- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu WA380-3 Wheel Loader Shop Manual SMEW380000

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SMEW380000

- Format: PDF

- Size: 38.8MB

- Number of Pages: 592

Category: Komatsu Shop Manual PDF

-

Model List:

- WA380-3 Wheel Loader

- 0.1. GENERAL ASSEMBLY DRAWING

- 0.2. SPCIFICATIONS

- 0.3. WEIGHT TABLE

- 0.4. LIST OF LUBRICANT AND WATER

- 1. STRUCTURE AND FUNCTION

- 1.1. POWER TRAIN

- 1.2. POWER TRAIN SYSTEM

- 1.3. TORQUE CONVERTERTRANSMISSION PIPING

- 1.4. TRANSMISSION HYDRAULIC SYSTEM DIAGRAM

- 1.5. TRANSMISSION HYDRAULIC CIRCUIT DIAGRAM

- 1.6. TORQUE CONVERTER

- 1.7. TORQUE CONVERTER OIL FILTER

- 1.8. TRANSMISSION

- 1.9. TRANSMISSION CONTROL VALVE

- 1.10. DRIVE SHAFT

- 1.11. AXLE

- 1.12. DIFFERENTIAL

- 1.13. FINAL DRIVE

- 1.14. AXLE MOUNT,CENTER HINGE PIN

- 1.15. STEERING PIPING

- 1.16. STEERING COLUMN

- 1.17. STEERING VALVE

- 1.18. ORBITROLL VALVE

- 1.19. STOP VALVE

- 1.20. BRAKE PIPING

- 1.21. BRAKE HYDRAULIC CIRCUIT DIAGRAM

- 1.22. BRAKE VALVE

- 1.23. ACCUMULATOR CHARGE VALVE

- 1.24. ACCUMULATOR(FOR BRAKE)

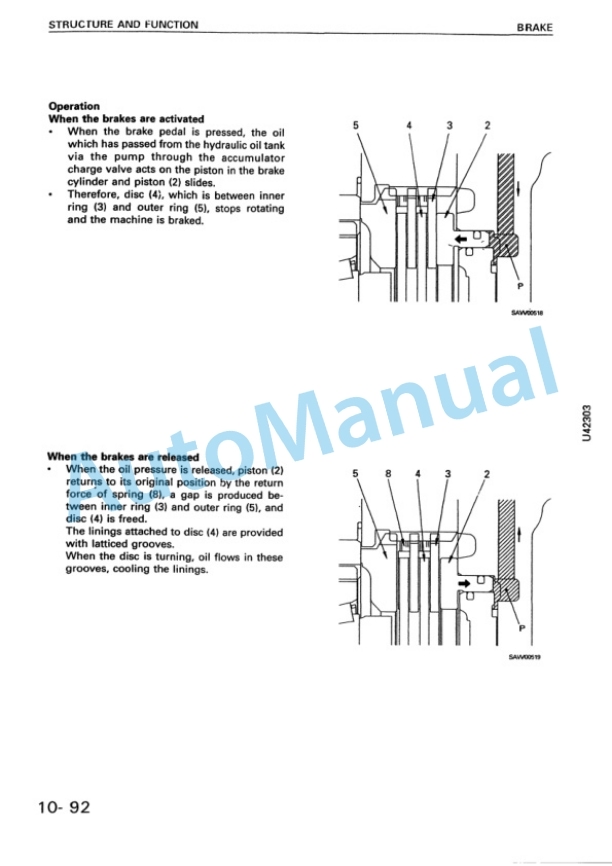

- 1.25. BRAKE

- 1.26. PARKING BRAKE CONTROL

- 1.27. PARKING BRAKE

- 1.28. PARKING BRAKE SOLENOID VALVE

- 1.29. PARKING BRAKE VALVE

- 1.30. HYDRAULIC PIPING

- 1.31. WORK EQUIPMENT HYDRAULIC SYSTEM DIAGRAM

- 1.32. WORK EQUIPMENT HYDRAULIC CUIRCUIT DIAGRAM

- 1.33. WORK EQUIPMENT LEVER LINKAGE

- 1.34. HYDRAULIC TANK

- 1.35. MAIN CONTROL VALVE

- 1.36. WORK EQUIPMENT LINKAGE

- 1.37. BUCKET

- 1.38. BUCKET POSITIONER AND BOOM KICKOUT

- 1.39. AIR CONDITIONER

- 1.40. ELECTRIC CIRCUIT DIAGRAM

- 1.41. ENGINE STARTING CIRCUIT

- 1.42. ENGINE STOP CIRCUIT

- 1.43. ENGINE STOP FUEL SOLENOID

- 1.44. ELECTRIC TRANSMISSION CONTROL

- 1.45. KICKDOWN SWITCH

- 1.46. KICKDOWN ELECTRIC CIRCUIT DIAGRAM

- 1.47. TRANSMISSION CUTOFF SWITCH

- 1.48. TRANSMISSION CUTOFF FUNCTION

- 2. TESTING AND ADJUSTING

- 2.1. STANDARD VALUE TABLE FOR ENGINE

- 2.2. STANDARD VALUE TABLE FOR CHASSIS

- 2.3. TOOLS FOR TESTING,ADJUSTING AND TROUBLESHOOTING

- 2.4. MEASURING ENGINE SPEED

- 2.5. MEASURING EXHAUST COLOR

- 2.6. TESTING AND ADJUSTING FUEL INJECTION TIMING

- 2.7. MEASURING ENGINE OIL PRESSURE

- 2.8. TESTING AND ADJUSTING AIR CONDITIONER COMPRESSOR BELT TENSION

- 2.9. MEASURING TORQUE CONVERTER, TRANSMISSION,PARKING BRAKE OIL PRESSURE

- 2.10. PROCEDURE FOR MOVING MATHINE WHEN TRANSMISSION VALVE FAILS

- 2.11. TESTING WHEEL BRAKE PERFORMANCE

- 2.12. TESTING DROP IN WHEEL BRAKE OIL PRESSURE

- 2.13. MEASURING CLEARANCE BETWEEN TIRE AND WHEEL

- 2.14. TESTING FOR BRAKE DISC WEAR

- 2.15. BLEEDING AIR FROM WHEEL BRAKE CIRCUIT

- 2.16. TESTING AND ADJUSTING ACCUMULATOR CHANRGE CUTIN AND CUTOUT PRESSURE

- 2.17. MEASURING PARKING BRAKE PERFORMANCE

- 2.18. TESTING WEAR OF PARKING BRAKE DISC

- 2.19. MEASURING WORK EQUIPMENT HYDRAULIC PRESSURE

- 2.20. BLEEDING AIR FROM WORK EQUIPMENT CIRCUIT

- 2.21. ADJUSTING WORK EQUIPMENT LEVER LINKAGE

- 2.22. TESTING AND ADJUSTING OF BUCKET PROXIMITY SWITCH

- 2.23. TESTING AND ADJUSTING OF BOOM PROXIMITY SWITCH

- 2.24. TESTING AND ADJUSTING STEERING CONTROL

- 2.25. TROUBLESHOOTING

- 2.25.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 2.25.2. SEQUENCE OF EVENTS IN TROUBLESHOOTING

- 2.25.3. PRECAUTIONS WHEN CARRYING OUT MAINTENANCE

- 2.25.4. HANDLING CONNECTORS

- 2.25.5. CHECK BEFORE TROUBLESHOOTING

- 2.25.6. METHOD OF USING TROUBLESHOOTING CHARTS

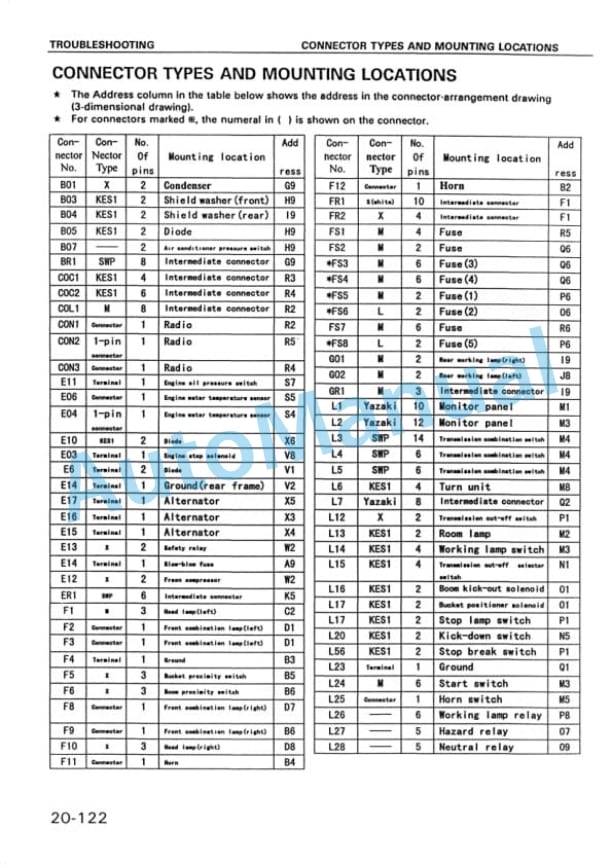

- 2.25.7. CONNECTOR TYPES AND MOUNTING LOCATIONS

- 2.25.8. CONNECTOR PIN ARRANGEMENT DIAGRAM

- 2.25.9. CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

- 2.25.10. TROUBLESHOOTING OF ENGINE SYSTEM(S MODE)

- 2.25.10.1. S1 STARTING PERFORMANCE IS POOR(STARTING ALWAYS TAKES TIME)

- 2.25.10.2. S2 ENGINE DOES NOT START

- 2.25.10.3. S3 ENGINE DOES NOT PICK UP SMOOTHLY(FOLLOWUP IS POOR)

- 2.25.10.4. S4 ENGINE STOPS DURING OPERATIONS

- 2.25.10.5. S5 ENGINE DOES NOT ROTATE SMOOTHLY(HUNTING)

- 2.25.10.6. S6 ENGINE LACKS OUTPUT(NO POWER)

- 2.25.10.7. S7 EXHAUST GAS IS BLACK(INCOMPLETE COMBUSTION)

- 2.25.10.8. S8 OIL CONSUMPTION IS EXCESSIVE (OR EXHAUST GAS IS BLUE)

- 2.25.10.9. S9 OIL BECOMES CONTAMINATED QUICKLY

- 2.25.10.10. S10 FUEL CONSUMPTION IS EXCESSIVE

- 2.25.10.11. S11 OIL IS IN COOLING WATER,OR WATER SPURTS BACK,OR WATER LEVEL GOES DOWN

- 2.25.10.12. S12 OIL PRESSURE LAMP LIGHTS UP(DROP IN OIL PRESSURE)

- 2.25.10.13. S13 OIL LEVEL RISES

- 2.25.10.14. S14 WATER TEMPERATURE BECOMES TOO HIGH(OVERHEATING)

- 2.25.10.15. S15 ABNORMAL NOISE IS MADE

- 2.25.10.16. S16 VIBRATION IS EXCESSIVE

- 2.25.11. TROUBLESHOOTING OF ELECTRICAL SYSTEM(E MODE)

- 2.25.11.1. E1 ENGINE DOES NOT START

- 2.25.11.2. E2 TRANSMISSION DOES NOT WORK NORMALLY

- 2.25.11.3. E3 KICKDOWN SWITCH DOES NOT WORK(THE REGULAR F1 TO F4 SHIFTS NORMALLY)

- 2.25.11.4. E4 KICKDOWN WORKS ONLY WHEN KICKDOWN SWITCH IN ON(KICKDOWN SWITCH RELAY DOES NOT HOLD IN POSITION)

- 2.25.11.5. E5 KICKDOWN OPERATION CANNOT BE CANCELED

- 2.25.11.6. E6 KICKDOWN SWITCH IS ACTUATED BY MISTAKE WHEN TRAVELING IN 2ND

- 2.25.12. TROUBLESHOOTING OF HYDRAULIC AND MECHANICAL SYSTEN(CHASSIS RELATED)(T MODE)

- 2.25.12.1. POWER TRAIN

- 2.25.12.2. STEERING SYSTEM

- 2.25.12.3. BRAKE SYSTEM

- 2.25.12.4. WORK QUIPMENT

- 3. DISASSEMBLY AND ASSEMBLY

- 3.1. METHOD OF USING MANUAL

- 3.2. PRECAUTIONS WHEN CARRYING OUT OPERAION

- 3.3. GENERAL TOOL LIST

- 3.4. TORQUE CONVERTER CHARGING PUMP

- 3.4.1. REMOVALE

- 3.4.2. INSTALLATION

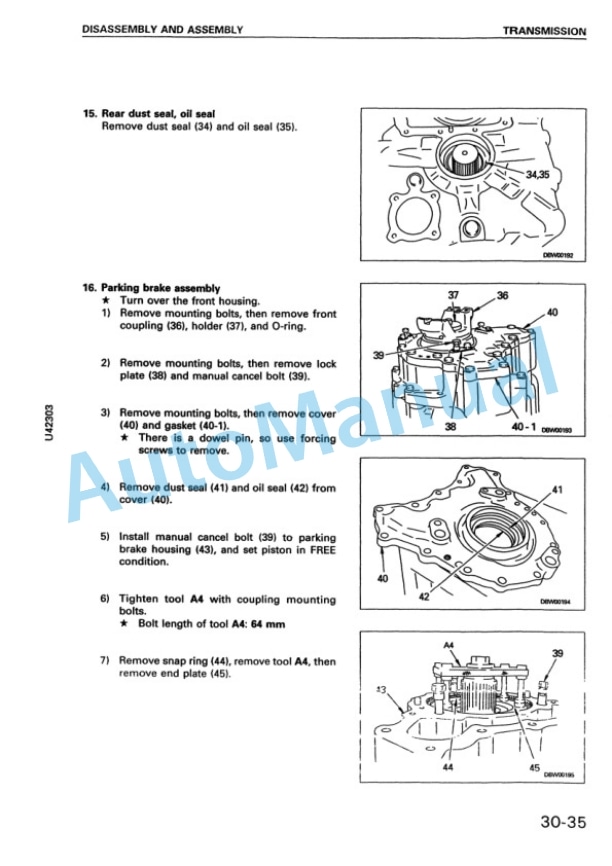

- 3.5. TORQUE CONVERTER,TRANSMISSION

- 3.5.1. REMOVAL

- 3.5.2. INSTALLATION

- 3.6. TORQUE CONVERTER

- 3.7. TRANSMISSION CLUTCH PACK

- 3.7.1. DISASSEMBLY

- 3.7.2. ASSEMBLY

- 3.8. TRANSMISSION CONTROL VALVE

- 3.8.1. REMOVAL

- 3.8.2. INSTALLATION

- 3.8.3. DISASSEMBLY

- 3.8.4. ASSEMBLY

- 3.9. TRANSMISSION ACCUMULATOR VALVE

- 3.9.1. DISASSEMBLY

- 3.9.2. ASSEMBLY

- 3.10. MODULATING VALVE

- 3.11. CENTER HINGE PIN

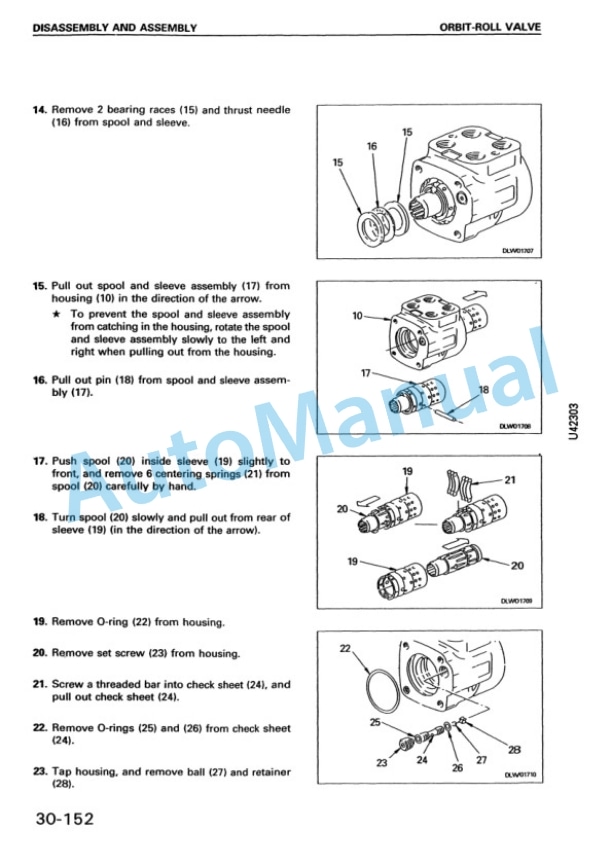

- 3.12. ORBITROLL VALVE

- 3.12.1. REMOVAL

- 3.12.2. INSTALLATION

- 3.12.3. DISASSEMBLY

- 3.12.4. ASSEMBLY

- 3.13. STEERING CYLINDER

- 3.14. BRAKE VALVETANDEM

- 3.14.1. DISASSEMBLY

- 3.14.2. ASSEMBLY

- 3.15. PARKING BRAKE DISC

- 3.16. HYDRAULIC FILTER

- 3.16.1. REMOVAL AND INSTALLATION

- 3.17. HYDRAULICSTEERINGSWITCHPPC PUMP

- 3.17.1. REMOVAL

- 3.17.2. INSTALLATION

- 3.18. MAIN CONTROL VALVE

- 3.18.1. REMOVAL

- 3.18.2. INSTALLATION

- 3.18.3. DISASSEMBLY

- 3.18.4. ASSEMBLY

- 3.19. BUCKET CYLINDER

- 3.20. HYDRAULCI CYLINDER

- 3.20.1. REMOVAL AND INSTALLATION

- 3.21. FUEL TANK

- 3.21.1. REMOVAL

- 3.21.2. INSTALLATION

- 3.22. CAB FLOOR FRAME

- 3.23. AIR CONDITION UNIT

- 3.23.1. REMOVAL

- 3.23.2. INSTALLATION

- 3.24. AIR CONDITIONER CONDENSER

- 3.24.1. REMOVAL

- 3.24.2. INSTALLATION

- 3.25. DRY RECEIVER

- 3.25.1. REMOVAL AND INSTALLATION

- 3.26. AIR CONDITIONER CONDENSER COMPRESSOR

- 3.26.1. REMOVAL AND STALLATION

- 3.27. TIRE AND WHEEL

- 3.27.1. REMOVAL OF TIRE

- 3.27.2. REMOVAL OF WHEEL

- 4. AINTENANCE STANDARD

- 4.1. ENGINE MOUNTTRANSMISSION MOUNT

- 4.2. TORQUE CONVERTER CHARGING PUMP

- 4.3. TORQUE CONVERTER

- 4.4. TRANSMISSION

- 4.5. TRANSMISSION CONTROL VALVE

- 4.6. MODULATION VALVE

- 4.7. ACCUMULATOR VALVE

- 4.8. DRIVE SHAFT

- 4.9. DIFFERENTIAL

- 4.10. FINAL DRIVE

- 4.11. AXLE MOUNT

- 4.12. CENTER HINGE PIN

- 4.13. STEERING COLUMN

- 4.14. STEERING VALVE

- 4.15. STEERING CYLINDER MOUNT

- 4.16. BRAKE

- 4.17. BRAKE VALVE

- 4.18. PARKING BRAKE

- 4.19. HYDRAULIC PUMP

- 4.20. MAIN CONTROL VALVE

- 4.21. HYDRAULIC CYLINDER

- 4.22. WORK EQUIPMENT LINKAGE

- 4.23. BUCKET

- 4.24. BUCKET POSITIONER AND BOOM KICKOUT

- 4.25. PROPOSAL

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF