- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu WA480-8 Wheel Loader Operation and Maintenance Manual PEN02052-00

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: PEN02052-00

- Format: PDF

- Size: 20.5MB

- Number of Pages: 563

-

Model List:

- WA480-8 Wheel Loader

- 1. Cover

- 2. Foreword

- 2.1. Table of Contents

- 2.2. Read This Manual

- 2.3. Safety Information

- 2.4. Introduction

- 2.4.1. Main Use of Machine

- 2.4.2. Directions of Machine

- 2.4.3. Visibility from Operators Seat

- 2.5. Engine Technology to Conform Exhaust Gas Emission

- 2.6. Product Information

- 2.6.1. Location of Product Identification Number (PIN) and Machine Serial No. Plate

- 2.6.2. Location of Engine Number Plate

- 2.6.3. Location of Authorization Label of Anchor Point for Tieoff

- 2.6.4. Service Meter Location

- 2.6.5. Your Machine Serial Numbers and Distributor

- 2.7. Abbreviation List

- 3. Safety

- 3.1. Safety Labels

- 3.1.1. Location of Safety Labels

- 3.1.2. Safety Labels

- 3.1.3. Location of Safety Labels for Technician

- 3.2. General Precautions Common to Operation and Maintenance

- 3.2.1. Precautions Before You Start Operation

- 3.2.2. Prepare for Safety Operation

- 3.2.3. Precautions to Prevent Fire

- 3.2.4. Precautions When You Get on or Off Machine

- 3.2.5. Do Not Get Caught

- 3.2.6. Precautions Related to Protective Structures

- 3.2.7. Unauthorized Modification

- 3.2.8. Precautions Related to Attachments and Options

- 3.2.9. Precautions When You Operate Engine Inside Building

- 3.3. Precautions for Operation

- 3.3.1. Precautions for Jobsite

- 3.3.2. Start Engine

- 3.3.3. Precautions for Operation

- 3.3.4. Precautions for Transportation

- 3.3.5. Towing and being Towed

- 3.4. Precautions for Maintenance

- 3.4.1. Precautions Before Inspection and Maintenance

- 3.4.2. Precautions for Check and Maintenance

- 3.4.3. Tires

- 3.5. Precautions for DEF

- 3.5.1. General Character and Precautions for Handling

- 3.5.2. Precautions When You Add

- 3.5.3. Precautions for Storage

- 3.5.4. Precautions for Fire Hazard and Leakage

- 3.5.5. Other Precautions

- 4. Operation

- 4.1. General View

- 4.1.1. Names of Machine Equipment

- 4.1.2. Control Levers and Pedals

- 4.1.3. Other Equipment Name

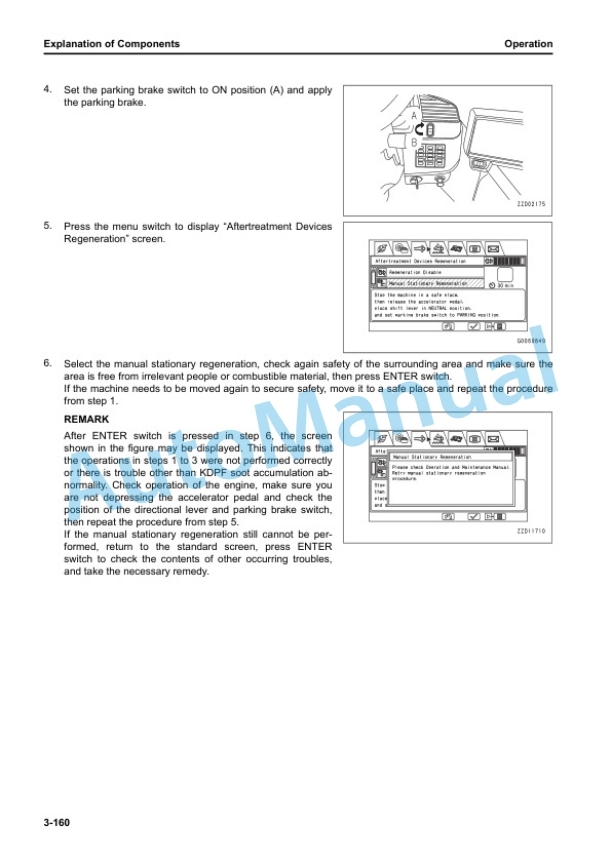

- 4.2. Explanation of Components

- 4.2.1. Machine Monitor Equipment

- 4.2.2. Switches

- 4.2.3. Control Levers and Pedals

- 4.2.4. Other Equipment

- 4.3. Machine Operations and Controls

- 4.3.1. Checks and Adjustment Before You Start Engine

- 4.3.2. How to Start Engine

- 4.3.3. Operations and Checks After You Start Engine

- 4.3.4. How to Stop Engine

- 4.3.5. Start Machine (Travel FORWARD and REVERSE, Gear Shift) and Stop Machine

- 4.3.6. How to Steer Machine

- 4.3.7. How to Operate Work Equipment

- 4.3.8. Precautions for Operation

- 4.3.9. Examine Bucket Angle

- 4.3.10. Recommended Applications

- 4.3.11. Remote Positioner

- 4.3.12. How to Park Machine

- 4.3.13. How to Examine After You Complete Work

- 4.3.14. Lock

- 4.3.15. Handle Tires

- 4.4. Handle Air Conditioner

- 4.4.1. Explanation of Air Conditioner Components

- 4.4.2. Operate Air Conditioner

- 4.5. Handle Radio

- 4.5.1. Explanation of Radio Equipment

- 4.5.2. Operate Radio

- 4.5.3. Radio Setting

- 4.6. Transportation

- 4.6.1. Transportation

- 4.6.2. Load onto and Unload from a Trailer

- 4.6.3. How to Lift Machine

- 4.7. Cold Weather Operation

- 4.7.1. Cold Weather Operation Information

- 4.7.2. Precautions After Daily Work Ends in Cold Weather

- 4.7.3. In Cold Weather

- 4.7.4. After Cold Weather Season

- 4.8. Precautions for LongTerm Storage

- 4.8.1. Prepare for LongTerm Storage

- 4.8.2. Maintenance During LongTerm Storage

- 4.8.3. Start Machine After LongTerm Storage

- 4.9. Troubles and Procedures

- 4.9.1. Procedures When You Run Out of Fuel

- 4.9.2. Precautions When You Tow Machine

- 4.9.3. Precautions for Discharged Battery

- 4.9.4. Other Trouble

- 5. Maintenance

- 5.1. Precautions for Maintenance

- 5.1.1. Examine Service Meter Reading

- 5.1.2. Komatsu Genuine Replacement Parts

- 5.1.3. Komatsu Genuine Lubricants

- 5.1.4. Always Use Clean Washer Fluid

- 5.1.5. Clean Lubricants

- 5.1.6. Examine Drained Oil and Used Filter

- 5.1.7. Precautions When You Refill Oil or Fuel

- 5.1.8. Precautions When You Add DEF

- 5.1.9. Precautions for Welding

- 5.1.10. Do Not Drop Things Inside Machine

- 5.1.11. Precautions for KDPF

- 5.1.12. Precautions for SCR Assembly

- 5.1.13. Dusty Jobsites

- 5.1.14. Avoid Mixing Oil

- 5.1.15. Lock Inspection Covers

- 5.1.16. Bleed Air from Hydraulic System

- 5.1.17. Precautions When You Install Hydraulic Hoses

- 5.1.18. Checks After Inspection and Maintenance

- 5.1.19. Select Fuel and Lubricants by Ambient Temperature

- 5.1.20. Close Engine Side Cover Securely

- 5.2. Outline of Maintenance

- 5.2.1. Handle Oil, Fuel, Coolant, and Do Oil Clinic

- 5.2.2. Battery Terminal

- 5.2.3. Handle Electrical Components

- 5.3. Standard Tightening Torque for Bolts and Nuts

- 5.4. Maintenance Schedule

- 5.4.1. Maintenance Schedule Table

- 5.5. Maintenance Procedure

- 5.5.1. Initial 250 Hours Maintenance (Only After the First 250 Hours)

- 5.5.2. When Required

- 5.5.3. Examine Before You Start Operation

- 5.5.4. Every 50 Hours Maintenance

- 5.5.5. Every 100 Hours Maintenance

- 5.5.6. Every 250 Hours Maintenance

- 5.5.7. Every 500 Hours Maintenance

- 5.5.8. Every 1000 Hours Maintenance

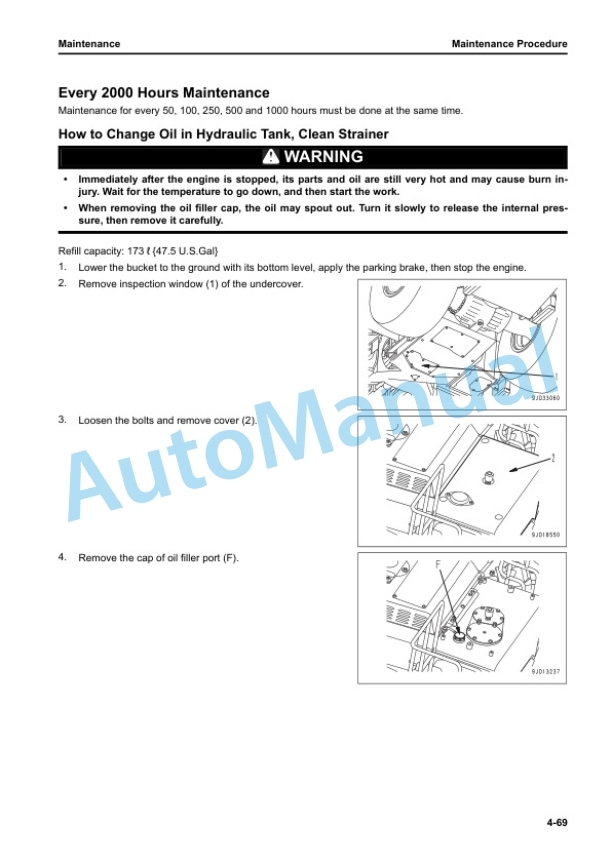

- 5.5.9. Every 2000 Hours Maintenance

- 5.5.10. Every 4000 Hours Maintenance

- 5.5.11. Every 4500 Hours Maintenance

- 5.5.12. Every 8000 Hours Maintenance

- 5.5.13. Every 9000 Hours Maintenance

- 5.5.14. Every 6 Months Maintenance

- 6. Specifications

- 6.1. Specifications

- 6.1.1. Specifications WA4808

- 7. Attachments and Options

- 7.1. Bucket and Tire Selection

- 7.1.1. Precautions When You Operate Machine with 5.5m3 Bucket

- 7.1.2. Precautions When Wide Tires are Installed

- 7.2. Handle Machines with AJSS

- 7.2.1. General View

- 7.2.2. Explanation of Components

- 7.2.3. Machine Operations and Controls

- 7.2.4. When Required

- 7.3. Handle Multifunction MonoLever

- 7.3.1. Explanation of Equipment on Multifunction MonoLever

- 7.3.2. Multifunction MonoLever

- 7.3.3. Kickdown Switch

- 7.3.4. Hold Switch

- 7.3.5. Directional Selector Switch on Multifunction MonoLever

- 7.3.6. PCS (Proportional Control Switch)

- 7.3.7. LCD Unit

- 7.3.8. Oil Flow Control Mode Pilot Lamp (Fixed Oil Flow Mode)

- 7.3.9. Oil Flow Control Mode Pilot Lamp (Proportional Oil Flow Mode)

- 7.3.10. Detent Operation Pilot Lamp

- 7.3.11. Attachment Oil Flow Level

- 7.3.12. How to set PCS

- 7.4. Seat Heater and Seat Ventilation

- 7.4.1. How to Heat the Seat

- 7.4.2. How to Use Seat Ventilation

- 7.5. Handle Seat Belt

- 7.5.1. How to Fasten and Unfasten Seat Belt

- 7.6. How to Clean Cab Front Glass

- 8. Replacement Parts

- 8.1. Defined Life Parts

- 8.1.1. Defined Life Parts List

- 8.2. Consumable Parts

- 8.2.1. Consumable Parts List

- 8.3. Recommended Fuel, Coolant, and Lubricant

- 8.3.1. Lubrication Chart

- 8.3.2. How to Use Fuel, Coolant and Lubricants by Ambient Temperature

- 8.3.3. Recommended Brands and Qualities Other Than Komatsu Genuine Oils

- 9. Index

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG725

Komatsu Operation and Maintenance Manual PDF

Komatsu 430FX-1, 430FXL-1, 445FXL-1 Operation and Maintenance Manual CEAM023702

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM013300

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Field Assembly Instruction CEAW004103

Komatsu Operation and Maintenance Manual PDF

Komatsu 530M Dump Truck Operation and Maintenance Manual DG716

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAD014800

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM006700

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG615

Komatsu Operation and Maintenance Manual PDF

Komatsu 101 Basics Forklift Truck Operation and Maintenance Manual

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG745

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF