- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu WA500-1L Wheel Loader Operation and Maintenance Manual CEAMW25010

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: CEAMW25010

- Format: PDF

- Size: 10.9MB

- Number of Pages: 190

-

Model List:

- WA500-1L Wheel Loader

- 1. MAIN MENU

- 2. FORWARD

- 3. SAFETY INFORMATION

- 4. INTRODUCTION

- 4.1. BREAKING IN THE NEW MACHINE

- 4.2. MACHINE AND ENGINE SERIAL NUMBERS

- 4.3. QUICK REFERENCE INFORMATION

- 5. CONTENTS

- 6. SAFETY PRECAUTIONS SECTION 1

- 6.1. GENERAL PRECAUTIONS

- 6.1.1. PERSONNEL PRECAUTIONS

- 6.1.2. MACHINE PRECAUTIONS

- 6.2. OPERATION

- 6.2.1. BEFORE STARTING

- 6.2.2. STARTUP

- 6.2.3. GENERAL OPERATING PRECAUTIONS

- 6.2.4. DRIVING THE MACHINE

- 6.2.5. OPERATING THE ATTACHMENTS

- 6.2.6. PULLING/TOWING

- 6.2.7. SHUTDOWN

- 6.3. MAINTENANCE

- 6.3.1. GENERAL MACHINE PRECAUTIONS

- 6.3.2. GENERAL WORK PRECAUTIONS

- 6.3.3. TIRES AND RIMS

- 6.3.4. TURBOCHARGER

- 6.4. SAFETY PRODUCT GRAPHICS AND LOCATIONS

- 7. OPERATION SECTION 2

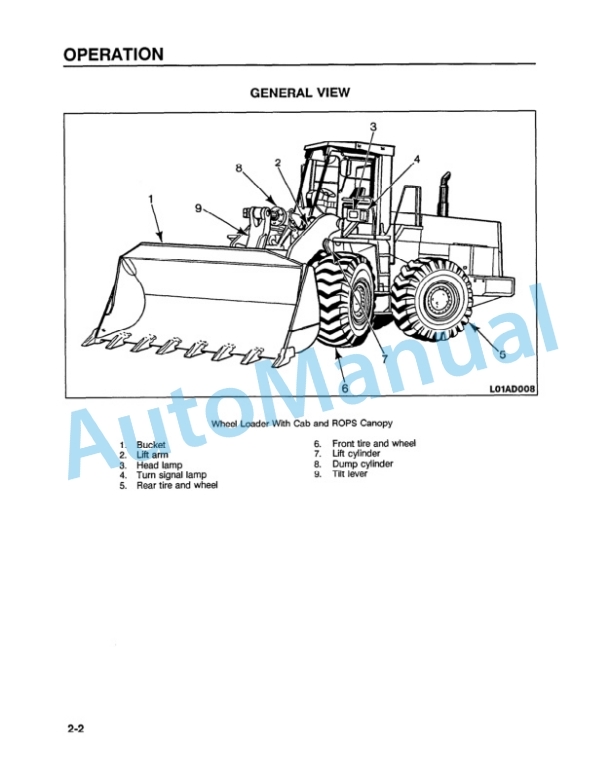

- 7.1. GENERAL VIEW

- 7.2. INSTRUMENTS AND CONTROLS

- 7.2.1. MONITOR PANEL

- 7.2.2. SWITCHES

- 7.2.3. LEVERS AND PEDALS

- 7.2.4. CAB DOOR HOLD OPEN LOCK IF EQUIPPED

- 7.2.5. AIR CLEANER SERVICE INDICATOR

- 7.2.6. FRAME LOCKING BAR

- 7.2.7. MAIN CIRCUIT BREAKER

- 7.2.8. FUSE BOXES

- 7.2.9. OPERATORS SEAT

- 7.3. CAB HEATER AND DEFROSTER IF EQUIPPED

- 7.3.1. CONTROL PANEL

- 7.3.2. METHOD OF OPERATION

- 7.4. CAB HEATER, DEFROSTER AND AIR CONDITIONER IF EQUIPPED

- 7.4.1. CONTROL PANEL

- 7.4.2. METHOD OF OPERATION

- 7.5. LOCKING FILLER CAPS

- 7.5.1. FUEL TANK FILLER CAP

- 7.5.2. HYDRAULIC TANK FILLER CAP

- 7.6. CHECKS BEFORE STARTING ENGINE

- 7.6.1. WALK AROUND CHECK

- 7.6.2. CHECKS BEFORE STARTING

- 7.7. OPERATING MACHINE

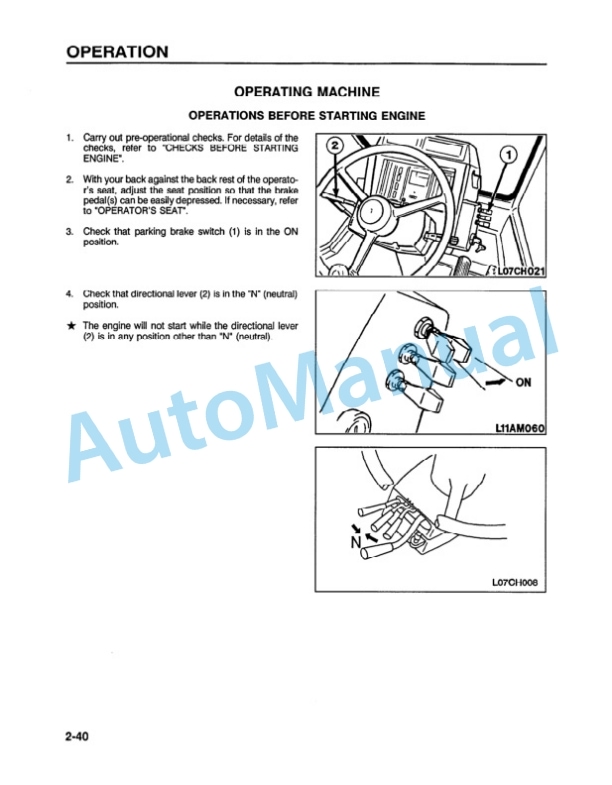

- 7.7.1. OPERATIONS BEFORE STARTING ENGINE

- 7.7.2. STARTING ENGINE

- 7.7.3. OPERATIONS AFTER STARTING ENGINE

- 7.7.4. COLD WEATHER WARMUP PROCEDURE

- 7.7.5. MOVING MACHINE OFF

- 7.7.6. SHIFTING GEAR

- 7.7.7. SHIFTING BETWEEN FORWARD AND REVERSE

- 7.7.8. STEERING MACHINE

- 7.7.9. STOPPING MACHlNE

- 7.7.10. OPERATIONAL PRECAUTIONS

- 7.7.11. POSSIBLE WORK USING LOADER

- 7.8. ADJUSTMENT OF WORK EQUIPMENT

- 7.8.1. ADJUSTING BOOM KICKOUT

- 7.8.2. ADJUSTING BUCKET POSITIONER

- 7.8.3. BUCKET LEVEL INDICATOR

- 7.9. HANDLING TIRES

- 7.9.1. PRECAUTIONS WHEN HANDLING TIRES

- 7.9.2. PRECAUTIONS WHEN DRIVING MACHINE

- 7.9.3. NORMAL OPERATING INFLATION PRESSURE

- 7.9.4. PROPER BUCKET AND TIRE SELECTION TABLE

- 7.10. TOWING

- 7.10.1. TOWING THE MACHINE

- 7.10.2. RELEASING PARKING BRAKE

- 7.11. TRANSPORTATION

- 7.12. COLD WEATHER OPERATION

- 7.12.1. PREPARATION FOR LOW TEMPERATURE

- 7.12.2. CAUTIONS AFTER COMPLETION OF WORK

- 7.12.3. AFTER COLD WEATHER

- 7.13. LONG TERM STORAGE

- 7.13.1. BEFORE STORAGE

- 7.13.2. DURING STORAGE

- 7.13.3. AFTER STORAGE

- 7.14. HANDLING OF BATTERY

- 7.14.1. PRECAUTIONS FOR CHARGING BAlTERY

- 7.14.2. REMOVAL AND INSTALLATION OF BAlTERY

- 7.14.3. STARTING ENGINE WITH BOOSTER CABLES

- 7.15. TROUBLESHOOTING

- 7.15.1. ELECTRICAL SYSTEM

- 8. MAINTENANCE SECTION 3

- 8.1. PERIODIC MAINTENANCE

- 8.2. MAINTENANCE GUIDELINES

- 8.3. OUTLINES OF SERVICE

- 8.3.1. LUBRICATION WHEN SHIPPED

- 8.3.2. RELATING TO ENGINE

- 8.3.3. RELATING TO HYDRAULIC SYSTEM

- 8.3.4. RELATING TO ELECTRICAL SYSTEM

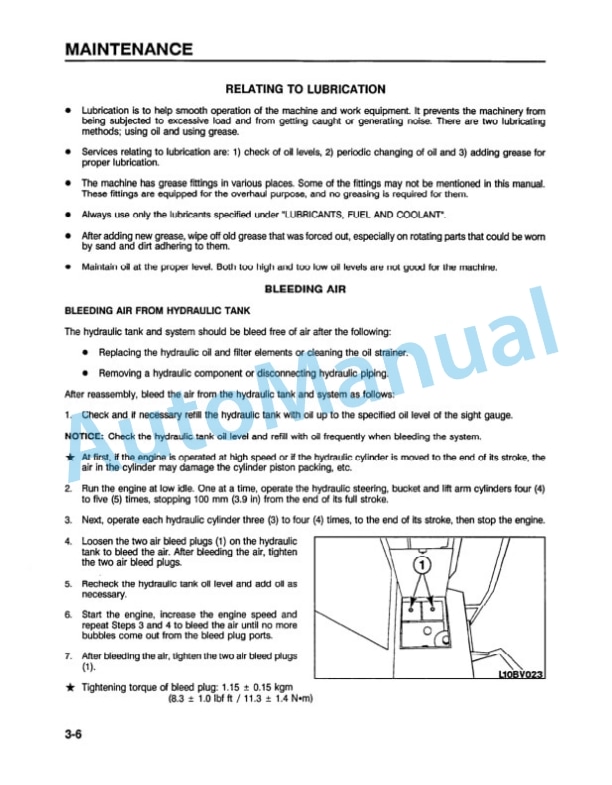

- 8.3.5. RELATING TO LUBRICATION

- 8.3.6. BLEEDING AIR

- 8.4. WEAR PARTS REPLACEMENT

- 8.5. PERIODICAL PART REPLACEMENT

- 8.6. LUBRICANTS, FUEL AND COOLANT

- 8.6.1. PROPER SELECTION TABLE

- 8.6.2. AXLE OIL

- 8.6.3. GREASE

- 8.6.4. DIESEL FUEL

- 8.6.5. COOLANT

- 8.7. SCHEDULED MAINTENANCE GUIDE

- 8.8. FILLER AND LEVEL GAUGE POSITIONS

- 8.9. INITIAL 250 HOURS SERVICE ONLY

- 8.9.1. TRANSMISSION OIL FILTER

- 8.9.2. FUEL FILTER

- 8.9.3. ENGINE VALVE CLEARANCE

- 8.10. WHEN REQUIRED

- 8.10.1. COOLING SYSTEM

- 8.10.2. AIR CLEANER ELEMENTS

- 8.10.3. TRANSMISSION OIL LEVEL

- 8.10.4. RADIATOR CORE

- 8.10.5. DRIVE AXLE OIL LEVEL

- 8.10.6. DRIVE AXLE HOUSING BREATHERS

- 8.10.7. AIR CONDITIONER REFRIGERANT CHARGE IF EQUIPPED

- 8.10.8. LUBRICATION

- 8.10.9. BUCKET TEETH IF EQUIPPED

- 8.10.10. BUCKET BOLTON CUTTING EDGE IF EQUIPPED

- 8.10.11. ELECTRICAL INTAKE AIR HEATER

- 8.10.12. WATER SEPARATOR

- 8.10.13. WINDOW WASHER TANKS IF EQUIPPED

- 8.10.14. AIR CONDITIONER CONDENSER IF EQUIPPED

- 8.10.15. TRANSMISSION CONTROL LEVERS

- 8.11. CHECKS BEFORE STARTING ENGINE

- 8.11.1. MONITOR PANEL

- 8.11.2. COOLANT LEVEL

- 8.11.3. ENGINE OIL LEVEL

- 8.11.4. FUEL LEVEL

- 8.11.5. AIR CLEANER SERVICE INDICATOR

- 8.11.6. AIR TANKS

- 8.11.7. BRAKE OIL LEVEL

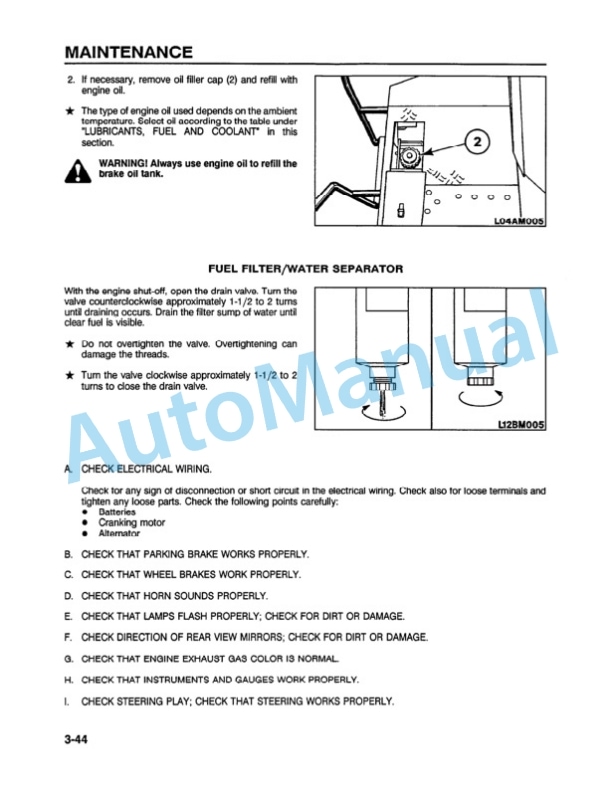

- 8.11.8. FUEL FILTER/WATER SEPARATOR

- 8.12. EVERY 50 HOURS SERVICE

- 8.12.1. FUEL TANK

- 8.12.2. TIRES

- 8.13. EVERY 100 HOURS SERVICE

- 8.13.1. HYDRAULIC TANK OIL LEVEL

- 8.13.2. LUBRICATION

- 8.13.3. CAB AIR FILTER IF EQUIPPED

- 8.14. EVERY 250 HOURS SERVICE

- 8.14.1. ENGINE OIL AND FILTERS

- 8.14.2. FAN BELT

- 8.14.3. ALTERNATOR BELT

- 8.14.4. AIR CONDITIONER COMPRESSOR BELT

- 8.14.5. LUBRICATION

- 8.14.6. WHEEL HUB NUTS

- 8.14.7. BAlTERY ELECTROLYTE LEVELS

- 8.15. EVERY 500 HOURS SERVICE

- 8.15.1. FUEL FILTER

- 8.15.2. TRANSMISSION OIL FILTER

- 8.15.3. LUBRICATION

- 8.15.4. AIR DRYER IF EQUIPPED

- 8.16. EVERY 1000 HOURS SERVICE

- 8.16.1. TRANSMISSION OIL AND STRAINER

- 8.16.2. TRANSMISSION CASE BREATHER

- 8.16.3. LUBRICATION

- 8.16.4. PARKING BRAKE

- 8.16.5. CORROSION RESISTOR

- 8.16.6. TURBOCHARGER VARIOUS FASTENERS

- 8.17. EVERY 2000 HOURS SERVICE

- 8.17.1. ENGINE

- 8.17.2. ENGINE MOUNTED HOSES

- 8.17.3. ENGINE MOUNTING HARDWARE

- 8.17.4. BATTERIES

- 8.17.5. HYDRAULIC TANK OIL AND FILTERS

- 8.17.6. HYDRAULIC TANK BREATHER

- 8.17.7. PPC CIRCUIT STRAINER

- 8.17.8. CAB AIR FILTER IF EQUIPPED

- 8.17.9. DRIVE AXLE OIL

- 8.17.10. ENGINE BREATHER

- 8.17.11. TURBOCHARGER ROTOR PLAY

- 8.17.12. TURBOCHARGER

- 8.17.13. ALTERNATOR AND STARTING MOTOR

- 8.17.14. ENGINE VALVE CLEARANCE

- 8.17.15. BRAKE DISC

- 8.17.16. ENGINE VIBRATION DAMPER

- 8.17.17. AIR DRYER IF EQUIPPED

- 8.17.18. ACCUMULATOR

- 8.18. EVERY 4000 HOURS SERVICE

- 8.18.1. WATER PUMP

- 8.18.2. FAN PULLEY AND TENSION PULLEY

- 8.18.3. AIR COMPRESSOR

- 9. SPECIFICATIONS SECTION 4

- 9.1. GENERAL SPECIFICATIONS

- 9.1.1. OPERATING WEIGHT

- 9.1.2. PERFORMANCE

- 9.1.3. ENGINE

- 9.2. DIMENSIONS

- 9.3. STANDARD TIGHTENING TORQUES

- 9.3.1. STANDARD TIGHTENING TORQUE OF BOLTS AND NUTS

- 9.3.2. TIGHTENING TORQUE OF SPLIT FLANGE BOLTS

- 9.3.3. TIGHTENING TORQUE FOR NUTS OF FLARED FITTINGS

Komatsu Operation and Maintenance Manual PDF

Komatsu 430FX-1, 430FXL-1, 445FXL-1 Operation and Maintenance Manual CEAM023702

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Field Assembly Instruction CEAW004103

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM011001

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM013300

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM014901

Komatsu Operation and Maintenance Manual PDF

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM010301

Komatsu Operation and Maintenance Manual PDF

Komatsu 330M Dump Truck Operation and Maintenance Manual DG713

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM018100

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG615

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF