- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu WA320-5H Wheel Loader Shop Manual VEBM240100

$40.00

- Type Of Manual: Shop Manual

- Manual ID: VEBM240100

- Format: PDF

- Size: 32.9MB

- Number of Pages: 972

Category: Komatsu Shop Manual PDF

-

Model List:

- WA320-5H Wheel Loader

- 1. SAFETY

- 1.1. SAFETY NOTICE

- 2. FOREWORD

- 2.1. GENERAL

- 2.2. HOW TO READ THE SHOP MANUAL

- 2.3. HOISTING INSTRUCTIONS

- 2.4. METHOD OF DISASSEMBLING, CONNECTING PUSHPULL TYPE COUPLER

- 2.5. COATING MATERIALS

- 2.6. STANDARD TIGHTENING TORQUE

- 2.7. ELECTRIC WIRE CODE

- 2.8. CONVERSION TABLE

- 2.9. UNITS

- 3. GENERAL

- 3.1. GENERAL ASSEMBLY DRAWINGS

- 3.2. SPECIFICATIONS

- 3.3. WEIGHT TABLE

- 3.4. PROPER SELECTION OF FUEL, COOLANT AND LUBRICANTS

- 4. STRUCTURE, FUNCTION AND MAINTENANCE STANDARD

- 4.1. Engine mount and transfer mount

- 4.2. Power train system diagram

- 4.3. Drive shaft (propeller shaft)

- 4.4. HST hydraulic piping diagram

- 4.5. Highpressure relief valve

- 4.6. Lowpressure relief valve

- 4.7. HST charge pump

- 4.8. Speedrelated valve (DA valve)

- 4.9. Highpressure cutoff valve

- 4.10. Forwardreverse shuttle valve

- 4.11. Transfer

- 4.12. Clutch solenoid valve

- 4.13. Axle

- 4.14. Differential

- 4.15. Limitedslip differential

- 4.16. Final drive

- 4.17. Axle mounting and center hinge pin

- 4.18. Steering piping

- 4.19. Steering column

- 4.20. Priority valve

- 4.21. Orbitroll valve

- 4.22. Cushion valve

- 4.23. Steering cylinder

- 4.24. Emergency steering piping

- 4.25. Emergency steering valve

- 4.26. Brake piping

- 4.27. Brake valve

- 4.28. Accumulator (for brake)

- 4.29. Slack adjuster

- 4.30. Brake

- 4.31. Parking brake control

- 4.32. Parking brake

- 4.33. Hydraulic piping

- 4.34. Work equipment lever linkage

- 4.35. Hydraulic tank

- 4.36. gear pump unit

- 4.37. Accumulator (for PPC circuit)

- 4.38. Lock valve

- 4.39. valve

- 4.40. Accumulator (forE.C.S.S.)

- 4.41. Hydraulic piping of cooling system

- 4.42. Cooling fan motor

- 4.43. Work equipment control valve

- 4.44. Work equipment PPC valve

- 4.45. Attachment PPC valve

- 4.46. Work equipment linkage

- 4.47. Bucket

- 4.48. Bucket positioner and boom kickout

- 4.49. Work equipment cylinder

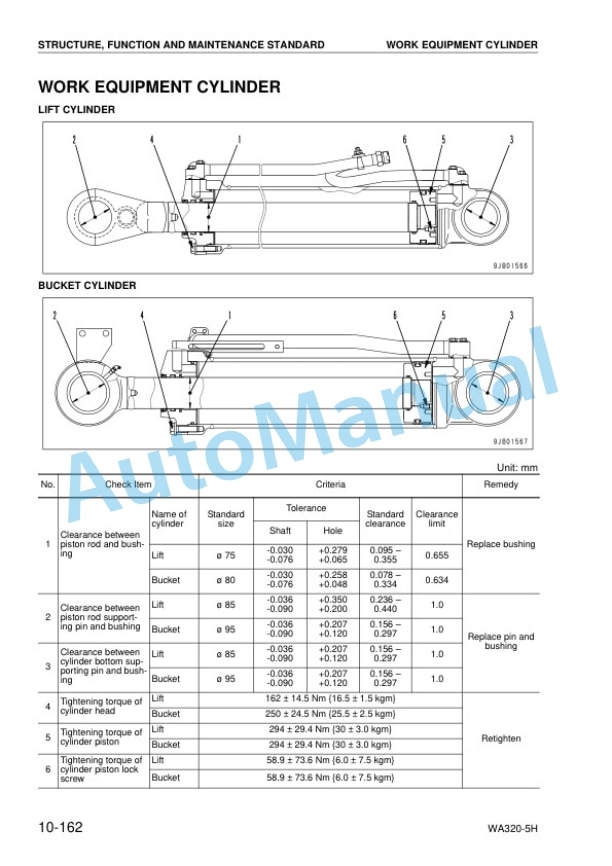

- 4.50. Air conditioner

- 4.51. Machine monitoring system

- 4.52. Machine monitor

- 4.53. List of items displayed on monitor

- 4.54. Electrical system (HST controller system)

- 4.55. HST controller

- 4.56. Function of selecting directional selector switch

- 4.57. Engine start circuit

- 4.58. Engine stop circuit

- 4.59. Preheating circuit (automatic preheating system)

- 4.60. Parking brake circuit

- 4.61. Electronically controlled suspension system

- 4.62. Sensors

- 4.63. STANDARD VALUE TABLE FOR engine

- 4.64. STANDARD VALUE TABLE FOR CHASSIS

- 5. TESTING AND ADJUSTING

- 5.1. Tools for testing, adjusting, and troubleshooting

- 5.2. Measuring engine speed

- 5.3. Measuring exhaust gas color

- 5.4. Adjusting valve clearance

- 5.5. Measuring compression pressure

- 5.6. Measuring blowby pressure

- 5.7. Testing and adjusting fuel injection timing

- 5.8. Measuring engine oil pressure

- 5.9. Measuring, testing operating force of accelerator pedal

- 5.10. Adjusting engine stop solenoid

- 5.11. Adjusting engine speed sensor

- 5.12. Testing and adjusting air conditioner compressor belt tension

- 5.13. Measuring directional lever

- 5.14. Testing and adjusting HST oil pressure

- 5.15. Measuring clutch control pressure

- 5.16. Testing and adjusting steering wheel

- 5.17. Testing and adjusting steering oil pressure

- 5.18. Bleeding air from steering circuit

- 5.19. Testing hydraulic fan

- 5.20. Measuring brake pedal

- 5.21. Testing and adjusting brake pedal linkage

- 5.22. Measuring brake oil pressure

- 5.23. Bleeding air from brake circuit

- 5.24. Measuring parking brake performance

- 5.25. Measuring and adjusting work equipment control lever

- 5.26. Testing and adjusting work equipment hydraulic pressure

- 5.27. Testing and adjusting work equipment PPC oil pressure

- 5.28. Bleeding air

- 5.29. Releasing remaining pressure in hydraulic circuit

- 5.30. Testing and adjusting bucket positioner

- 5.31. Testing and adjusting of boom kickout

- 5.32. Checking proximity switch actuation display lamp

- 5.33. Special functions of machine monitor

- 5.34. Pm CLINIC INSPECTION CHART

- 5.35. TESTING AND ADJUSTING

- 5.36. Points to remember when troubleshooting

- 5.37. Sequence of events in troubleshooting

- 5.38. Precautions when carrying out maintenance

- 5.39. Check before troubleshooting

- 5.40. Categories, procedure, and method of using troubleshooting charts

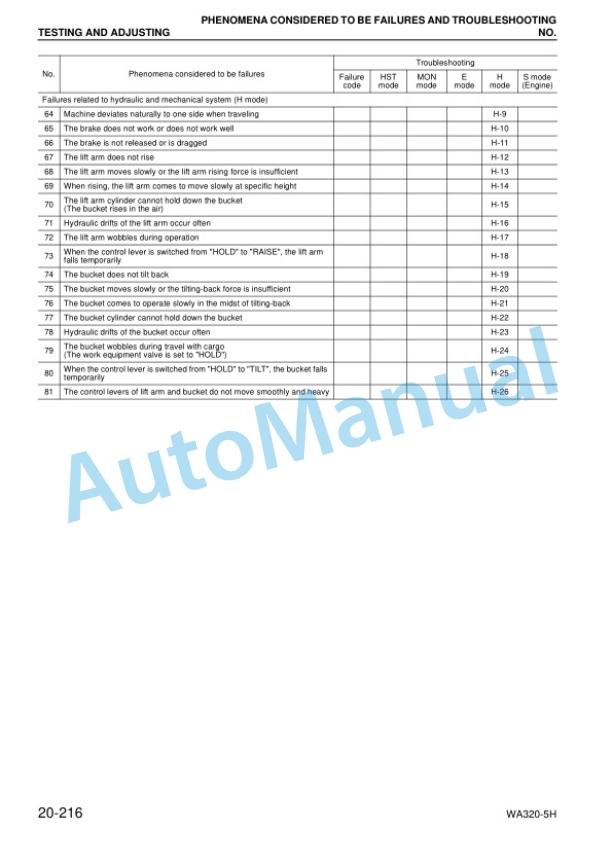

- 5.41. Phenomena considered to be failures and troubleshooting no.

- 5.42. Connection table for connector pin numbers

- 5.43. Tadapter table

- 5.44. Connector types and mounting locat

- 5.45. ions

- 5.46. Connector layout drawing

- 5.47. TROUBLESHOOTING

- 5.48. Before troubleshooting code display

- 5.49. Before troubleshooting electrical system

- 5.50. Information contained in troubuleshooting table

- 5.51. TROUBLESHOOTING OF HST CONTROLLER SYSTEM (HST MODE)

- 5.52. Before troubleshooting code display

- 5.53. Before troubleshooting electrical system

- 5.54. Information contained in troubuleshooting table

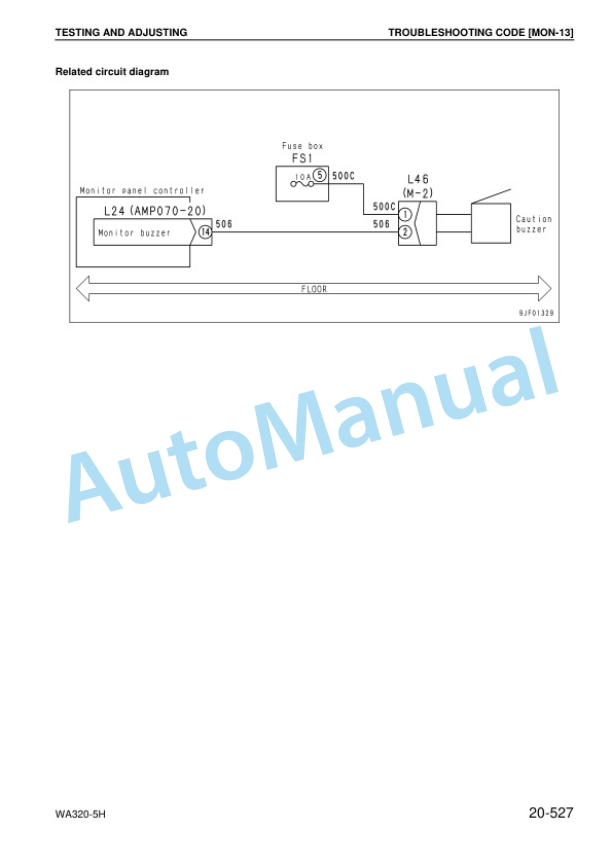

- 5.55. TROUBLESHOOTING OF monitor SYSTEM (mon MODE)

- 5.56. Before troubleshooting electrical system

- 5.57. Information contained in troubuleshooting table

- 5.58. TROUBLESHOOTING OF ELECTRICAL SYSTEM (E MODE)

- 5.59. Method of using troubleshooting chart

- 5.60. Failure code and cause table

- 5.61. TROUBLESHOOTING OF HYDRAULIC, MECHANICAL SYSTEM (H MODE)

- 5.62. Method of using troubleshooting charts

- 5.63. TROUBLESHOOTING OF ENGINE (S MODE)

- 5.64. How to read this manual

- 5.65. Precautions when carrying out operation

- 5.66. Special tool list

- 5.67. Sketch of special tools

- 5.68. Removal, installation of fuel injection pump assembly

- 5.69. Removal, installation of nozzle holder assembly

- 5.70. Removal, installation of cylinder head assembly

- 5.71. Removal, installation of engine assembly

- 5.72. Removal, installation of radiator assembly

- 5.73. Removal, installation of air aftercooler

- 5.74. Removal, installation of hydraulic oil cooler assembly

- 5.75. Removal, installation of cooling fan and fan motor assembly

- 5.76. Removal, installation of fuel tank assembly

- 5.77. Removal, installation of transfer

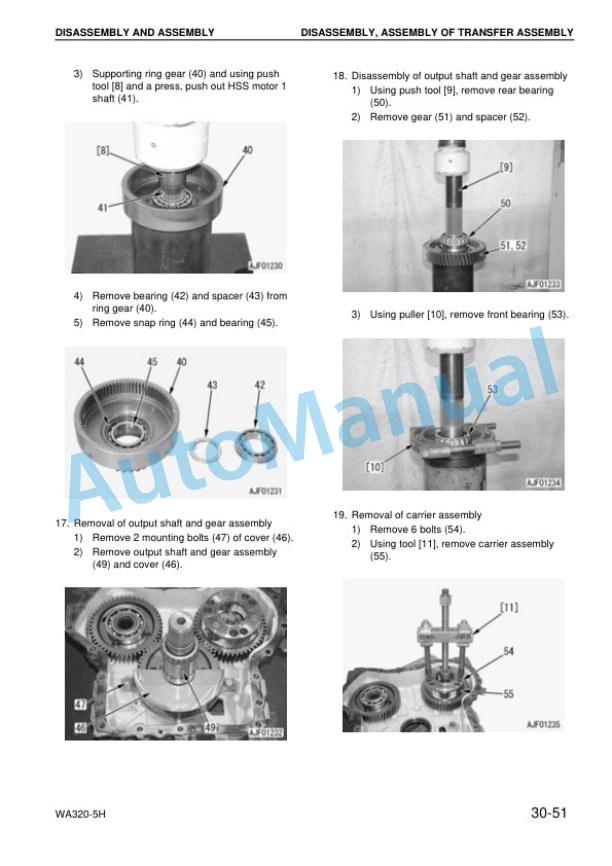

- 5.78. Disassembly, assembly of transfer assembly

- 5.79. Removal, installation of parking brake assembly

- 5.80. Disassembly, assembly of parking brake assembly

- 5.81. Removal, installation of front axle assembly

- 5.82. Removal, installation of rear axle assembly

- 5.83. Disassembly, assembly of axle housing assembly

- 5.84. Disassembly, assembly of differential assembly

- 5.85. Removal, installation of HST pump and 4gear pump assembly

- 5.86. Removal, installation of HST motor 1 assembly

- 5.87. Removal, installation of HST motor 2 assembly

- 5.88. Removal, installation of work equipment control valve assembly

- 5.89. Removal, installation of travel damper valve assembly

- 5.90. Removal, installation of hydraulic tank assembly

- 5.91. Removal, installation of work equipment assembly

- 5.92. Disassembly and assembly of HST pump assembly

- 5.93. Disassembly and assembly of HST motor assembly

- 5.94. Disassembly, assembly of hydraulic cylinder assembly

- 5.95. Removal, installation of operators cab assembly

- 5.96. Removal, installation of operators cab glass (Stuckglass)

- 5.97. Removal, installation of center hinge pin

- 5.98. Removal, installation of counterweight

- 5.99. Removal, installation of air conditioner unit assembly

- 5.100. Removal, installation of air conditioner compressor assembly

- 5.101. Removal, installation of monitor panel

- 6. DISASSEMBLY AND ASSEMBLY

- 7. OTHERS

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF