- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF

Komatsu WA900-3E0 Wheel Loader Shop Manual SEN05654-01

$40.00

- Type Of Manual: Shop Manual

- Manual ID: SEN05654-01

- Format: PDF

- Size: 3.5MB

- Number of Pages: 173

Category: Komatsu Shop Manual PDF

-

Model List:

- WA900-3E0 Wheel Loader

- 1. COVER

- 2. Notice of revision

- 3. Index and foreword

- 3.1. Table of Contents

- 3.1.1. Table of Contents

- 3.2. Foreword

- 3.2.1. Before reading this manual

- 4. Specification

- 4.1. Specification

- 4.1.1. Specification dimension drawing

- 4.1.2. Specifications

- 4.1.3. Weight table

- 4.1.4. Table of fuel, coolant and lubricants

- 5. Structure and function

- 5.1. Cooling system and related devices

- 5.1.1. Cooling system

- 5.2. Hydraulic system

- 5.2.1. Power ladder system

- 5.3. Electrical system

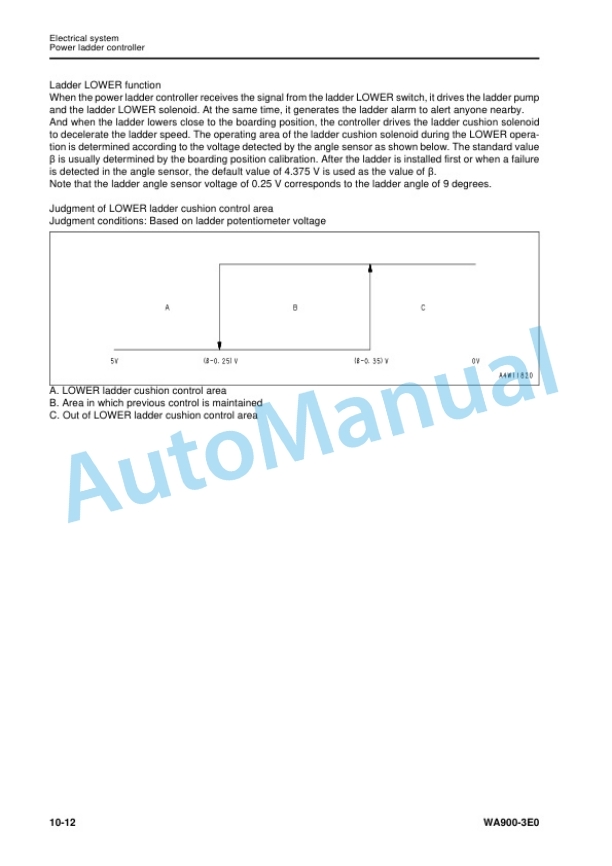

- 5.3.1. Power ladder controller

- 5.3.2. Rear view monitor system

- 5.3.3. Engine service monitor system

- 5.3.4. Parking brake circuit

- 5.3.5. Sensor

- 6. Standard value table

- 6.1. Standard value table

- 6.1.1. Standard value table for chassis

- 6.1.2. Standard value table for electrical system

- 7. Testing and adjusting

- 7.1. Testing and adjusting

- 7.1.1. Inspection and adjustment of potentiometer

- 7.1.2. Ladder position calibration procedure

- 7.1.3. Procedure for testing diodes

- 8. Troubleshooting

- 8.1. General information on troubleshooting

- 8.1.1. Classification and procedures of troubleshooting

- 8.1.2. Failure codes table

- 8.1.3. Fuse locations

- 8.2. Troubleshooting by failure code

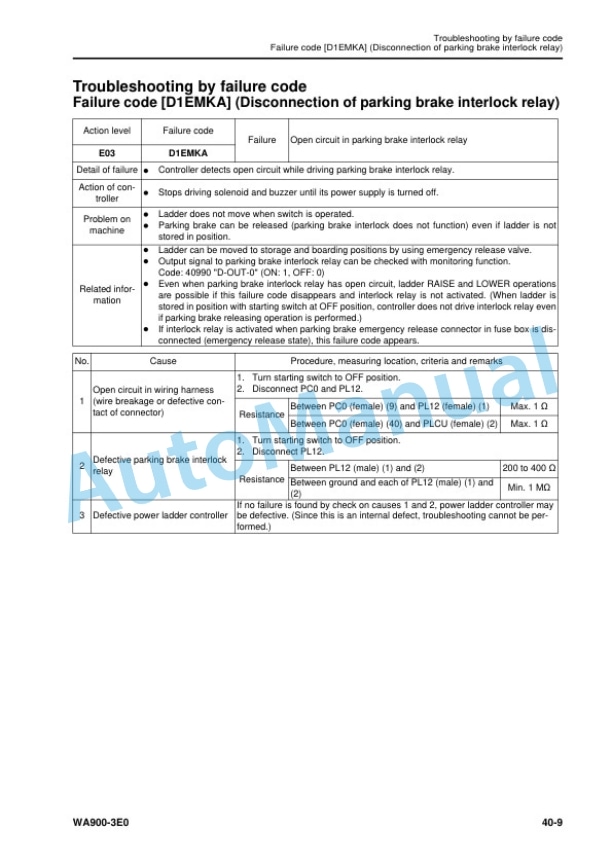

- 8.2.1. Failure code D1EMKA (Disconnection of parking brake interlock relay)

- 8.2.2. Failure code D1EMKB (Ground fault of parking brake interlock relay)

- 8.2.3. Failure code D1EMKY (Hot short of parking brake interlock relay)

- 8.2.4. Failure code D1EPKA (Disconnection of ladder drive pump relay)

- 8.2.5. Failure code D1EPKB (Ground fault of ladder drive pump relay)

- 8.2.6. Failure code D1EPKY (Short circuit of ladder drive pump relay)

- 8.2.7. Failure code D1EQKY (Ladder operation alarm relay output hot short circuit)

- 8.2.8. Failure code D1EQKZ (Ladder operation alarm relay output abnormalityOpen circuit, ground fault)

- 8.2.9. Failure code D1ERKB (Ladder raise solenoid output ground fault)

- 8.2.10. Failure code D1ERKZ (Ladder raise solenoid output abnormality Open circuit, hot short circuit)

- 8.2.11. Failure code D1ESKB (Ladder lower solenoid output ground fault)

- 8.2.12. Failure code D1ESKZ (Ladder lower solenoid output abnormality Open circuit, hot short circuit)

- 8.2.13. Failure code DBL0KR (Power ladder controller CANNET signal line open circuit)

- 8.2.14. Failure code DBL0KT (Nonvolatile memory write error)

- 8.2.15. Failure code DBL1KK (Power Low Error Battery direct)

- 8.2.16. Failure code DBL2KK (Solenoid Power Low Error)

- 8.2.17. Failure code DDB6KZ (Parking brake system abnormality)

- 8.2.18. Failure code DDDGKY (Ladder operation switch hot short circuit)

- 8.2.19. Failure code DDDKKY (Ladder raise operation switch hot short circuit)4035

- 8.2.20. Failure code DDDLKY (Ladder lower operation switch hot short circuit)4038

- 8.2.21. Failure code DK5VKX (Ladder angle sensor abnormality Out of range)

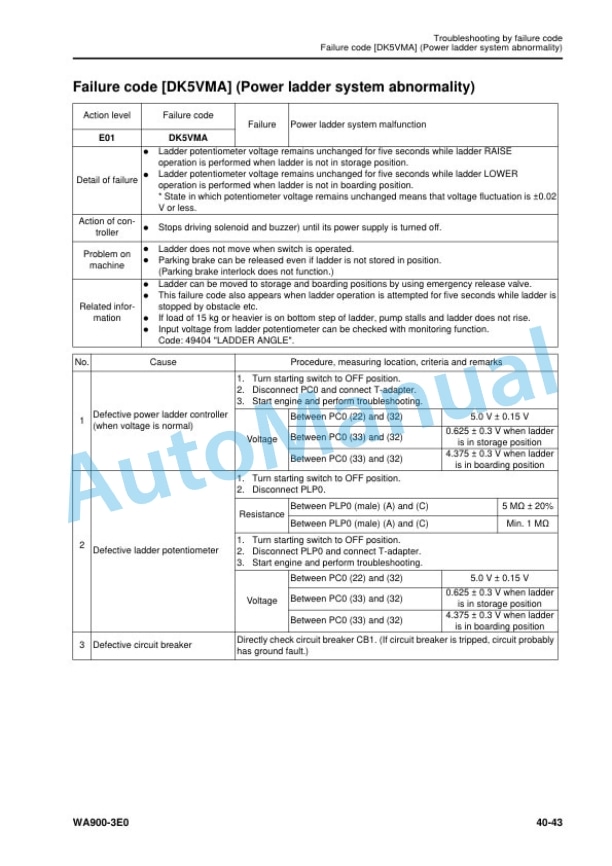

- 8.2.22. Failure code DK5VMA (Power ladder system abnormality)

- 8.2.23. Failure code DUM9KY (Ladder indicator output hot short circuit)

- 8.2.24. Failure code DUM9KZ (Ladder indicator output abnormality Open circuit, hot short circuit)

- 8.2.25. Failure code DV00KY (Ladder interlock caution output hot short circuit)

- 8.2.26. Failure code DV00KZ (Ladder interlock caution output abnormality Open circuit, ground fault)

- 8.2.27. Failure code DWNLKA (Ladder cushion valve output open circuit)

- 8.2.28. Failure code DWNLKB (Ladder cushion valve output ground fault)

- 8.2.29. Failure code DWNLKY (Ladder cushion valve output hot short circuit)

- 8.3. Troubleshooting of electrical system (Emode)

- 8.3.1. E1 Power ladder does not operate

- 8.3.2. E2 Brake oil temperature warning keeps lighting

- 8.3.3. E3 Parking brake does not operate (as emergency brake)

- 8.3.4. E4 Parking brake is applied while machine is traveling.

- 8.3.5. E5 Parking brake is released as starting switch is turned to ON position.

- 8.4. Troubleshooting of hydraulic and mechanical system (Hmode)

- 8.4.1. H1 Power ladder does not move or its speed is low

- 8.4.2. H2 Fan of ADD cooler does not rotate

- 8.5. Troubleshooting of maintenance monitor system (K mode)

- 8.5.1. Maintenance monitor system

- 8.5.2. K1 Hydraulic oil level gauge flashes

- 8.6. Troubleshooting for machine monitor (Mmode)

- 8.6.1. M1 Rear view monitor does not operate

- 8.6.2. M2 While clearance lamp is turned on, illuminance of rear view monitor remains dark

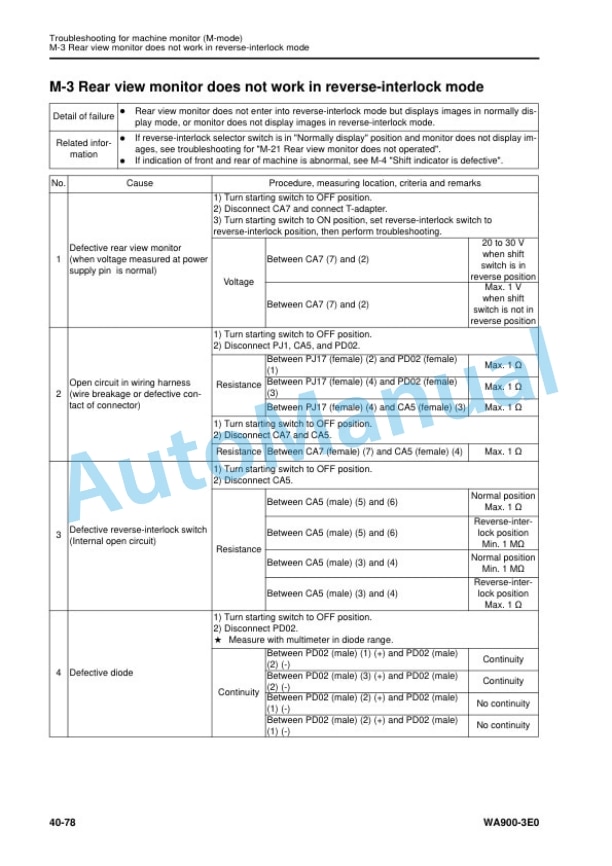

- 8.6.3. M3 Rear view monitor does not work in reverseinterlock mode

- 8.6.4. M4 Illuminance of rear view monitor cannot be adjusted

- 8.6.5. M5 Optional controller error and realtime monitor sreen are not displayed on engine service monitor

- 8.6.6. M6 Engine compartment lamp does not light up

- 8.6.7. M7 Step lamp does not light up

- 9. Diagrams and drawings

- 9.1. Hydraulic circuit diagram

- 9.1.1. Symbols used in hydraulic circuit diagram

- 9.1.2. Power train hydraulic circuit diagram

- 9.1.3. Brake, power ladder and additional cooler Hydraulic circuit diagram

- 9.1.4. Work equipment hydraulic circuit diagram

- 9.2. Electrical circuit diagram

- 9.2.1. Symbols used in electric circuit diagram

- 9.2.2. Electrical circuit diagram

- 9.2.3. Connector arrangement diagram

Rate this product

You may also like

- Claas

- Grove

- New Holland

- Komatsu

- Kubota

- John Deere

- Linde

- Bomag

- CASE

- Clark

- JCB

- Jungheinrich

- Linde

- Yale

- Yanmar

- Manitou

- Manitowoc

- CNH

- Doosan

- Fiatagri

- Fiatallis

- Fiatallis Other Manual PDF

- Flexi Coil

- Ford New Holland

- Ford New Holland Other Manual PDF

- Huyndai

- Hypac

- Hyster

- Hyster Service Manual PDF

- Isuzu

- Kobelco

- Kohler

- Krupp

- Lombardini

- Mahindra

- Nuvera

- Perkins

- Sperry New Holland

- Utilev

- Versatile

- ZF