- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu WA470-3 Avance Custom Wheel Loader Shop Manual SMEW4700K0

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SMEW4700K0

- Format: PDF

- Size: 23.9MB

- Number of Pages: 664

Category: Komatsu Shop Manual PDF

-

Model List:

- WA470-3 Avance Custom Wheel Loader

- 1. COVER

- 2. CONTENTS

- 3. ENERAL

- 3.1. GENERAL ASSEMBLY DRAWING

- 3.2. SPECIFICATIONS

- 3.3. WEIGHT TABLE

- 3.4. LIST OF LUBRICANT AND WATER

- 4. STRUCTURE AND FUNCTION

- 4.1. POWER TRAIN

- 4.2. POWER TRAIN SYSTEM

- 4.3. TORQUE CONVERTERTRANSMISSION PIPING

- 4.4. TRANSMISSION HYDRAULIC SYSTEM DIAGRAM

- 4.5. TRANSMISSINO HYDRAULIC CIRCUIT DIAGRAM

- 4.6. TORQUE CONVERTER

- 4.7. TORQUE CONVERTER OIL FILTER

- 4.8. TRANSMISSION

- 4.9. TRANSMISSION CONTROL VALVE

- 4.10. TRANSMISSION SOLENOID VALVE

- 4.11. PILOT OIL FILTER

- 4.12. DRIVE SHAFT

- 4.13. AXLE

- 4.14. DIFFERENTIAL

- 4.15. FINAL DRIVE

- 4.16. AXLE MOUNT CENTER HINGE PIN

- 4.17. STEERING PIPING

- 4.18. STEERING COLUMN

- 4.19. STEERING VALVE

- 4.20. ORBITROLL VALVE

- 4.21. STOP VALVE

- 4.22. BRAKE PIPING

- 4.23. BRAKE CIRCUIT DIAGRAM

- 4.24. BRAKE VALVE

- 4.25. CHARGE VALVE

- 4.26. ACCUMULATORFOR BRAKE

- 4.27. SLACK ADJUSTER

- 4.28. BRAKE

- 4.29. PARKING BRAKE CONTROL

- 4.30. PARKING BRAKE

- 4.31. PARKING BRAKE SOLENOID VALVE

- 4.32. PARKING BRAKE VALVE

- 4.33. HYDRAULIC PIPING

- 4.34. WORK EQUIPMENT HYDRAULIC SYSTEM DIAGRAM

- 4.35. WORK EQUIPMENT HYDRAULIC CIRCUIT DIAGRAM

- 4.36. WORK EQUIPMENT LEVER LINKAGE

- 4.37. HYDRAULIC TANK

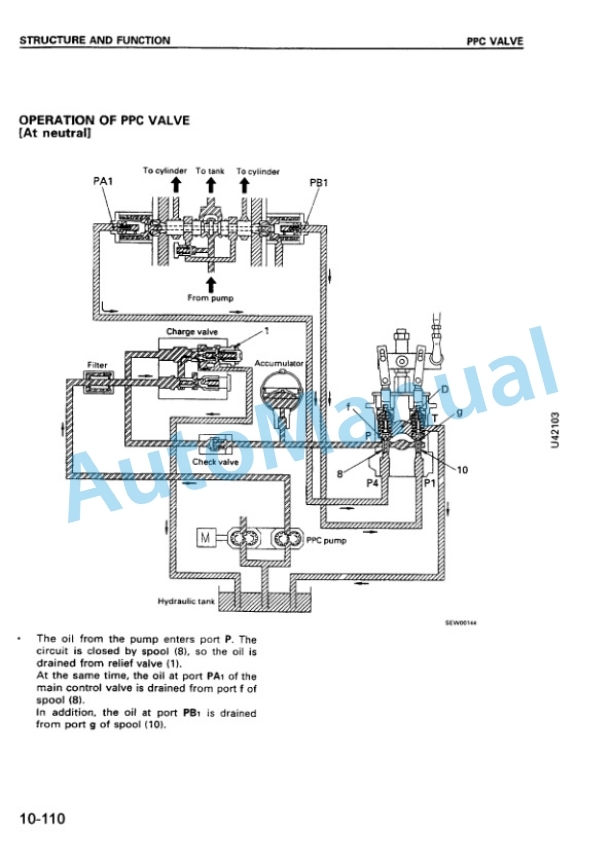

- 4.38. PPC VALVE

- 4.39. PPC RELIEF VALVE

- 4.40. ACCUMULATORFOR PPC VALVE

- 4.41. MAIN CONTROL VALVE

- 4.42. WORK EQUIPMENT LINKAGE

- 4.43. BUCKET

- 4.44. BUCKET PISITIONER AND BOOM KICKOUT

- 4.46. AIR CONDITIONER

- 4.47. SENSORS

- 4.48. ENGINE STARTING CIRCUIT

- 4.49. ENGINE STOP CIRCUIT

- 4.50. PREHEATING CIRCUIT

- 4.51. ELECTRIC TRANSMISSION CONTROL

- 4.52. KICKDOWN HOLD SWITCH

- 4.53. TRANSMISSION CUTOFF SWITCH

- 4.54. ELECTRIC CIRCUIT DIAGRAM

- 5. TESTING AND ADJUSTING

- 5.1. STANDARD VALUE TABLE FOR ENGINE

- 5.2. STANDARD VALUE TABLE FOR CHASSIS

- 5.3. STANDARD VALUE TABLE FOR ELECTRICAL PARTS

- 5.4. TOOLS FOR TESTINGADJUSTING AND TROUBLESHOOTING

- 5.5. MEASURING ENGINE SPEED

- 5.6. MEASURING INTAKE AIR PRESSUREBOOST PRESSURE

- 5.7. ADJUSTING VALVE CLEARANCE

- 5.8. MEASURING EXHAUST COLOR

- 5.9. MEASURING EXHAUST GAS TEMPERATURE

- 5.10. MEASUREING BLOWBY PRESSURE

- 5.11. MEASURING COMPRESSION PRESSURE

- 5.12. MEASURING ENGINE OIL PRESSURE

- 5.13. TESTING AND ADJUSTING FUEL INJECTION TIMING

- 5.14. METHOD FOR ADJUSTING ENGINE STOP MOTOR CABLE

- 5.15. TESTING AND ADJUSTING FAN BELT TENSION

- 5.16. MEASURING ACCELERATOR PEDAL

- 5.17. MEASURING OPERATING FORCE TRAVEL OF SPEED LEVER

- 5.18. MEASURING STALL SPEED

- 5.19. MEASURING TORQUE CONVERTERTRANSMISSIONPARKING BRAKE OIL PRESSURE

- 5.20. METHOD OF OPERATING EMERGENCY MANUAL SPOOL

- 5.21. MEASURING CLEARANCE BETWEEN TIRE AND WHEEL

- 5.22. TESTING AND ADJUSTING STEERING WHEEL

- 5.23. TESTING AND ADJUSTING STEERING CONTROL

- 5.24. MEASURING STEERING OIL PRESSURE

- 5.25. MEASURING OPERATING FORCETRAVEL OF BRAKE PEDAL

- 5.26. TESTING BRAKE OIL PRESSURE

- 5.27. MEASURING BRAKE PERFORANCE

- 5.28. MEASURING BRAKE DISC WEAR

- 5.29. BLEEDING AIR FROM BRAKE SYSTEM

- 5.30. MEASURING PARKING BRAKE PERFORMANCE

- 5.31. MANUAL RELEASE METHOD FOR PARKING BRAKE

- 5.32. TESTING WEAR OF PARKING BRAKE DISC

- 5.33. MEASURING WORK EQUIPMENT CONTROL LEVER

- 5.34. MEASURING WORK EQUIPMENT HYDRAULIC PRESSURE

- 5.35. MEASURING WORK EQUIPMENT

- 5.36. TESTING AND ADJUSTING BUCKET POSITIONER

- 5.37. TESTING AND ADJUSTING BOOM KICKOUT

- 5.38. TROUBLESHOOTING

- 5.38.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 5.38.2. SEQUENCE OF EVENTS IN TROUBLESHOOTING

- 5.38.3. PRECAUTIONS WHEN CARRYING OUT MAINTENANCE

- 5.38.4. HANDLING CONNECTORS

- 5.38.5. CHECKS BEFORE TROUBLESHOOTING

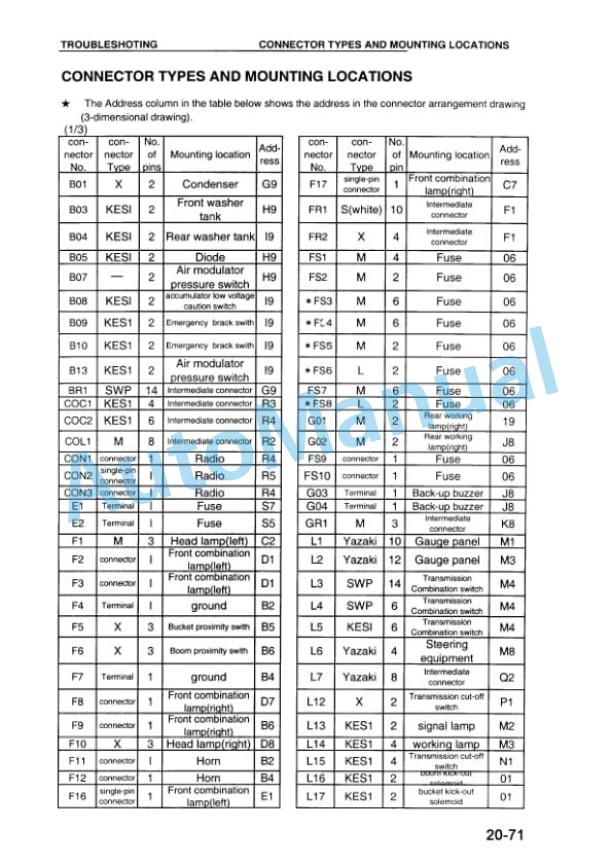

- 5.38.6. CONNECTOR TYPES AND MOUNTING LOCATIONS

- 5.38.7. CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

- 5.38.8. TROUBLESHOOTING OF ENGINE SYSTEMS MODE

- 5.38.8.1. S1 STARTING PERFORMANCE IS POOR

- 5.38.8.2. S2 ENGINE DOES NOT START

- 5.38.8.3. S3 ENGINE DOES NOT PICK UP SMOOTHLY

- 5.38.8.4. S4 ENGINE STOPS DURING OPERATIONS

- 5.38.8.5. S5 ENGINE DOES NOT ROTATE SMOOTHLY

- 5.38.8.6. S6 ENGINE LACKS OUTPUT

- 5.38.8.7. S7 EXHAUST GAS IS BLACK

- 5.38.8.8. S8 OIL CONSUMPTION IS EXCESSIVE

- 5.38.8.9. S9 OIL BECOMES CONTAMINATED QUICKLY

- 5.38.8.10. S10 FUEL CONSUMPTION IS EXCESSIVE

- 5.38.8.11. S11 OIL IS IN COOLING WATER OR WATER SPURTS BACKOR WATER LEVEL GOES DOWN

- 5.38.8.12. S12 OIL PRESSURE PAMP LIGHTS UP

- 5.38.8.13. S13 OIL LEVEL RISES

- 5.38.8.14. S14 WATER TEMPERATURE BECOMES TOO HIGH

- 5.38.8.15. S15 ABNORMAL NOISE MADE

- 5.38.8.16. S16 VIBRATION IS EXCESSIVE

- 5.38.9. TROUBLESHOOTING OF HYDRAULIC AND MACHANICAL SYSTEMT MODE

- 5.38.9.1. POWER DRAIN

- 5.38.9.2. STEERING SYSTEM

- 5.38.9.3. BRAKE SYSTEM

- 5.38.9.4. WORK EQUIPMENT

- 5.38.10. TROUBLESHOOTING OF ELECTRICAL SYSTEME MODE

- 5.38.10.1. E1 ENGINE DOES NOT START

- 5.38.10.2. E2 ENGINE DOES NOT STOP

- 5.38.10.3. E3 ENGINE STOPS WHEN MACHINE IS TRAVLING

- 5.38.10.4. E4 PARKING BRAKE DOES NOT WORK

- 5.38.10.5. E5 PARKING BRAKE IS APPLIED WHEN MACHINE IS TRAVELING

- 5.38.10.6. E6 PARKING BRAKE IS RELEASED WHEN STARTING SWITCH IS TURNED ON

- 5.38.10.7. E7 TRANSMISSION DOES NOT CHANGE TO NEUTRAL WHEN PARKING BRAKE IS APPLIED

- 5.38.10.8. E8 TRANSMISSION DOES NOT WORK NORMALLY

- 5.38.10.9. E9 KICKDOWN SWITCH DOES NOT WORK

- 5.38.10.10. E10 KICKDOWN WORKS ONLY WHEN KICKDOWN IS ON

- 5.38.10.11. E11 KICKDOWN OPERATION CANNOT BE CANCELED

- 5.38.10.12. E12 KICKDOWN SWITCH IS ACTUATED BY MISTAKE WHEN TRAVELING IN 2ND

- 6. DISASSEMBLY AND ASSEMBLY

- 6.1. METHOD OF USING MANUAL

- 6.2. PRECAUTIONS WHEN CARRYING OUT OPERATION

- 6.3. COMMON TOOL LIST

- 6.4. ENGINE OIL COOLER

- 6.4.1. REMOVAL

- 6.4.2. INSTALLATION

- 6.5. FUEL INJECTION PUMP

- 6.6. TORQUE CONVERTER,TRANSMISSION

- 6.6.1. REMOVAL

- 6.6.2. INSTALLATION

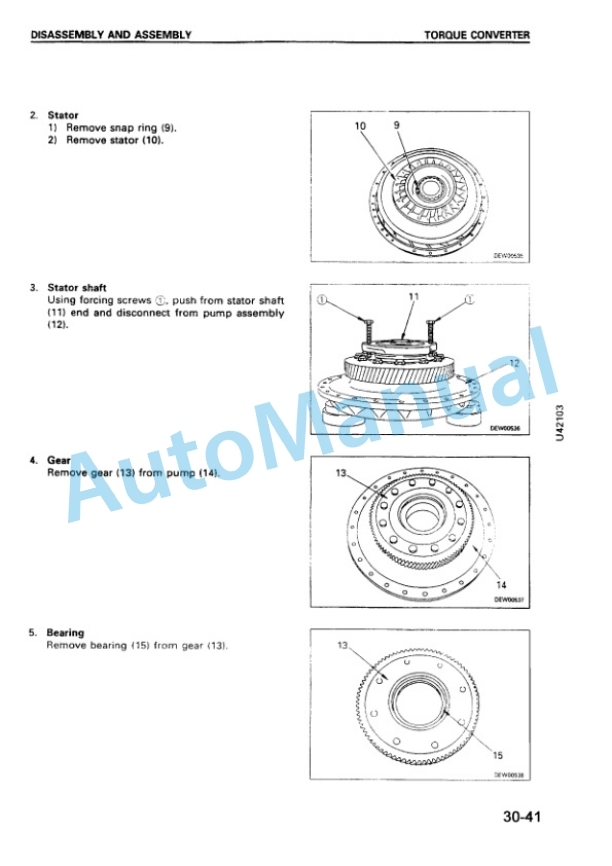

- 6.7. TORQUE CONVERTER

- 6.8. TRANSMISSION CLUTCH PACK

- 6.9. TRANSMISSION CONTROL VALVE

- 6.9.1. INSTALLATION

- 6.9.2. DISASSEMBLY

- 6.9.3. REMOVAL

- 6.9.4. ASSEMBLY

- 6.10. TRANSMISSION ACCUMULATOR VALVE

- 6.11. FRONT DIFFERENTIAL

- 6.11.1. REMOVAL

- 6.11.2. INSTALLATION

- 6.12. REAR DIFFERENTIAL

- 6.13. CENTER HINGE PIN

- 6.13.1. REMOVAL

- 6.13.2. INSTALLATION

- 6.14. STEERING VALVE(ORBIT ROLL)

- 6.15. STEERING DEMAND VALVE

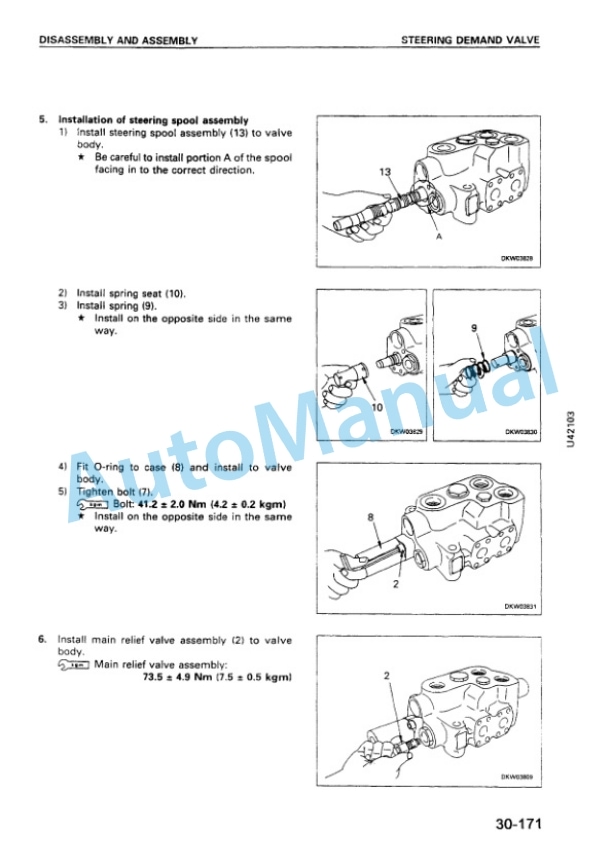

- 6.15.1. DISASSEMBLY

- 6.15.2. ASSEMBLY

- 6.16. STEERING SWITCH PUMP

- 6.16.1. REMOVAL

- 6.16.2. INSTALLATION

- 6.17. STEERING CYLINDER

- 6.18. PARKING BRAKE DISC

- 6.19. WORK EQUIPMENT,PPC PUMP

- 6.20. MAIN CONTROL VALVE

- 6.20.1. REMOVAL

- 6.20.2. INSTALLATION

- 6.20.3. DISASSEMBLY

- 6.20.4. ASSEMBLY

- 6.21. BUCKET CYLINDER

- 6.22. HYDRAULCI CYLINDER

- 6.23. CAB,FLOOR FRAME

- 6.24. AIR CONDITIONER UNT

- 6.25. AIR CONDITIONER CONDESER COMPRESSOR

- 6.25.1. REMOVAL

- 6.25.2. INSTALLATION

- 7. MAINTENANCE STANDARD

- 7.1. ENGINE MOUNT TRANSMISSION MOUNT

- 7.2. TORQUE CONVERTER

- 7.3. TRANSMISSION

- 7.4. TRANSMISSION CONTROL VALVE

- 7.5. DRIVE SHAFT

- 7.6. DIFFERENTIAL

- 7.7. FINAL DRIVE

- 7.8. AXLE MOUNT

- 7.9. STEERING COLUMN

- 7.10. STEERING VALVE

- 7.11. STEERING CYLINDER MOUNT

- 7.12. SLACK ADJUSTER

- 7.13. BRAKE VALVE

- 7.14. BRAKE

- 7.15. PARKING BRAKE

- 7.16. TORQUE CONVERTER,TRANSMISSION PUMP

- 7.17. STEERING,SWITCH PUMP

- 7.18. HYDRAULIC,PPC PUMP

- 7.19. PPC VALVE

- 7.20. CUTOFF VALVE

- 7.21. MAIN CONTROL VALVE

- 7.22. BOOM CYLINDER

- 7.23. BUCKET CYLINDER

- 7.24. CENTER HINGE PIN

- 7.25. WORK EQUIPMENT LINAGE

- 7.26. BUCKET

- 7.27. BUCKET POSITIONER AND BOOM KICKOUT

- 8. PROPOSAL

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF