- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu WA470-3 Avance Wheel Loader Shop Manual SMEW4700M0

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SMEW4700M0

- Format: PDF

- Size: 19.4MB

- Number of Pages: 645

Category: Komatsu Shop Manual PDF

-

Model List:

- WA470-3 Avance Wheel Loader

- 0.1. GENERAL ASSEMBLY DRAWING

- 0.2. SPECIFICATIONS

- 0.3. WEIGHT TABLE

- 0.4. LIST OF LUBRICANT AND WATER

- 1. STRUCTURE AND FUNCTION

- 1.1. POWER TRAIN

- 1.2. POWER TRAIN SYSTEM

- 1.3. TORQUE CONVERTER,TRANSMISSION PIPING

- 1.4. TRANSMISSION HYDRAULIC SYSTEM DIAGRAM

- 1.5. TRANSMISSION HYDRAULIC CIRCUIT DIAGRAM

- 1.6. TORQUE CONVERTER

- 1.7. TORQUE CONVERTER OIL FILTER

- 1.8. TRANSMISSION

- 1.9. TRANSMISSION CONTROL VALVE

- 1.10. TRANSMISSION SOLENOID VALVE

- 1.11. PILOT OIL FILTER

- 1.12. DRIVER SHAFT

- 1.13. AXLE

- 1.14. DIFFERENTIAL

- 1.15. FINAL DRIVE

- 1.16. AXLE MOUNT,CENTER HINGE PIN

- 1.17. STEERING PIPING

- 1.18. STEERING COLUMN

- 1.19. STEERING VALVE

- 1.20. ORBITROLL VALVE

- 1.21. STOP VALVE

- 1.22. BRAKE PIPING

- 1.23. BRAKE CIRCUIT DIAGRAM

- 1.24. BRAKE VALVE

- 1.25. CHARGE VALVE

- 1.26. ACCUMULATOR(FOR BRAKE)

- 1.27. SLACK ADJUSTER

- 1.28. BRAKE

- 1.29. PARKING BRAKE CONTROL

- 1.30. PARKING BRAKE

- 1.31. PARKING BRAKE SOLENOID VALVE

- 1.32. PARKING BRAKE VALVE

- 1.33. HYDRAULIC PIPING

- 1.34. WORK EQUIPMENT HYDRAULIC DIAGRAM

- 1.35. WORK EQUIPMENT HYDRAULIC CIRCUIT DIAGRAM

- 1.36. WORK EQUIPMENT LEVER LINKAGE

- 1.37. HYDRAULIC TANK

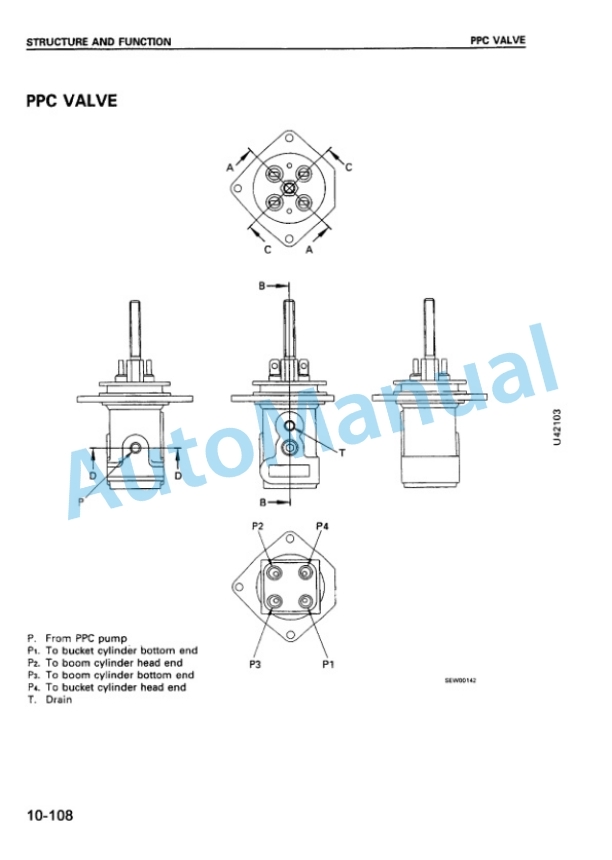

- 1.38. PPC VALVE

- 1.39. PPC RELIEF VALVE

- 1.40. ACCUMULATOR(FOR PPC VALVE)

- 1.41. MAIN CONTROL VALVE

- 1.42. WORK EQUIPMENT LINKAGE

- 1.43. BUCKET

- 1.44. BUCKET POSITIONER AND BOOM KICKOUT

- 1.46. AIR CONDITIONER

- 1.47. SENSORS

- 1.48. ENGINE STARTING CIRCUIT

- 1.49. ENGINE STOP CIRCUIT

- 1.50. PREHEATING CIRCUIT

- 1.51. ELECTRIC TRANSMISSION CONTROL

- 1.52. KICKDOWN,HOLD SWITCH

- 1.53. KICKDOWN ELECTRIC CIRCUIT DIAGRAM

- 1.54. TRANSMISSION CUTOFF SWITCH

- 2. TESTING AND ADJUSTING

- 2.1. STANDARD VALUE TABLE FOR ENGINE

- 2.2. STANDARD VALUE TABLE FOR CHASSIS

- 2.3. STANDARD VALUE TABLE FOR ELECTRICAL PARTS

- 2.4. TOOLS FOR TESTING,ADJUSTING AND TROUBLESHOOTING

- 2.5. MEASURING ENGINE SPEED

- 2.6. MEASURING INTAKE AIR PRESSURE(BOOST PRESSURE)

- 2.7. ADJUSTING VALVE CLEARANCE

- 2.8. MEASURING EXHAUST COLOR

- 2.9. MEASURING EXHAUST GAS TEMPERATURE

- 2.10. MEASURING BLOWBY PRESSURE

- 2.11. MEASURING COMPRESSION PRESSURE

- 2.12. MEASURING ENGINE OIL PRESSURE

- 2.13. TESTING AND ADJUSTING FUEL INJECTION TIMING

- 2.14. METHOD FOR ADJUSTING ENGINE STOP MOTOR CABLE

- 2.15. TESTING AND ADJUSTING FAN BELT TENSION

- 2.16. MEASURING ACCELERATOR PEDAL

- 2.17. MEASURING OPERATING FORCE,TRAVEL OF SPEED LEVER

- 2.18. MEASURING STALL SPEED

- 2.19. MEASURING TORQUE CONVERTER,TRANSMISSION,PARKING BRAKE OIL PRESSURE

- 2.20. METHOD OF OPERATING EMERGENCY MANUAL SPOOL

- 2.21. MEASURING CLEARANCE BETWEEN TIRE AND WHEEL

- 2.22. TESTING AND ADJUSTING STEERING WHEEL

- 2.23. TESTING AND ADJUSTING STEERING CONTROL

- 2.24. MEASURING STEERING OIL PRESSURE

- 2.25. MEASURING OPERATING FORCE,TRAVEL OF BRAKE PEDAL

- 2.26. TESTING BRAKE OIL PRESSURE

- 2.27. MEASURING BRAKE PERFORMANCE

- 2.28. MEASURING BRAKE DISC WEAR

- 2.29. BLEEDING AIR FROM BRAKE SYSTEM

- 2.30. MEASURING PARKING BRAKE PERFORMANCE

- 2.31. MANUAL RELEASE METHOD FOR PARKING BRAKE

- 2.32. TESTING WEAR OF PARKING BRAKE DISC

- 2.33. MEASURING WORK EQUIPMENT CONTROL LEVER

- 2.34. MEASURING WORK EQUIPMNT HYDRAULIC PRESSURE

- 2.35. MEASURING WORK EQUIPMENT HYDRAULIC PRESSURE

- 2.36. MEASURING WORK EQUIPMENT

- 2.37. TESTING AND ADJUSTING BUCKET POSITIONER

- 2.38. TESTING AND ADJUSTING BOOM KICKOUT

- 2.39. TROUBLESHOOTING

- 2.39.1. POINTS TO REMEMBER WHEN TROUBLESHOOTING

- 2.39.2. SEQUENCE OF EVENTS IN TROUBLESHOOTING

- 2.39.3. PRECAUTIONS WHEN CARRYING OUT MAINTENACE

- 2.39.4. HANDLING CONNECTORS

- 2.39.5. CHECKS BEFORE TROUBLESHOOTING

- 2.39.6. CONNECTOR TYPES AND MOUNTING LOCATIONS

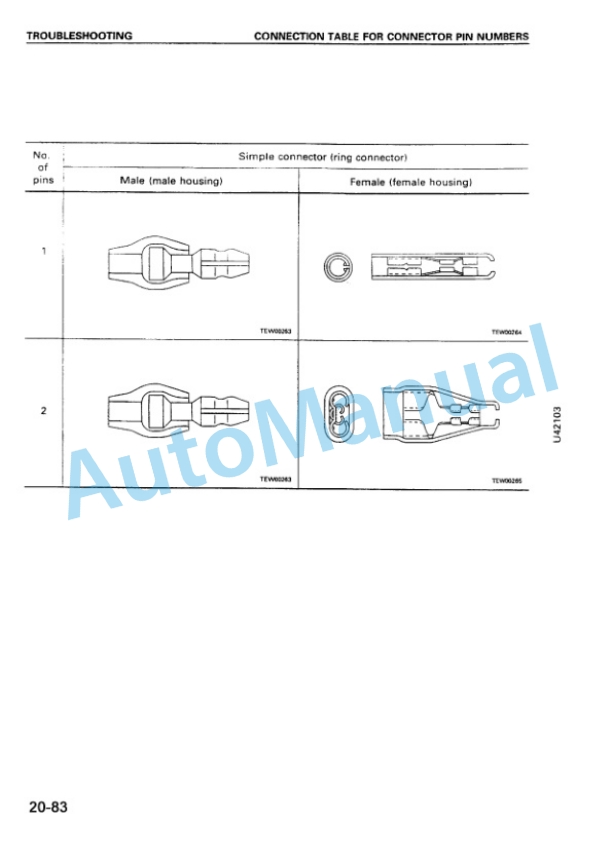

- 2.39.7. CONNECTION TABLE FOR CONNECTOR PIN NUMBERS

- 2.39.8. TROUBLESHOOTING OF ENGINE SYSTEM(S MODE)

- 2.39.8.1. S1 STARTING PERFORMANCE IS POOR

- 2.39.8.2. S2 ENGINE DOES NOT START

- 2.39.8.3. S3 ENGINE DOES NOT PICK UP SMOOTHLY

- 2.39.8.4. S4 ENGINE STOPS DURING OPERATIONS

- 2.39.8.5. S5 ENGINE DOSE NOT ROTATE SMOOTHLY

- 2.39.8.6. S6 ENGINE LACKS OUTPUT

- 2.39.8.7. S7 EXHAUST GAS IS BLACK

- 2.39.8.8. S8 OIL CONSUMPTION IS EXCESSIVE

- 2.39.8.9. S9 OIL BECOMES CONTAMINATED QUICKLY

- 2.39.8.10. S10 FUEL CONSUMPTION IS EXCESSIVE

- 2.39.8.11. S11 OIL IS IN COOLING WATER,OR WATER SPURTS BACK,OR WATER LEVEL GOES DOWN

- 2.39.8.12. S12 OIL PRESSURE LAMP LIGHTS UP

- 2.39.8.13. S13 OIL LEVEL RISES

- 2.39.8.14. S14 WATER TEMPERATURE BECOMES TOO HIGHT

- 2.39.8.15. S15 ABNORMAL NOISE IS MADE

- 2.39.8.16. S16 VIBRATION IS EXCESSIVE

- 2.39.9. TROUBLESHOOTING OF HYDRAULIC AND MECHANICAL SYSTEM(CHASSIS RELATED)(T MODE)

- 2.39.9.1. POWER TRAIN

- 2.39.9.2. STEERING SYSTEM

- 2.39.9.3. BRAKE SYSTEM

- 2.39.9.4. WORK EQUIPMENT

- 2.39.10. TROUBLESHOOTING OF ELECTRICAL SYSTEM(E MODE)

- 2.39.10.1. E1 ENGINE DOES NOT START

- 2.39.10.2. E2 ENGINE DOES NOT STOP

- 2.39.10.3. E3 ENGINE STOP WHEN MACHINE IS TRAVELING

- 2.39.10.4. E4 PARKING BRAKE DOES NOT WORK

- 2.39.10.5. E5 PARKING BRAKE IS APPLIED WHEN MACHINE IS TRAVELING

- 2.39.10.6. E6 PARKING BRAKE IS RELESED WHEN STARTING AWITCH IS TURNED ON

- 2.39.10.7. E7 TRANSMISSION DOES NOT CHANGE TO NEUTRAL WHEN PARKING BRAKE IS APPLIED

- 2.39.10.8. E8 TRANSMISSION DOES NOT WORK NORMALLY

- 2.39.10.9. E9 KICKDOWN SWITCH DOES NOT WORK

- 2.39.10.10. E10 KICKDOWN WORKS ONLY WHEN KICKDOWN SWITCH IS ON

- 2.39.10.11. E11 KICKDOWN OPERATION CANNOT BE CONCELED

- 2.39.10.12. E12 KICKDOWN SWITCH IS ACTUATED BY MISTAKE WHEN TRAVELING IN 2ND

- 3. DISASSEMBLY AND ASSEMBLY

- 3.1. METHOD OF USING MANUAL

- 3.2. PRECATIONS WHEN CARRYING OUT OPERATION

- 3.3. COMMON TOOL LIST

- 3.4. STARTING MOTOR

- 3.5. ALTERNATOR

- 3.6. ENGINE OIL COOLER

- 3.7. FUEL INJECTION PUMP

- 3.8. TORQUE CONVERTER,TRANSMISSION ASSEMBLY

- 3.9. TORQUE CONVERTER

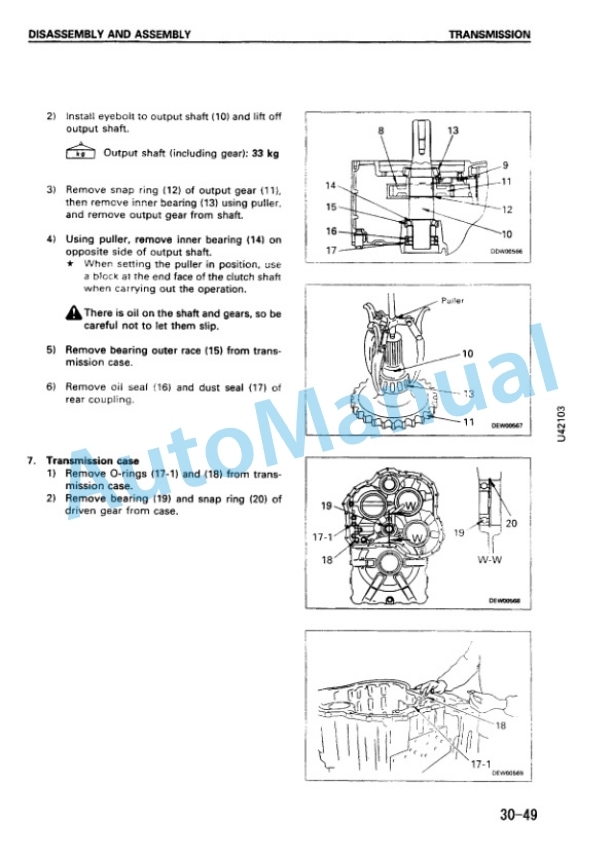

- 3.10. TRANSMISSION

- 3.11. TRANSMISSION CLUTCH PARK

- 3.12. PARKING BRAKE

- 3.13. TRANSMISSION CONTROL VALE

- 3.14. TRANSMISSION ACCUMULATOR VALVE

- 3.15. DRIVE SHAFT

- 3.16. FRONT AXLE

- 3.17. REAR AXLE

- 3.18. FRONT DIFFERENTIAL

- 3.19. REAR DIFFERNTIAL

- 3.20. DIFFERENTIAL

- 3.21. FINAL DRIVE

- 3.22. CENTER HINGE PIN

- 3.23. STEERING VALVE

- 3.24. STEERING DEMAND VALVE

- 3.25. STEERING,SWITCH PUMP

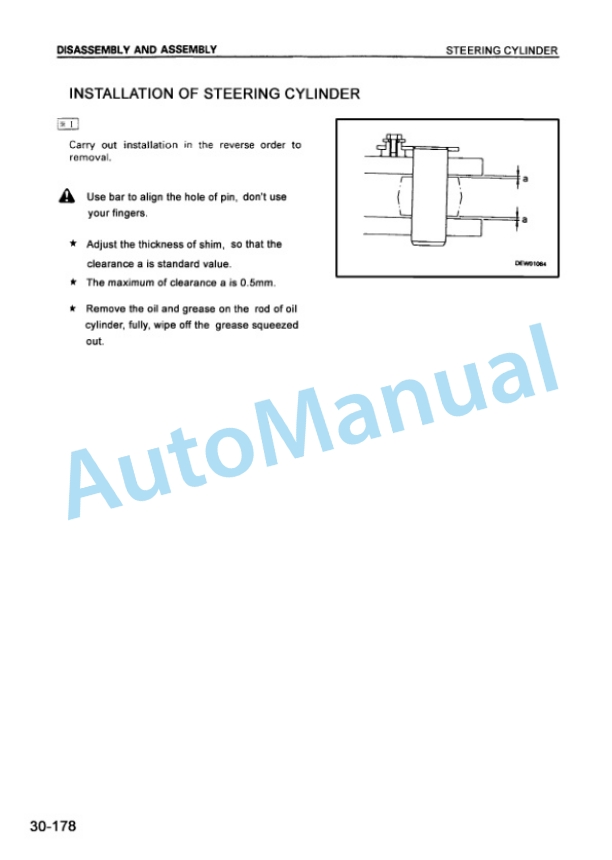

- 3.26. STEERING CYLINDER

- 3.27. BRAKE VALVE

- 3.28. RIGHT BRAKE VALVE

- 3.29. SLACK ADJUSTER

- 3.30. BRAKE

- 3.31. PARKING BRAKE DISC

- 3.32. HYDRAULIC TANK

- 3.33. WORK EQUIPMENT,PPC PUMP

- 3.34. PPC VALVE

- 3.35. MAIN CONTROL VALVE

- 3.36. BUCKET CYLINDER

- 3.37. BOOM CYLINDER

- 3.38. HYDRAULIC CYLINDER

- 3.39. WORK EQUIPMENT

- 3.40. COUNTERWEIGHT

- 3.41. FUEL TANK

- 3.42. CAB FLOOR FRAME

- 3.43. CAB,FLOOR FRAME ASSEMBLY

- 3.45. GUAGE PANEL

- 3.46. AIR CONDITIONER UNIT

- 3.47. AIR CONDITIONER CONDENSER

- 3.48. RECEIVER

- 3.49. AIR CONDITIONER CONDESER COMPRESSOR

- 4. MAINTENANCE STANDARD

- 4.1. ENGINE MOUNT,TRANSMISSION MOUNT

- 4.2. TORQUE CONVERTER

- 4.3. TRANSMISSION

- 4.4. TRANSMISSION CONTROL VALVE

- 4.5. DRIVE SHAFT

- 4.6. DIFFERENTIAL

- 4.7. FINAL DRIVE

- 4.8. AXLE MOUNT

- 4.9. STEERING COLUMN

- 4.10. STEERING VALVE

- 4.11. STEERING CLINDER MOUNT

- 4.12. SLACK ADJUSTER

- 4.13. BRAKE VALVE

- 4.14. BRAKE

- 4.15. PARKING BRAKE

- 4.16. TORQUE CONVERTER,TRANSMISSION PUMP

- 4.17. STEERING,SWITCH PUMP

- 4.18. HYDRAULIC,PPC PUMP

- 4.19. PPC VALVE

- 4.20. CUTOFF VALVE

- 4.21. MAIN CONTROL VALVE

- 4.22. BOOM CYLINDER

- 4.23. BUCKET CYLINDER

- 4.24. CENTER HINGE PIN

- 4.25. WORK EQUIPMENT LINKAGE

- 4.26. BUCKET

- 4.27. BUCKET POSITIONER AND BOOM KICKOUT

- 5. ELECTRIC CIRCUIT DIAGRAM

Rate this product

You may also like

Komatsu Shop Manual PDF

$40.00

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF