- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu WA270-3, WA270PT-3 Wheel Loader Shop Manual VEBM340200

$40.00

- Type Of Manual: Shop Manual

- Manual ID: VEBM340200

- Format: PDF

- Size: 38.6MB

- Number of Pages: 588

Category: Komatsu Shop Manual PDF

-

Model List:

- WA270-3 Wheel Loader

- WA270PT-3 Wheel Loader

- 1. Shop Manual VEBM340200

- 1.1. Contents

- 1.2. Safety notice

- 1.3. Foreword

- 1.4. How to read the shop manual

- 1.5. Hoisting instructions

- 2. General

- 2.1. WA2703 Dimensions, Operating Data

- 2.2. WA270PT3 Dimensions, Operating Data

- 2.3. Specifications

- 2.4. WA2703 Weight Table

- 2.5. WA270PT3 Weight Table

- 2.6. Lubricants and Operating Equipment

- 2.7. Maintenance Schedule

- 2.8. Outlines of Service

- 2.9. Torque List

- 2.10. General View of Controls and Gauges

- 2.11. Emergency Drive

- 3. Structure and Function

- 3.1. Power Train

- 3.2. Power Train System

- 3.3. Torque Converter and Gearbox Piping

- 3.4. Torque Converter

- 3.4.1. Principle of Operation

- 3.5. Powershift Transmission

- 3.5.1. Reversing Transmission 4WG150

- 3.5.1.1. Front View

- 3.5.1.2. Side View

- 3.5.1.3. Rear View

- 3.5.1.4. Electro Hydraulic Control Valve

- 3.5.1.4.1. Detail X

- 3.5.1.5. Inductive Sender

- 3.5.1.6. Proximity Switch

- 3.5.1.7. Pressure Check Points

- 3.5.1.8. Transmission Hydraulic Diagram

- 3.5.1.9. Solenoid Expansion Valve and Overlap Valve

- 3.5.1.10. Thermostat Valve

- 3.5.2. Reversing Transmission 4WG160

- 3.5.2.1. Front View

- 3.5.2.2. Side View

- 3.5.2.3. Rear View

- 3.5.2.4. ElectroHydraulic Shift Control with Proportional Valves

- 3.5.2.5. Measuring Points and Conenctions

- 3.5.2.6. Oil Circuit Diagram Forward 1. Speed

- 3.5.2.7. Inductive Sender

- 3.5.2.8. Proximity Switch

- 3.5.2.9. Thermostat Valve

- 3.6. Drive Shaft

- 3.7. Front and Rear Axles

- 3.8. Differential Unit CK

- 3.9. Differential

- 3.9.1. Limited Slip Differential

- 3.10. Wheel Hub

- 3.11. Axle Mounting

- 3.12. Steering Articulation Joint

- 3.12.1. Outline

- 3.12.2. Assembly

- 3.13. Steering System

- 3.13.1. Steering Column, Orbit Roll

- 3.13.2. Steering Hydraukic Diagram

- 3.13.3. Hydraulic Steering System

- 3.13.3.1. In Neutral

- 3.13.3.2. In Use

- 3.13.4. Steering Servostat Control Valve

- 3.13.4.1. Neutral Position

- 3.13.4.2. Steering Position

- 3.13.5. Steering and Working Hydraulic Pump

- 3.13.6. Steering Orbit Roll

- 3.13.7. Steering Valve Block

- 3.13.8. Steering Damper

- 3.14. Steering Cylinder

- 3.14.1. Steering Cylinder

- 3.15. Emergency Steering Pump

- 3.16. Brake System

- 3.16.1. Brake Valve

- 3.16.1.1. Operating

- 3.16.2. Brake System Circuit

- 3.16.3. Gear Pump

- 3.16.4. Pressure Filter

- 3.16.5. Pressure Regulating Valve

- 3.16.6. Operation

- 3.16.7. Pressure Switch

- 3.16.8. Brake Accumulator

- 3.16.8.1. Hydraulic Circuit

- 3.17. Work Equipment Hydraulic System

- 3.17.1. Pilot Servo System

- 3.17.2. Oil Cooler

- 3.17.3. Combined Cooler

- 3.17.4. Working Hydraulic Pump

- 3.17.5. WA2703 Hydraulic System Diagram

- 3.17.6. WA270PT3 Hydraulic System Diagram

- 3.17.7. WA2703 Cut Off Valve

- 3.17.8. WA270PT3 Pilot Solenoid Valve

- 3.17.9. Main Control Valve

- 3.17.9.1. Shock and Anticavitation Valve

- 3.17.9.2. Anticavitation Valve

- 3.17.10. Pressure Control Valve

- 3.17.11. Joystick, Servo Control Valve

- 3.17.12. Lift Cylinder

- 3.17.13. Tilt Cylinder

- 3.17.14. ALSControl Unit

- 3.17.15. ALS Hydraulic Diagram

- 3.17.16. GasSide Test

- 3.17.17. Topping Up Gas Pressure

- 3.17.18. Hydraulic Accumulator

- 3.18. Lifting Frame

- 3.18.1. WA2703

- 3.18.2. WA270PT3

- 3.19. Bucket Positioner and Boom Kick Out

- 3.19.1. WA2703

- 3.19.2. WA270PT3

- 3.19.2.1. Bucket or Fork Positioner

- 3.19.2.2. Boom Kick Out

- 3.20. Machine Monitor System

- 3.20.1. Main Monitor

- 3.20.1.1. Display Function

- 3.20.1.2. Switch Function

- 3.20.2. Maintenance Monitor

- 3.20.2.1. Display Function

- 3.21. Electrical System

- 3.21.1. PreHeater Plug

- 3.21.2. Fuses

- 3.21.2.1. Slow Blow Fuses

- 3.21.3. Relays

- 3.21.4. Heating and Ventilation System

- 3.21.5. Wiring Diagrams

- 3.22. Air Conditioner

- 3.22.1. In General

- 3.22.2. Characteristics

- 3.22.3. Physical Datas

- 3.22.4. Function

- 3.22.4.1. Coolant Circuit

- 3.22.4.2. Handling Coolants

- 3.22.4.3. Regular Maintenance

- 3.22.4.4. Filling

- 3.22.4.5. Evacuation

- 3.22.4.6. Siphoning Coolant

- 3.22.4.7. Filling Quantity

- 3.22.4.8. Checking Coolant Level

- 3.22.4.9. Compressor Oil Change

- 3.22.4.10. Exchange of Magnetic Clutch

- 3.22.4.11. Exchange of Compressor

- 3.22.4.12. Service Operations

- 3.22.5. Electrical System

- 3.22.5.1. Pin assignment

- 3.22.5.2. Wiring Diagram

- 3.22.6. Technical Data

- 3.22.7. Fault Diagnosis

- 3.22.7.1. Preconditions

- 3.22.7.3. Operating Mode Switch

- 3.22.7.4. Circulating Air Mode

- 3.22.7.5. Temperature Setting

- 3.22.7.6. Air Conditioning Mode

- 3.22.8. Troubleshooting

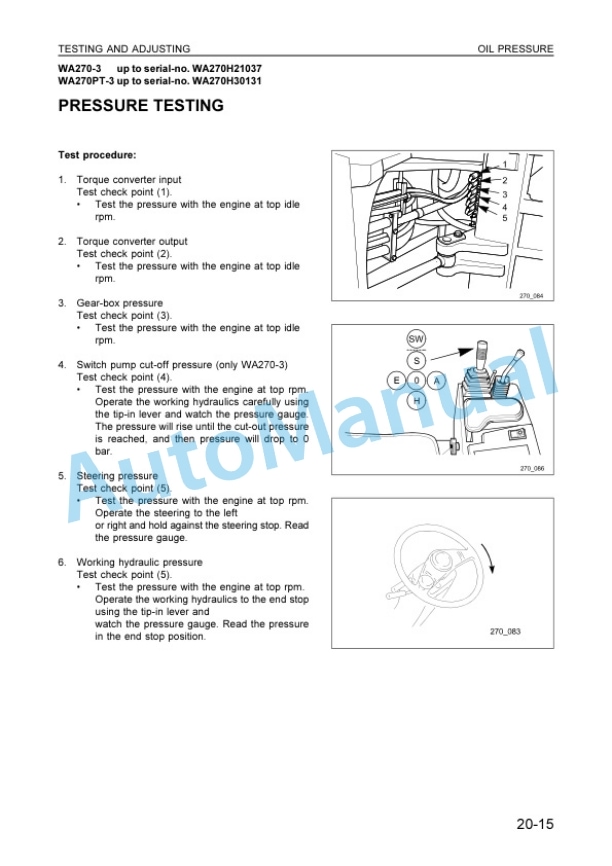

- 4. Testing and Adjusting

- 4.1. Contents

- 4.1.1. Standard Value Table

- 4.1.2. Test Certificate

- 4.1.2.1. WA2703, current

- 4.1.2.2. WA270PT3, current

- 4.1.2.3. WA2703, new

- 4.1.2.4. WA270PT3, new

- 4.1.3. Engine RPM Load

- 4.1.4. Hydraulic RPM Load

- 4.1.5. Torque Converter And Transmission Pressure

- 4.1.5.1. Current, with 4WG150

- 4.1.5.2. New, with 4WG160

- 4.1.6. Inductive Sender

- 4.1.7. Proximity Switch

- 4.1.8. Operating Force and Travel of Speed Lever

- 4.1.9. Operating Force of Steering Wheel

- 4.1.10. Operating Time for Steering Wheel

- 4.1.11. Steering Pressure

- 4.1.12. Switch Pump Pressure CutOff

- 4.1.13. Working Hydraulic Pressure

- 4.1.14. Servo Pilot Pressure

- 4.1.15. Hydraulic Drift of Work Equipment

- 4.1.16. Work Equipment

- 4.1.17. Brake Oil Pressure

- 4.1.18. Brake Wear

- 4.1.19. Bleeding of Brake

- 4.1.20. Main Brake Performance

- 4.1.21. Parking Brake Performance

- 4.1.22. Main Monitor

- 4.1.22.1. Speedometer Modul

- 4.1.23. Boom KickOut

- 4.1.24. Accelerator Pedal

- 4.2. Troubleshooting

- 4.2.1. Datas

- 4.2.2. Connecting of AEBStarter and ZFDisplay

- 4.2.3. Operating Instructions AEBStarter

- 4.2.3.1. Introduction

- 4.2.3.2. List of abbreviations

- 4.2.3.3. Procedures to start AEB

- 4.2.3.4. Display

- 4.2.4. Description of fault codes for ERGOControl EST37

- 4.2.4.1. Introduction

- 4.2.4.2. Display during operation

- 4.2.4.3. Display during AEBMode

- 4.2.4.4. Definition of operating modes

- 4.2.4.5. Table of fault codes

- 4.2.4.6. Measuring of resistance at actuator/sensors and cable

- 5. Disassembly and Assembly

- 5.1. Contents

- 5.1.1. Method Of Using Manual

- 5.1.2. Precautions

- 5.1.3. Special Tool List

- 5.1.4. Removal and Install

- 5.1.4.1. Hydraulic Filter

- 5.1.4.2. Steering Cylinder

- 5.1.4.3. Bucket Cylinder

- 5.1.4.4. Boom Cylinder

- 5.1.4.6. Main Monitor

- 5.1.4.7. Maintenance Monitor

- 5.1.4.8. PPCValve

- 5.1.4.9. Main Control Valve

- 5.1.4.10. Steering Valve

- 5.1.4.11. Priority Valve

- 5.1.4.12. Working and Steering Pump

- 5.1.4.13. Drive Shaft

- 5.1.4.14. Front Axle

- 5.1.4.15. Rear Axle

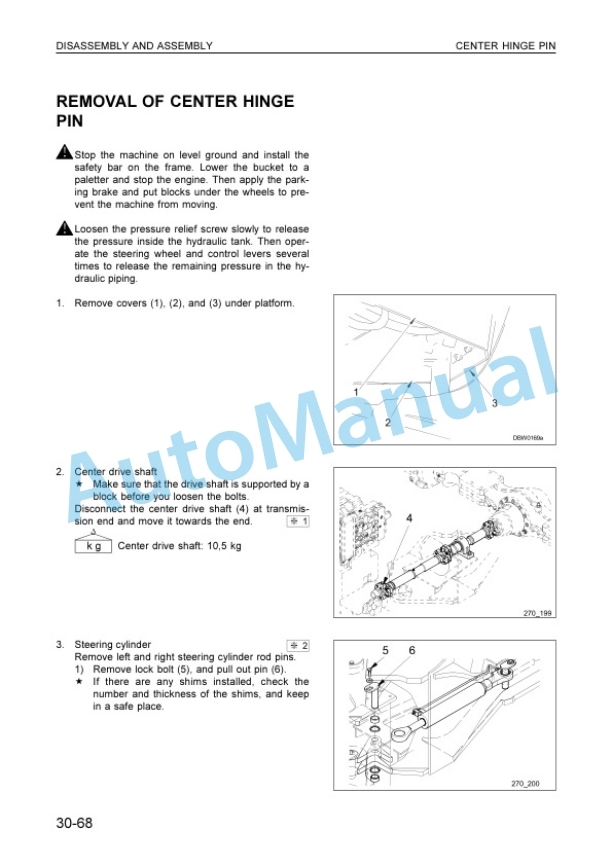

- 5.1.4.16. Center Hinge Pin

- 5.1.4.18. Air Conditioner

- 5.1.4.18.1. Condenser/Dry Receiver

- 5.1.4.18.2. Compressor

- 5.1.5. Disassembly and Assembly

- 5.1.5.1. Axle AP408

- 5.1.5.1.1. Overview

- 5.1.5.1.2. Gear ToothContact

- 5.1.5.1.3. Braking System

- 5.1.5.1.4. Special Tools

- 5.1.5.1.5. Planetary Rigid Axle

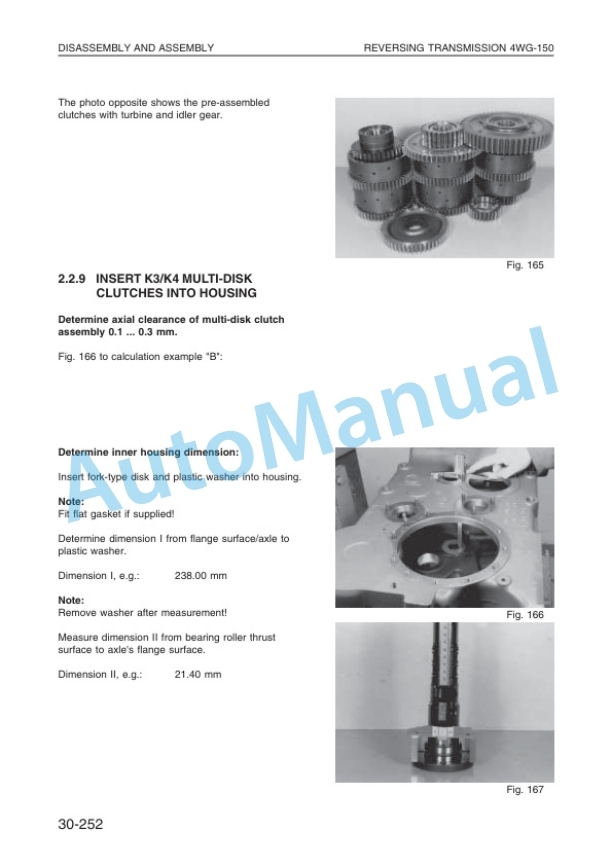

- 5.1.5.2. Reversing Transmission 4WG150

- 5.1.5.2.1. Special Tools

- 5.1.5.2.2. ElectroHydraulic Shifting Mechanism

- 5.1.5.2.3. Gear Box

- 5.1.5.3. Reversing Transmission 4WG160

- 5.1.5.3.1. General View

- 5.1.5.3.2. Special Tools

- 5.1.5.3.3. Hydraulic Control Unit

- 5.1.5.3.4. Powershift Transmission

- 6. trouble1.pdf

- 6.1. Connecting of AEBStarter and ZFDisplay

- 6.2. Operating Instructions AEB Starter

- 6.3. KOMATSUP/N 34Y00H0P01

- 6.3.1. Introduction

- 6.3.2. List of abbreviations

- 6.3.2.1. Procedure to start AEB

- 6.3.2.1.2. Display

- 6.4. Introduction

- 6.4.1. Abbreviations

- 6.4.2. ZF Display (42100H0R05)

- 6.4.3. Display during operation

- 6.4.4. Display during AEBMode

- 6.5. Definition of operating modes

Rate this product

You may also like

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF