- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu WA80M-8E0 Wheel Loader Operation and Maintenance Manual VENAM08002

$20.00

- Type Of Manual: Operation and Maintenance Manual

- Manual ID: VENAM08002

- Format: PDF

- Size: 42.3MB

- Number of Pages: 382

-

Model List:

- WA80M-8E0 Wheel Loader

- 1. Foreword

- 1.1. Table of Contents

- 1.2. Read This Manual

- 1.3. EU Directives

- 1.4. KOMATSU Machine Operator Privacy Policy

- 1.5. Safety Information

- 1.6. Safety Labels

- 1.7. Noise Emission Levels

- 1.8. Vibration Level

- 1.9. Introduction

- 1.10. Engine Technology to Conform Exhaust Gas Emission

- 1.11. Machine Information

- 1.11.1. Location of Product Identification Number (PIN) and Machine Serial No. Plate

- 1.11.2. Location of Engine Number Plate

- 1.11.3. Location of ROPS and FOPS Plate

- 1.11.4. Location of Axle Serial Plate

- 1.11.5. Location of Seat Plate

- 1.11.6. Fluorinated Greenhouse Gases

- 1.11.7. Service Meter Location

- 1.12. Your Machine Serial Numbers and Distributor

- 1.13. Serial Plate

- 1.14. Alternative Serial Plate

- 1.15. Declaration of Conformity

- 1.16. Retrofitting by Thirdparty Suppliers

- 1.17. Abbreviation List

- 2. Safety

- 2.1. Safety Labels

- 2.2. General Precautions Common to Operation and Maintenance

- 2.2.1. Precautions Before You Start Operation

- 2.2.2. Prepare for Safety Operation

- 2.2.3. Procedures If Fire Occurs

- 2.2.4. Precautions to Prevent Fire

- 2.2.5. Precautions When You Get on or off Machine

- 2.2.6. Precautions for Machine and Jobsite

- 2.3. Precautions for Operation

- 2.3.1. Precautions for Jobsite

- 2.3.2. Start Engine

- 2.3.3. Precautions for Operation

- 2.3.4. Precautions for Transportation

- 2.3.5. Towing and being Towed

- 2.4. Precautions for Maintenance

- 2.4.1. Precautions Before Inspection and Maintenance

- 2.4.2. Precautions for Check and Maintenance

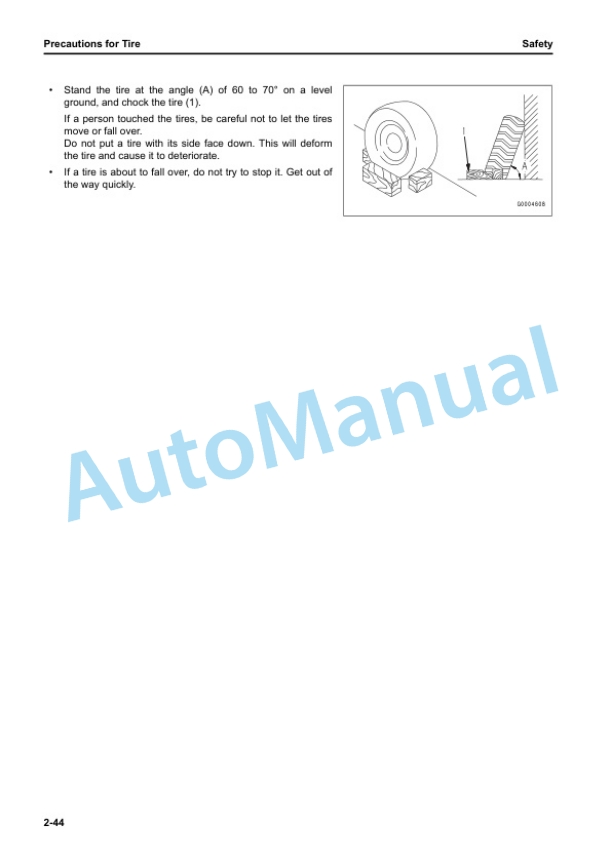

- 2.5. Precautions for Tire

- 3. Operation

- 3.1. General View

- 3.1.1. Machine Equipment Name

- 3.1.2. Controls and Gauges Names

- 3.1.3. Cabin Switches Names with PPC

- 3.1.4. Cabin Switches Names with EPC

- 3.1.5. Machine Monitor Equipment Name

- 3.1.6. Other Equipment Names

- 3.2. Explanation of Components

- 3.2.1. Machine Monitor Equipment

- 3.2.2. Cabin Switches Descriptions with PPC

- 3.2.3. Cabin Switches Descriptions with EPC

- 3.2.4. Controls and Gauges Descriptions

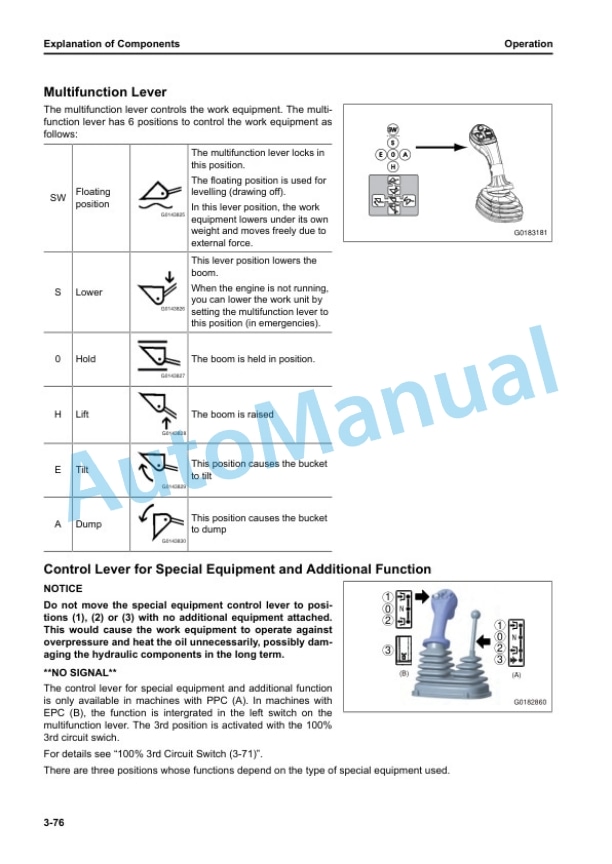

- 3.2.5. Control Levers Description

- 3.2.6. Other Equipment

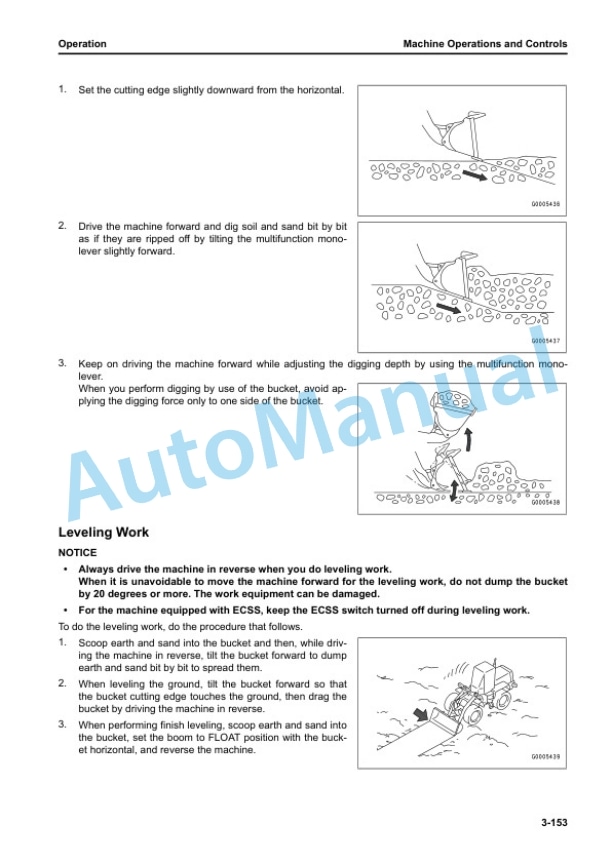

- 3.3. Machine Operations and Controls

- 3.3.1. Checks and Adjustment Before You Start Engine

- 3.3.2. How to Start Engine

- 3.3.3. Operations and Checks After You Start Engine

- 3.3.4. How to Stop Engine

- 3.3.5. How to Start and Stop Machine

- 3.3.6. Steer Machine

- 3.3.7. Operate Work Equipment

- 3.3.8. Work Precautions

- 3.3.9. Recommended Applications

- 3.3.10. Park Machine

- 3.3.11. How to Examine and Report After You Complete Work

- 3.3.12. Lock

- 3.4. Handle Tires

- 3.4.1. Tire Pressure

- 3.4.2. Precautions for LoadandCarry Operation

- 3.5. Air Conditioner Component

- 3.5.1. How to Set Ventilation and Heating System

- 3.5.2. How to Set Air Conditioner

- 3.6. Transportation

- 3.6.1. Load onto and Unload from a Trailer

- 3.6.2. Precautions When You Lift Machine

- 3.7. Cold Weather Operation

- 3.7.1. Cold Weather Operation Information

- 3.7.2. Fuel and Lubricants

- 3.7.3. Coolant

- 3.7.4. Battery

- 3.7.5. Precautions After Daily Work Ends in Cold Weather

- 3.7.6. In Cold Weather

- 3.7.7. After Cold Weather Season

- 3.8. LongTerm Storage Precautions

- 3.8.1. Prepare for LongTerm Storage

- 3.8.2. Maintenance During LongTerm Storage

- 3.8.3. Start Machine After LongTerm Storage

- 3.9. Troubles and Procedures

- 3.9.1. Procedures When You Run Out of Fuel

- 3.9.2. How to Examine Service Brake

- 3.9.3. How to Examine Parking Brake

- 3.9.4. Emergency Steering Properties

- 3.9.5. Emergency Lowering

- 3.9.6. Precautions When You Tow Machine

- 3.9.7. Precautions for Discharged Battery

- 3.9.8. Precautions When You Charge Battery

- 3.9.9. Start Engine with Jumper Cables

- 3.9.10. Other Trouble

- 4. Maintenance

- 4.1. Precautions for Maintenance

- 4.2. Guide to Maintenance

- 4.2.1. How to Tip up Operators Cab (Standard, without Tipping Cylinder)

- 4.2.2. How to Tip down the Operators Cab (Standard, without Tipping Cylinder)

- 4.2.3. How to Tip up Operators Cab (Option, with Tipping Cylinder)

- 4.2.4. How to Tip down the Operators Cab (Option, with Tipping Cylinder)

- 4.3. Maintenance Information

- 4.3.1. Oil, Fuel, and Coolant

- 4.3.2. Battery Terminal

- 4.3.3. Electrical Components

- 4.4. Standard Torque

- 4.5. Maintenance Schedule

- 4.5.1. Periodic Maintenance for Engine

- 4.5.2. Maintenance Schedule Table

- 4.6. Maintenance Procedure

- 4.6.1. Initial 10 Hours Maintenance (Only for the First 100 Hours)

- 4.6.2. When Required

- 4.6.3. How to Examine Before You Start Operation

- 4.6.4. Initial 50 Hours Maintenance (Only after the First 50 Hours)

- 4.6.5. Initial 500 Hours Maintenance (Only After the First 500 Hours)

- 4.6.6. Every 10 Hours Maintenance

- 4.6.7. Every 50 Hours Maintenance

- 4.6.8. Every 250 Hours Maintenance

- 4.6.9. Every 500 Hours Maintenance

- 4.6.10. Every 1000 Hours Maintenance

- 4.6.11. Every 1500 Hours Maintenance

- 4.6.12. Every 2000 Hours Maintenance

- 4.6.13. Every 3000 Hours Maintenance

- 4.6.14. Every 4000 Hours Maintenance

- 4.6.15. Every 6000 Hours Maintenance

- 4.6.16. Every 8000 Hours Maintenance

- 4.6.17. End of Service Life

- 5. Specifications

- 5.1. Specifications WA80M8E0

- 6. Attachments and Options

- 6.1. Electromagnetic Proportional Controlled 3rd Hydraulic Circuit (EPC)

- 6.2. Central Lubrication System

- 6.2.1. How to Change Central Lubrication System Interval

- 6.2.2. How to Use Central Lubrication System

- 6.2.3. Display and Operating Unit

- 6.2.4. Initial 10 Hours Maintenance (Only for the First 100 Hours)

- 6.2.5. How to Examine Central Lubrication System and Fill Grease

- 6.3. ECSS

- 6.3.1. How to Operate ECSS

- 6.4. Bucket Position Indicator

- 6.5. Return to Dig

- 6.6. Differential Lock Switch

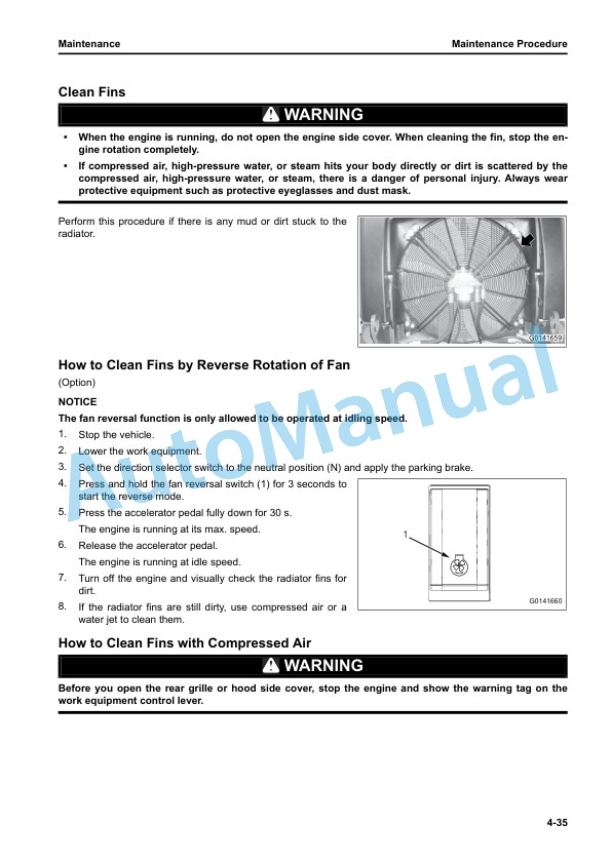

- 6.7. Reversible Fan

- 6.7.1. How to Clean Radiator Fins

- 6.8. Air Conditioner Component

- 6.9. Towing Pin

- 6.10. Speed Control

- 6.11. Road Homologation (for Italy)

- 6.12. Cold Area Kit

- 7. Replacement Parts

- 7.1. Defined Life Parts

- 7.1.1. Defined Life Parts List

- 7.2. Consumable Parts

- 7.2.1. Consumable Parts List

- 7.3. Recommended Fuel, Coolant, and Lubricant

- 7.3.1. Lubrication Chart

- 7.3.2. How to Use Fuel, Coolant and Lubricants by Ambient Temperature

- 7.3.3. Recommended Brands and Qualities Other Than Komatsu Genuine Oils

- 8. Index

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM013300

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG615

Komatsu Operation and Maintenance Manual PDF

Komatsu 410W Hydraulic Excavator Operation and Maintenance Manual UMGB410W1

Komatsu Operation and Maintenance Manual PDF

Komatsu 150A, 150FA Crane Operation and Maintenance Manual CEAMC20081

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM014901

Komatsu Operation and Maintenance Manual PDF

Komatsu 730E Dump Truck Operation and Maintenance Manual CEAM018100

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG725

Komatsu Operation and Maintenance Manual PDF

Komatsu 4D104E, S4D104E Series Diesel Motor Operation and Maintenance Manual WHBMNEF000

Komatsu Operation and Maintenance Manual PDF

Komatsu 430FX-1, 430FXL-1, 445FXL-1 Operation and Maintenance Manual CEAM023702

Komatsu Operation and Maintenance Manual PDF

Komatsu 210M Dump Truck Operation and Maintenance Manual DG714

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF