOR

- 3.3.3. ENGINE OIL COOLER

- 3.3.4. FUEL INJUCTION PUMP

- 3.3.5. WATER PUMP

- 3.3.6. NOZZLE HOLDER

- 3.3.7. CYLINDER HEAD

- 3.3.8. RADIATOR

- 3.3.9. ENGINE

- 3.3.10. FUEL TANK

- 4. POWER TRAIN

- 4.1. STRUCTURE AND FUNCTION

- 4.1.1. GENERAL

- 4.1.2. HYDRAULIC CIRCUIT FOR POWER TRAIN

- 4.1.3. HYDRAULIC CIRCUIT DIAGRAM FOR POWER TRAIN

- 4.1.4. TORQUE CONVERTER AND TRANSMISSION PIPING

- 4.1.5. TORQUE CONVERTER CHARGING PUMP

- 4.1.6. TORQUE CONVERTER

- 4.1.7. TORQUE CONVERTER OIL FILTER

- 4.1.8. TORQUE CONVERTER OIL COOLER AND RADIATOR

- 4.1.9. TORQUE CONVERTER REGULATOR VALVE

- 4.1.10. TORQFLOW TRANSMISSION

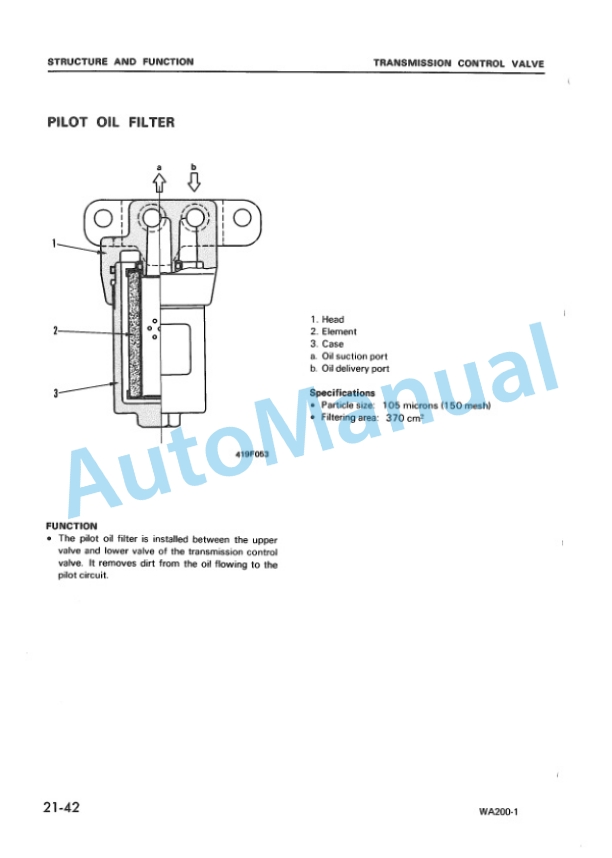

- 4.1.11. TRANSMISSION CONTROL VALVE

- 4.1.12. TRANSMISSION CONTROL VALVE

- 4.1.13. TRANSMISSION CONTROL VALVE

- 4.1.14. TIRE AND WHEEL

- 4.2. TESTING AND ADJUSTIOG

- 4.2.1. STANDARD VALUE TABLE

- 4.2.2. TOOL LIST FOR TESTING AND ADJUSTING

- 4.2.3. MEASURING ENGINE STALL SPEED

- 4.2.4. MEASURING OIL PRESSURE OF TORQUE CONVERTER AND TRANSMISSION

- 4.2.5. MEASURING SHIFT LEVER

- 4.2.6. METHOD FOR OPERATION OF EMERGENCY MANUAL SPOOL

- 4.2.7. TIRE AND WHEEL

- 4.2.8. TROUBLESHOOTING

- 4.3. DISASSEMBLY AND ASSEMBLY

- 4.3.1. TORQUE CONVERTER CHARGING PUMP

- 4.3.2. TORQUE CONVERTER, TRANSMISSION

- 4.3.3. TORQUE CONVERTER

- 4.3.4. TRANSMISSION

- 4.3.5. CLUTCH PACK

- 4.3.6. TRANSMISSION CONTROL VALVE

- 4.3.7. TRANSMISSION SOLENOID VALVE

- 4.3.8. SELECTOR VALVE

- 4.3.9. DRIVE SHAFT

- 4.3.10. FRONT AXLE

- 4.3.11. REAR AXLE

- 4.3.12. DIFFERENTIAL

- 4.3.13. AXLE HOUSING

- 4.4. MAINTENANCE STANDARD

- 4.4.1. TRANSMISSION AND ENGINE MOUNT

- 4.4.2. TORQUE CONVERTER CHARGING PUMP

- 4.4.3. TORQUE CONVERTER

- 4.4.4. TORQUE CONVERTER REGULATOR VALVE

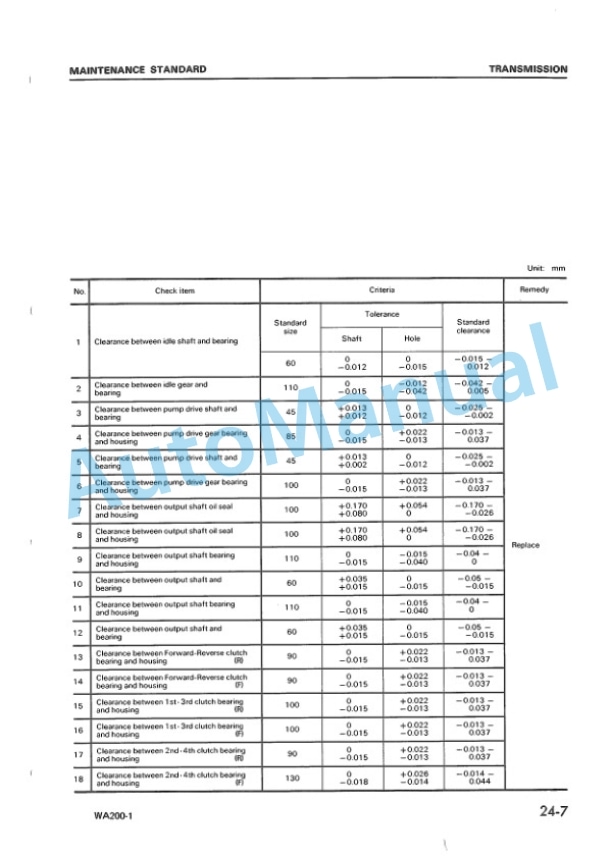

- 4.4.5. TRANSMISSION

- 4.4.6. TRANSMISSION CLUTCH ASSEMBLY

- 4.4.7. TRANSMISSION CONTROL VALVE

- 4.4.8. SOLENOID VALVE

- 5. STEERING SYSTEM

- 5.1. STRUCTURE AND FUNCTION

- 5.1.1. GENERAL

- 5.1.2. HYDRAULIC CIRCUIT FOR STEERING

- 5.1.3. STEERING VALVE

- 5.1.4. HYDRAULIC CIRCUIT FOR STEERING

- 5.1.5. STTERING VALVE

- 5.1.6. STEERING COLUMN AND GEAR BOX

- 5.1.7. STEERING LINKAGE

- 5.1.8. STEERING CYLINDER

- 5.1.9. CENTER HINGE PIN

- 5.2. TESTING AND ADJUSTING

- 5.2.1. STANDARD VALUE TABLE

- 5.2.2. TOOL LIST FOR TESTING AND ADJUSTING

- 5.2.3. MEASURING STEERING WHEEL PLAY

- 5.2.4. MEASURING OPERATING FORCE OF STEERING WHEEL

- 5.2.5. OPERATING TIME OF STEERING WHEEL

- 5.2.6. TESTING STEERING LINKAGE

- 5.2.7. ADJUSTING STEERING LINKAGE

- 5.2.8. STEERING OIL PRESSURE

- 5.2.9. TROUBLESHOOTING

- 5.3. DISASSEMBLY AND ASSEMBLY

- 5.3.1. STEERING GEAR BOX

- 5.3.2. STEERING VALVE

- 5.3.3. PRIORITY VALVE

- 5.3.4. STEERING CYLINDER

- 5.3.5. CENTER HINGE PIN

- 5.4. MAINTENANCE STANDARD

- 5.4.1. STEERING VALVE

- 5.4.2. STTEERING CYLINDER MOUNT

- 5.4.3. STEERING CYLINDER

- 5.4.4. CENTER HINGE PIN

- 5.4.5. STEERING LINKAGE

- 5.4.6. STEERING COLUMN AND GEAR BOX

- 6. BRAKE AND AIR SYSTEM

- 6.1. STRUCTURE AND FUNCTION

- 6.1.1. GENERAL

- 6.1.2. POWER MASTER CYLINDER

- 6.1.3. BRAKE

- 6.1.4. PARKING BRAKE

- 6.2. TESTING AND ADJUSTING

- 6.2.1. STANDARD VALUE TABLE

- 6.2.2. TOOL LIST FOR TESTING AND ADJUSTING

- 6.2.3. MEASURING BRAKE PEDAL

- 6.2.4. TESTING AND ADJUSTING BRAKE PEDAL LINKAGE

- 6.2.5. CHECKING BRAKE PERFORMANCE

- 6.2.6. CHECKING BRAKE PISTON LEAKAGE

- 6.2.7. MEASURING WEAR OF BRAKE DISC

- 6.2.8. AIR BLEEDING FROM BRAKE CIRCUIT

- 6.2.9. CHECKING PARKING BRAKE PERFORMANCE

- 6.2.10. CHECKING AND ADJUSTING PARKING BRAKE

- 6.2.11. MEASURING CLEARANCE OF PARKING BRAKE

- 6.2.12. TROUBLESHOOTING

- 6.3. DISASSEMBLY AND ASSEMBLY

- 6.3.1. POWER MASTER CYLINDER

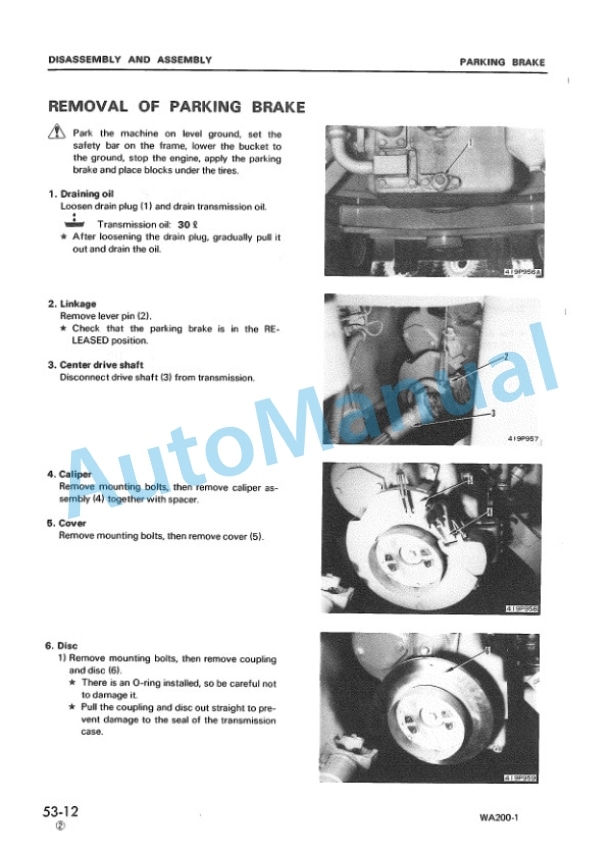

- 6.3.2. PARKING BRAKE

- 6.3.3. PARKING BRAKE PAD

- 6.4. MAINTENANCE STANDARD

- 6.4.1. POWER MASTER CYLINDER

- 6.4.2. BRAKE

- 6.4.3. PARKING BRAKE

- 7. WORK EQUIPMENT SYSTEM

- 7.1. STRUCTURE AND FUNCTION

- 7.1.1. GENERAL

- 7.1.2. HYDRAULIC CIRCUIT

- 7.1.3. HYDRAULIC CIRCUIT DIAGRAM

- 7.1.4. WORK EQUIPMENT LEVER LINKAGE

- 7.1.5. BUCKET LINKAGE

- 7.1.6. BUCKET POSITIONER AND BOOM KICKOUT

- 7.1.7. HYDRAULIC TANK

- 7.1.8. HYDRAULIC AND STEERING PUMPS

- 7.1.9. MAIN CONTROL VALVE

- 7.1.10. HYDRAULIC CYLINDER

- 7.2. TESTING AND ADJUSTING

- 7.2.1. STANDARD VALUE TABLE

- 7.2.2. TOOL LIST FOR TESTING AND ADJUSTING

- 7.2.3. MEASURING DUMP AND LIFT CONTROL LEVERS

- 7.2.4. ADJUSTING DUMP AND LIFT CONTROL LEVERS

- 7.2.5. MEASURING HYDRAULIC PRESSURE

- 7.2.6. MEASURING LIFT ARM AND BUCKET

- 7.2.7. MEASURING HYDRAULIC DRIFT OF LIFT ARM AND BUCKET

- 7.2.8. ADJUSTING BUCKET POSITIONER

- 7.2.9. ADJUSTING BOOM KICKOUT

- 7.2.10. TROUBLESHOOTING

- 7.3. DISASSEMBLY AND ASSEMBLY

- 7.3.1. HYDRAULIC TANK

- 7.3.2. HYDRAULIC FILTER

- 7.3.3. HYDRAULIC, STEERING PUMP

- 7.3.4. MAIN CONTROL VALVE

- 7.3.5. DUMP CYLINDER

- 7.3.6. LIFT CYLINDER

- 7.3.7. DUMP CYLINDER

- 7.3.8. LIFT CYLINDER

- 7.3.9. WORK EQUIPMENT

- 7.3.10. COUNTERWEIGHT

- 7.4. MAINTENANCE STANDARD

- 7.4.1. MAIN CONTROL VALVE

- 7.4.2. DUMP CYLINDER

- 7.4.3. LIFT CYLINDER

- 7.4.4. DUCKET LINKAGE

- 7.4.5. DUCKET LINKAGE

- 7.4.6. BUCKET

- 7.4.7. HYDRAULIC AND STEERING PUMP

- 8. ELECTRICAL AND ELECTRONIC SYSTEM

- 8.1. STRUCTURE AND FUNCTION

- 8.1.1. ELECTRICAL CIRCUIT DIAGRAM

- 8.1.2. ENGINE STOP CIRCUIT

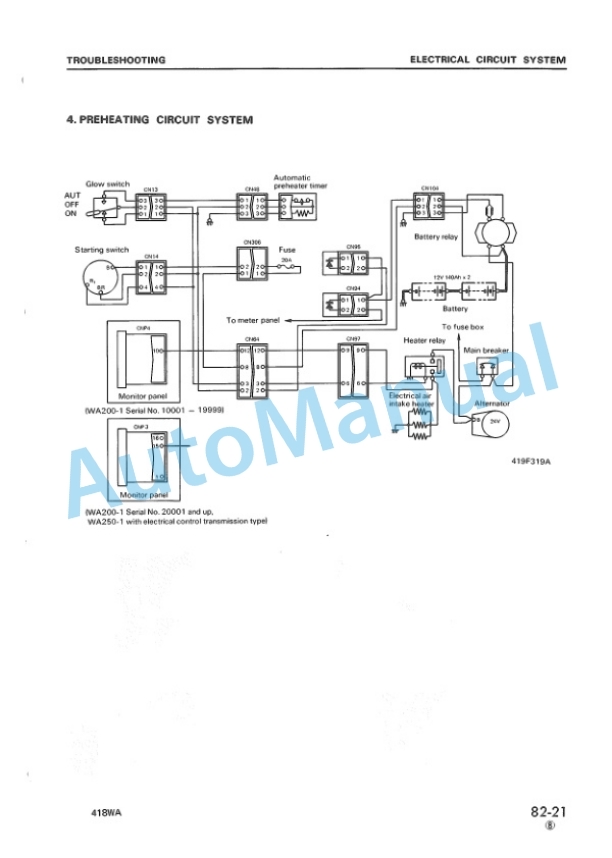

- 8.1.3. PREHATING CIRCUIT

- 8.1.4. COMBINATION SWITCH

- 8.1.5. ELECTRICAL TRANSMISSION CONTROL

- 8.1.6. ELECTRONIC VEHICLE MONITORING SYSTEM (EVMS)

- 8.2. TESTING AND ADJUSTING

- 8.2.1. ADJUSTING SPEEDOMETER MODULE

- 8.2.2. TROUBLESHOOTING

- 8.3. DISASSEMBLY AND ASSEMBLY

- 8.3.1. REMOVAL OF MACHINE MONITOR

- 8.3.2. INSTALLATION OF MACHINE MONITOR

- 9. OTHERS

- 9.1. STRUCTURE AND FUNCTION

- 9.1.2. AIR CONDITIONER (OPTION)

- 9.2. DISASSEMBLY AND ASSEMBLY

- 9.2.2. AIR CONDITIONER UNIT

- 9.2.3. CONDENSER FOR AIR CONDITIONER

- 9.2.4. DRY RECEIVER

- 9.2.5. COMPRESSOR FOR AIR CONDITIONER

- 9.3. GEARPUMP

- 9.3.1. GENERAL

- 9.3.2. PRINCIPLE OF OPERATION

- 9.3.3. PRESSURE LOADED TYPE GEAR PUMP

- 9.3.4. FIXED SIDE PLATE TYPE GEAR PUMP

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF