- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu WA250PZ-5 Wheel Loader Shop Manual VEBM945100

$40.00

- Type Of Manual: Shop Manual

- Manual ID: VEBM945100

- Format: PDF

- Size: 48.4MB

- Number of Pages: 830

Category: Komatsu Shop Manual PDF

-

Model List:

- WA250PZ-5 Wheel Loader

- 1. VEBM945100 WA250PZ5

- 2. SAFETY

- 3. FOREWORD

- 4. GENERAL

- 4.1. GENERAL ASSEMBLY DRAWINGS

- 4.2. SPECIFICATIONS

- 4.3. WEIGHT TABLE

- 4.4. LIST OF LUBRICANT AND COOLANT

- 5. STRUCTURE, FUNCTION AND MAINTENANCE STANDARD

- 5.1. ENGINE MOUNT AND TRANSFER MOUNT

- 5.2. DAMPER

- 5.3. COOLING SYSTEM

- 5.4. POWER TRAIN

- 5.5. POWER TRAIN SYSTEM DIAGRAM

- 5.6. DRIVE SHAFT (PROPELLER SHAFT)

- 5.7. HST HYDRAULIC PIPING DIAGRAM

- 5.8. HST PUMP

- 5.9. HIGHPRESSURE RELIEF VALVE

- 5.10. LOWPRESSURE RELIEF VALVE

- 5.11. HST CHARGE PUMP

- 5.12. SPEEDRELATED VALVE (DA VALVE)

- 5.13. HIGHPRESSURE CUTOFF VALVE

- 5.14. HST MOTOR

- 5.15. EP SERVO VALVE

- 5.16. HA SERVO VALVE

- 5.17. FORWARDREVERSE SHUTTLE VALVE

- 5.18. TRANSFER

- 5.19. TRANSFER OIL COOLER

- 5.20. CLUTCH SOLENOID VALVE

- 5.21. AXLE

- 5.22. DIFFERENTIAL

- 5.23. LIMITEDSLIP DIFFERENTIAL

- 5.23.1. Operation of limitedslip differential

- 5.24. FINAL DRIVE

- 5.25. AXLE MOUNTING AND CENTER HINGE PIN

- 5.26. STEERING PIPING

- 5.27. STEERING COLUMN

- 5.28. PRIORITY VALVE

- 5.29. ORBITROLL VALVE

- 5.30. WAY RESTRICTOR VALVE

- 5.31. STEERING CYLINDER

- 5.32. EMERGENCY STEERING PIPING

- 5.33. EMERGENCY STEERING VALVE

- 5.34. BRAKE PIPING

- 5.35. BRAKE VALVE

- 5.36. INCHING VALVE

- 5.37. CHARGE VALVE

- 5.38. ACCUMULATOR (FOR BRAKE)

- 5.39. SLACK ADJUSTER

- 5.40. BRAKE

- 5.41. PARKING BRAKE CONTROL

- 5.42. PARKING BRAKE

- 5.43. HYDRAULIC PIPING

- 5.44. WORK EQUIPMENT LEVER LINKAGE

- 5.45. HYDRAULIC TANK

- 5.46. GEAR PUMP UNIT

- 5.47. ACCUMULATOR (FOR PPC CIRCUIT)

- 5.48. LOCK VALVE

- 5.49. BYPASS VALVE

- 5.50. VALVE

- 5.51. ACCUMULATOR (FOR E.C.S.S.)

- 5.52. HYDRAULIC PIPING OF COOLING SYSTEM

- 5.53. COOLING FAN MOTOR

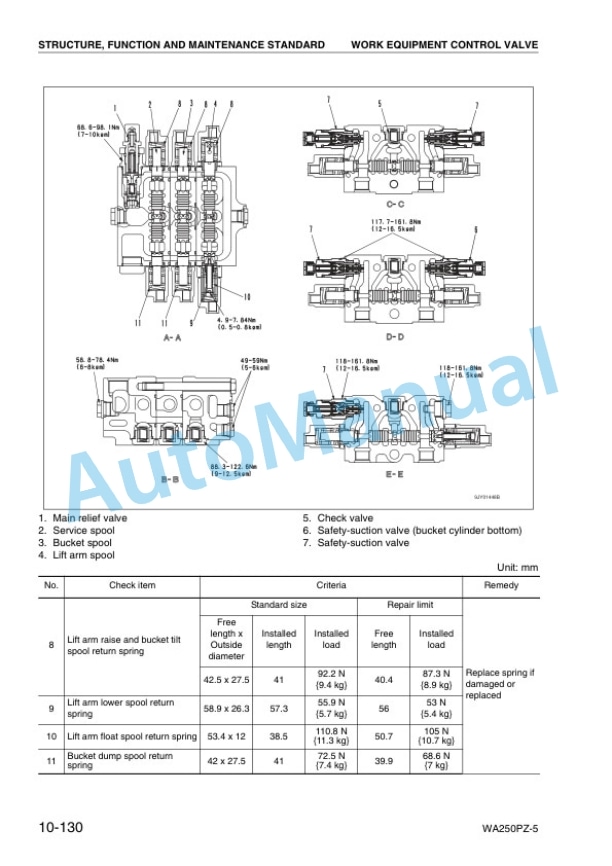

- 5.54. WORK EQUIPMENT CONTROL VALVE

- 5.55. WORK EQUIPMENT PPC VALVE

- 5.56. ATTACHMENT PPC VALVE (IF EQUIPPED)

- 5.57. WORK EQUIPMENT LINKAGE

- 5.58. BUCKET

- 5.59. CONTROL OF BUCKET POSITIONER, BOOM KICKOUT

- 5.60. WORK EQUIPMENT CYLINDER

- 5.61. AIR CONDITIONER

- 5.62. MACHINE MONITORING SYSTEM

- 5.63. MACHINE MONITOR

- 5.64. LIST OF ITEMS DISPLAYED ON MONITOR

- 5.65. ELECTRICAL SYSTEM (HST CONTROLLER SYSTEM)

- 5.66. HST CONTROLLER

- 5.67. FUNCTION OF SELECTING FORWARDREVERSE SELECTOR SWITCH

- 5.68. ENGINE START CIRCUIT

- 5.69. ENGINE STOP CIRCUIT

- 5.70. PREHEATING CIRCUIT

- 5.71. (AUTOMATIC PREHEATING SYSTEM)

- 5.72. PARKING BRAKE CIRCUIT

- 5.73. ELECTRONICALLY CONTROLLED SUSPENSION SYSTEM

- 5.74. SENSORS

- 6. TESTING AND ADJUSTING

- 6.1. STANDARD VALUE TABLE FOR engine

- 6.2. STANDARD VALUE TABLE FOR CHASSIS

- 6.3. TOOLS FOR TESTING, ADJUSTING, AND TROUBLESHOOTING

- 6.4. MEASURING ENGINE SPEED

- 6.5. Measuring exhaust gas color

- 6.6. ADJUSTING VALVE CLEARANCE

- 6.7. MEASURING COMPRESSION PRESSURE

- 6.8. MEASURING BLOWBY PRESSURE

- 6.9. TESTING AND ADJUSTING FUEL INJECTION TIMING

- 6.10. MEASURING ENGINE OIL PRESSURE

- 6.11. MEASURING, TESTING OPERATING FORCE OF ACCELERATOR PEDAL

- 6.12. ADJUSTING ENGINE STOP SOLENOID

- 6.13. ADJUSTING ENGINE SPEED SENSOR

- 6.14. MEASURING DIRECTIONAL LEVER

- 6.15. TESTING AND ADJUSTING HST OIL PRESSURE

- 6.16. MEASURING CLUTCH CONTROL PRESSURER

- 6.17. TESTING AND ADJUSTING STEERING WHEEL

- 6.18. TESTING AND ADJUSTING STEERING OIL PRESSURE

- 6.19. BLEEDING AIR FROM STEERING CIRCUIT

- 6.20. TESTING HYDRAULIC FAN

- 6.21. MEASURING BRAKE PEDAL

- 6.22. TESTING AND ADJUSTING BRAKE PEDAL LINKAGE

- 6.23. MEASURING BRAKE PERFORMANCE

- 6.24. TESTING AND ADJUSTING ACCUMULATOR CHARGE PRESSURE

- 6.25. MEASURING BRAKE OIL PRESSURE

- 6.26. MEASURING WEAR OF BRAKE DISC

- 6.27. BLEEDING AIR FROM BRAKE CIRCUIT

- 6.28. MEASURING PARKING BRAKE PERFORMANCE

- 6.29. TESTING AND ADJUSTING PARKING BRAKE LINKAGE

- 6.30. MEASURING PARKING BRAKE RELEASE PRESSURE

- 6.31. MEASURING AND ADJUSTING WORK EQUIPMENT CONTROL LEVER

- 6.32. TESTING AND ADJUSTING WORK EQUIPMENT HYDRAULIC PRESSURE

- 6.33. TESTING AND ADJUSTING WORK EQUIPMENT PPC OIL PRESSURE

- 6.34. BLEEDING AIR

- 6.35. RELEASING REMAINING PRESSURE IN HYDRAULIC CIRCUIT

- 6.36. TESTING AND ADJUSTING BUCKET POSITIONER

- 6.37. TESTING AND ADJUSTING OF BOOM KICKOUT

- 6.38. CHECKING PROXIMITY SWITCH ACTUATION DISPLAY LAMP

- 6.39. PROCEDURE FOR CHECKING DIODE

- 6.40. special functions of machine monitor

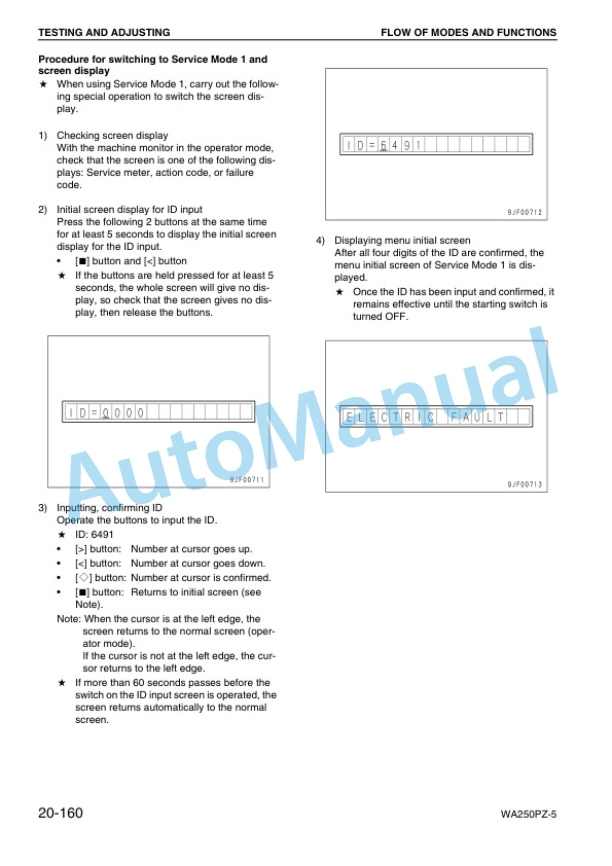

- 6.41. Flow of modes and functions

- 6.42. Pm CLINIC INSPECTION CHART

- 6.43. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 6.44. SEQUENCE OF EVENTS IN TROUBLESHOOTING

- 6.45. PRECAUTIONS WHEN CARRYING OUT MAINTENANCE

- 6.46. CHECK BEFORE TROUBLESHOOTING

- 6.47. Categories, procedure, and method of using troubleshooting charts

- 6.48. PHENOMENA CONSIDERED TO BE FAILURES AND TROUBLESHOOTING No.

- 6.49. Connection table for connector pin numbers

- 6.50. TADAPTER TABLE

- 6.51. CONNECTOR TYPES AND MOUNTING LOCATIONS

- 6.52. Connector layout drawing

- 6.53. HST controller system diagram

- 6.54. Before troubleshooting code display

- 6.55. Before troubleshooting electrical system

- 6.56. Information contained in troubuleshooting table

- 6.57. Monitor system circuit diagram

- 6.58. Before troubleshooting code display

- 6.59. Before troubleshooting electrical system

- 6.60. Information contained in troubuleshooting table

- 6.61. Electrical system diagram

- 6.62. Parking brake related diagram

- 6.63. Before troubleshooting electrical system

- 6.64. Information contained in troubuleshooting table

- 6.65. Method of using troubleshooting chart

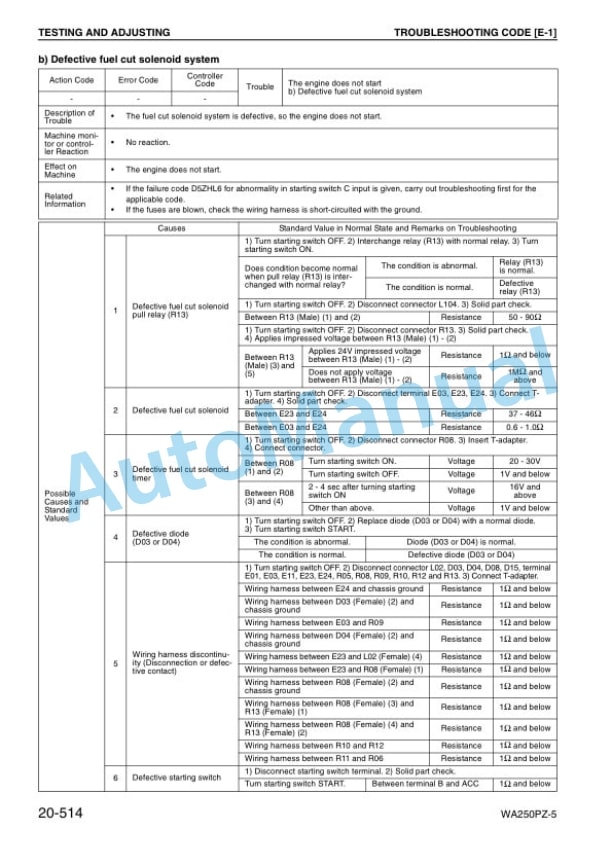

- 6.66. Failure code and cause table

- 6.67. Method of using troubleshooting charts

- 7. DISASSEMBLY AND ASSEMBLY

- 7.1. How to read this manual

- 7.2. Precautions when performing operation

- 7.3. Special tool list

- 7.4. Sketches of special tools

- 7.5. Removal, installation of fuel injection pump assembly

- 7.6. Removal, installation of nozzle holder assembly

- 7.7. Removal, installation of cylinder head assembly

- 7.8. Removal, installation of engine assembly

- 7.9. Removal, installation of radiator assembly

- 7.10. Removal, installation of air aftercooler

- 7.11. Removal, installation of hydraulic oil cooler assembly

- 7.12. Removal, installation of cooling fan and fan motor assembly

- 7.13. Removal, installation of fuel tank assembly

- 7.14. Removal, installation of transfer

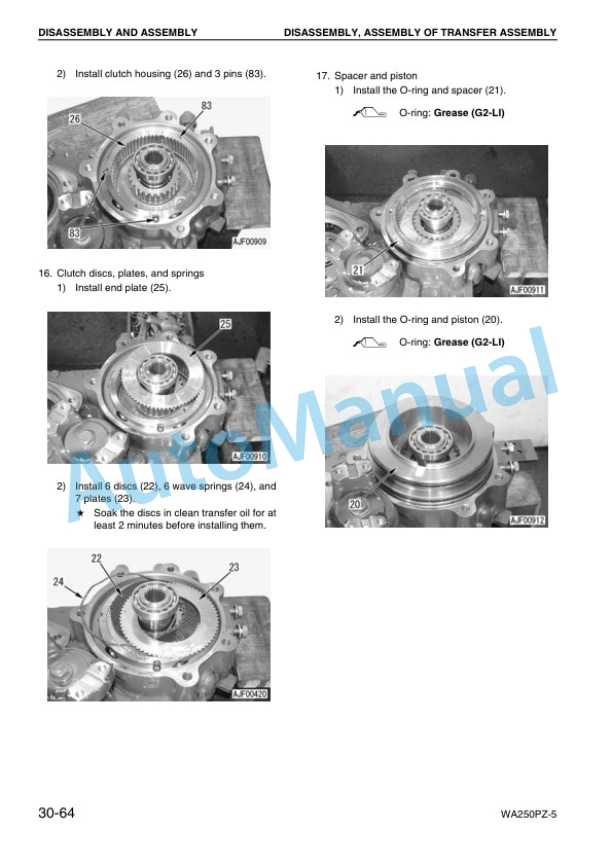

- 7.15. Disassembly, assembly of transfer assembly

- 7.16. Removal, installation of parking brake assembly

- 7.17. Disassembly, assembly of parking brake assembly

- 7.18. Removal, installation of front axle assembly

- 7.19. Removal, installation of rear axle assembly

- 7.20. Disassembly, assembly of axle housing assembly

- 7.21. Disassembly, assembly of differential assembly

- 7.22. Removal, installation of HST pump and 4gear pump assembly

- 7.23. Disassembly and assembly of HST pump assembly

- 7.24. Removal, installation of HST motor 1 assembly

- 7.25. Removal, installation of HST motor 2 assembly

- 7.26. Disassembly and assembly of HST motor assembly

- 7.27. Removal, installation of work equipment control valve assembly

- 7.28. Removal, installation of travel damper valve assembly

- 7.29. Removal, installation of hydraulic tank assembly

- 7.30. Removal, installation of work equipment assembly

- 7.31. Disassembly, assembly of hydraulic cylinder assembly

- 7.32. Removal, installation of operators cab assembly

- 7.33. Removal, installation of operators cab glass (Stuck glass)

- 7.34. Removal, installation of center hinge pin

- 7.35. Removal, installation of counterweight

- 7.36. Removal, installation of air conditioner unit assembly

- 7.37. Removal, installation of air conditioner compressor assembly

- 7.38. Removal, installation of monitor panel

- 8. OTHERS

- 8.1. HYDRAULIC CIRCUIT DIAGRAM

- 8.2. ELECTRICAL CIRCUIT DIAGRAM 1/4 (1/4)

- 8.3. ELECTRICAL CIRCUIT DIAGRAM 1/4 (2/4)

- 8.4. ELECTRICAL CIRCUIT DIAGRAM 1/4 (3/4)

- 8.5. ELECTRICAL CIRCUIT DIAGRAM 1/4 (4/4)

- 8.6. ELECTRICAL CIRCUIT DIAGRAM 2/4

- 8.7. ELECTRICAL CIRCUIT DIAGRAM 3/4

- 8.8. ELECTRICAL CIRCUIT DIAGRAM 4/4

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00

Komatsu Shop Manual PDF

$40.00

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF