- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu WA420-3 Wheel Loader Shop Manual VEBM470104

$40.00

- Type Of Manual: Shop Manual

- Manual ID: VEBM470104

- Format: PDF

- Size: 28.2MB

- Number of Pages: 970

Category: Komatsu Shop Manual PDF

-

Model List:

- WA420-3 Wheel Loader

- 1. COVER

- 2. Contents

- 3. General

- 3.1. Up to SN WA420H30296

- 3.2. Dimensions and weights

- 3.3. Specifications

- 3.4. Weight table

- 3.5. SN WA420H30297 and up

- 3.6. Dimensions and weights

- 3.7. Specifications

- 3.8. Weight table

- 3.9. List of lubricant and water

- 3.10. Outlines of service

- 3.11. General view of controls and gauges

- 3.12. Torque list

- 4. Structure and function

- 4.1. Power train

- 4.2. Power train system

- 4.3. Torque converter, transmission piping

- 4.4. Transmission hydraulic system diagram

- 4.5. Transmission hydraulic circuit diagram

- 4.6. Torque converter

- 4.7. Transmission

- 4.8. Clutch

- 4.9. Transmission control valve

- 4.10. Transmission solenoid valve

- 4.11. Pilot reducing valve

- 4.12. Main relief valve

- 4.13. Torque converter outlet port valve

- 4.14. Priority valve

- 4.15. Transmission oil pressure system diagram

- 4.16. HL selector valve and range selector valve

- 4.17. Emergency manual spool

- 4.18. Electronic control modulation valve

- 4.19. Pilot oil filter

- 4.20. Accumulator valve

- 4.21. Axle mount, center hinge pin

- 4.22. Steering piping

- 4.23. Steering column, orbit roll

- 4.24. Hydraulic circuit diagram for steering

- 4.25. Orbitroll valve

- 4.26. Steering demand valve

- 4.27. Overload relief valve

- 4.28. Steering relief valve

- 4.29. Operation of demand valve

- 4.30. Emergency steering

- 4.31. Brake piping

- 4.32. Brake circuit diagram

- 4.33. Brake valve

- 4.34. Charge valve

- 4.35. Accumulator for system brake

- 4.36. Slack adjuster

- 4.37. Brake circuit diagram

- 4.38. Brake valve (dual circuit)

- 4.39. Brake valve (single circuit)

- 4.40. Brake pressure regulating valve

- 4.41. Accumulator (for brake)

- 4.42. Accumulator for PPC valve

- 4.43. Brake accumulator unit

- 4.44. Brake

- 4.45. Parking brake control

- 4.46. Parking brake

- 4.47. Parking brake valve

- 4.48. Hydraulic piping

- 4.49. Work equipment hydraulic circuit diagram

- 4.50. Work equipment lever linkage

- 4.51. Hydraulic tank

- 4.52. PPC valve

- 4.53. PPC relief valve

- 4.54. Accumulator for PPC valve

- 4.55. Main control valve (up to H30296)

- 4.56. Relief valve (up to H30296

- 4.57. Safety valve (with suction)

- 4.58. Suction valve

- 4.59. Main control valve (H30297 and up)

- 4.60. Safety valve with suction (H30297 and up)

- 4.61. Anticavitation valve (H30297 and up)

- 4.62. Safety valve (H30297 and up)

- 4.63. Hydraulic safety system

- 4.64. Hydraulic safety system location (up to H30431)

- 4.65. Hydraulic safety valve (up to H30431)

- 4.66. Work equipment linkage

- 4.67. Bucket

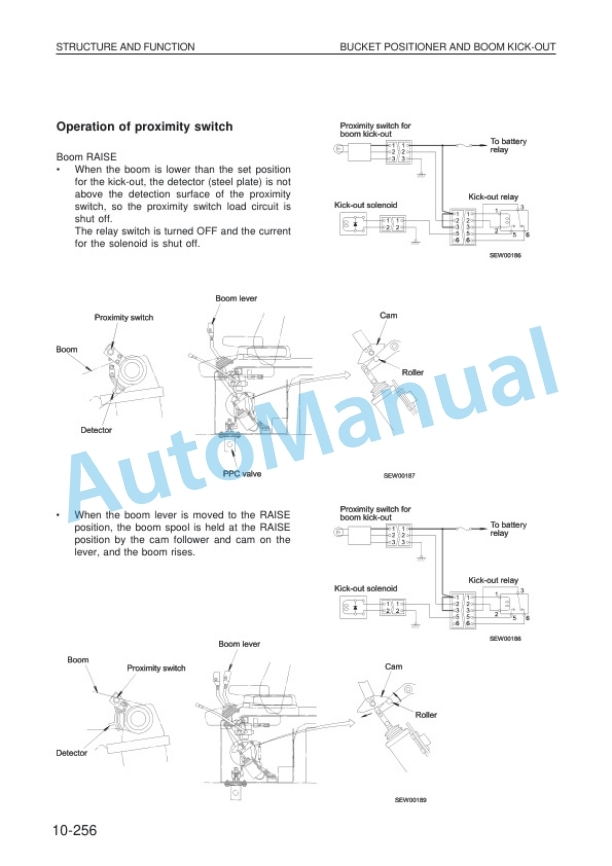

- 4.68. Bucket positioner and boom kickout

- 4.69. Machine monitor system

- 4.70. Main monitor

- 4.71. Maintenance monitor

- 4.72. Transmission autoshift control system

- 4.73. Transmission controller

- 4.75. Sensors

- 4.76. Engine start circuit

- 4.77. Ether start

- 4.78. Electric transmission control

- 4.79. Combination switch

- 4.80. Kickdown, hold switch

- 4.81. Transmission electric circuit diagram

- 4.82. Transmission cutoff switch

- 4.83. Transmission cutoff function

- 4.84. Electric parking brake control

- 4.85. Airconditioner

- 4.86. Wiring diagrams

- 5. Testing and adjusting

- 5.1. Standard value table for engine

- 5.2. Standard value table for chassis

- 5.3. Test certificate

- 5.4. Standard value table for electrical parts

- 5.5. Tools for testing, adjusting and troubleshooting

- 5.6. Adjusting valve clearance

- 5.7. Measuring compression pressure

- 5.8. Measuring blowby pressure

- 5.9. Testing and adjusting fuel injection timing

- 5.10. Mesuring exhaust color

- 5.11. Measuring intake air pressure (boost pressure)

- 5.12. Measuring engine oil pressure

- 5.13. Testing the fan belt tension

- 5.14. Measuring accelerator pedal

- 5.15. Basic adjustment of accelerator pedal

- 5.16. Measuring operating force, travel of speed lever

- 5.17. Measuring stall speed

- 5.18. Measuring torque converter, transmission, parking brake oil pressure

- 5.19. Method of operating emergency manual spool

- 5.20. Measuring clearance between tyre and wheel

- 5.21. Measuring operating force of steering wheel

- 5.22. Measuring steering oil pressure

- 5.23. Measuring operating force, travel of brake pedal

- 5.24. Measuring brake performance

- 5.25. Testing brake oil pressure

- 5.26. Measuring brake disc wear

- 5.27. Bleeding air from brake system

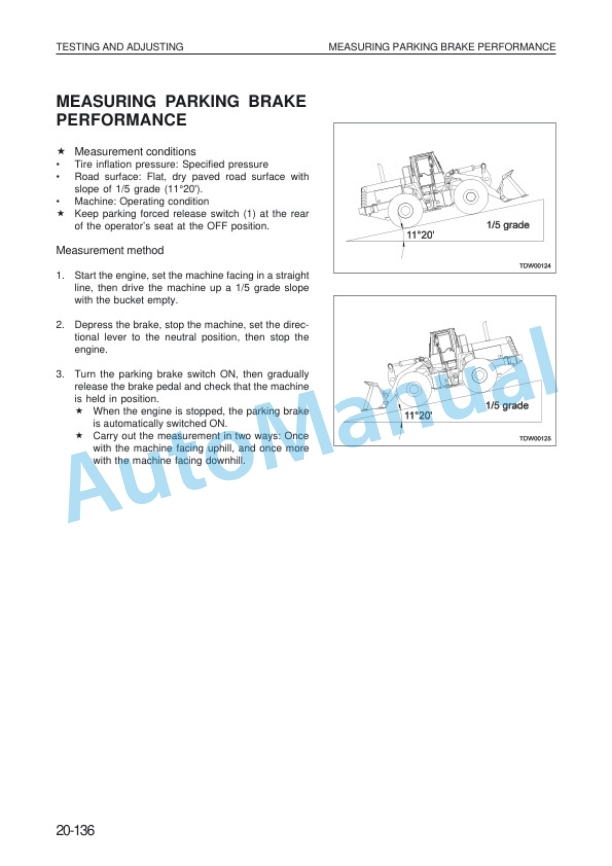

- 5.28. Measuring parking brake performance

- 5.29. Method of manual release of parking brake

- 5.30. Testing wear of parking brake disc

- 5.31. Measuring work equipment control lever

- 5.32. Measuring PPC valve pressure

- 5.33. Measuring work equipment

- 5.34. Testing and adjusting bucket positioner

- 5.35. Testing and adjusting boom kickout

- 5.36. Adjusting main monitor (speedometer modul)

- 5.37. Checking for abnormality in fuel level sensor

- 5.38. Troubleshooting

- 5.39. Points to remember when troubleshooting

- 5.40. Sequence of events in troubleshooting

- 5.41. Precautions when carrying out maintenance

- 5.42. Handling connectors

- 5.43. Checks before troubleshooting

- 5.44. Method of using troubleshooting charts

- 5.45. Connector types and mounting locations, connector pin arrangement diagram

- 5.46. Connection table for connector pin numbers

- 5.47. Troubleshooting of engine system (S mode)

- 5.48. Troubleshooting of main monitor system (M mode)

- 5.49. Troubleshooting of maintenance monitor system (K mode)

- 5.50. Troubleshooting of electrical system (E mode)

- 5.51. Troubleshooting of transmission controller system (A mode)

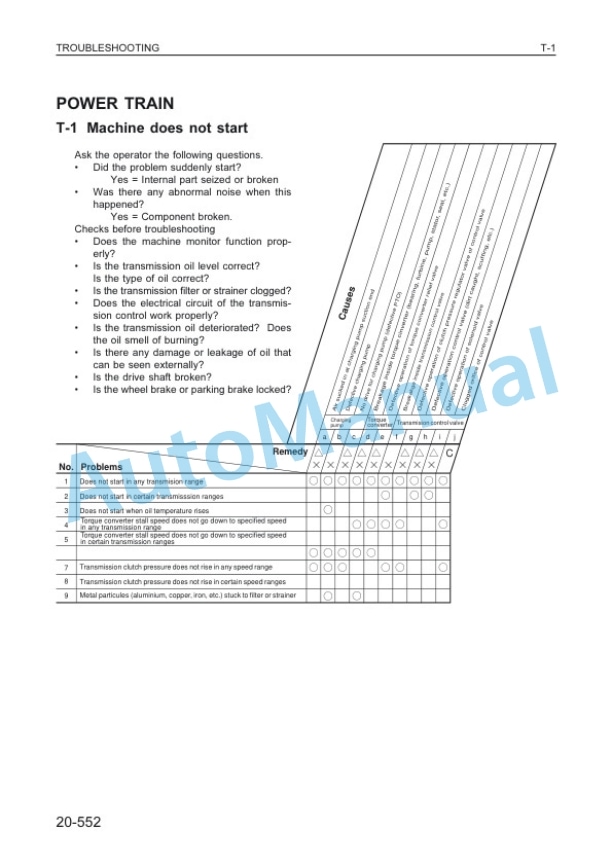

- 5.52. Troubleshooting of hydraulic and mechanical system (Chassis related) (T mode)

- 5.53. Troubleshooting of ECSS (Electronically Controlled Suspension System) (D mode)

- 6. Disassembly and assembly

- 6.1. Method of using manual

- 6.2. Precautions when carrying out operation

- 6.3. Special tool list

- 6.4. Starting motor

- 6.5. Alternator

- 6.6. Engine oil cooler

- 6.7. Fuel injection pump

- 6.8. Water pump

- 6.9. Turbocharger

- 6.10. Thermostat

- 6.11. Cylinder head

- 6.12. Torque converter charging pump

- 6.13. Torque converter, transmission

- 6.14. Torque converter

- 6.15. Tranmission

- 6.16. Transmission clutch pack

- 6.17. Parking brake

- 6.18. Transmission control valve

- 6.19. Transmission accumulator valve

- 6.20. Drive shaft

- 6.21. Front axle

- 6.22. Rear axle

- 6.23. Front differential

- 6.24. Rear differential

- 6.25. Differential

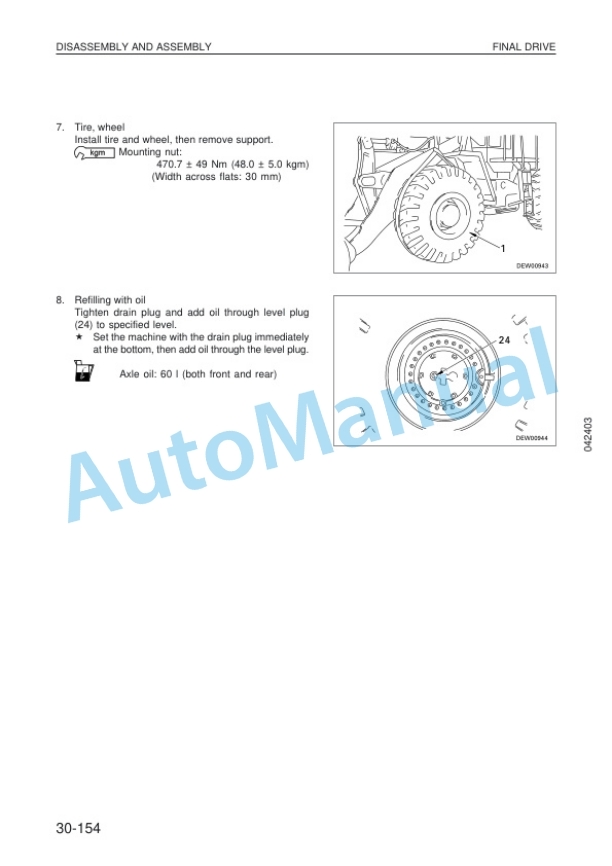

- 6.26. Final drive

- 6.27. Center hinge pin

- 6.28. Steering, orbit roll

- 6.29. Steering valve

- 6.30. Steering, switch pump

- 6.31. Steering cylinder

- 6.32. Brake valve

- 6.33. Right brake valve (tandem)

- 6.34. Left brake valve (single)

- 6.35. Slack adjuster

- 6.36. Brake

- 6.37. Parking brake disc

- 6.38. Hydraulic tank

- 6.39. Work equipment, PPC pump

- 6.40. PPC valve

- 6.41. Main control valve

- 6.42. Bucket cylinder

- 6.43. Boom cylinder

- 6.44. Hydraulic cylinder

- 6.45. Maintenance monitor

- 6.46. Air conditioner unit

- 6.47. Air conditioner condenser

- 6.48. Dry receiver

- 6.49. Air conditioner compressor

- 7. Maintenance standard

- 7.1. Engine mount, transmission mount

- 7.2. Torque converter

- 7.3. Transmission

- 7.4. Transmission control valve

- 7.5. Drive shaft

- 7.6. Diffential

- 7.7. Final drive

- 7.8. Axle mount

- 7.9. Steerig column, orbit roll

- 7.10. Steering valve

- 7.11. Steering cylinder mount

- 7.12. Slack adjuster

- 7.13. Brake valve

- 7.14. Brake

- 7.15. Parking brake

- 7.16. Torque converter, transmission pump

- 7.17. Steering, switch pump

- 7.18. Hydraulic, PPC pump

- 7.19. PPC valve

- 7.20. Cutoff valve

- 7.21. Main control valve

- 7.22. Boom cylinder

- 7.23. Bucket cylinder

- 7.24. Center hinge pin

- 7.25. Work equipment linkage

- 7.26. Bucket

- 7.27. Bucket positioner and boom kickout

Rate this product

You may also like

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF